In this post, I will give you some advice before purchasing the laser or an engraving/cutting machine.

First of all, you need to understand:

1. Do you need it for business or for a hobby?

2. Do you already have a frame like a 3D printer, CNC, or a plotter where you can install the laser.

3. What exactly do you want to do with it: cut or engrave or maybe something else.

4. Do you need professional assistance about using the laser or the machine or would you like to explore everything yourself with no support?

Let’s get started.

An industrial business laser engraving machine vs. a hobby (entry-level) engraver or cutter.

There are 2 types of machines on the market. Professional and industrial machines for metal cutting and metal marking on the one hand and soft material cutting such as 2-3 mm (3/16”) plywood on the other hand.

Most professional machines and frames are quite big and use fiber laser emitters or Co2 gas tubes. The power output of fiber laser emitters varies from 30 watts in a CW mode to 2-3 kW. Some fiber lasers have a CW mode with constant power, some have a pulse mode.

Which one to use really depends on your business needs. For example, if you want to do metal cutting you need 2-3 kW power. Pulse lasers can also do metal cutting but CW fiber lasers do it better.

So fiber laser can work in a continuous or pulse mode. Usually, pulse lasers are used for metal marking.

As for Co2 lasers, they are all CW power and their max power can reach a few kW too.

However, you can cut a few mm of stainless steel with even 300-400 watt Co2 power.

There is a lot of differences between a Co2 and fiber laser but the key thing you need to know is that they have different wavelengths. All Co2 lasers have a 10600 nm (10.6 um) wavelength, however, most fiber emitters have a wavelength of 1-1.5 um (1064 – 1565 nm)

Different materials absorb and reflect different wavelengths with different coefficients.

For example, if you want to cut a transparent acrylic you need Co2 lasers since its wavelength is absorbed effectively so you can cut it. Fiber lasers wavelength goes through and does not all to cut.

Also, woodcutting is better to do with a Co2 laser since wood better absorbs 10600 nm (10,6 um) wavelength.

However, if you want to engrave inside the acrylic you need a fiber or a DPSS laser module that allows to etch acrylic inside and do 2D laser engraving.

There is a lot of data on which material has a better wavelength absorption, reflectance, scattering, etc.

Comparison of a different types of lasers and different wavelength

Absorption wavelength spectrum for different materials: glass, metal and others.

For example, glass cutting could be a trick for all types of lasers not because of its wavelength absorption but because of its crystal structure and thermal conductivity. Often when doing laser cutting, cracks might appear in the glass but you can still laser-cut using some lifehacks.

So if you are not confident about the material you want to cut or engrave – you are always very welcome to ask us in a Livechat. We can help you with choosing the best laser for your needs.

So if you are not confident about the material you want to cut or engrave – you are always very welcome to ask us in a Livechat. We can help you with choosing the best laser for your needs.

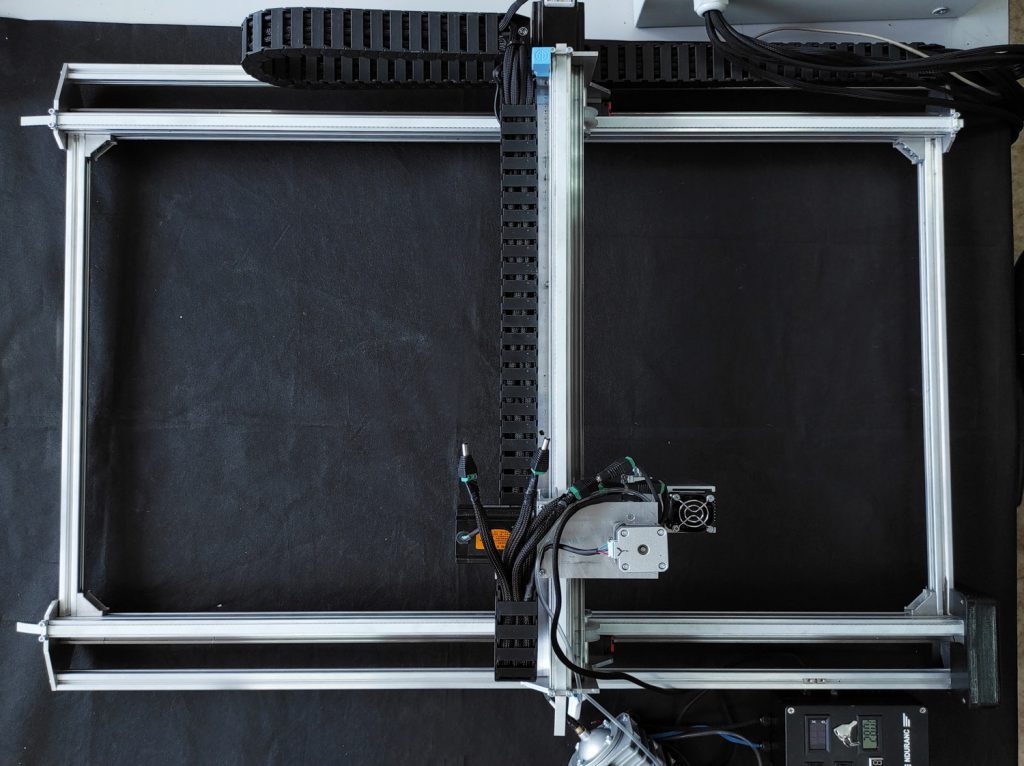

Your 3D printer, CNC machine or XY plotter can be converted into a powerful laser cutting/engraving machine.

It’s good that many people already have 3D printers, CNC machines, or XY plotters at home or at their workshops. If you do not have one – I really encourage you to get one. You can do really great things with 3D printers, printing out literally anything you like.

10 watt SE laser installation on Ortur / CNC 3018 SainSmart and Universal laser engraver – a detailed video guide

Mostly all 3D printers and CNC machines can be upgraded by adding diode lasers on it.

Installing Endurance lasers on difference CNC machines – upgraded routers

Some people might say that diode lasers are not powerful enough and you can not do a lot of things with it.

There is a yes and no answer.

Yes – diode lasers are less powerful (15 watt power is the max output you can have at the moment for a single beam)

However, there are some multi-beam diode lasers available now

No – diode lasers can still beat low-power Co2 lasers.

However, even with 15-watt diode power, you can cut 3 mm (3/16”) MDF and up to 6 mm (1/4”) of wood and plywood and engrave on almost all metals.

For example, 40 watts Co2 laser can not engrave on metals at all.

Diode lasers vs. Co2 laser tubes. Advantages and disadvantages

As I said before if you already have an engraving frame like Ortur, Eleksmaker, CNCC Laseaxe, Neje, Wainlux, Foxalien machine, Universal laser engraver, Atomstack and similar you can still upgrade your frame with a Co2 tube

Assemble your own Co2 laser machine (Upgrade your existing engraving frame)

This process is not very easy however if you have all the necessary components you can upgrade it to 40-150 watt Co2 laser p

ower output.

That kind of upgrade can really save you a lot of space in your workshop or at home. But be careful Co2 laser has invisible ra

diation (10,6 um) so you MUST OPERATE IT with enclosure (you can build your own laser protective enclosure) and always wear protective goggles.

We suggest using at least OD4 or OD5+ goggles.

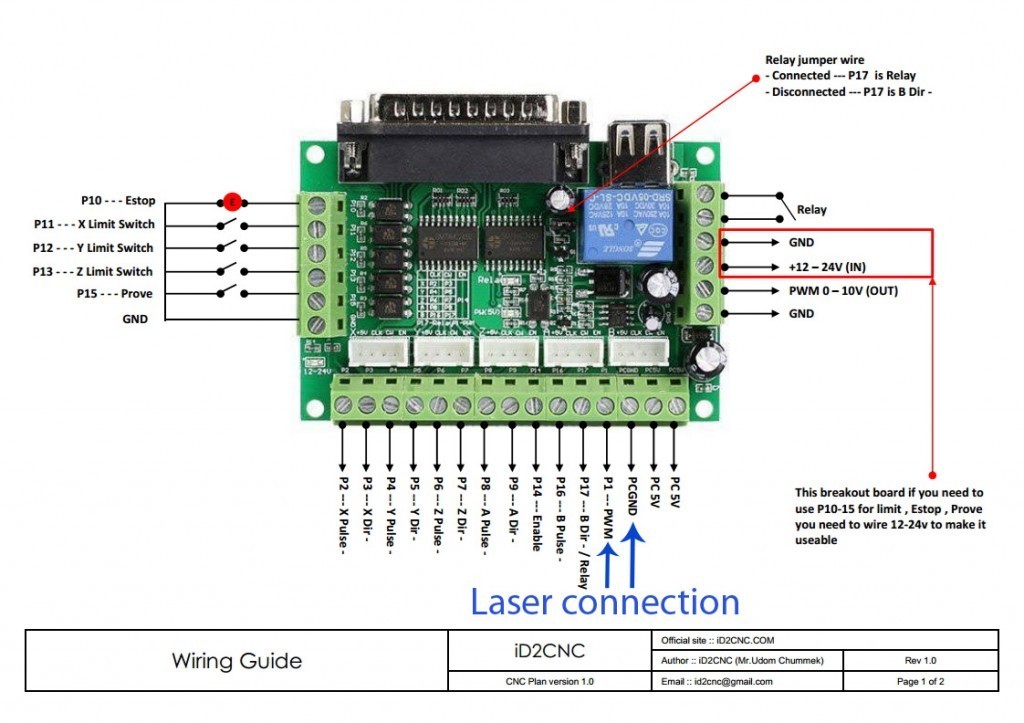

So, adding the diode laser on an existing 3D printer, CNC machine or engraving frame is not difficult at all. You just need to find a PWM pin (for 3D printers it is FAN1 pin usually) and wire the laser.

Hooking (mounting) the laser shouldn’t also cause any trouble. Most 3D printers do not even need you to remove the extruder. So you can have the laser and extruder at the same time.

At the end, if you already have a laser but do not know how to hook it or wire – we are always ready to help you with that.

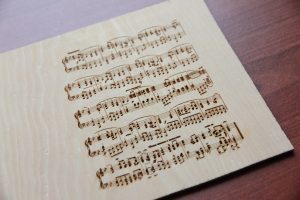

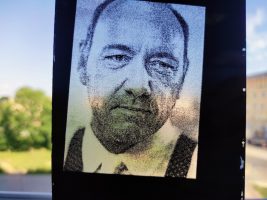

With the laser you can literally do anything: cut metal and wood, engrave on plastics and ceramics, etch glass and acrylic, mark stainless steel, copper, brass and other metals.

Once you decide to get into the laser space you need to understand what materials do you want to process.

Unfortunately, there is no one universal laser for all needs. One is good for one application like laser cutting and the other one is good for another application like accurate laser etching.

In our lab, we do a lot of tests and experiments and share them on our YouTube channel.

We also have created a page with key abilities of different types of lasers with different power.

Endurance lasers: all about cutting and engraving abilities of diode, DPSS, fiber, Co2 lasers.

There are a lot of different guide books about laser parameters for cutting and engraving and roughly speaking it would be a whole big book for all types of lasers and all types of materials.

Here is just an example for Co2 cutting table

Briefly, we can say that:

Diode lasers with 5-15 watt optical power output are good for soft materials cutting like 2-6 mm plywood/laser ply, dark acrylic, leather, felt, fabric, hardboard, cardboard, paper. Engraving on all materials excluding pure aluminum, galvanized steel, and some sorts of brass and copper alloys.

Co2 lasers with optical power 40-150 watt are good for all types of laser cutting of all soft materials and you can cut quite thick pieces of MDF, wood, plywood, transparent acrylic, silicone, etc. Engraving is also possitble on almost all materials and almost all metals.

Fiber lasers with optical power 30-50 watt are good for metal marking/engraving and thin metal cutting (0.5 mm), good for engraving on mirrors, inside acrylic

Fiber lasers with optical power of more than 200 watt are good metal cutting

DPSS lasers with an optical power of 4-10 watt are good for multiple applications including metal cutting, engraving, rust removal, color engraving on steel, titanium, engraving on glass, mirror, acrylic.

Endurance lasers is always happy to assist with the best option for laser cutting or laser engraving.

High-quality tech support will save your nerves time and money.

How would you feel about this case?!

A lot of people get upset once they order something on eBay or Amazon and the product stop working and the supplier is not answering.

In fact, it is a common problem for all low-cost laser products. During the last 5 years, we saw a lot of companies disappear and people are left with nonworking laser or engraving machines.

Another problem is that many suppliers lie about their real parameters and that is a big pain for the laser community.

My Experience With Non-Branded Chinese Made Lasers. Fake laser modules! WARNING!

For example Neje, Ortur advertise not an optical power but a laser consumed power which is actually can be 5 and even 10 times more.

And then people get really upset that their “so-called 20 or 40-watt laser” does not cut even 3 mm of soft plywood.

There could be different types of problems, like the mechanical issue of the frame, it could be the problem with the laser itself, sometimes diodes lose power unexpectedly and the laser can not cut or engrave anything. It could be a problem with laser beam focusing

it could be a problem with software or firmware.

So, all that issues can cause a very bad mood and experience working with the lasers but you need to know that lasers are fragile matter.

It means that once you buy something you’d better check how reliable is a supplier and for how long he is been on the market. If the supplier just appeared on eBay or Amazon a few days ago and sells something very cheap – be ready that in a short period of time you will face some problems with the product and you will get no support from a seller.

We invite everyone to join our Facebook community. It is very friendly and we help different people with different problems together.