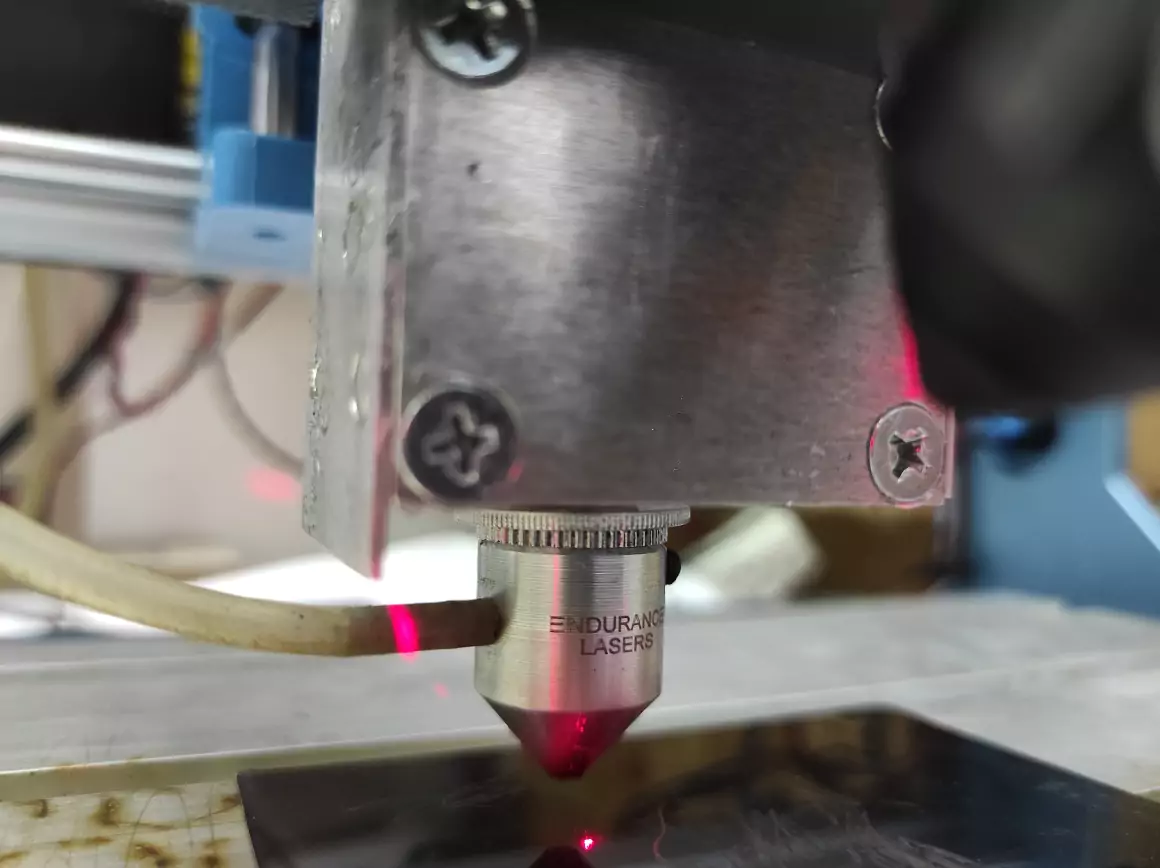

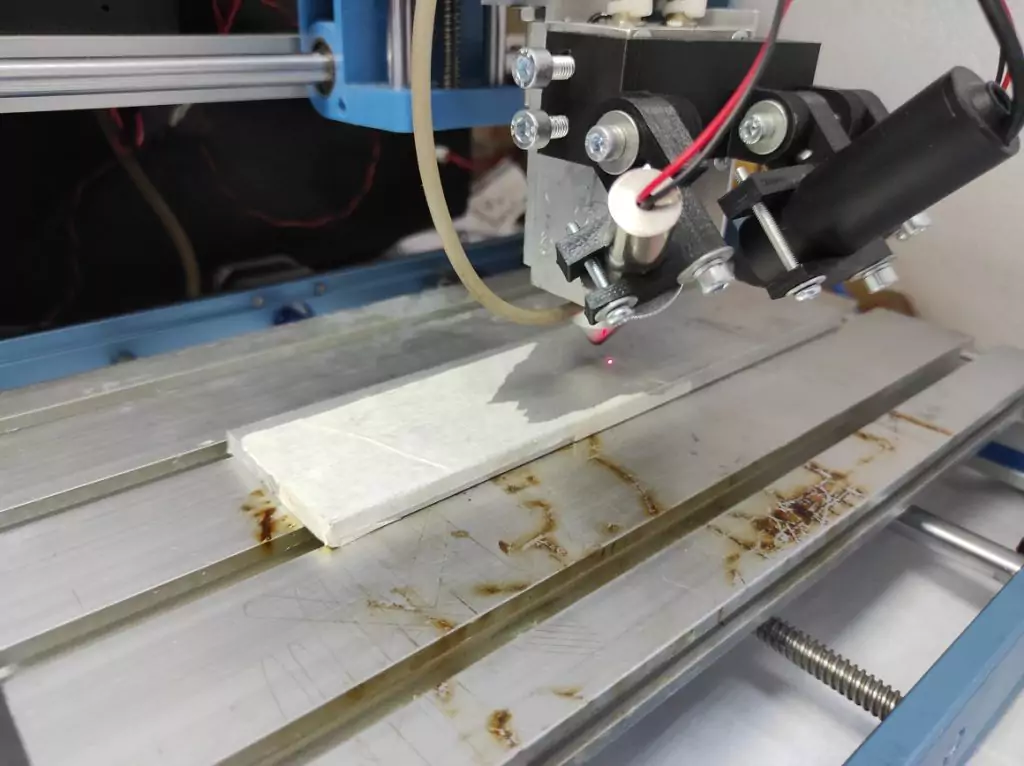

An Endurance 15 watt (real power output) water – cooled laser with an autofocusing system. Cuts 10 mm of wood (2/5″)

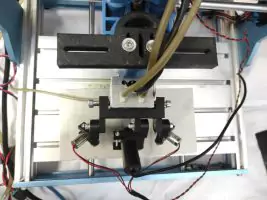

Endurance lasers developed a laser autofocusing system for diode, DPSS and Co2 lasers.

Now you can always remain in focus and the system will keep your laser in focus all the time you do laser cutting and laser engraving.

What do you need to become an Endurance beta software tester?

- 3D printer, CNC machine, or engraving machine with the Z axis.

- 3.7MM Lens Mini HD 1080P USB Camera Micro 2MP Bullet Web USB2.0 UVC Webcam For Windows Computer PC Laptop

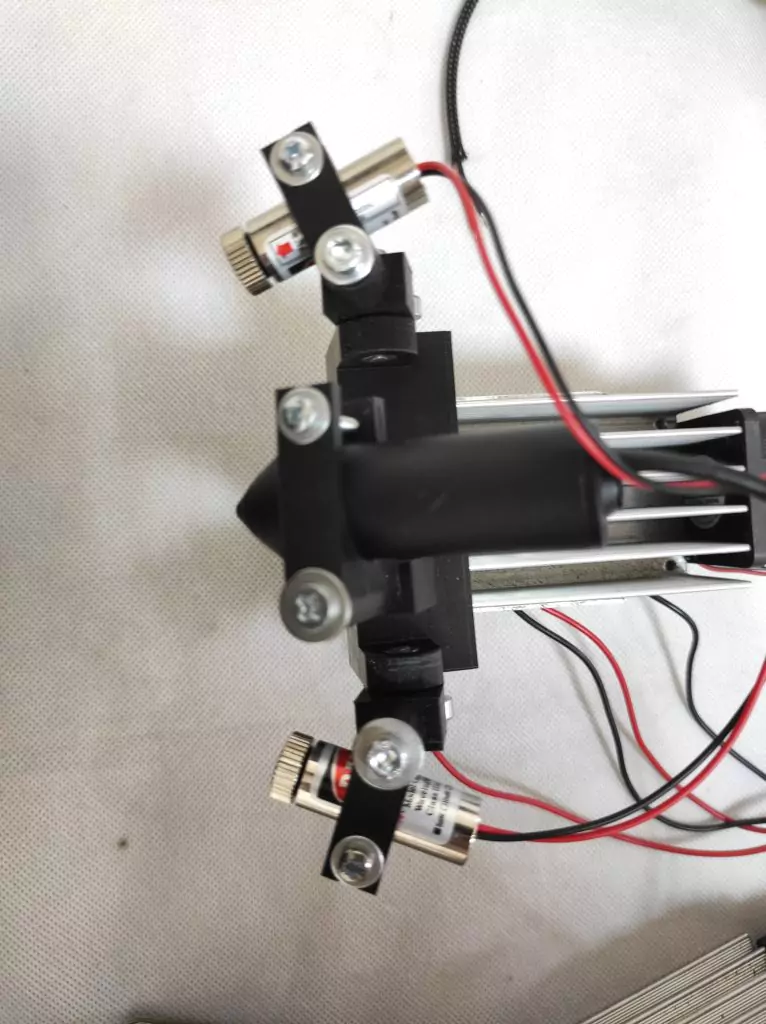

- 2 red laser diodes

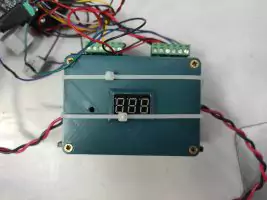

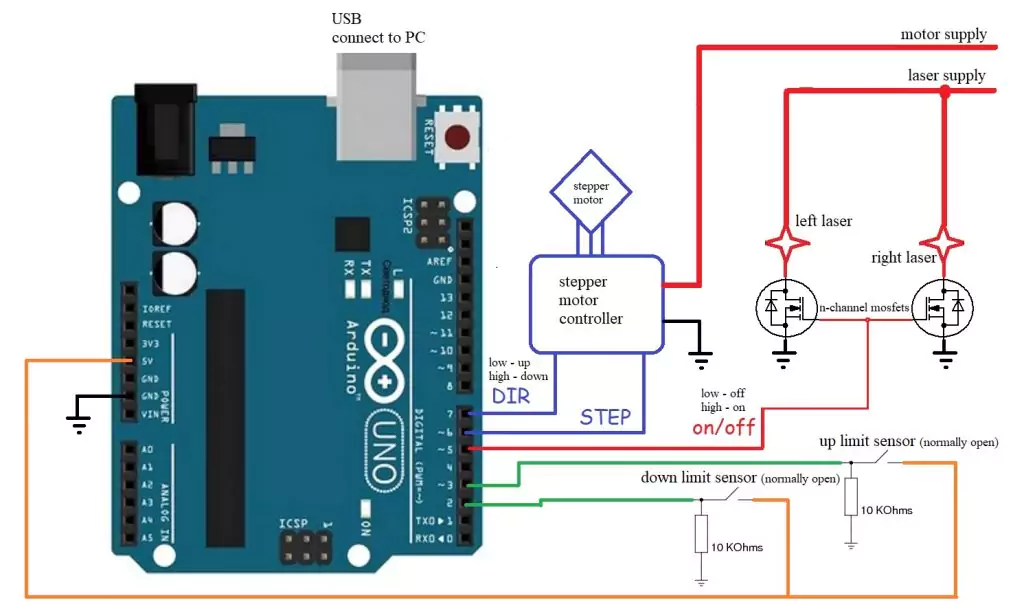

- Arduino Uno

- External stepper motor drivers DM542 (DC/DC for the driver)

- 2 end-stops on Z-axis

- 2×10 kOhm resistors

- Breadboard

- Wires and connectors

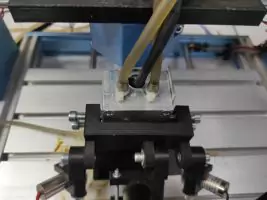

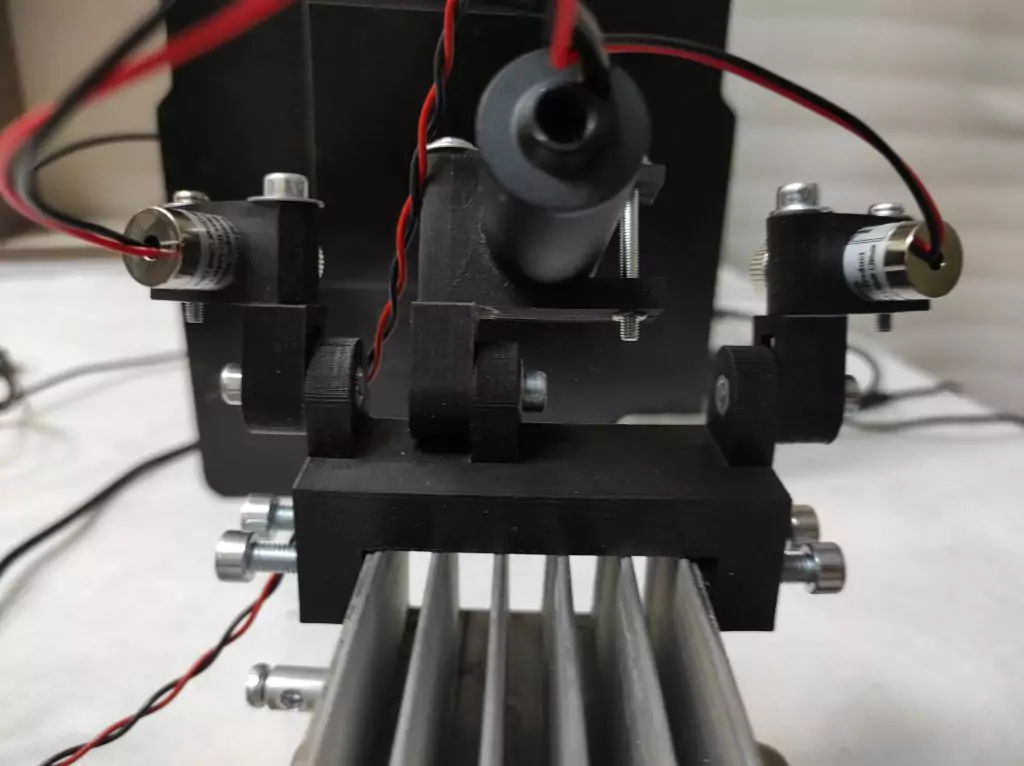

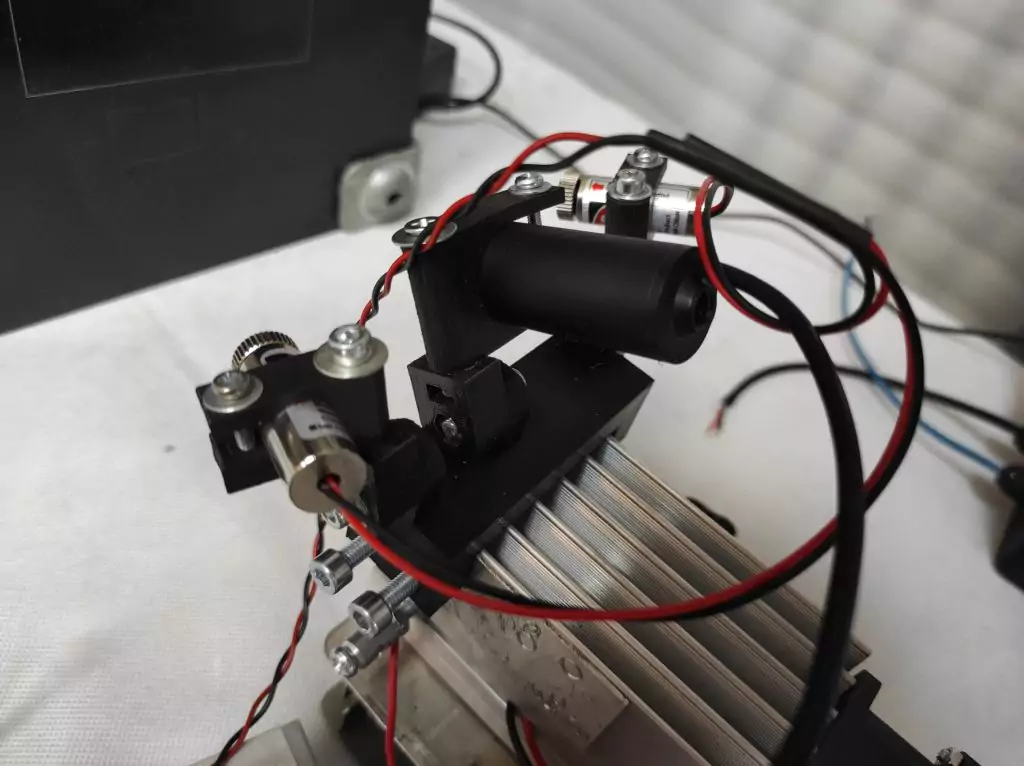

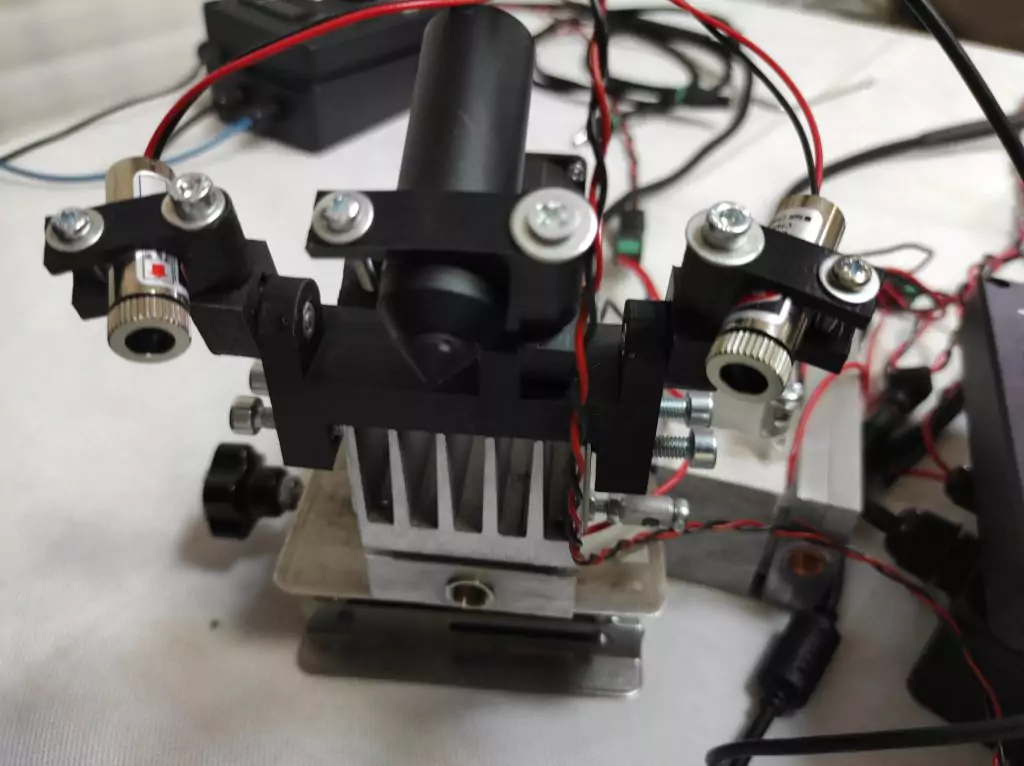

- 3D printed mount for the camera and 2 red diodes

Make that schematic first

Download an Arduino sketch >>>

Download a software (Windows version)>>>

Testing firmware steps

Open COM port via terminal (Arduino IDE) serial monitor in tools) and type symbols

N – laser on

F – laser off

D – down 1000 steps

E – up 1000 steps

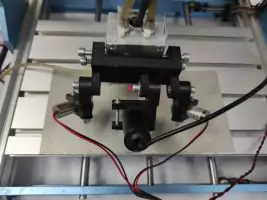

Electronics and wiring

An Endurance laser autofocusing system

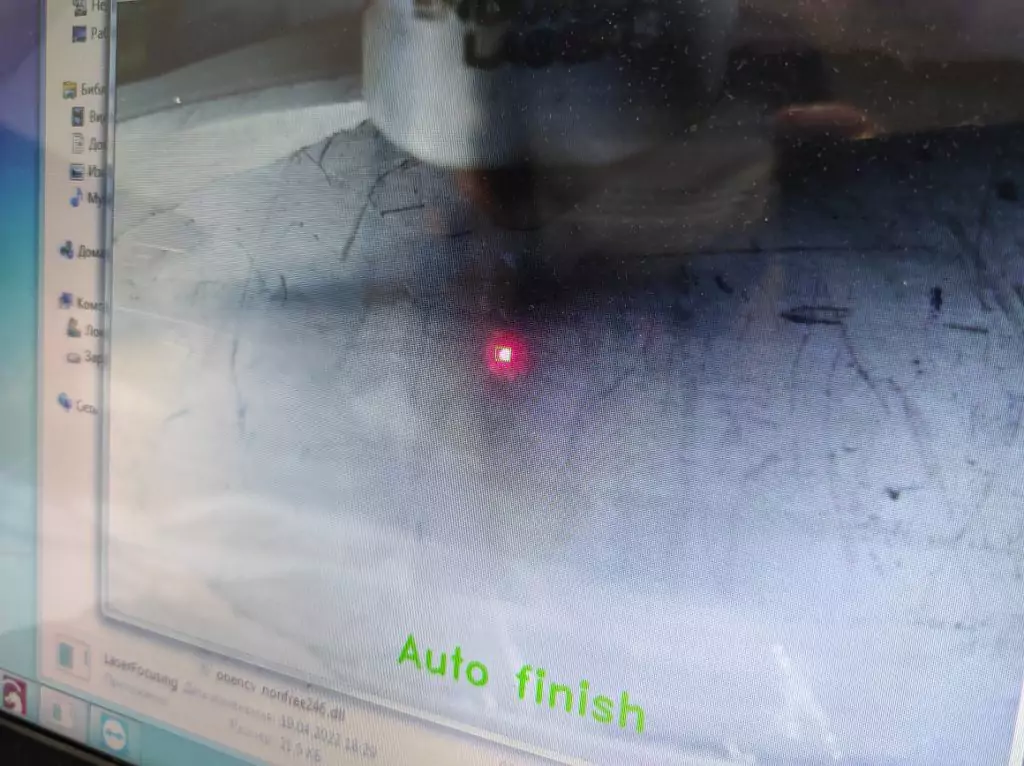

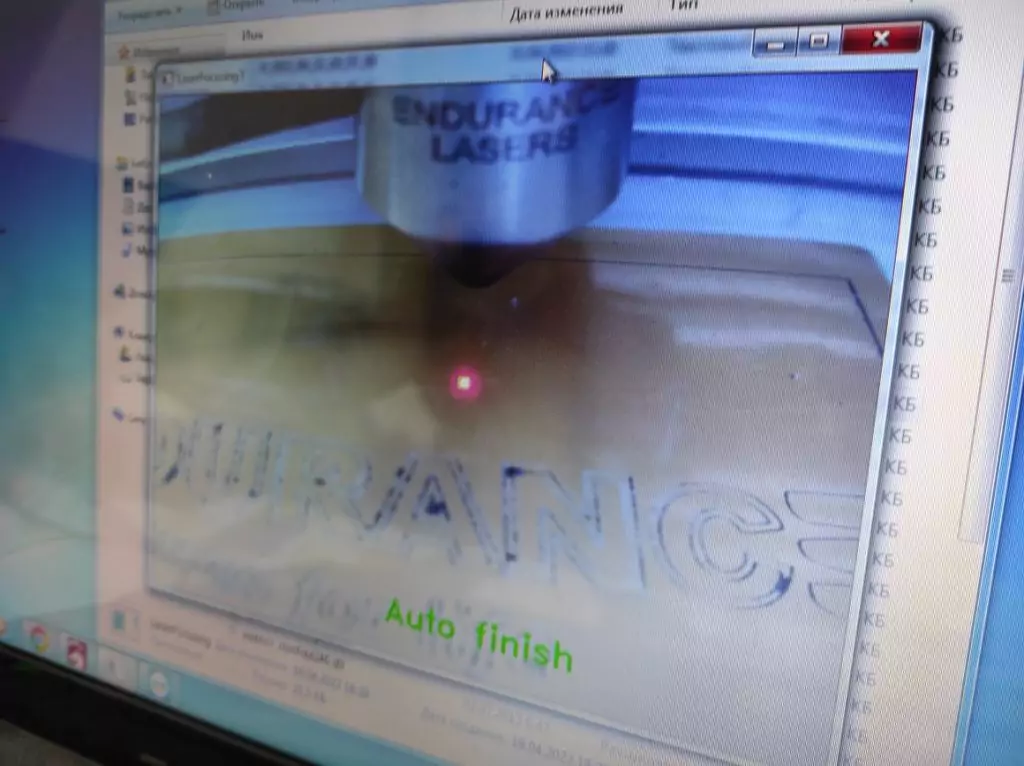

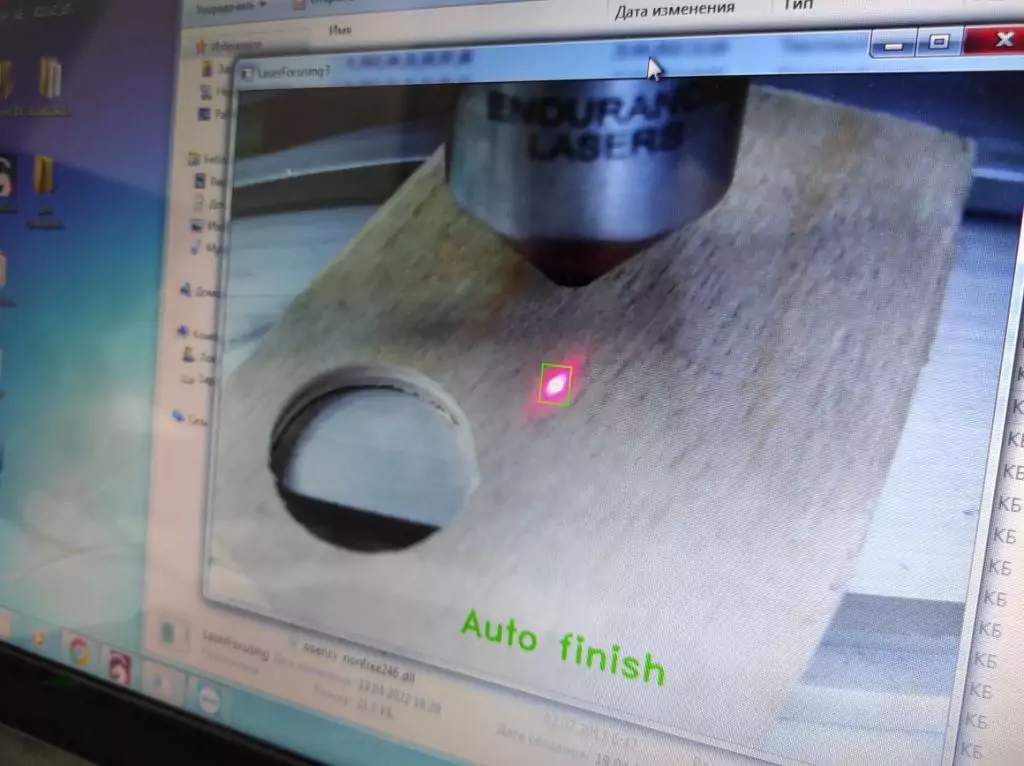

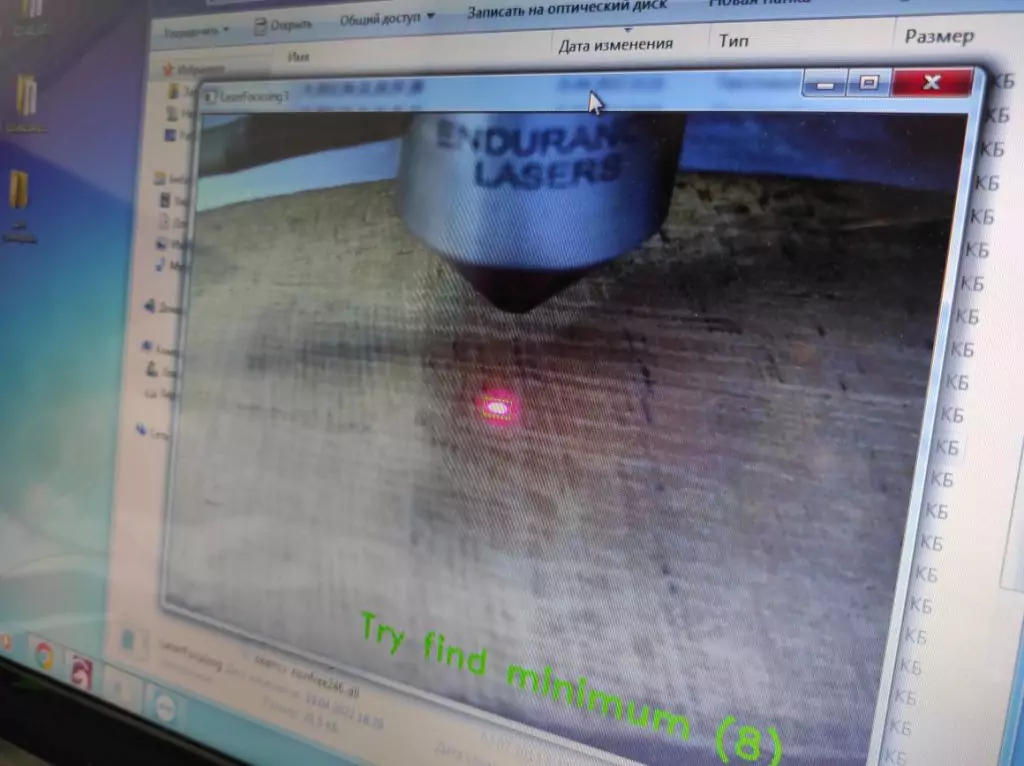

The current state of testing the program for autofocus – version Alfa1

Testing successful focus times. AF was triggered 10 times.

Plywood – 3/10

Aluminum 8/10

Titanium 8/10 (different laser power effects)

Copper

Wood 8/10

Stainless steel 9/10

Copper 9/10

Brass 9/10

Plastic from the printer – 7/10

Pink anodized plate – 9/10

Depends on the light in the room.

The laser power for calibration is not always correctly determined.

It is supposed to launch one laser first, choose the most correct spot size for it, and then focus. Later in the program, there will be a list of materials in the program from which the user will choose, and the program will adjust.

If the material is strong out of focus – autofocus sometimes does not start

Current development status (laser autofocusing system)

How the autofocus software works (alpha version)

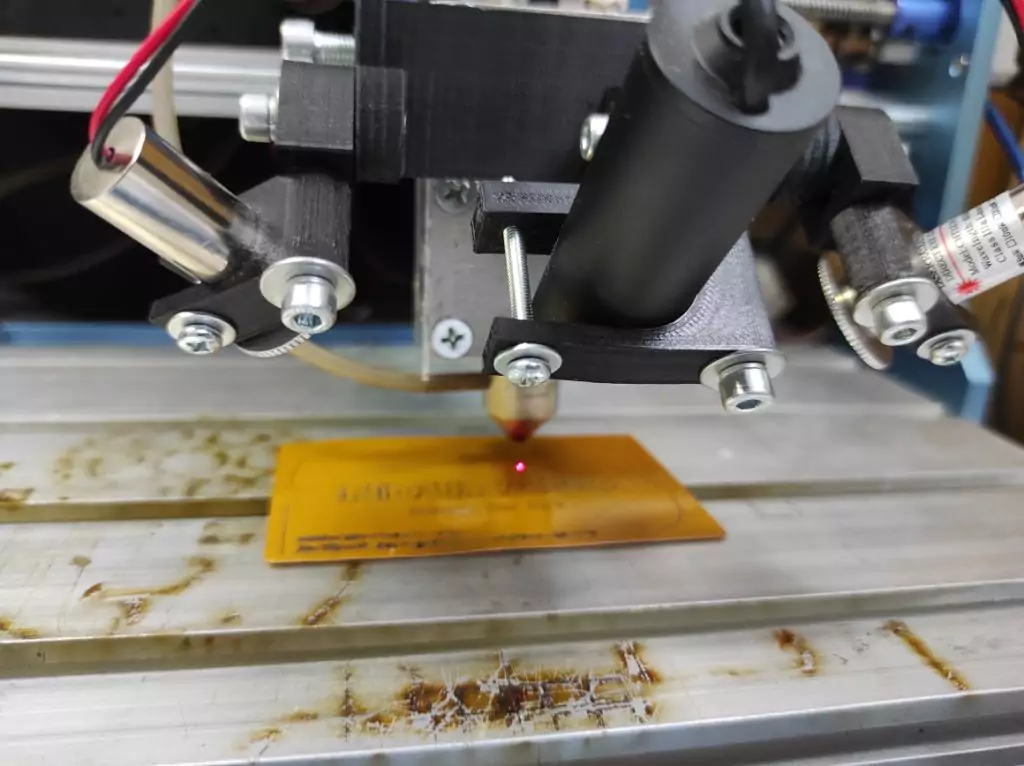

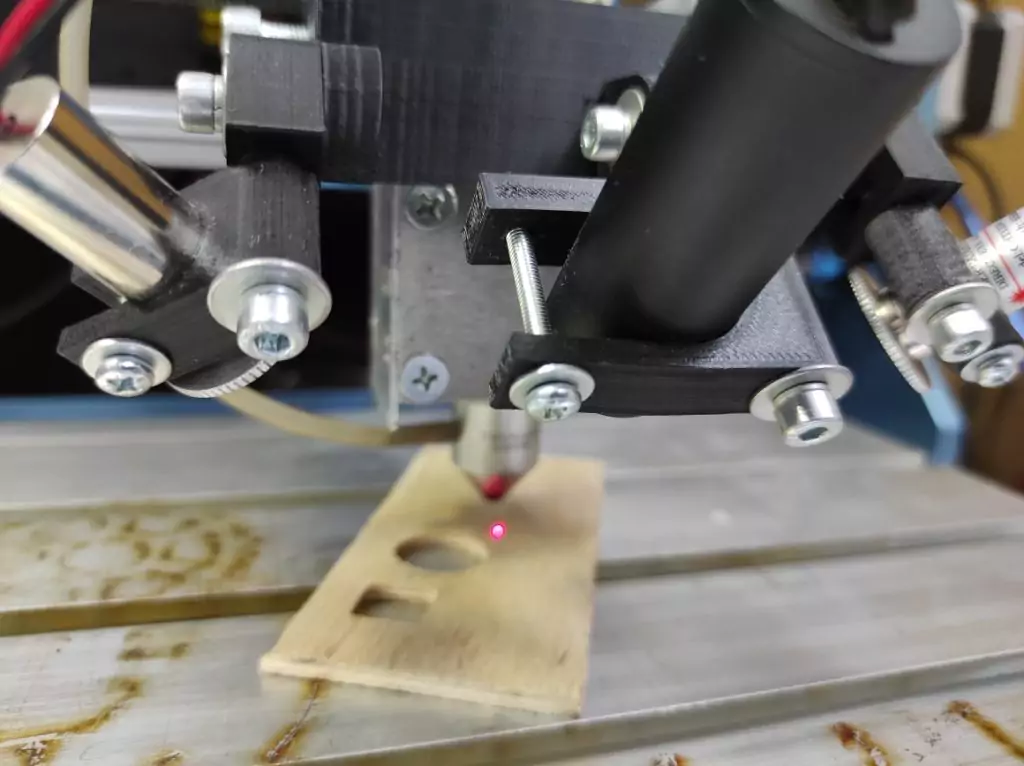

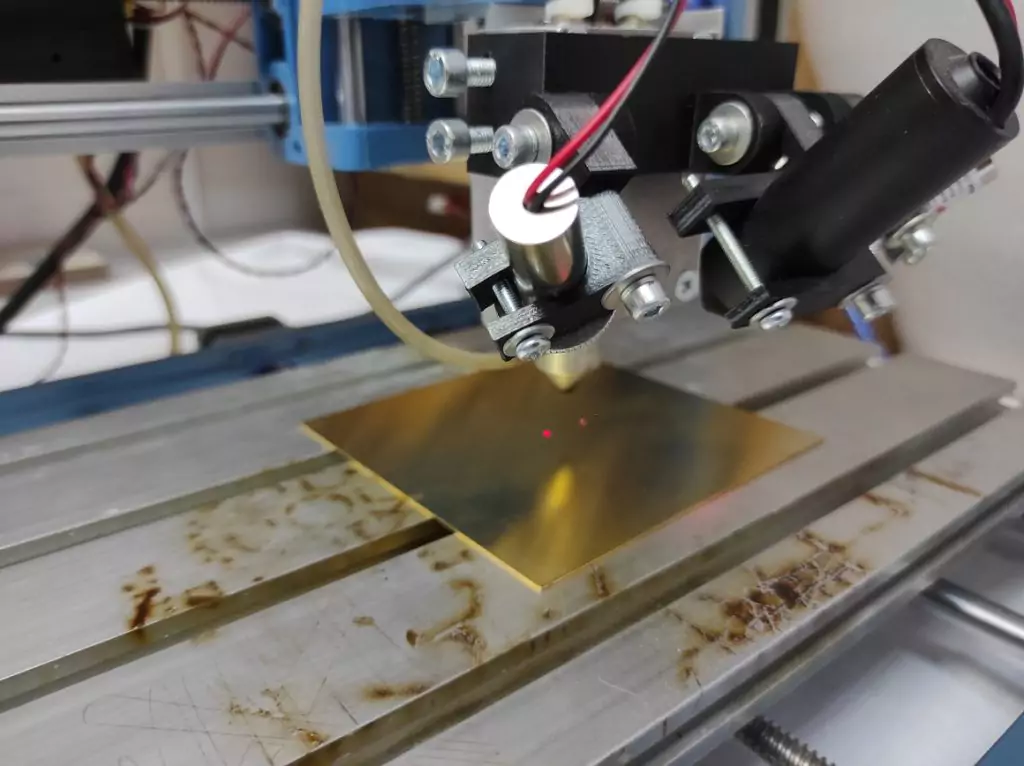

1. Install 2 red lasers with a camera to any Endurance laser.

2. Launch the program for working with the camera.

3. Start the console to control the Z axis to raise and lower the laser.

4. Connect the Endurance laser focusing kit to your machine and computer.

5. First, using the camera, set the minimum focus for the blue laser, alternately lowering and raising the laser itself. A painted or anodized aluminum plate is used for focusing. The Mo2 boxes use the focusing method. Mo1 boxes use Focus mode with Arduino.

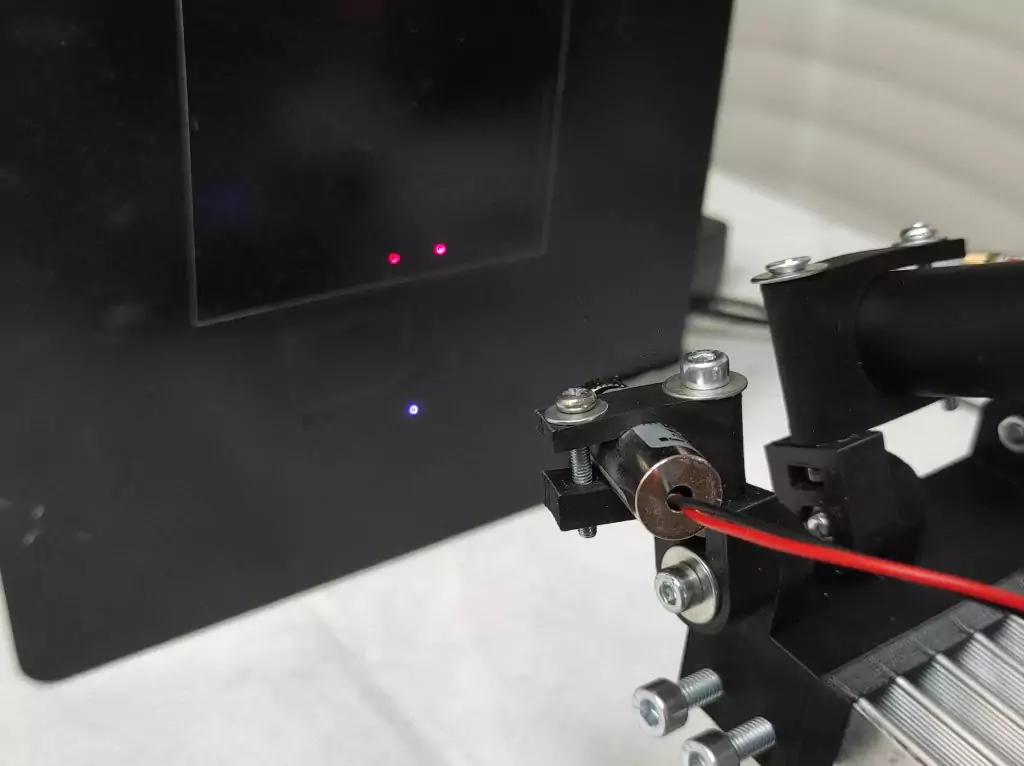

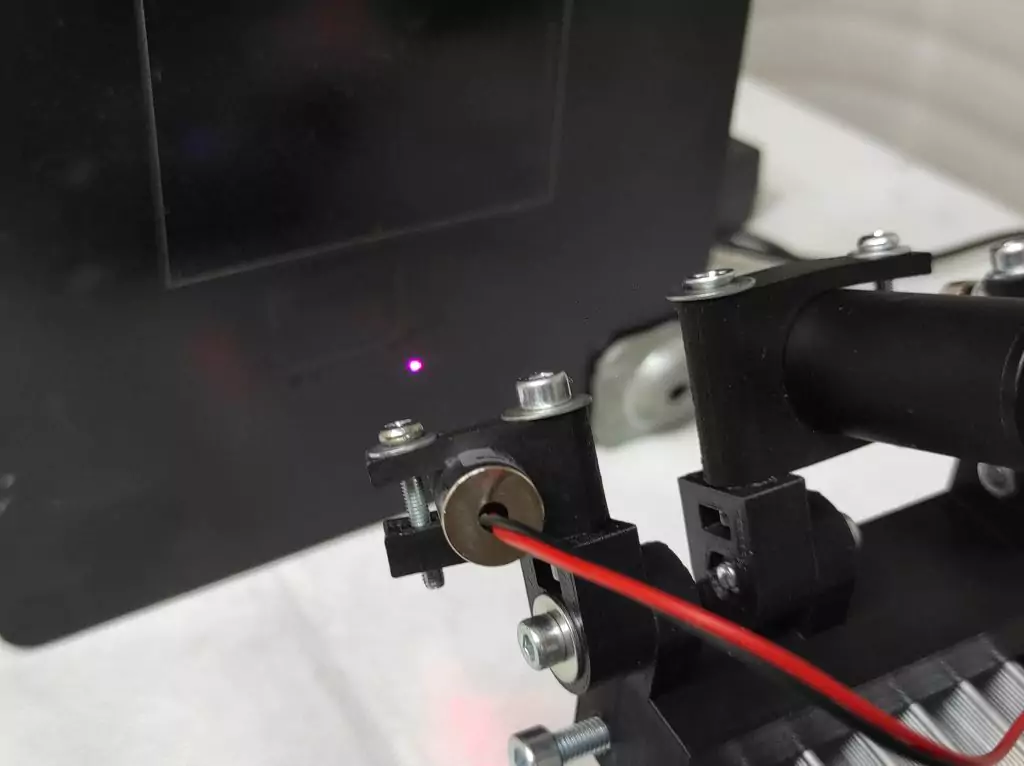

6. After determining the optimal focus – 2 red lasers converge to a point.

7. Launch the program for determining the focus, connected to the camera for determining the focus.

8. We put on the working field of the machine the part for cutting or engraving.

9. We use the program and the control console in order to bring 2 red lasers into one point.

A program for automatic focusing is currently under development.

The basic principle:

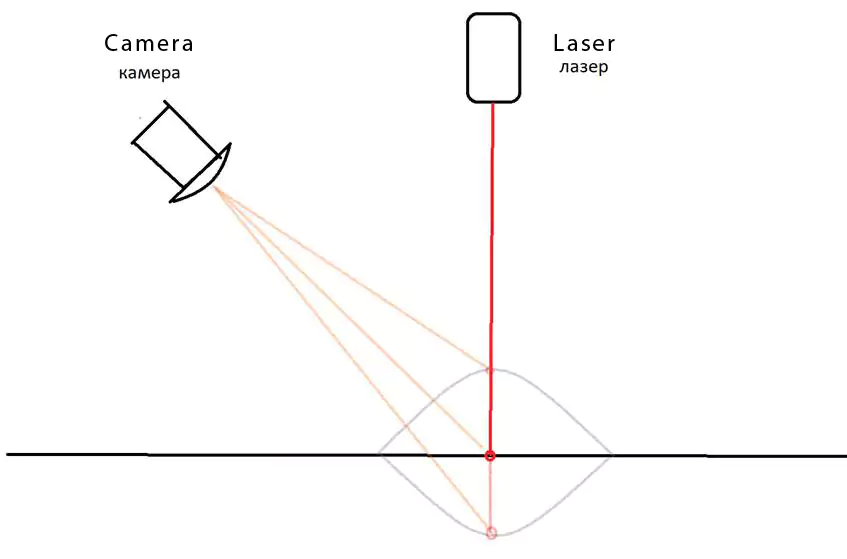

2 red lasers shine at one point, with the focus adjusted, if defocus occurs, the distance between the 2 red lasers will increase.

The camera is installed in close proximity to the intersection point of the 2-diodes (red).

The data from the camera is transferred to a computer (version 1) and analyzed in the program.

The program shows the image from the camera and indicates the distance between two points.

If 2 points are connected into one, then the screen indicates that the laser is focused.

Method 1:

With this method, the user himself controls the focus of the laser and can independently raise/lower the Z-axis for focusing from a program, for example, LightBurn.

Method 2 is autofocusing from the program.

In this case, the stepper motor is connected to an external driver and controlled by an external signal.

For example Com port -> Arduino → Stepper motor Driver -> Stepper motor

In this case, 3 operating modes can be selected

Operating modes:

- surveillance (no signal is sent),

- focusing (focusing occurs only once),

- dynamic autofocus (continuous autofocus occurs as the laser engraves).

Focusing lasers must also be controlled from the Com port program.

For example: Com port -> Arduino -> Endurance Mo1 -> Focusing lasers

Other owls from the program can turn on, turn off, change the brightness of the focusing lasers.

If it is impossible to focus the laser, for example, after 2-3 iterations, the system gives an error that it is impossible to focus and the problem may be that 2 focusing lasers are misaligned, there may be a mirror surface or insufficient distance for the movement of the Z-axis.

The data from the camera should be possible: save as a picture or video in available formats. (to send for diagnostics)

Version 2

The data from the camera is transmitted to the Raspberry Pi and analyzed there.

Also, an external Z-axis driver is connected to the Raspberry Pi for focusing.

Similarly, there are 3 modes of operation described above, only, in this case, all processing and image output is carried out on Raspberry Pi

It is possible to connect an external screen and simple control and a choice of 3 modes of operation.

Controller: raspberry

Optical camera: Noir

Additional sensor: Ultrasonic rangefinder

A new laser focusing system. Now you will be always in focus!

Components:

2. Brio Ultra HD Pro Webcam (4K HDR webcam with Windows Hello face recognition)