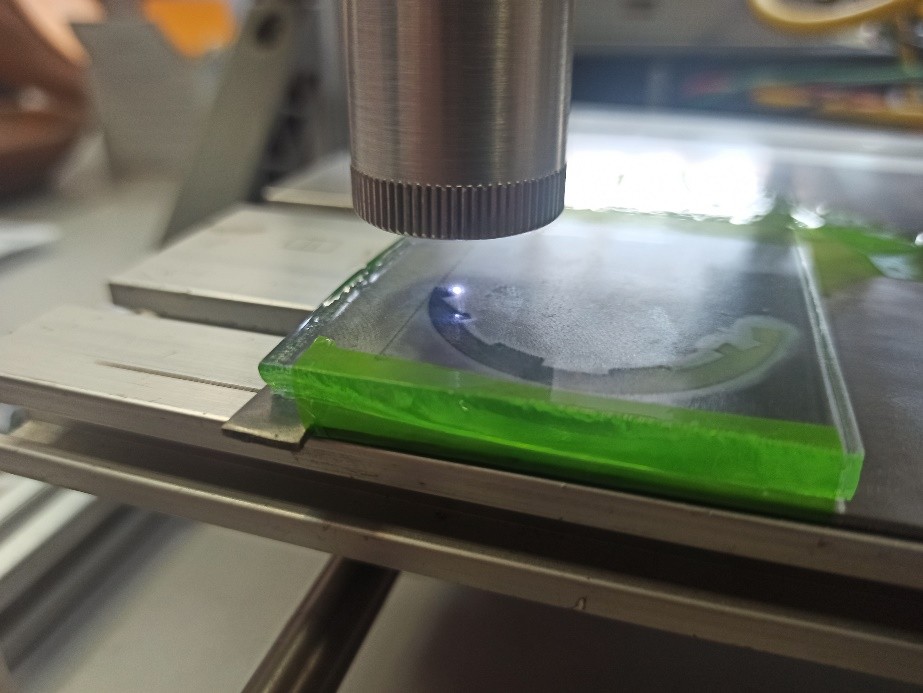

Experimental Color Glass Engraving with a Solid-state Diode-Pumped laser (Endurance 4 Watt DPSS Laser Nd:YAG, 1064 nm, with short focal lens F=20 mm).

Installation

We use CNC 3018 machine and a lightburn software

Thr Endurance CNC 3018 laser engraving / cutting machine / carving machine

Task:

Color image creation on a glass surface without using any colorants.

Work procedures:

Image preparation

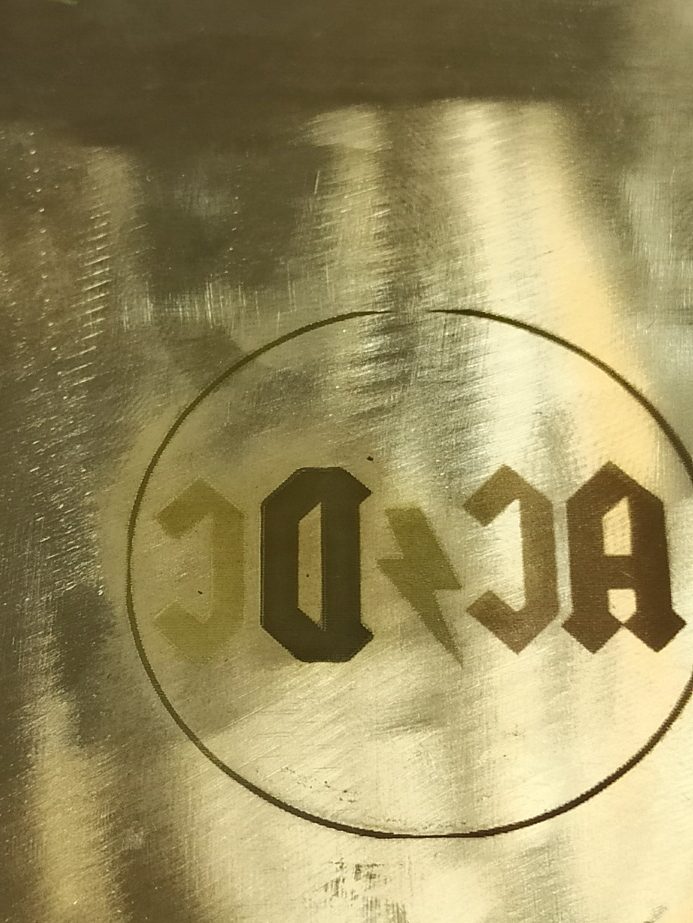

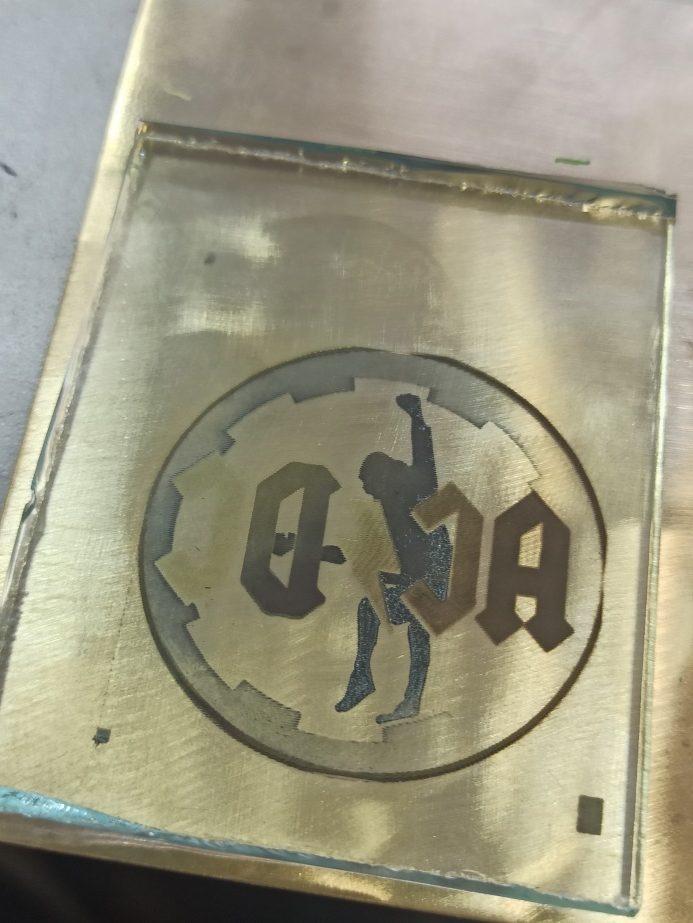

As a sample pattern we took the AC/DC rock band logo. We divided the pattern into separate elements. Each element will have its own color. Следует отметить, что для корректного нанесения рисунка, исходное изображение должно быть отражено по горизонтали.

The original pattern and its separate elements:

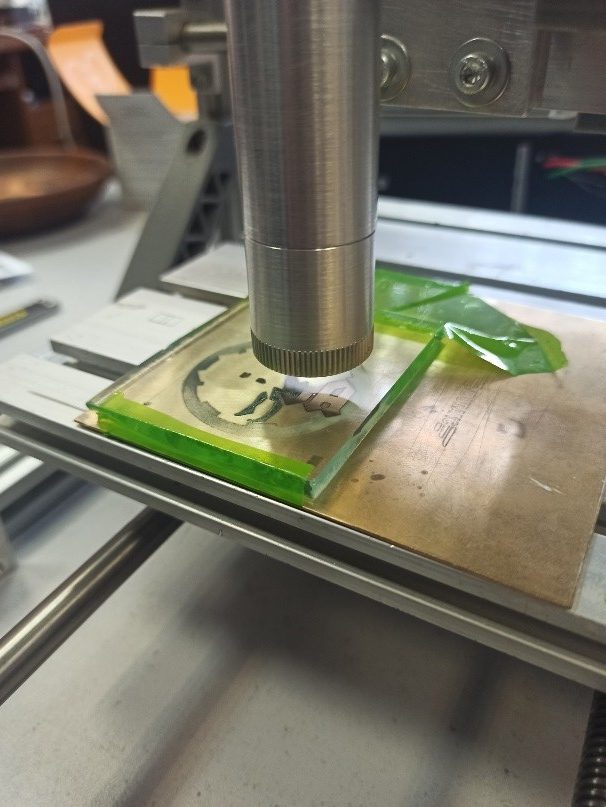

To avoid shifting of the pattern elements when metal plates are changed we made special markings on the glass. These markings will help restore the initial position of the processed glass.

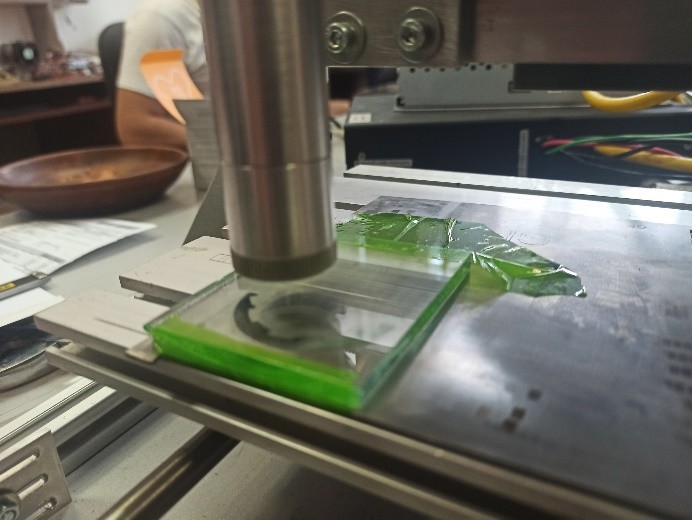

Plates positioning and mode selection

On the worktable, we position a plate of some metal (the color will depend on the metal type). We fix a glass plate, 4 mm thick, on the surface of this metal with sticky tape. The lens focusing is a very important moment. The range between the glass surface and the lower part of the laser emitter should be 142 mm.

The plate to laser orientation along X and Y axes is done using the marks.

The first used metal type was titanium.

The process parameters:

- Speed – 850 mm/min., power 60%, interval 0,1 mm,passes 1.

The resulting layer color was gray.

- Speed – 850 mm/min., power 90%, interval 0,1 mm, passes 1.

The resulting layer color was blue.

The next metal plate was made of brass.

The process parameters:

- Speed – 500 mm/min., power 20%, interval 0,1 mm, passes 1. The acquired layer color was brown.

- Speed – 700мм/мин., Power 15%, interval 0,1 mm, passes1.

The resulting layer color was grayish-blue.

- Speed – 800мм/мин., Power 30%, interval 0,1 mm, passes 1.

The resulting layer color was bronze (semitransparent).

- Speed – 500мм/min., Power 70%, interval 0,1 mm, passes 1.

The resulting layer color was yellow.

- Speed – 500мм/мин., Power 15%, interval 0,1 mm, passes 1.

The resulting layer color was grayish-green (semitransparent).

- Speed – 900мм/min., Power 90%, interval 0,1 mm, passes 1. The resulting layer color was black.

As a result of the work done, we got a clear color image on normal glass.

Below is a table of colors depending on the material and technical parameters

| №, material | Speed | Power | Focus, mm | Result |

| 1 titan | 300 | 99 | 14,2 | Golden black |

| 2 | 400 | 99 | 14,2 | Bluish golden |

| 3 | 500 | 99 | 14,2 | Golden blue |

| 4 | 600 | 99 | 14,2 | same |

| 5 | 700 | 99 | 14,2 | Dark gray |

| 6 | 300 | 59 | 14,2 | Bluish golden |

| 7 | 400 | 59 | 14,2 | Golden blue |

| 8 | 500 | 59 | 14,2 | same |

| 9 | 600 | 59 | 14,2 | Light blue |

| 10 | 550 | 59 | 14,2 | Blue |

| 11 | 550 | 99 | 14,2 | Blackish blue |

| 12 | 850 | 90 | 14,2 | Blue (clear shade) |

| 13 | 850 | 70 | 14,2 | Turquoise |

| 14 | 850 | 60 | 14,2 | Dark gray |

| 15 | 850 | 50 | 14,2 | Blue at an angle |

| 16 | 650 | 50 | 14,2 | Golden green |

| 17 | 850 | 40 | 14,2 | Blue at an angle |

| 18 | 850 | 30 | 14,2 | Violet at an angle |

| 19 | 850 | 25 | 14,2 | Light gray-blue |

| 20 | 500 | 99 | 15,2 | Glass slightly burnt |

| 21 | 350 | 99 | 14,3 | Golden black |

| 22 | 200 | 99 | 14,3 | Black (Glass slightly burnt) |

| 23 brass | 200 | 99 | 14,3 | Black |

| 24 | 400 | 99 | 14,3 | Golden black |

| 25 | 500 | 99 | 14,3 | Golden |

| 26 | 500 | 80 | 14,3 | Light golden |

| 27 | 500 | 70 | 14,3 | Golden with red |

| 28 | 500 | 60 | 14,3 | Light bronze |

| 29 | 500 | 50 | 14,3 | Orange golden |

| 30 | 500 | 40 | 14,3 | Light orange golden |

| 31 | 500 | 30 | 14,3 | Lighter |

| 32 | 500 | 20 | 14,3 | Pink shade |

| 33 | 500 | 10 | 14,3 | Same semitransparent |

| 34 | 700 | 10 | 14,3 | Semitransparent sordid gray |

| 35 | 700 | 20 | 14,3 | Darker |

| 36 | 700 | 40 | 14,3 | Darker |

| 37 | 700 | 60 | 14,3 | Dark bronze |

| 38 | 700 | 80 | 14,3 | Gray sheen |

| 39 | 700 | 99 | 14,3 | Darker |

| 40 медь | 400 | 99 | 15,2 | Brown |

| 41 | 300 | 99 | 15,2 | Darker |

| 42 | 500 | 99 | 15,2 | Lighter |

| 43 | 900 | 99 | 15,2 | Brown (transparent) |

| 44 | 900 | 60 | 15,2 | Bronze, semitransparent |

| 45 aluminum | 500 | 99 | 14,3 | Matting |

| 46 | 300 | 99 | 14,3 | Darker |

| 47 | 500 | 99 | 15,2 | Satin white semi transparent |

| 48 | 300 | 99 | 15,2 | Satin white |

| 49 stainless steel | 500 | 99 | 15,2 | Bronze |

| 50 | 300 | 99 | Brown | |

| 51 | 600 | 99 | Brown semitransparent | |

| 52 | 500 | 80 | Bronze (lighter) | |

| 53 | 500 | 60 | Dark golden | |

Pictures of different layers

Enjoy!

Learn more about Endurance 4 watt DPSS laser module and laser lens pack for DPSS!