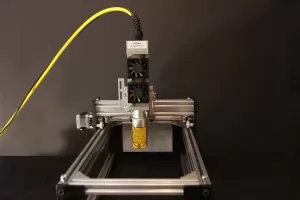

We make custom CNC frames for makers, hobbyists and professionals. A CNC frame can be equipped with a spindle, Co2 laser, diode-pumped solid-state laser, fiber laser, diode laser, plasma cutter, etc.

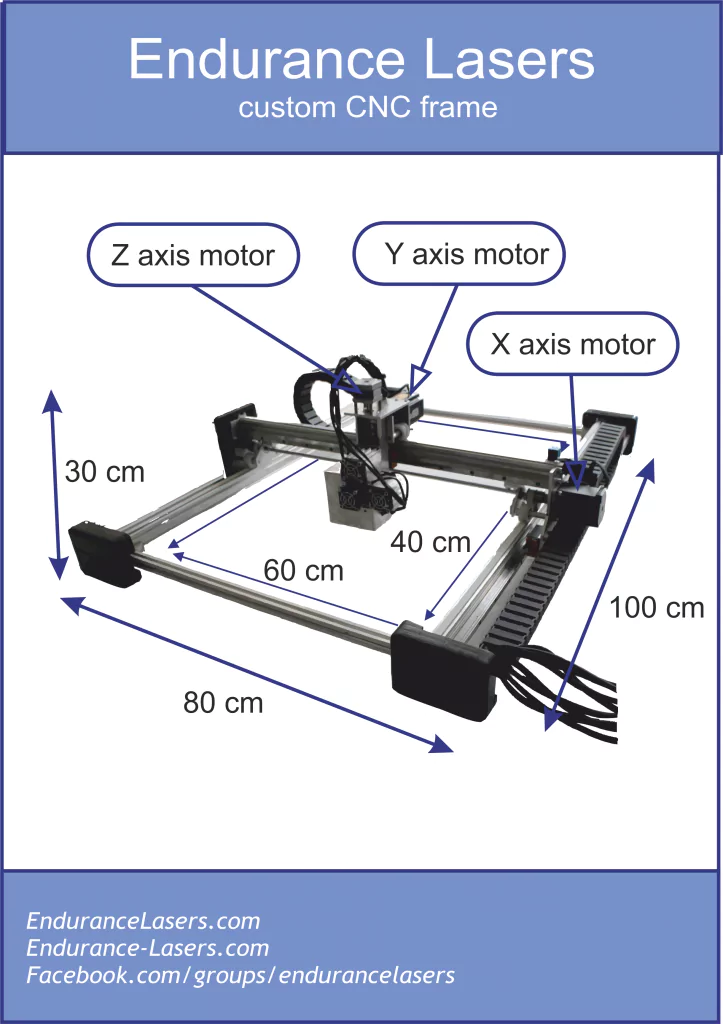

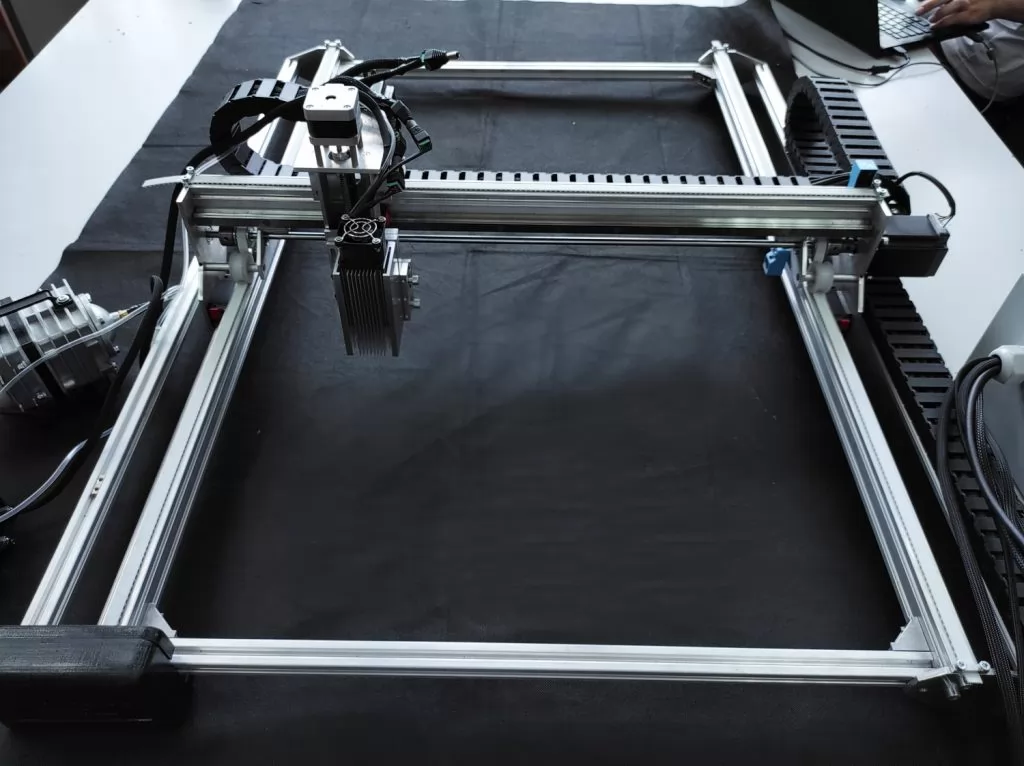

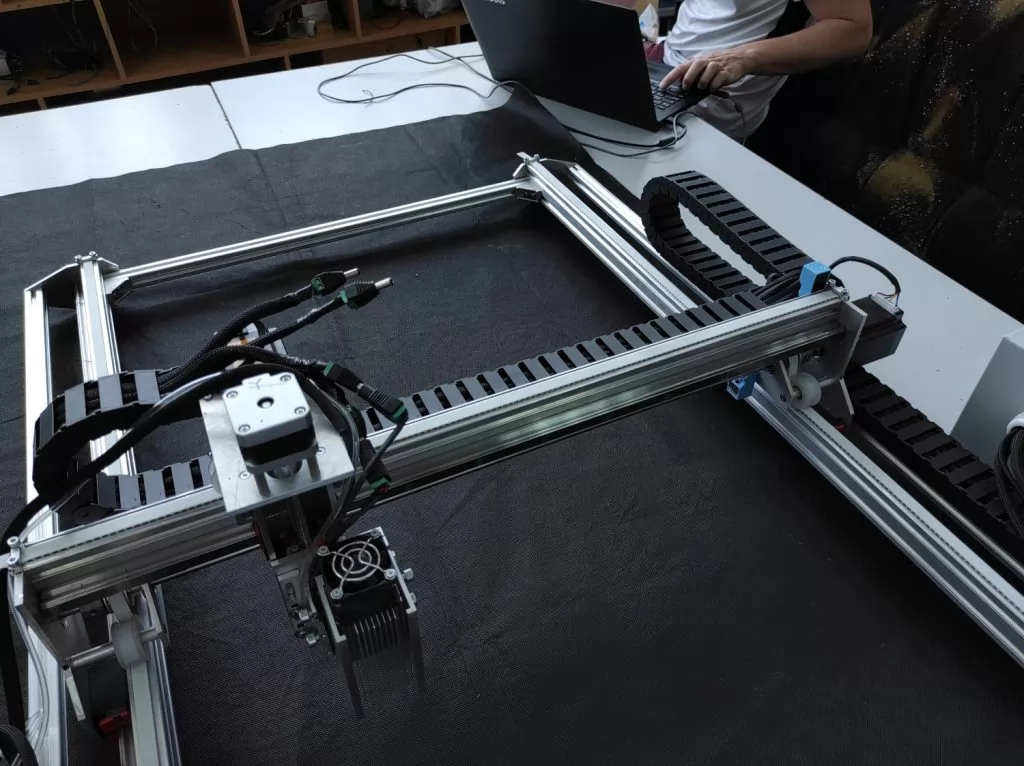

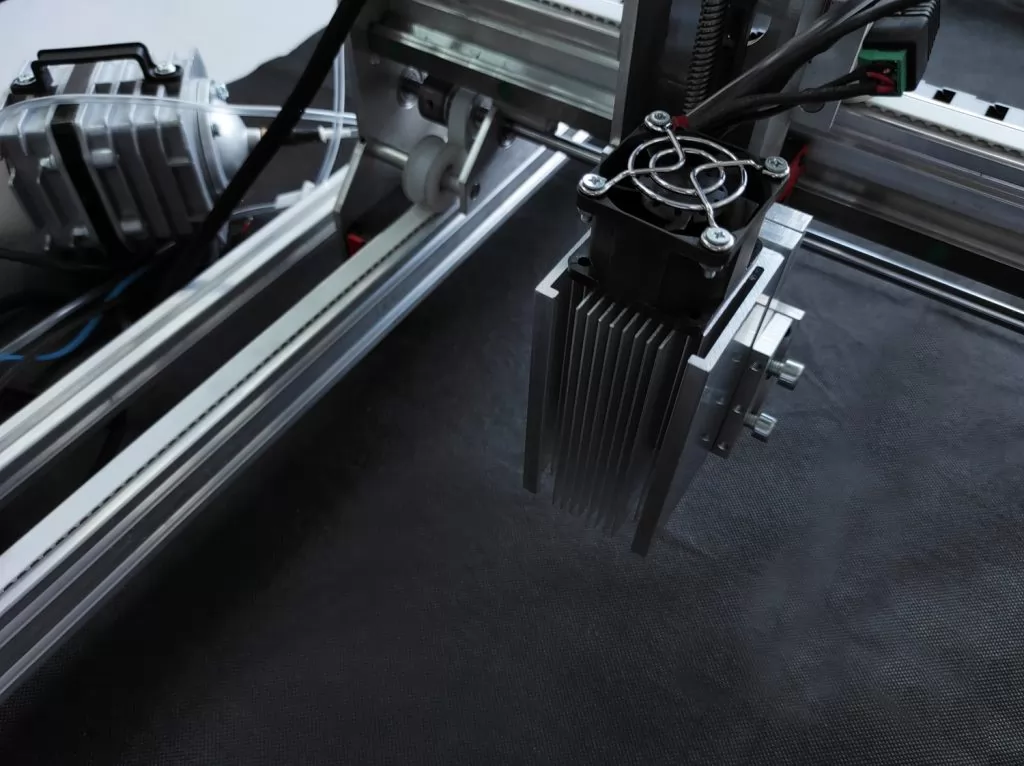

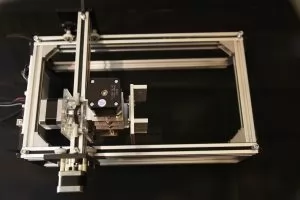

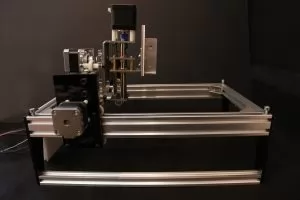

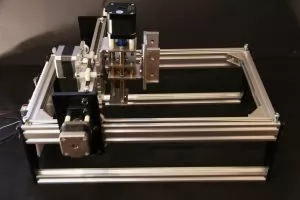

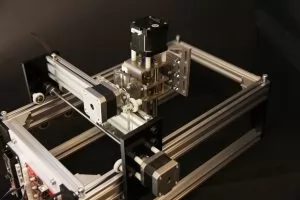

CNC frame 100×60 cm (40×24”) working size with Z axis for 15 watt dual laser system

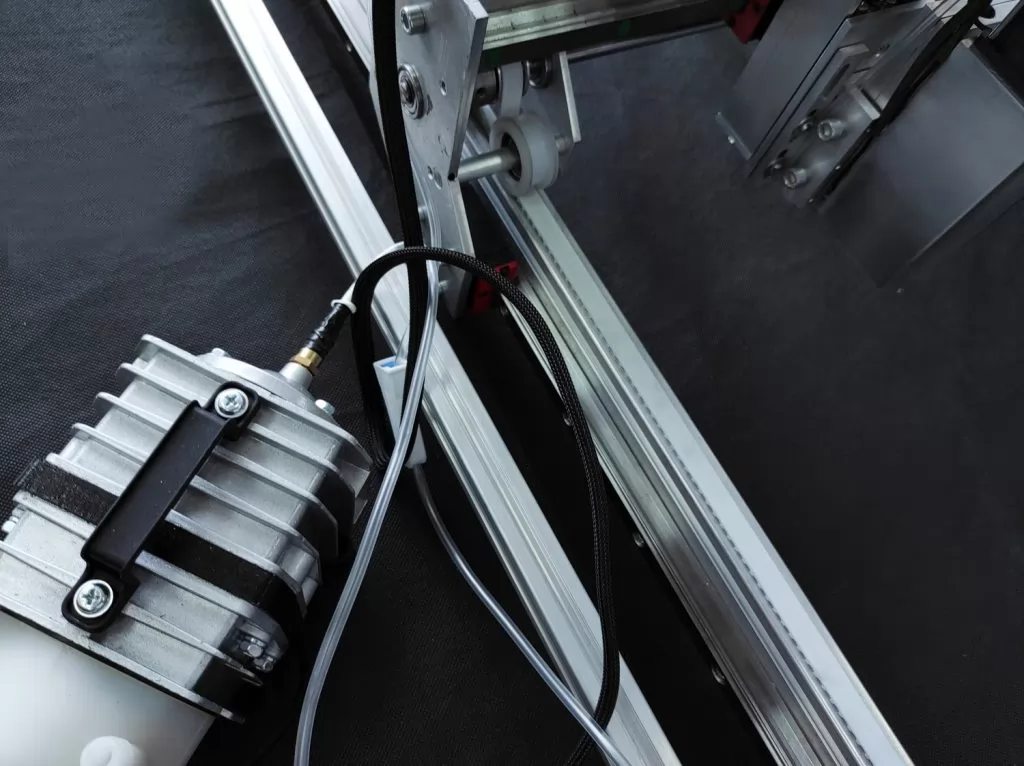

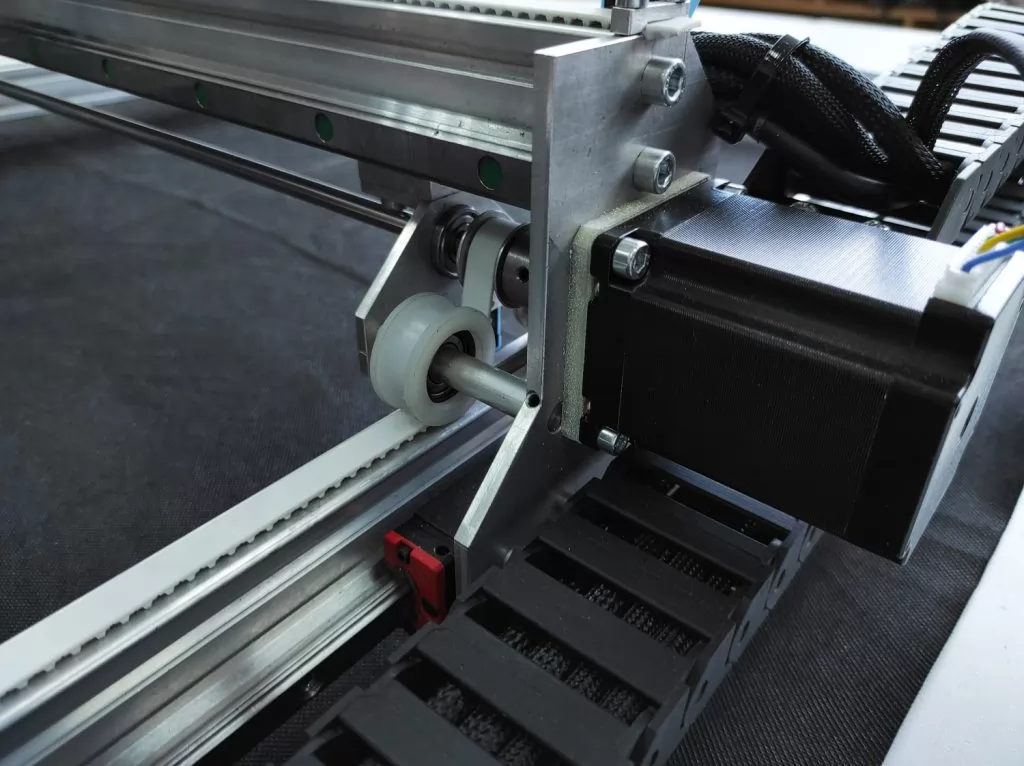

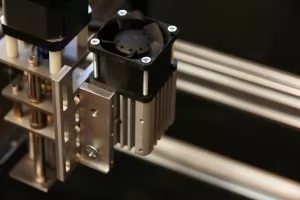

Mechanical components

Our CNC frame is made of an aluminum profile 20×40 mm, has a Y-axis drive via XL-5.08mm 10mm belt. For high precision we use a profile guide 15 mm with pulley z – 20 teeth bore 6.35 mm.

High precision & a high speed with no vibrations are keys mechanical features of this frame.

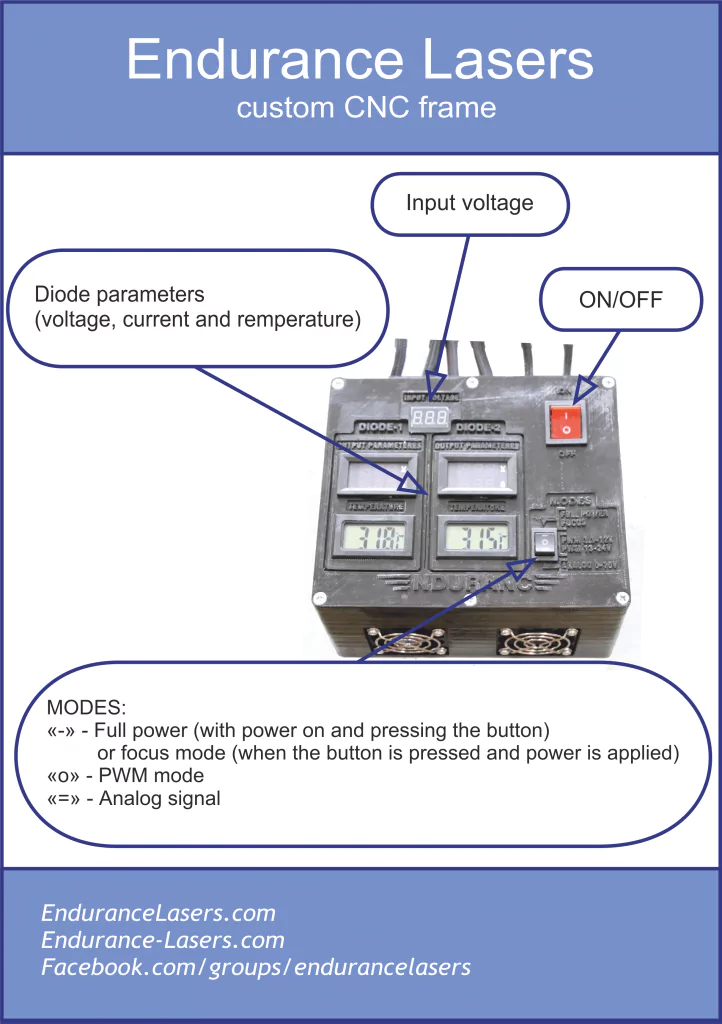

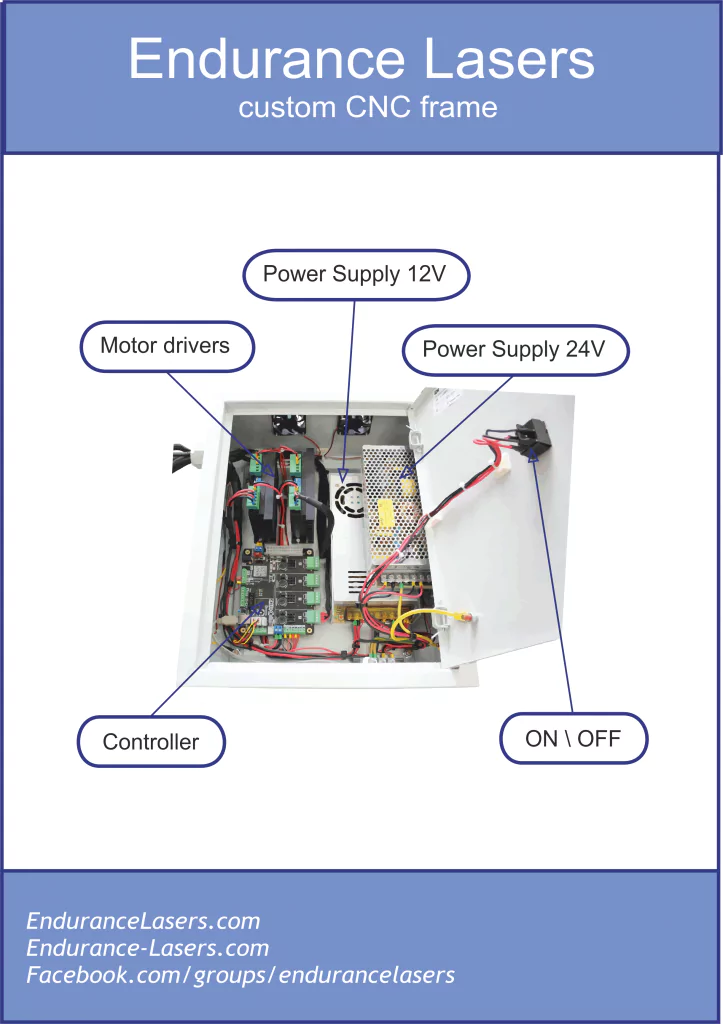

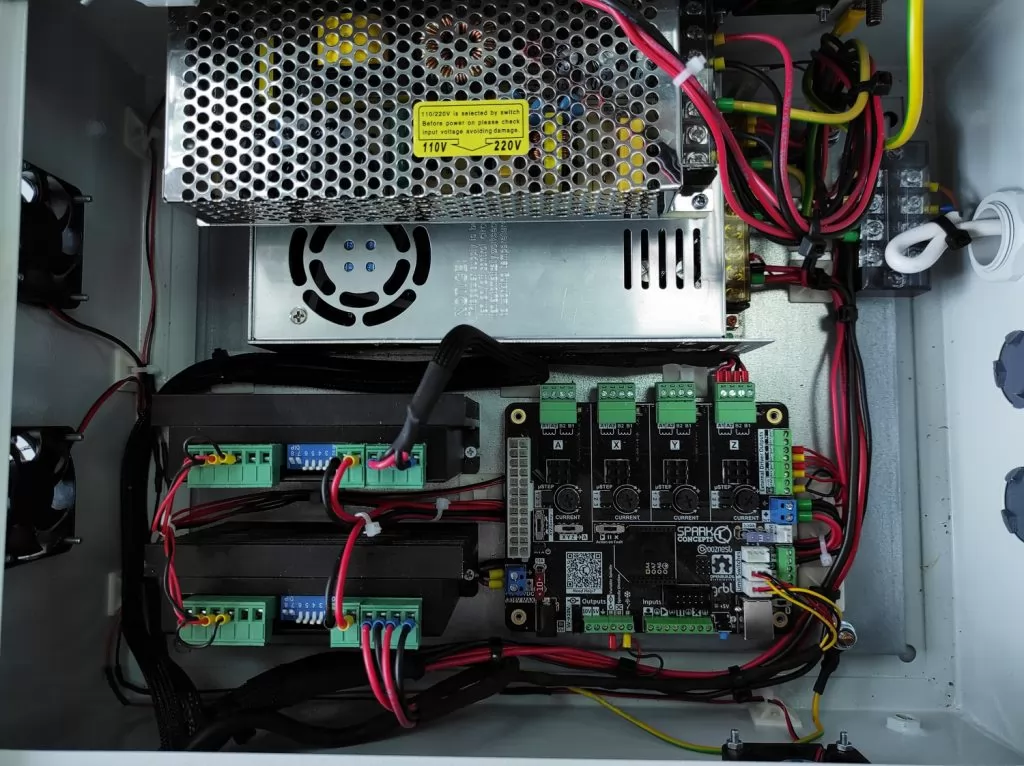

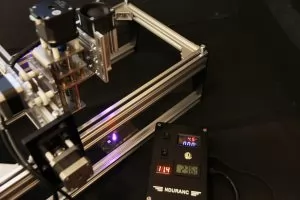

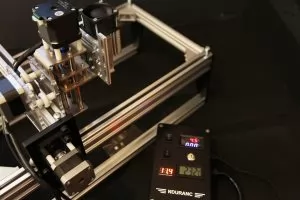

Electronic components and wiring

We pay much attention to electronics components. All components are being securely tested before installing them.

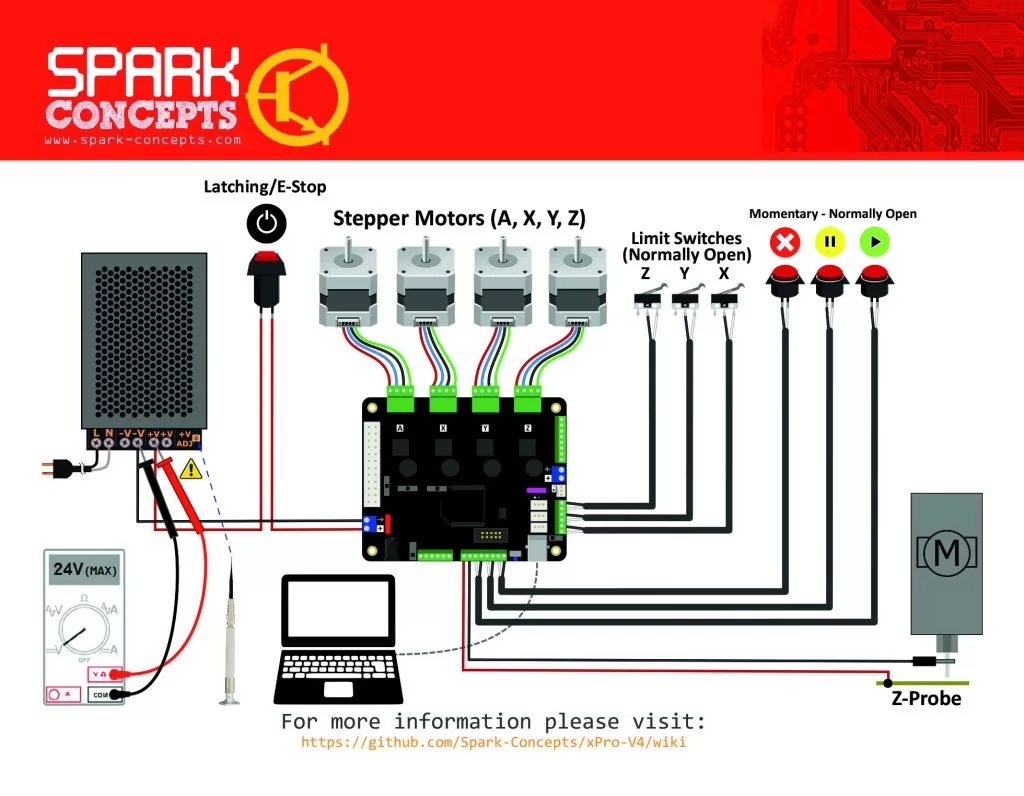

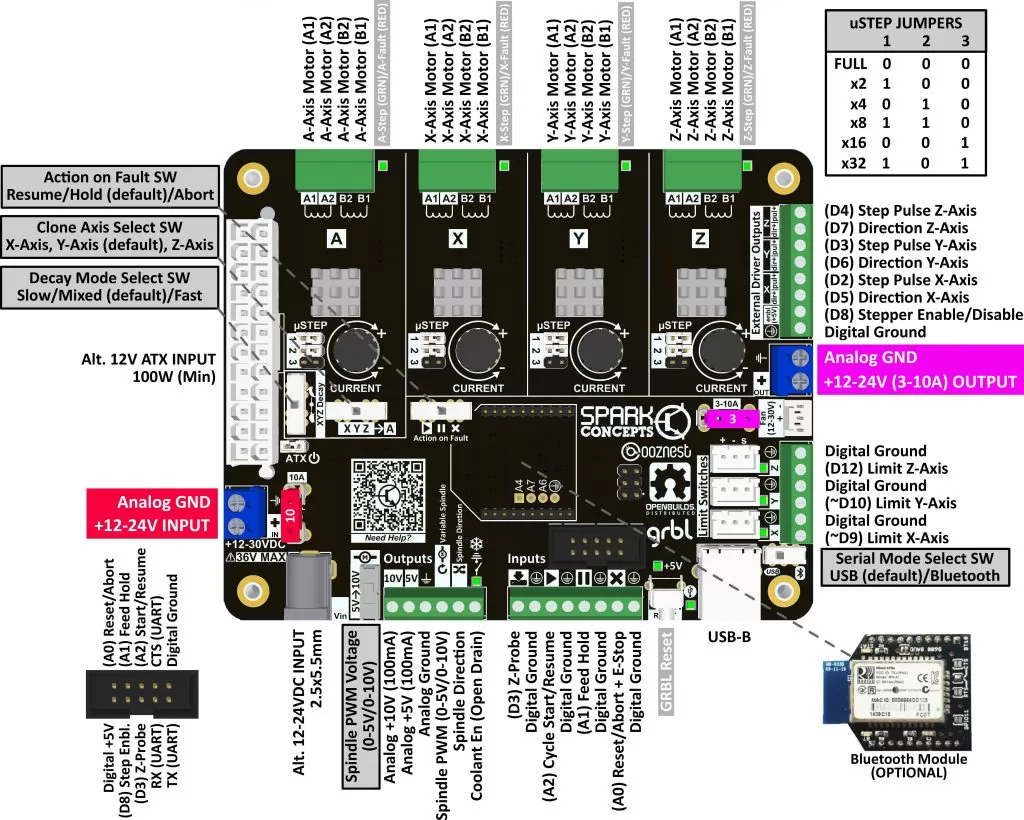

In this frame, we used a CNC xPRO V4 Controller (by Spark Concepts) and Leadshine stepper motor drivers.

- 2x stepper motor drivers

- 3x NEMA stepper motor enginers

- 36V PSU

- 12V PSU

- CNC xPro ver. 4

However, a Ruida controller (RDC6442G) can be used upon request.

Keep in mind that low-cost electronics that are used on such frames ar Ortur, Genmitsu (Sain Smart), Eleksmaker, CNCC Laseraxe, etc can not be used on a professional machine.

Endurance lasers make and deliver custom CNC frames of all sizes for different industrial applications: milling, cutting, engraving, marking. Multi-level testing system. Ultra-high reliability.

Tech specs

| Name | Endurance Custom CNC frame 1 | |

| Size | 825 x 1070 x 332 | mm |

| Material | Aluminum Alloy | |

| Working Area | 450 x 750 | mm |

| Max Z Travel | 60 | mm |

| Max Travel Speed (X / Y / Z) | 3000 / 3000 / 100 | mm / min |

| Accuracy | 0.01 | mm |

| Motor Drivers (X / Y / Z) | Darxton ST57-76 / Hanpose 23HS7628S / Darxton ST57-76 | |

| Steps / mm (X / Y / Z) | 104.588 / 104.509 / 199.1 | |

| Communication Interface | USB | |

| Control Board | Spark Concepts CNC xPRO V4 | |

| Firmware | Grbl 1.1h | |

| Software Support | LaserGRBL, LightBurn | |

| Supported OS | Windows 7/8/10 | |

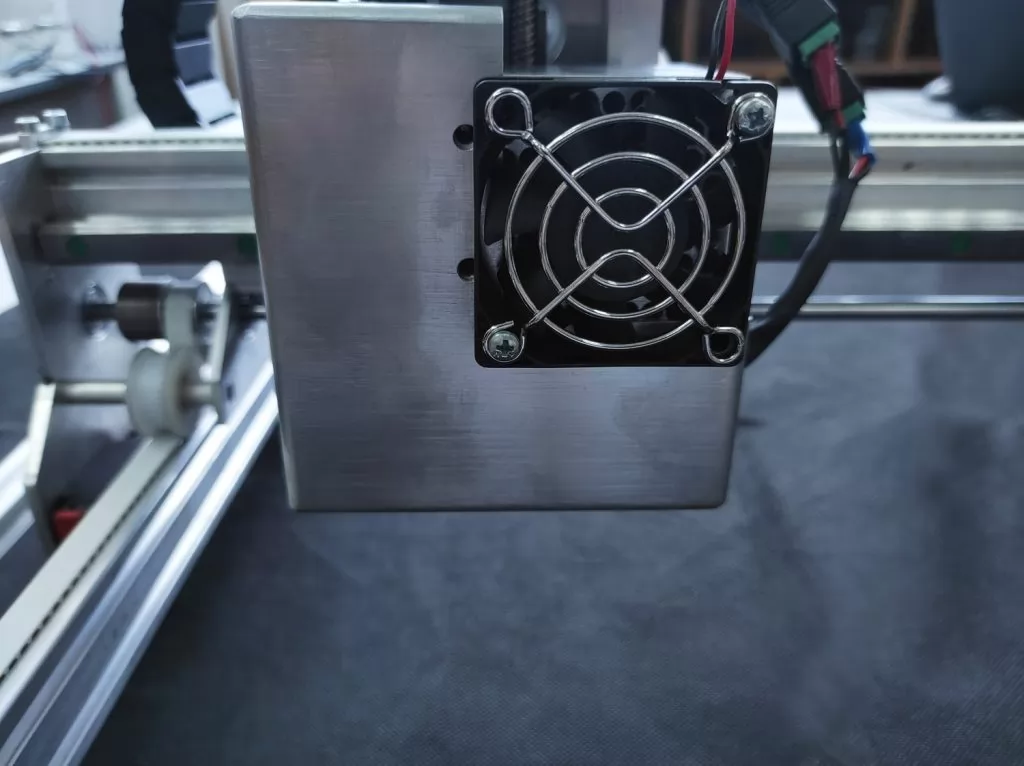

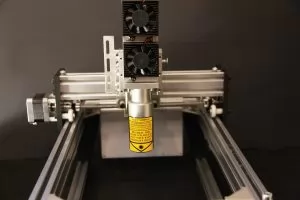

| Laser | Endurance 15W “Duos” Laser Beam System | |

| Power Supply Box Size | 350 x 430 x 160 | mm |

| Air assist | 2 x air nozzle ver. 1. | |

| OS | Win / MacOS | |

| Warranty | 1 year | |

| Maintenance | Keep the frame and the laser clean | |

| Laser Box Size | 181 x 162 x 106 | mm |

| TEC Control Box Size | 134 x 115 x 45 | mm |

| Supply Voltage | 240 | V AC |

We have huge expertise in building all types of custom CNC frames.

Our recent projects.

A CNC vertical frame 2×2 meters (6×6′). Lead time 4 weeks.

A CNC vertical frame 6×4 meters (18×12′). Lead time 4 weeks.

A huge CNC frame 6×4 meter (18×12′). Ultimate laser engraving machine

All Endurance frames are assembled, tested and ready to go!

Examples of our CNC frame abilities.

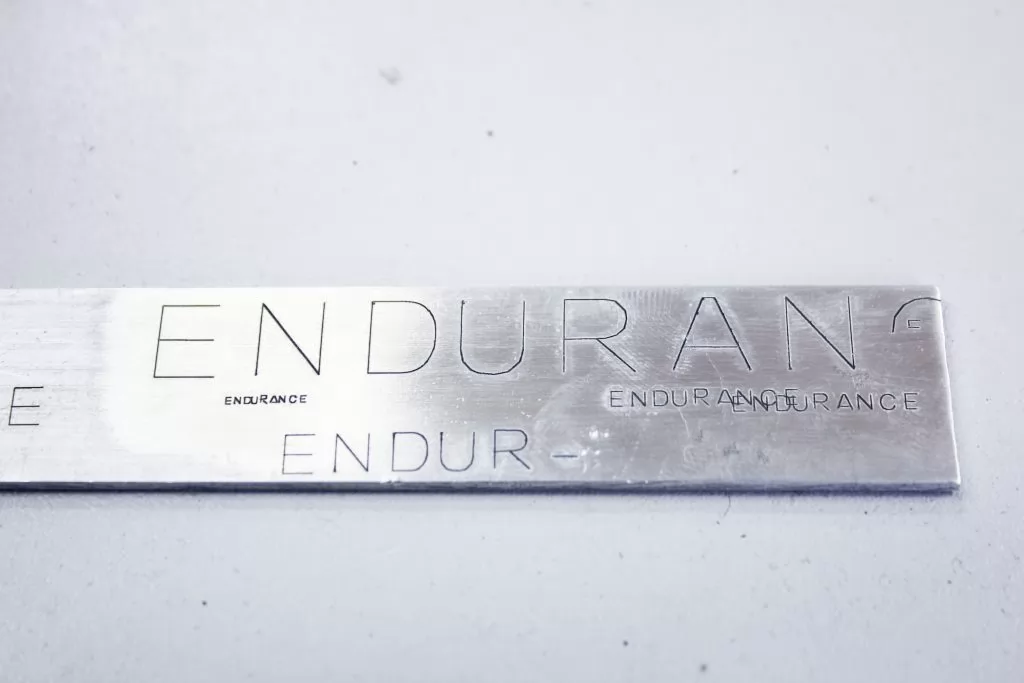

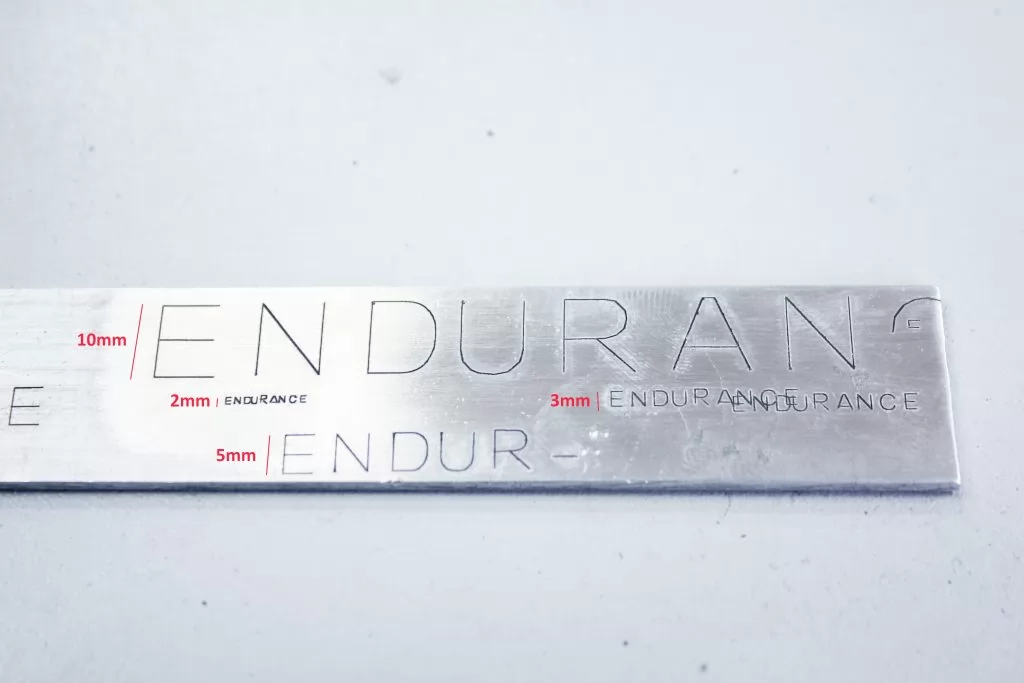

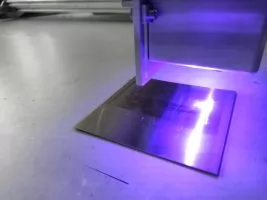

Metal engraving with a 10 watt DPSS laser module.

Metal engraving using a 15 watt “Duos” Endurance laser

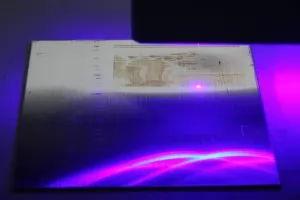

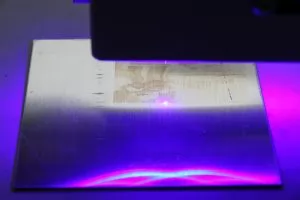

Photo-engraving on stainless steel

MDF / plywood (laser ply) cutting. Live test!

Live video of laser engraving on granite using 15 watt “Duos” laser.

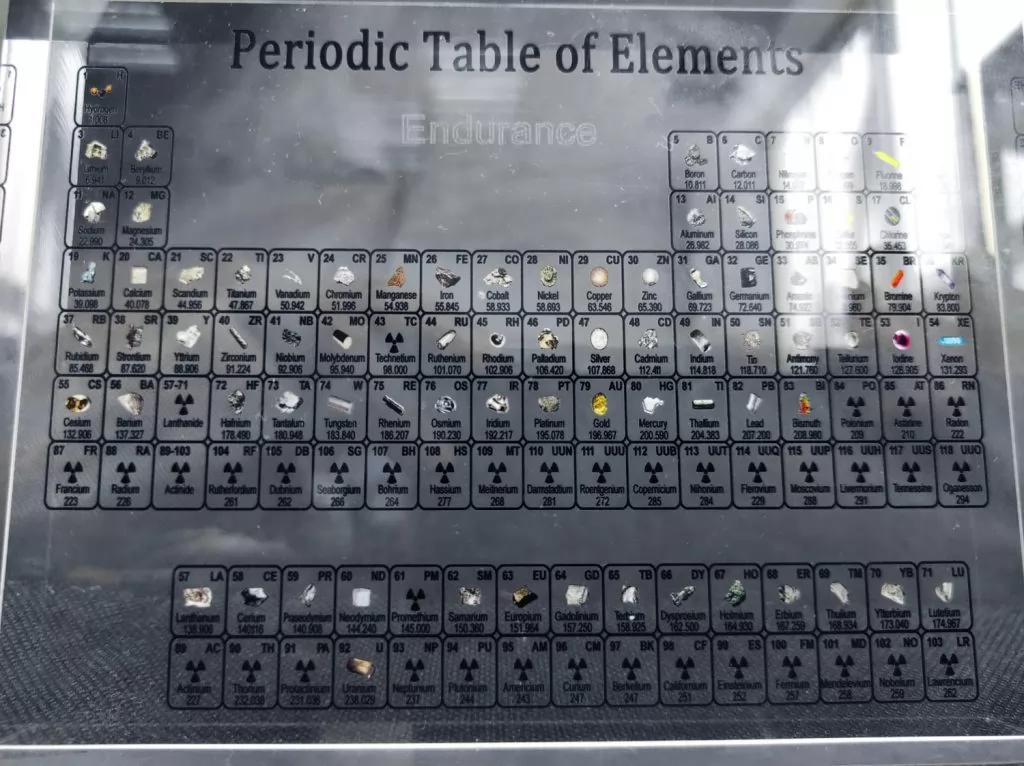

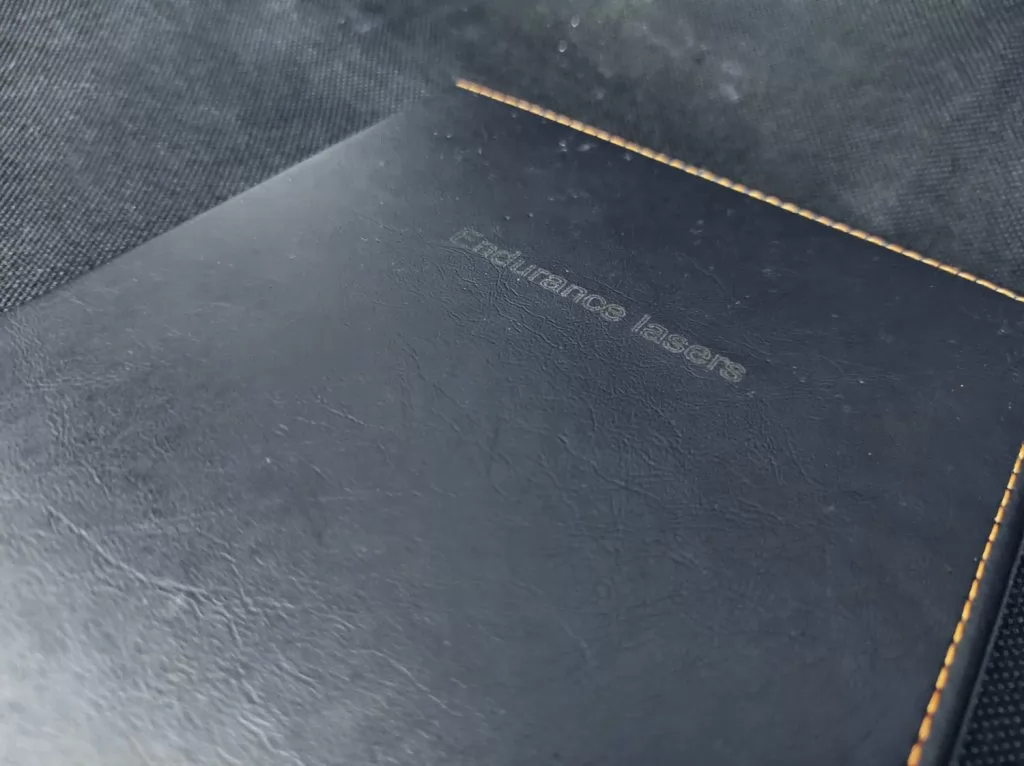

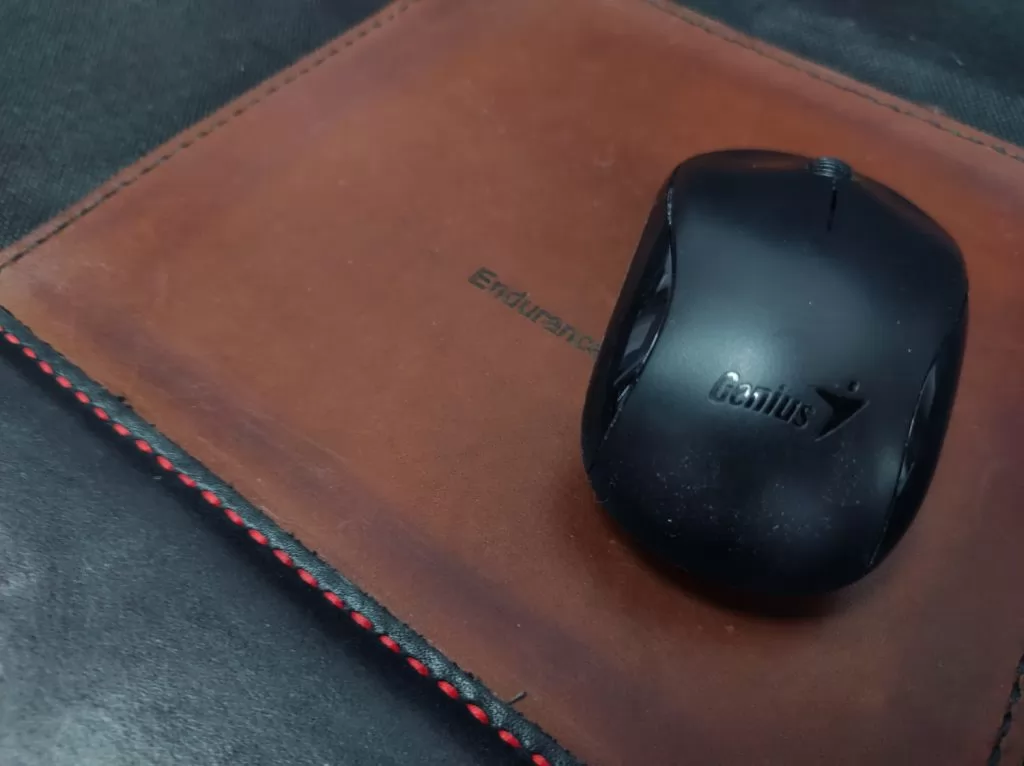

Other examples: engraving on leather, glass, acrylic, and ceramics.

Live laser engraving demo

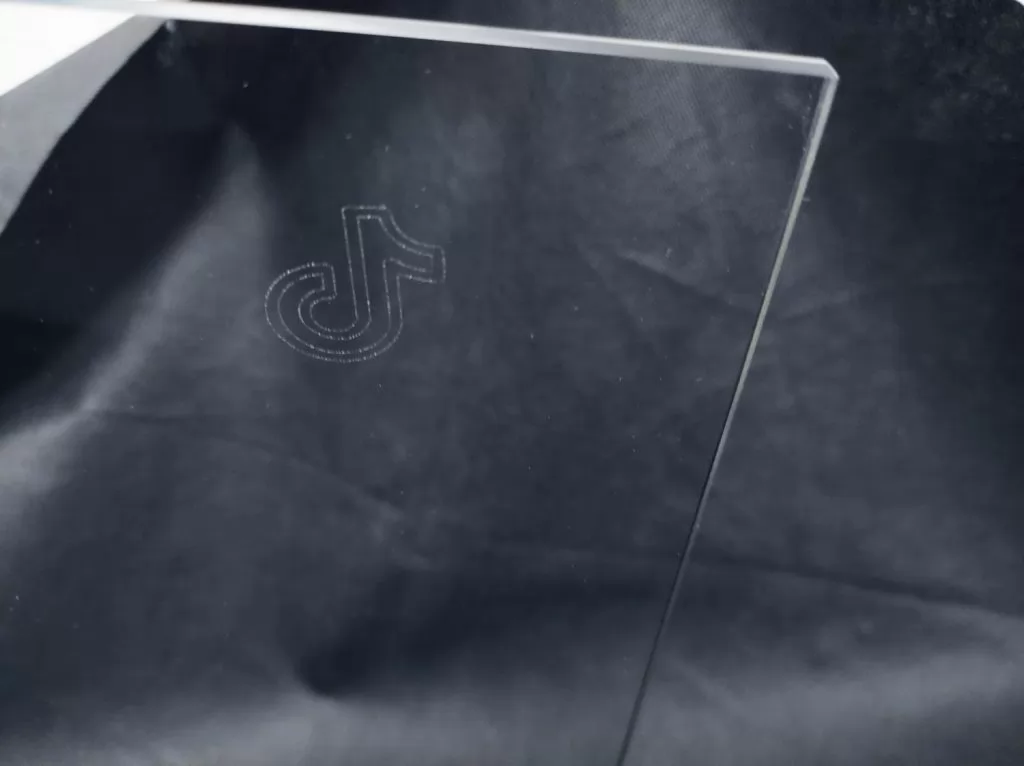

Engraving on a transparent acrylic and glass

Before the shipment, we make all necessary final tests

Final CNC frame tests

| CNC test check report | Electronics |

| Final test | Control board stability |

| Working size | Laser temperature |

| Lightburn | PWM |

| Max cutting speed | Focusing |

| Max engraving speed | Laser beam spot |

| Z-axis length | Motors test |

| End stops | Drivers test |

| Photoengraving | Firmware test |

| Home position | Resonance test |

| 100 repeats test | |

| MAX / MIN travel speed | Mechanical |

| Laser engraving parameters | Backlashes |

| X-axis travel speed | XY vibrations |

| Y-axis travel speed | Z-axis vibrations |

| The maximum workpiece height | Z-axis power |

| The maximum workpiece height | Stepper motors temperature |

| Machine weight |

Getting started: guides and tutorials.

readme 3-First start LightBurn

DHL express delivery worldwide.

The estimated price range for CNC frame (different sizes and different modifications) *

| Working size of a CNC frame | Mechanics costs | Electronics costs | Assembling | Total costs | Lead time | DHL express delivery costs | ||||

| minimum, USD | optimal, USD | minimum, USD | optimal, USD | minimum, USD | optimal, USD | minimum, USD | optimal, USD | 3-5 days | ||

| 1×1 m (3×3′) | 750 | 1000 | 750 | 1000 | 750 | 1500 | 2250 | 3500 | 3-4 weeks | 1000 |

| 2×2 m (6×6′) | 2000 | 3000 | 2000 | 3000 | 2000 | 4500 | 6000 | 10500 | 3-6 weeks | 2500 |

| 3×2 m(9×6′) | 2500 | 3500 | 2500 | 3000 | 2500 | 4875 | 7500 | 11375 | 3-8 weeks | 3500 |

| 3×3 m (9×9′) | 3000 | 4000 | 3000 | 3500 | 3000 | 5625 | 9000 | 13125 | 4-8 weeks | 5000 |

| 6×4 m (18×12′) | 5000 | 7500 | 4000 | 5000 | 4500 | 9375 | 13500 | 21875 | 4-8 weeks | 7500 |

* those prices are given as an average estimation.

Our CNC frame can be equipped with a:

- Diode laser (1-20 watt),

- DPSS laser (1-10 watt),

- Spindle (up to 2.2kW),

- Fiber laser (30-200 watt),

- Co2 laser (40-500 watt),

- Plasma

- Knife.

There is an opportunity that it will be a combo “2 in 1” or “3 in 1” like DPSS+Spinder+Diode.

We can add a vacuum cleaner, a fume extractor, an enclosure, and a working table upon request.

We also can build a CNC frame that will operate in a horizontal and vertical position.

Basic mechanical components for a CNC frame:

We always use aluminum profiles for the mainframe.

We use guides with a deviation of not more than 5 microns (0.005 mm)

To move the carriage we are using a helical rack, or using a ball screw pair, or using belts.

- Gearboxes (are used to reduce the load on a stepper motor.)

- Worm gearboxes

- Structural shapes (are used to connect the frame)

- Aluminum shapes: 40 x 40 – 60 x 120 mm (basic construction material for a frame)

- Steel guides (are used to secure accurate movement)

- Metal belts (are used for the movements)

- Shapes connectors (are used to connect all elements)

- Aluminum sheets (are used for a custom development)

- Runner slides

- Cylindrical rails (are used for the movement, more accurate comparing to belts)

- Runner blocks

- Helical rack modules (are used for the movement.)

- Screw (helical) gear modules (are used for the movement.)

- Ball screws (are used for main connections)

Basic electronics components for a CNC frame:

- Stepper motors with encoders (are used as a main component for the movement)

- Drivers of a servo-stepper motor (SSM) (are used to control and operate the motor)

- Microswitches

- Signal cables (are used to wire control)

- Power supply cables (are used to feed components with power)

- Connectors (are used to make connection easy and nice)

- Controller with/without a display

- Flexible plastic cable ducts (are used to carry cables)

- Mount for a cable ducts

An example of an Endurance 600x400x150 mm CNC metalworking machine. Full components list a PDF file >>> CNC frame components list

An example components list of 100×100 cm light CNC frame (3,28′ x 3.28′ )

An example of a 20 x 40 cm (8×16”) light CNC frame machine with belts

Do you have a question or do you need a quote?!

Ask us in LiveChat or email us your request to [email protected]