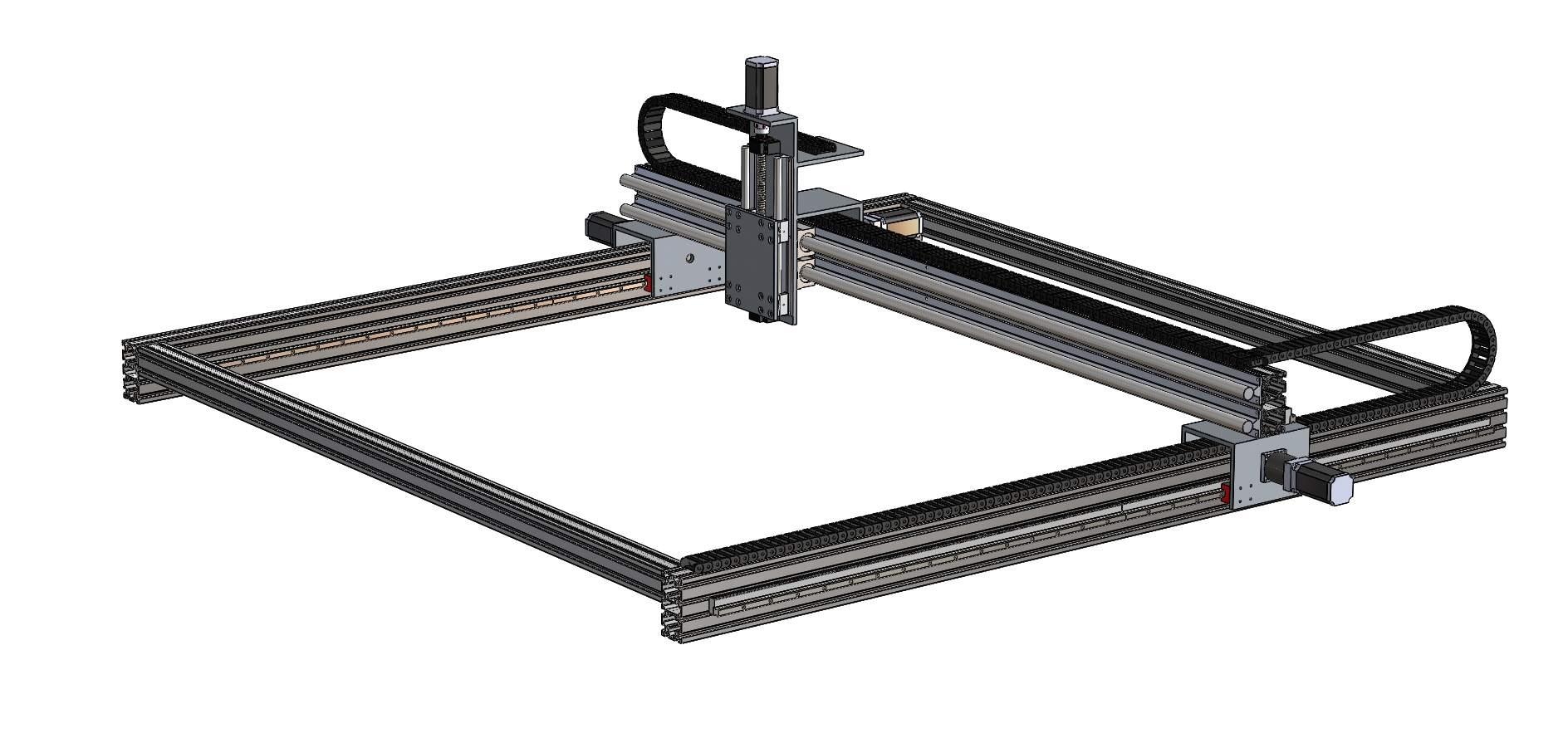

Big industrial CNC frame from Endurance lasers – custom solution #1.

A new word in the CNC industry!

We are proud to present a custom CNC frame.

- The working area is 2×2 meters (6.5×6.5 feet)

- Reliable controller by Pure logic.

- Professional laser box with drivers and controlling systems

- Ultra-high precision.

- Accuracy is 0.1 mm.

- The maximum working speed is 3000 mm/min

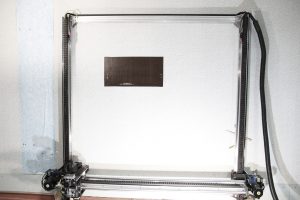

- It can work in horizontal and vertical positions.

- It can operate with a diode laser, DPSS laser or a spindle.

- It can carry up to 80 kilos on Y-axis and operates perfectly.

We are proud of this machine and you will be more than satisfied.

Presentation of a machine by CEO and founder of Endurance – George I Fomitchev

Can operate in vertical position.

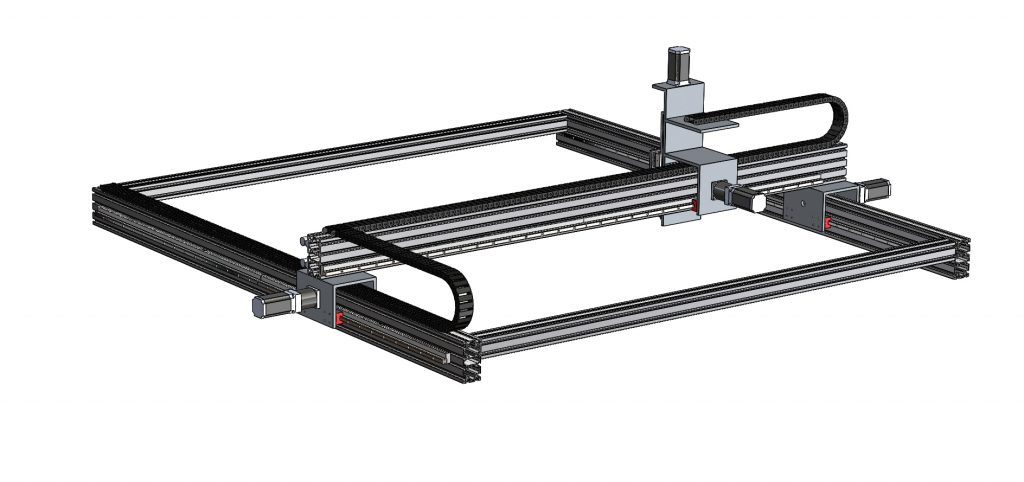

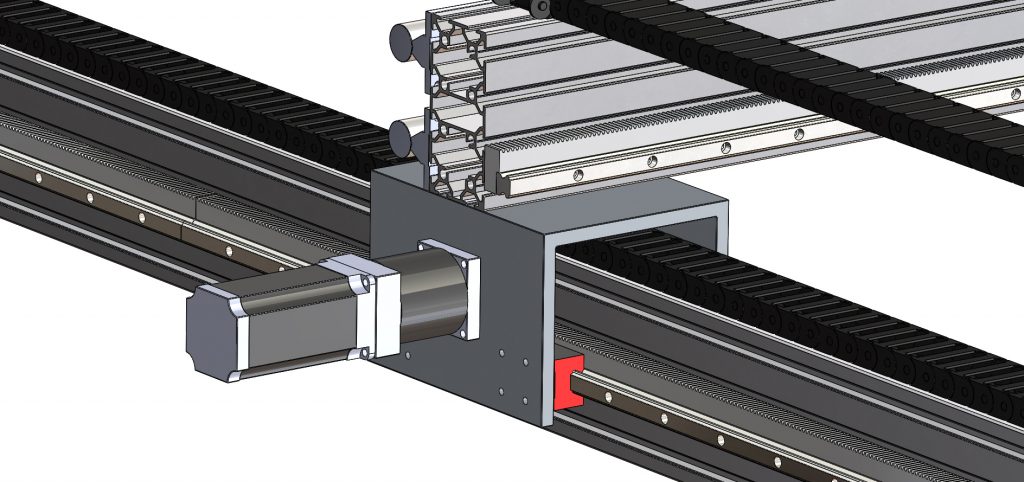

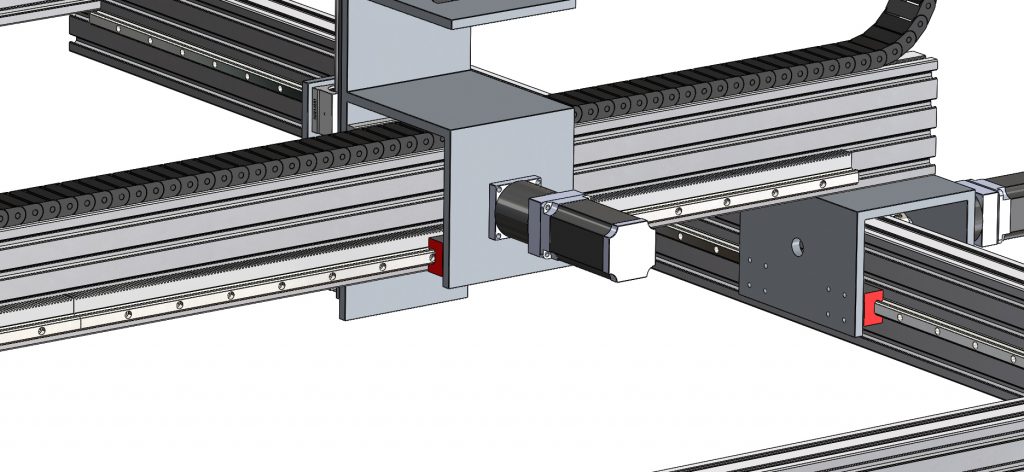

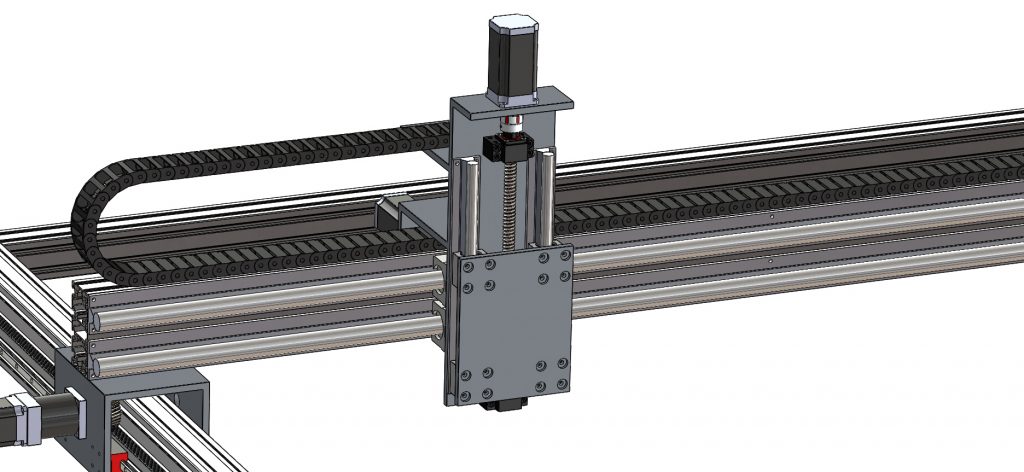

3D Design of 2×2 m CNC machine.

Sketches and drawings

Full assembling drawing

02_SBR16_Rail_300

03_SBR16UU_carriage

04_OB-60120B-BP

05_OB-6060B-BP

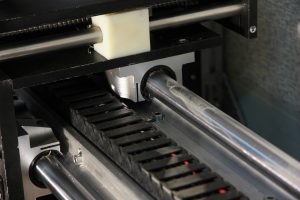

06_Helical rack

07_GHR15CA_carriage

08_GHR15_rail 09_57PX10K-145_gearbox

10_PL47H110_stepper motor

11_П plate

12_Drive 1605-400

13_SBR25UU 01.00

14_П-plate-Y

15_ballscrew 1605 nut housing

16_plate-Z

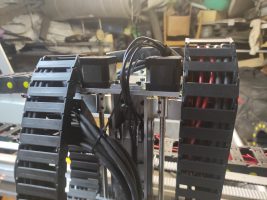

17_Chain track cell

Mechanical components – full list.

| Name of parts | Pcs |

| module 1 number of teeth 30 for a 14 mm spindle long flange | 3 |

| Gearboxes | |

| Worm gearbox 86 mm | 1 |

| NMRV-40 1:5 | 2 |

| Worm gearbox 57 mm | 1 |

| NMRV-30 (planetary) 1:5 | 1 |

| Structural shapes | |

| shape 60 x 120 segments 2 m | 3 |

| shape 60 x 60 segments 2 m | 2 |

| Shapes connectors : | |

| Right-angle connectors for shapes 60 x 60 | 6 |

| End plates connectors | 4 |

| Aluminum sheets: 10-12 mm thick, size 200 x 300 mm | 9 |

| Runner slides : | |

| Section-shaped rail 15 mm – 2 m long | 5 |

| Runner blocks for runner slide 15mm / (simple flangeless ) and (long flangeless) | 10+2 |

| Cylindrical rail ф25 segments 2 m long | 2 |

| Runner blocks for runner slide ф25 | 4 |

| Cylindrical rail segment ф16 1m | 1 |

| Runner blocks for ф16 rail | 4 |

| Helical rack module 1 – segments 2 m long | 3 |

| Screw (helical) gear module 1 with a long flange and 30 cogs | 3 |

| Ball screw (BS) 1605 400 mm long with a screw nut | 1 |

| Ball screw mounting supports for 2 ends | 1 |

| Stepper motors | 4 |

| Name of the part for a machine 6×4 meters | |

| The list of parts | |

| — shapes 60 х 120 sections : | |

| 2 m | 2 |

| 4 m | 5 |

| —-TRH15 15mm (shaped guidance rail) sections: | |

| 2 m | 4 |

| 4 m | 5 |

| 1 m | 1 |

| TRH15-B / HGH15CA | flangeless carriage 15 mm | 12 |

| SBR-C20 cylindric rail sections D20mm: | |

| 4 m | 1 |

| SBR20UU | (carriage for sBR D20mm) | 4 |

| 1605-4 | (ball screw D16mm, step 5mm) — section length L- 400 mm | |

| SFU1605-4 | 1605 (ball nut) | 1 |

| EF-12 | (floating bearing support D10mm) | 1 |

| EK-12 | (Fixating bearing support D12mm) | 1 |

| MGD16 | SFU1605 (ball nut mount) | 1 |

| 1031 | 60х60 (simplified right angle connector) | 14 |

| S8S30 | (insert block, solid aluminum, groove 8) –section length 2 m | 6 |

| 2027 | (Linear steel connector 160 mm, groove 8 ) | 20 |

| 5296 | (thread insert M4x5mm) | 20 |

| 5079 | (thread insert M6x8mm) | 100 |

| Г-12-У-30 | (Connecting plate L-type, 12 holes, heavy duty) | 4 |

| Helical rack RH1BG-15, code ER-00005586 module 1, for a shaped rail HGR15 or GHR15 L 2m — 8 pcs | 8 |

| Skew gear GH1-T30D14 module 1, for a spindle 14mm, 30 cogs | 1 |

| Joint 20mm, L=25mm, d1=8mm, d2=8mm, moment 3Н*m | 1 |

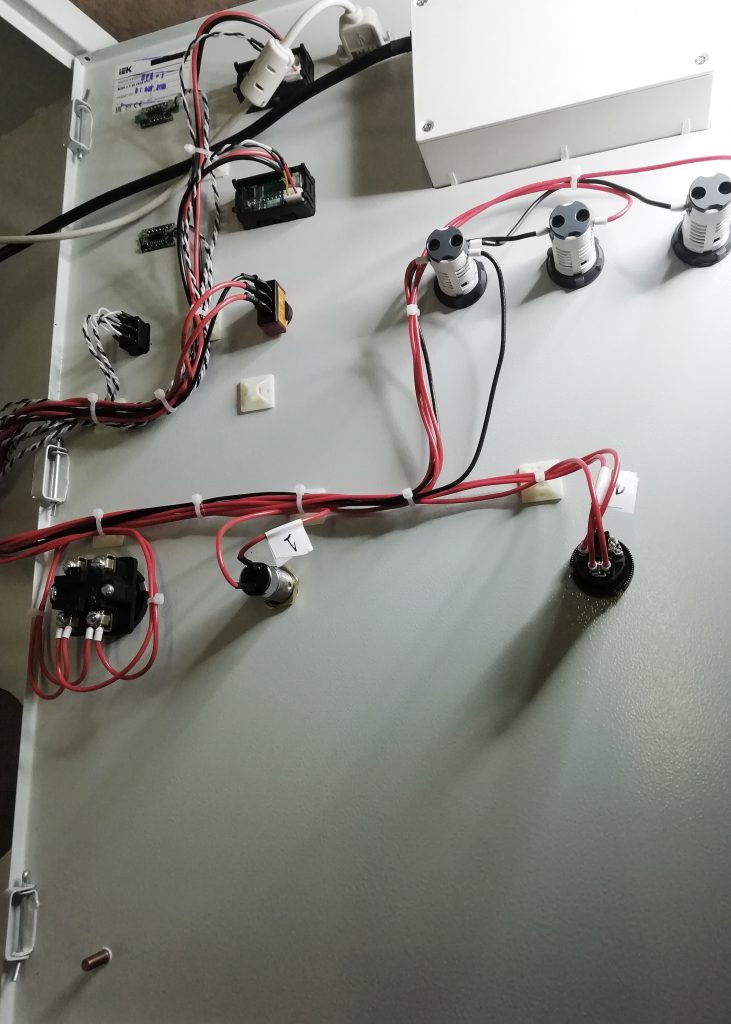

Electronic components – a full list

Electronic components

| Spindle Х (based on 6.7НхМ + power margin) | ||

| Description | Model | Features |

| Stepper motor with an encoder | PL86H4401-D14-1K | 86x140mm, 2 phases, 80kg. cm, spindle 14mm, current 5.6А, step 1.8°, 0.45 Оm, 1000PPR |

| Servo-stepper motor driver | PLDS880 | The driver of a servo-stepper motor or of a stepper motor … … 80V/10А/200KHz |

| Microswitch | XV-154-1C25 | 7.5A/250VAC, |

| two-way, НР+НЗ, | ||

| tenon 30mm, IP40 | ||

| Spindle Y (based on 2НхМ +power margin) | ||

| Stepper motor with an endcoder | PL57H1404-D8-1K | (57x126mm, 2- phase, |

| 28 kg.cm, spindle 8mm, current 4.2А, | ||

| Step 1.8°, 0.7 Ом, 1000PPR) | ||

| Servo-stepper motor driver | PLDS880 | Driver of a servo-stepper motor or of a stepper motor … … 80V/10А/200KHz |

| Microswitch | XV-154-1C25 | 7.5A/250VAC, |

| two-way, НР+НЗ, | ||

| tenon 30mm, IP40 | ||

| Spindle Z (based on 0,4НхМ +power margin) | ||

| Stepper motor | PL57H56-D8 | 57x56mm, 12.6 kg.cm, |

| spindle 8mm, current 2.6А, | ||

| step 1.8°) | ||

| Stepper motor driver | PLD330 | 2-phase (4 wires) stepper motor 30V/3А/100KHz |

| Microswitch | XV-154-1C25 | 7.5A/250VAC, |

| two-way, НР+НЗ, | ||

| tenon 30mm, IP40 | ||

| Cable and wire | ||

| Flexible mounting wire | 1х1.5 | Black |

| Flexible mounting wire | 1х1.5 | Red |

| Flexible mounting wire | 1х0,75 | Black |

| Flexible mounting wire | 1х0,75 | Red |

| Shielded signal cables | PVC0.2x8STP | Shielded signal, twisted-pair cable, |

| 8 pcs.(4 pairs)*0.2mm²) | ||

| Power unit | ||

| Power unit | 70В 17А | 70V 17А |

| Power unit | 24В 6,3А | 24V 6,3А |

| Power unit | ARS-150-12 | 12V 12,5А |

| Controller | ||

| Controller | RDC6442G | |

| Display | RDC6442G |

|

Full photo assembling process

Unassembling/assembling process of 2×2 CNC frame (photo gallery)

Building a new 2 x 2 custom machine. Technical requirements from a customer #2.

Basic Requirements of the Customer

- Development and assembling of a laser CNC machine for engraving and obtaining photos from the camera.

2 . The CNC machine controller should work on the basis of the GRBL v 1.1 firmware (the manufacturer chooses the models of the controller, stepper motor driver and other electronics).

- The computer and CNC controller connection is via a USB port or Ethernet, optionally (up to the manufacturer).

- The laser CNC machine should have 3 movement axes (2X 1Y 2 different Z) and laser power, controlled by the controller with the GRBL firmware by way of performing G-code commands of the control software. The laser power is set by the G-code commands of the control program (e.g. Lightburn, LaserGBRL (open source – MIT) too) and is controlled by the CNC controller using a PWM signal.

- The size of the CNC machine working area along X axis = 1700 mm (width of scanner), along Y axis = 2000 mm (length of scanner), along Z axis = 200 mm (hight of scanning area laser and camera)

- The maximum size of the laser CNC machine inclusive of the stepper motors protruding beyond the frames of the machine, space intervals for the sensors and safety switches of the X axis = 2000 mm, Y axis = 2300 mm, Z axis = 500 mm.

- To develop and install a Z2 axis for a video camera. To control the Z2 axis movement by Up and Down buttons on the control panel. A provision must be included for holder fasteners on the Z2 axis according to the customer drawings. Manufacturing and installment of the holder and camera is the customer’s responsibility.

- To run an interface USB3 cable (data interface) from the place of the smartphone camera installment on the Z2 axis to the control box plus extra 0.5m on both sides for the camera and computer connection,

https://www.sab-kabel.de/produkte/kabelkonfektion/usb30_leitung_handkonfektionierten_steckern.html

is to install

Also power supply cable S960 (07521215) 12×1.5mm2 https://www.sab-kabel.de/produkte/flexible-kabel-und-leitungen-schleppkettenleitungen/s-960.html

and

a cable for data transfer SD960CY (07851001) 10×0.14mm (https://www.sab-kabel.de/produkte/flexible-kabel-und-leitungen-schleppkettenleitungen/sd-960.html ), is to install.

- The maximum X and Y motion speed is 2000 mm/min, For both z-axis – motion speed so fast as you can make it.

- Make provisions for X and Y home sensors, necessarily. Make provisions for the 2 z-home sensors if possible.

- Make provisions for X, Y and z end sensors, optionally (up to the manufacturer).

- Make provisions for safety switches at the beginning and end of the X and Y axes for safe operation of the laser CNC machine along the X and Y axes.

- Make provisions for the panic button on the CNC laser machine frame (its location must be approved by the customer).

- The power supply part (the power supply unit, laser control unit, CNC machine controller) should be housed in a separate box with a mechanical ventilation system to prevent overheating.

- The control box should have a plug connection with the laser CNC machine frame and have an extra length of the wire of 1,5 m or more.

- The power supply of the CNC laser machine is 220V 50 hz.

- To install and connect an Endurance 15W Duos laser on the Z axis.

Additional requirements of the customer

Provide the possibility of switching off the laser power supply by the TTL external pulse. 0V – the laser is off. 5V – the laser is on.

BOM (components list)

Electonics

| Power supply unit 2X 1Y | RSP-750-48 | 48В,15.7А,753.6W |

| Power supply unit Z | RS-75-24 | 24В,3.2А,76.8W |

| Power supply unit | MDR-10-24 | 24В,0.42А,10W\MEAN WELL |

| Yellow emergency shutdown station | XALK178 | Emergency button 1НЗ |

| Switch | S202Z-2(S202UZ-2) | Electronic lock\Jin Tay |

| ON-OFF lighted toggle switch | ASW-14D (red) | (20A12VDC) SPST 3P\Jietong Switch |

| Fan 220V | EC1225A2HBL | 120х120х25mm, подшипниккачения, 2000 об/мин\Evercoo |

| Plug-in relay | HHC68A-1Z-24D | 24VDC / 15A,240VAC\NCR |

| Relay block | PTF08A | HHC68A-2Z (LY2)\NCR |

| Filter | FGF-120/M silver | Fan filter120х120 mm (metal)\Evercool |

| Button | КЕ-021 | “Stop” red mushroom |

| Alarm lamp | XB7EV03MP | 22mm 230V green (LED) |

| Alarm lamp | XB7EV04MP | 22mm 230V red (LED) |

| Button SB-7 | BBT40-SB7-K06 | Start (green) |

| Contactor | ПМЛ 1160ДМ | 16А 220AC УХЛ4 Б КЭАЗ 110546\КЭАЗ |

| Bar-type terminal | НШВИ 0.25-8 | blue 0.25 mm² |

| Bar-type terminal | НШВИ 0.5-8 | white 0.5 mm² |

| Bar-type terminal | НШВИ 0.75-12 | gray, 0.75mm², L 12mm |

| Bar-type terminal | НШВИ 1.5-8 | (8mm) black 1.5 mm² |

| Slotted ducting | 40х40 | L2000 RL12 G ДКС 00134RL |

| Slotted ducting | 25х40 | L2000 RL12 G ДКС 00128RL |

| Elastic mesh guards | 15PET-6 black | diameter 4 -10,5mm |

| Elastic mesh guards | 15PET-12 black | Diameter 10 -16mm |

| Elastic mesh guards | 15PET-3 black | Diameter 2,5 – 5м |

| Power supply unit (laser +tec) | LRS-100-12 | 12В,8.5А,102W |

| Ethernet transformer | UART TO ETH | (TCP/UDP) UART |

| Programable controller | Arduino Uno R3 | Orig |

| Stepper motor (2X 1Y) | ST57-100 | 4.2 А 2.6 Nm 3.8 mH |

| Stepper motor (Z) | ST42-40 | 1.2 А 0.32 Nm 2.4 mH |

| Stepper motor driver (X Y) | EM705 | voltage 20-70 V, current up to 7.0 А |

| Stepper motor driver (Z) | EM402 | voltage 18-40 V, current up to 2.2 А |

| Inductance sensor | SN04-N | NPN, NO |

| End switches | SS-5GL2 | End mini switch |

Photo gallery

Firmware + GRBL settings

A demo video (assembling process)

Laser machine protocol test