Air assist for your diode laser. Free STLs. A detailed guide on how to make your own air nozzle. 3D print an air nozzle.

Fully compatible with all diode lasers (Eleksmaker, Neje, Atomstack, CNCC Laseraxe, Ortur, Wainlux, and others lasers)

About air assist and air blowing

When laser processing various materials, to improve the quality, it is necessary to blow off the point of application of the laser. The material burns out under the influence of the laser. In most cases, combustion products remaining in the working area of the laser interfere with further processing.

For example, when cutting and engraving such a popular material as plywood, the combustion products make a cut of an ugly black color. To get rid of combustion products, blowing is used.

The theoretical part about assist

During laser processing, the material burns out. Its combustion products not only impair the quality of the product but can also harm the laser. The smoke from the material is warm. Rising up, it approaches the optical system of the laser and can settle on it. Over time, from the settled smoke, the lens will lose transparency, and, accordingly, the power of the laser will decrease.

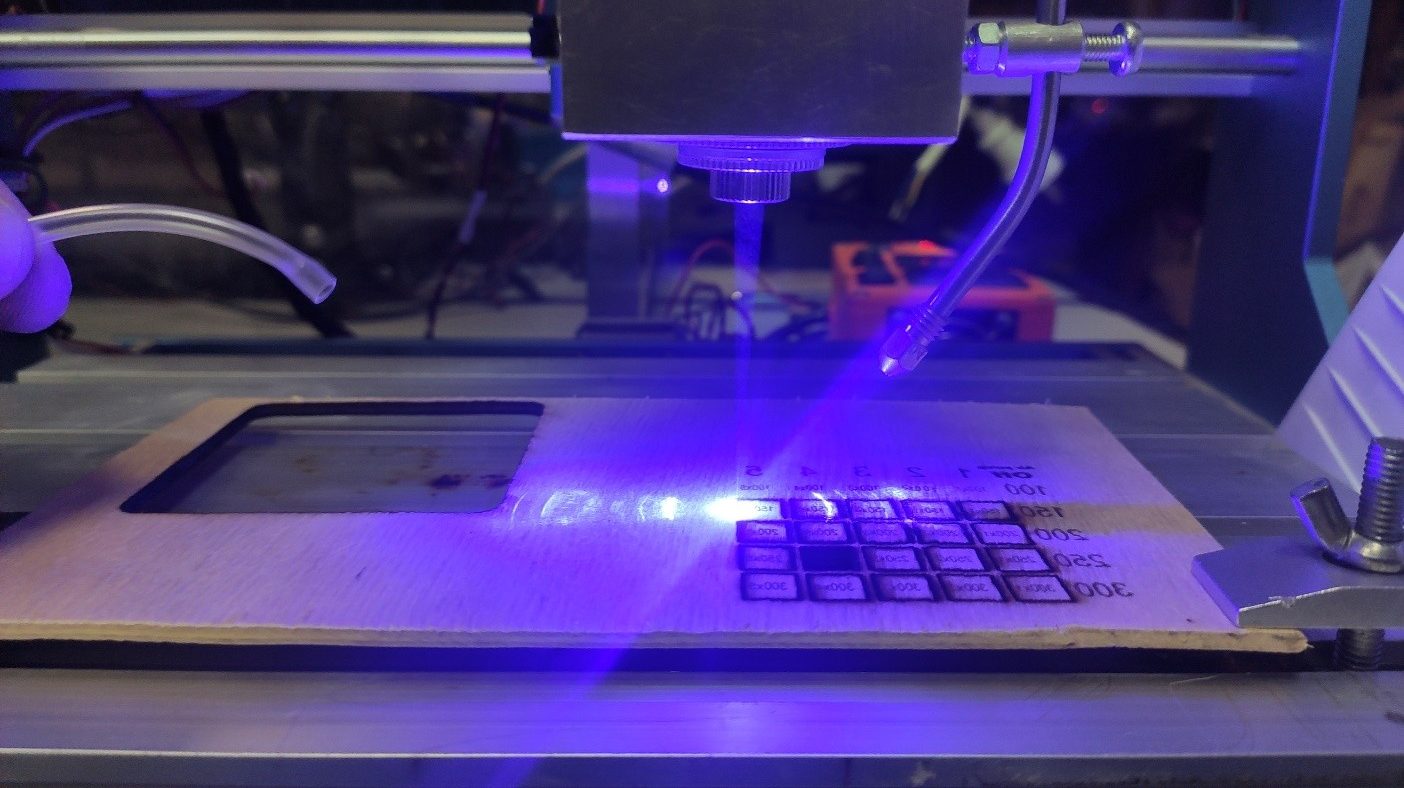

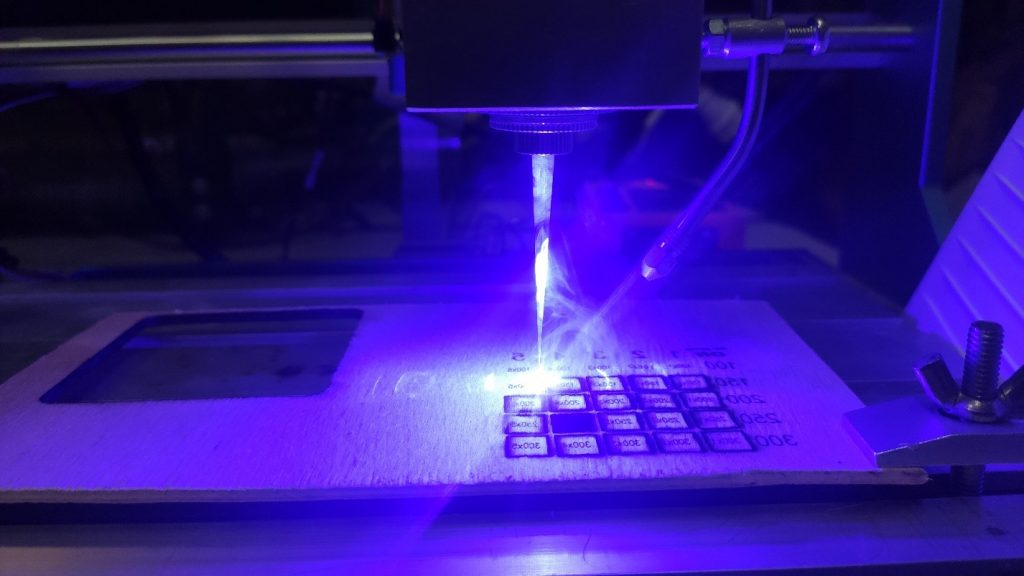

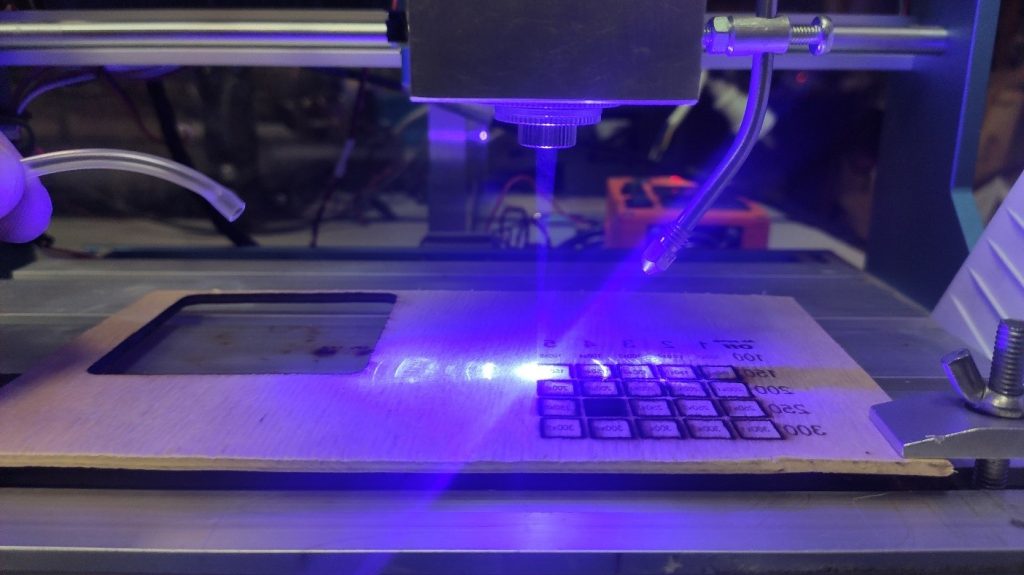

In the photo below you can see the operation of the laser when the airflow is off

We purposely focused the beam at such a distance to clearly show the difference. In the photo above, you can see a lot of smoke, which is even near the optical system of the laser.

We purposely focused the beam at such a distance to clearly show the difference. In the second photo, you can see a lot of smoke, which is even near the optical system of the laser. Also, due to a large amount of smoke, the operation of the optical system that focuses the beam is clearly visible.

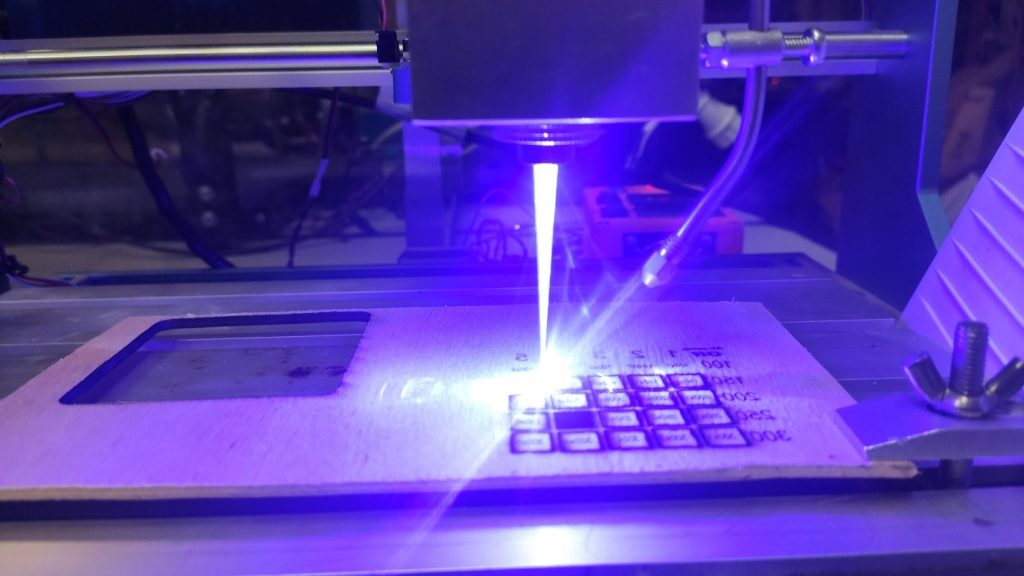

When the airflow is on, the laser beam is seen much weaker, this indicates that it passes through the air, with minimal

Airflow on

Blowing also cools the area near the cut what makes the area clean.

Practical part

Comparison of 2 versions of air-assist(ver 1.0 “side” and ver 2.0 “vertical”) and laser cutting without air assist.

We will use:

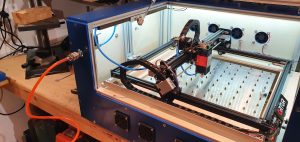

– CNC Router Kit Sain Smart CNC 3018

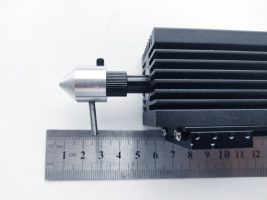

– 10 Watt 445 nm blue laser module “DeLux”

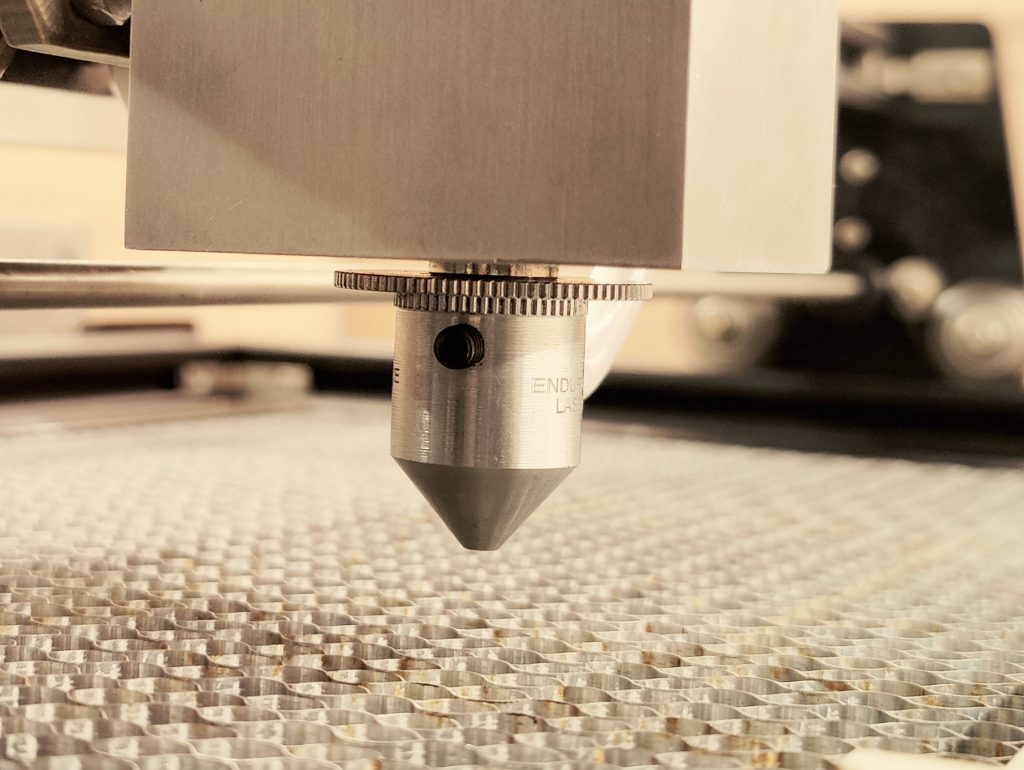

– Endurance air nozzle. Ver 1.0

– Endurance air nozzle. Ver 2.0

– Plywood 3mm (3/16”), density = 0.7 g / cm^3

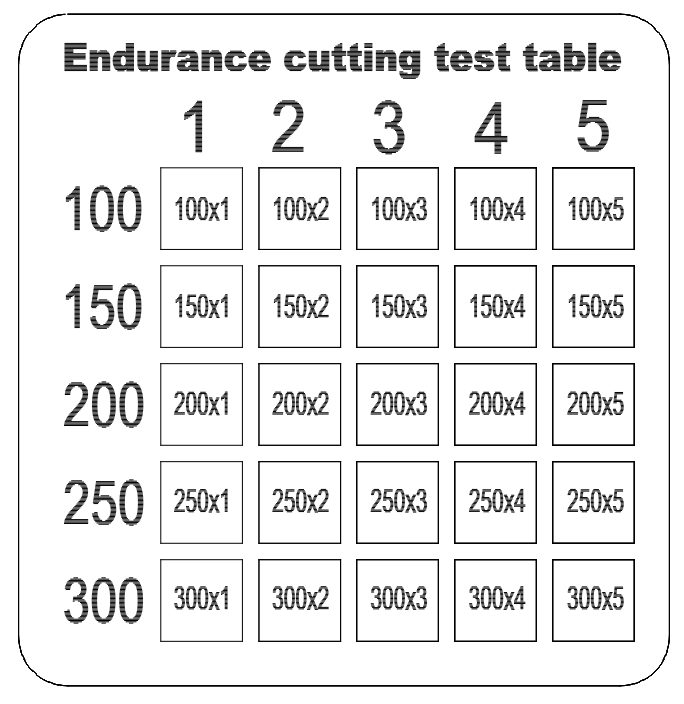

For experiments, we will use a test cutting table. (You can use it to determine the cutting parameters of your laser for any material). It will give us the opportunity to compare the quality of the cut in different modes.

For tests, we use a cutting test chart. It consists of a 5 by 5 grid, in which the number of repetitions increases horizontally (1-5), and the speed changes vertically (100-300 mm / min). Cutting power set to 100%

Laser engraving parameters:

– Speed 1000 mm / min

– Power 30%

– Line density 0.2 mm

Download laser cutting table (free)

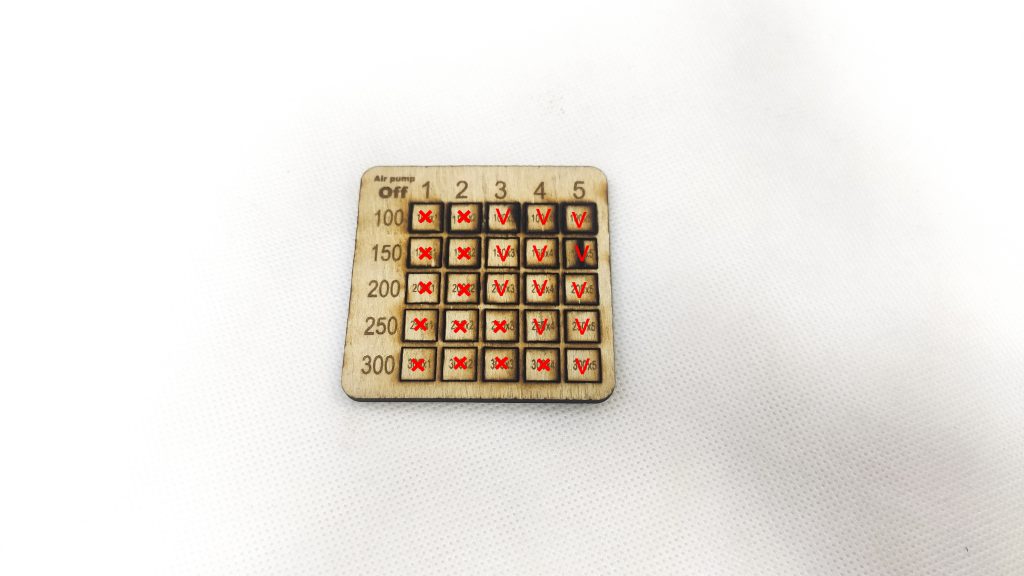

Test #1 Laser cutting without an air assist (airflow is off)

To begin with, we put the test table into operation, without any blowing. During the cutting process, there was a lot of smoke that flew in all directions from the laser.

After 20 minutes, the cutting was finished. In green, we will mark the squares that can be considered cut.

This photo clearly shows the poor cut quality. There is a burnt area around each cut. This is due to the fact that heat from the cut site spreads in all directions through the material and heats it up.

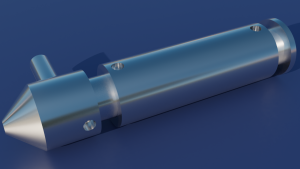

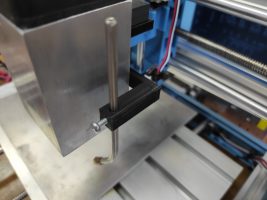

10 watt Delux laser with an Endurance air nozzle. Ver 1.0

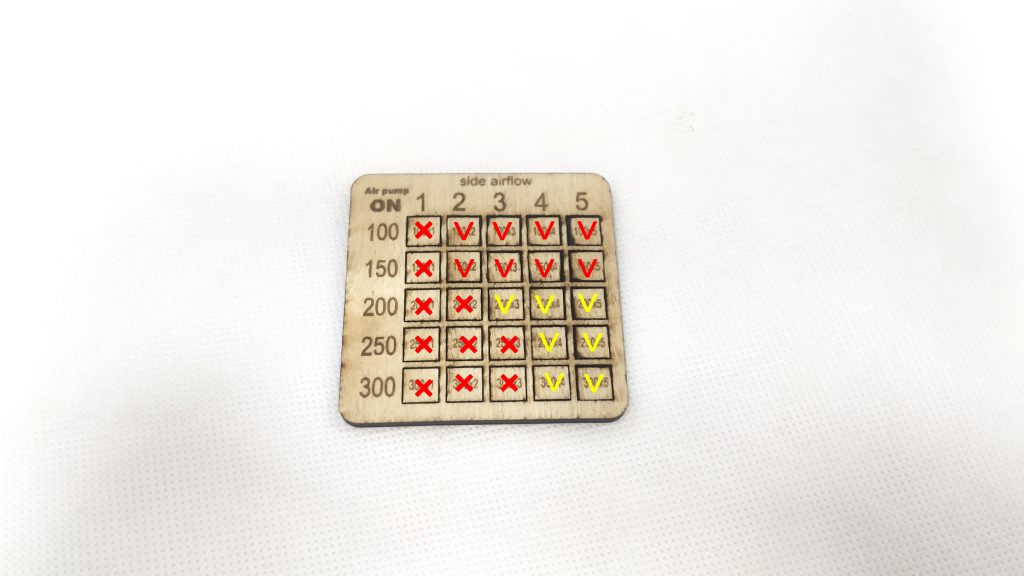

Test #2 Endurance 10 watt Delux with air nozzle ver 1.0 (airflow is on)

Install it on the laser and run the table. The design of this airflow creates airflow from the side. In our case, the airflow was to the left of the laser. Therefore, the material is clearly visible burnt to the right of the cut line. (since the blowing blew away everything exactly in this direction)

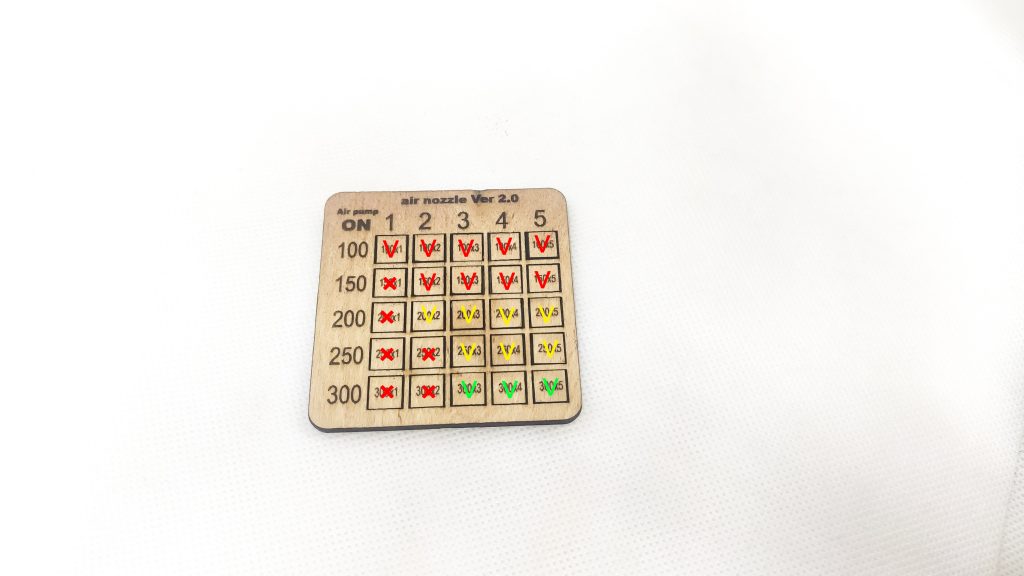

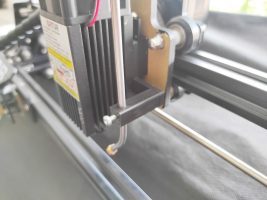

Test #3 Endurance 10 watt Delux with air nozzle ver 2.0 (airflow is on)

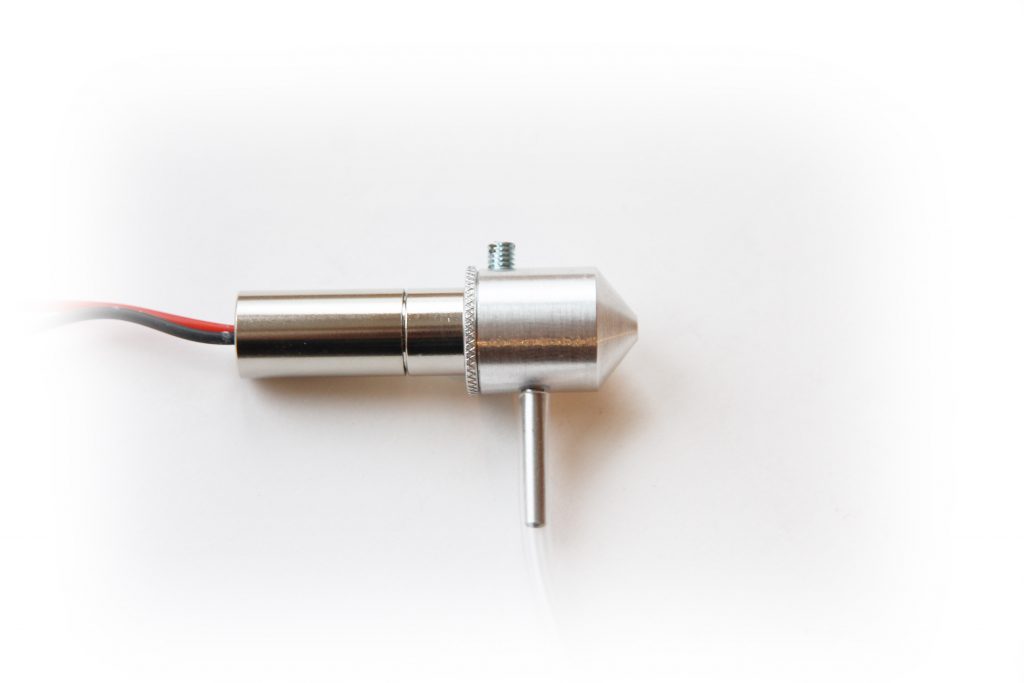

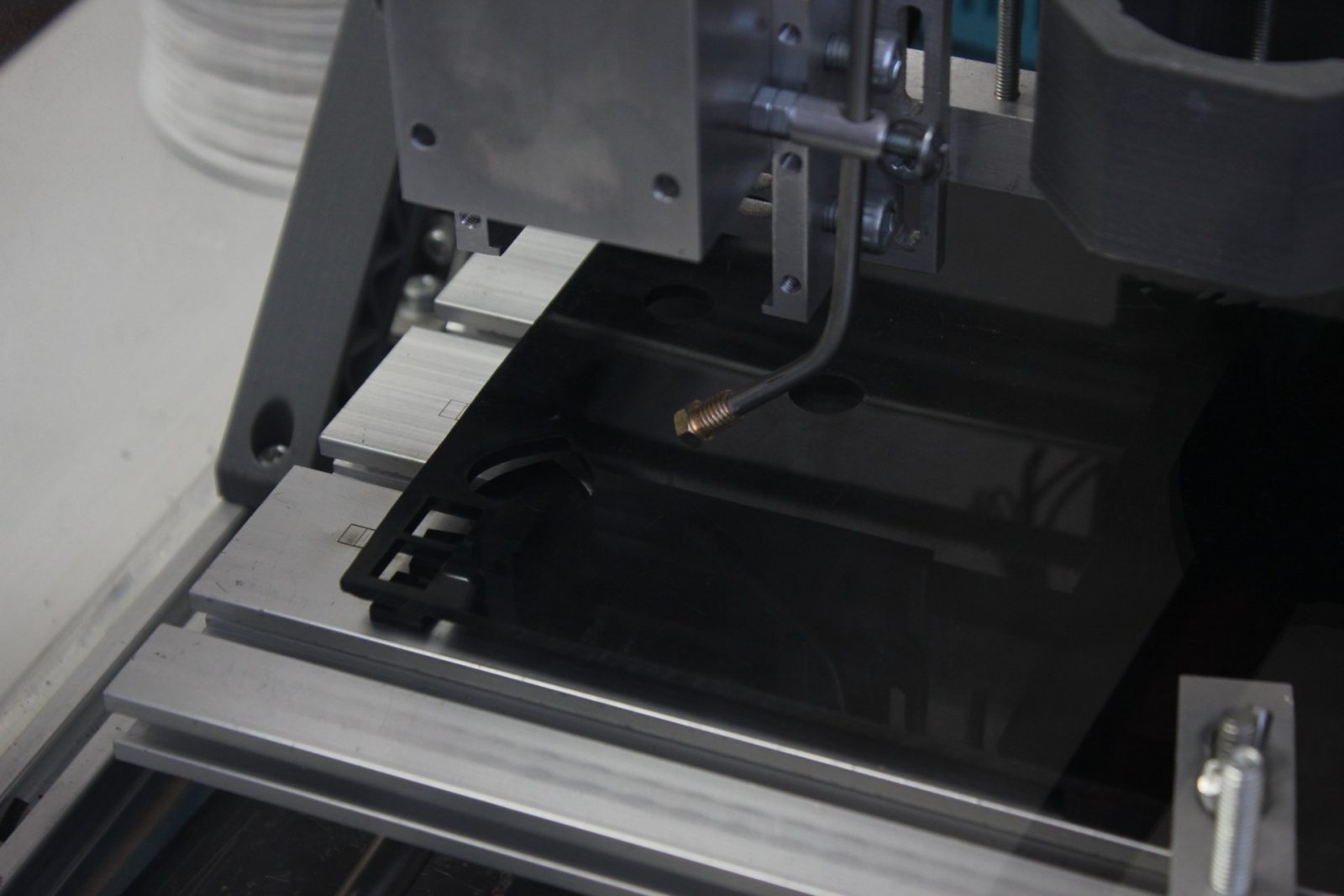

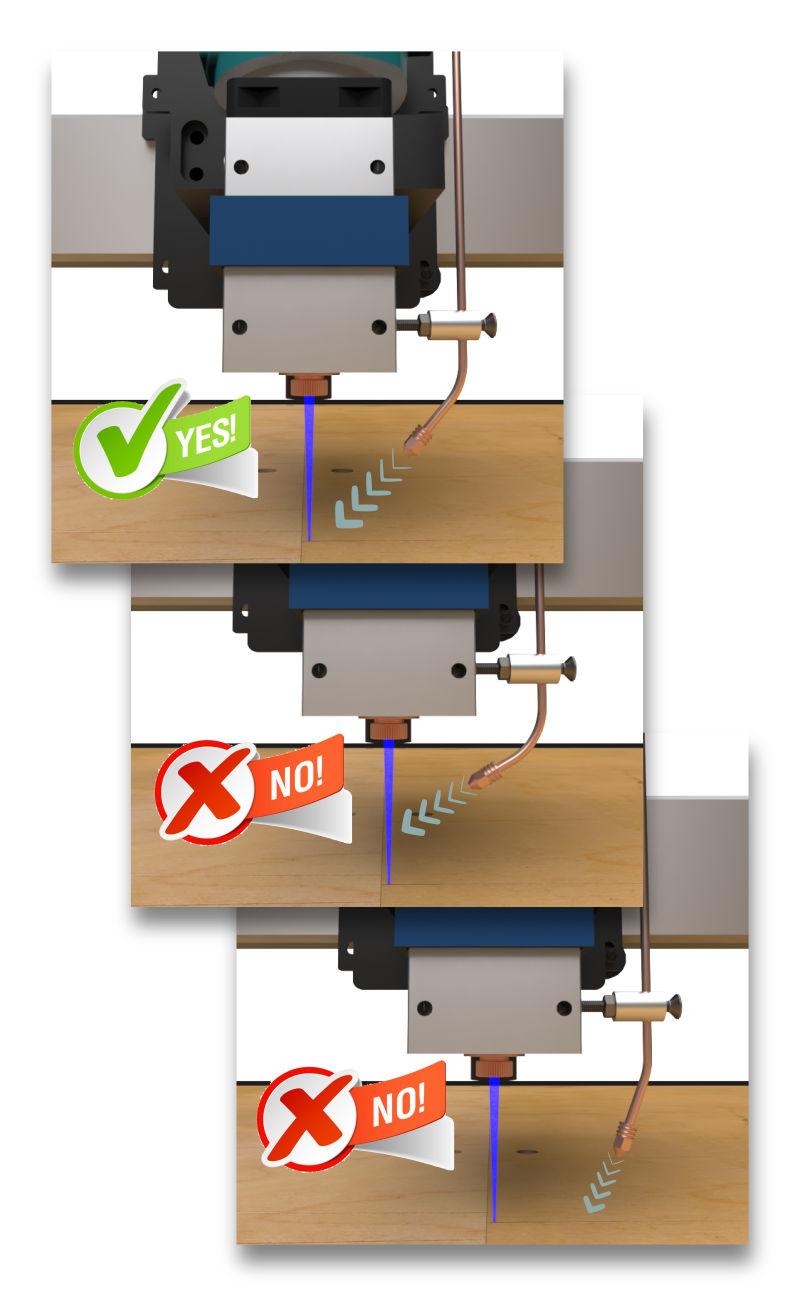

The second blowing version is a modification of the nozzle. Thanks to it, the air is directed exactly to the point of action of the laser. This option is most effective. It perfectly protects the optical system from the ingress of smoke and most effectively removes combustion products from the area of the laser.

In this case, we have the best result. The cut is clean, there are no burnt areas around it.

To get the best possible quality from your products, we recommend using the Endurance air nozzle. Ver 2.0 and G2 lens.

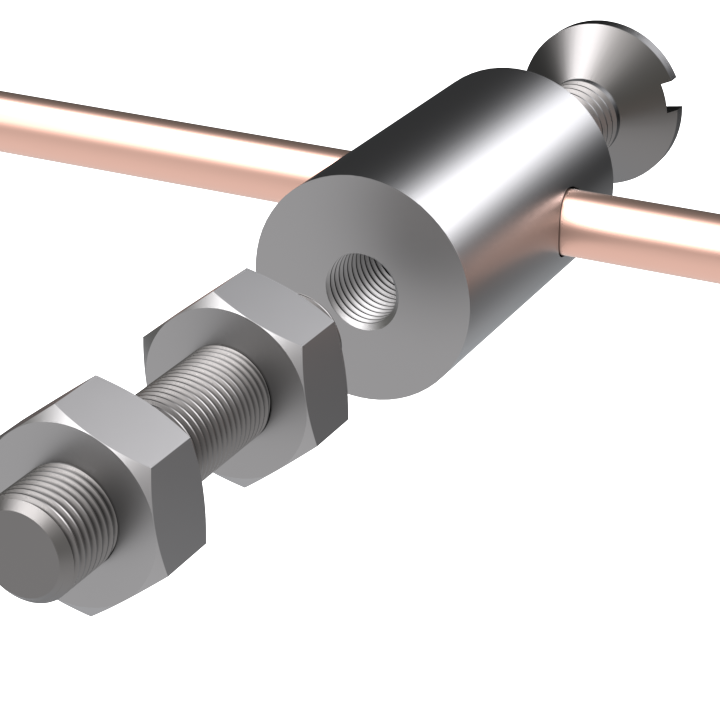

Endurance air nozzles (2 options: ver 1.0 and ver 2.0)

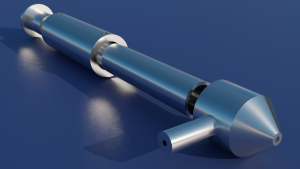

Endurance brand new air nozzle ver 2.0

Air nozzles: for DPSS, fiber. For Endurance. Ortur, Eleksmaker, CNCC and other lasers

Air nozzle 3D models ver 2.0 (+extended)

Explore our drawings (PDF format)

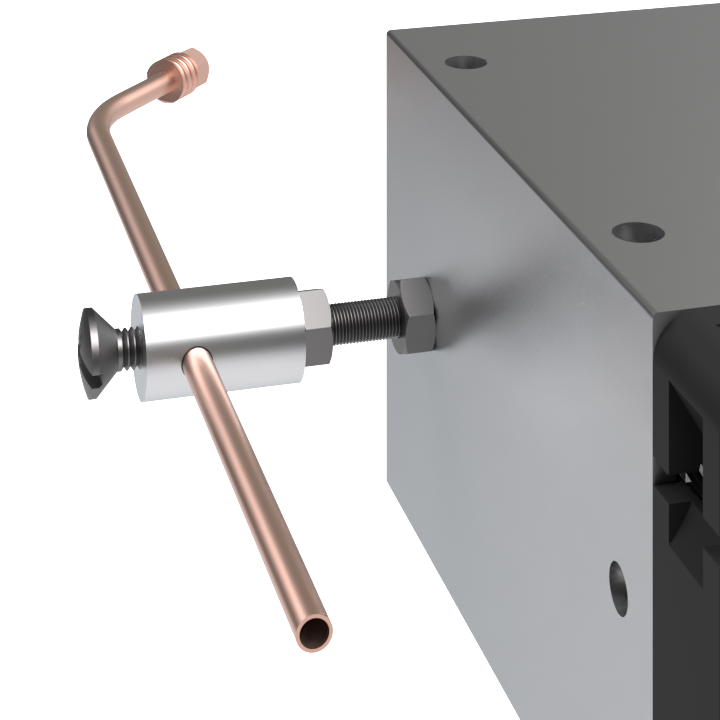

How to use an Endurance air nozzle ver 2.0 with your laser.

Installing the air nozzle ver 2.0 a complete video tour

Laser beam spot | Focal range | Focal depth

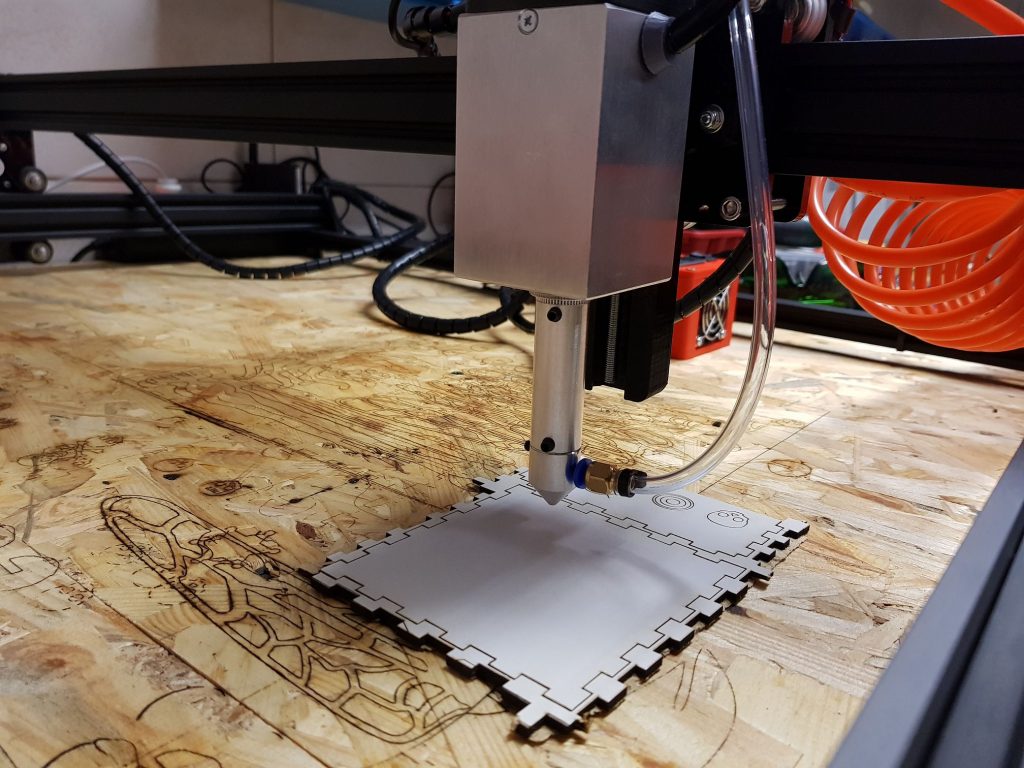

An Endurance air nozzle (ver 2.0) in action – laser cutting

Upgrade your Chinese laser with a laser lens pack, lens spacer, and add an air nozzle for better laser cutting

Air nozzle ver 2.0 on Ortur laser

Upgrading Chinese lasers with an Endurance air nozzle ver 2.0. A full guide.

Cardboard cutting with G2 lens + air nozzle ver 2.0

Free STL of the air nozzle

STL is available on Thingiverse by Ady Penny >>>

Updated 3 versions by Endurance lasers lab (3 different internal sizes, depending on the type of plastics you are using) Nozzles ZIP download >>>

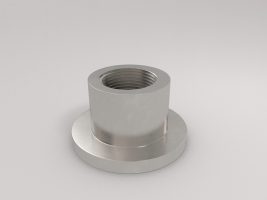

Air nozzle STL for 3 element / G2/ G7/ G8 lens

https://www.thingiverse.com/thing:4516272

Air nozzle STL for Chinese laser with a bigger focusing spacer (20 mm)

https://www.thingiverse.com/thing:4544637

Air nozzle holder for an Endurance ver 1.0 air nozzle. Fully compatible with all Chinese lasers including SainSmart, Ortur, Eleksmaker and others.

https://www.thingiverse.com/thing:4910059

Free STLs for mounting the laser to CNC 3018. Alternative mount for an air nozzle by Endurance lasers ver. 1

https://www.thingiverse.com/thing:4906682

An Endurance air nozzle ver 1.0

An Endurance DIY air assist. Make your own air nozzle for your diode laser.

A detailed video of how to make your own air nozzle in your workshop

A universal fully 3D printed mount for air nozzle ver 1.0 (compatible with Ortur, Endurance, Eleksmaker, Neje, Atomstack and other lasers)

Download our free STL files >>>

Laser cutting with an air nozzle ver 1.0 and without it

Setting up the proper airflow direction for the most efficient laser cutting

How to add an air nozzle on Ortur laser

Acclaim Crafts – Acclaim Air Assist Nozzle for Laser Cutting (Read a full PDF guide)

Our customers install and share Endurance air nozzles on their machines and cutting gantries

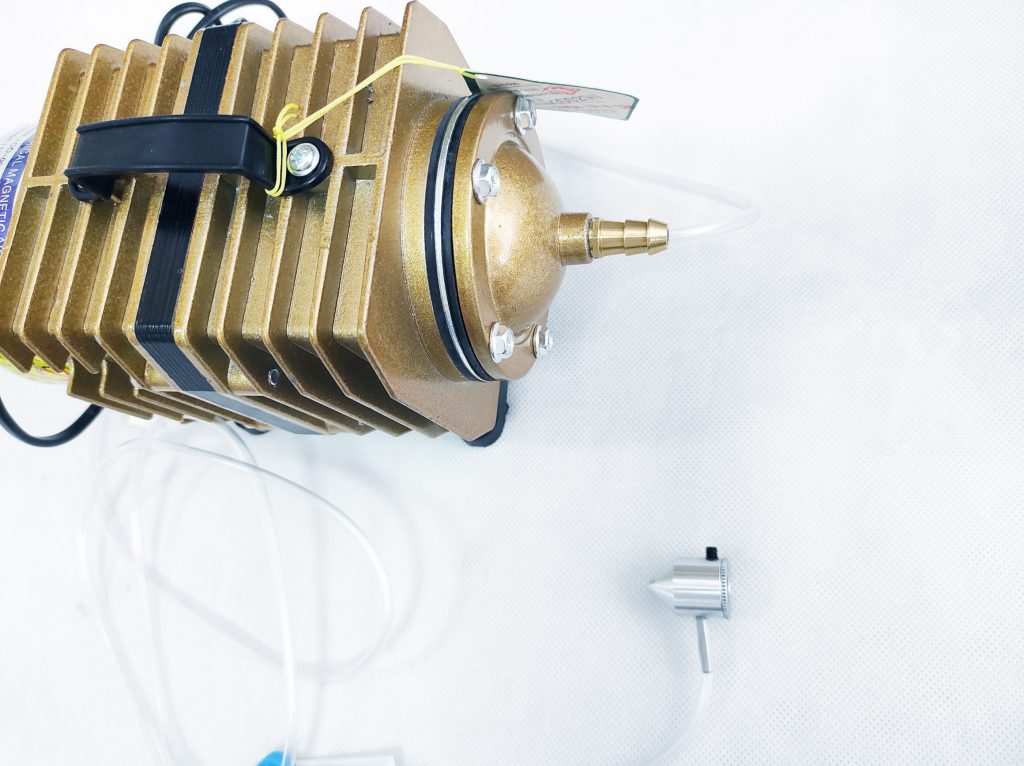

Recommended air compressor for air assist

Has to have 0.05-0.1MPA pressure and at least 60-70 L / min airflow capacity.

If you have any questions – let us know in a Livechat.

Order Endurance air nozzles on our official online store >>>