Differences between Endurance lasers and different laser wavelengths.

ChatGPT is helping you to learn more about lasers.

I’d like to know about lasers

A laser is a device that produces a beam of light through a process called stimulated emission. The light produced by a laser is unique in that it is very intense, highly collimated (meaning it forms a tight beam), and is of a single, narrow frequency (or color). Lasers have many applications. They can cut and weld materials, read and write data on CDs and DVDs, measure distances. They are indispensable in some medical procedures, such as eye surgery. The word “laser” is an acronym for “light amplification by stimulated emission of radiation.”

Where lasers are being used

Lasers have a wide range of applications across many industries. They are used:

1. In medicine in a variety of medical procedures, including eye surgery, dermatology, and dentistry.

2. In a variety of industries, such as automotive, aerospace, and electronics in the process of manufacturing to cut, weld, and mark materials.

3. In communication: particularly, in fiber-optic communication systems to transmit information over long distances.

4. For data Storage: to read and write data on CDs, DVDs, and Blu-Ray discs.

5. In Science and Research: in spectroscopy and other scientific experiments to produce and study light.

6. In military: as targeting devices in weapons systems.

7. In entertainment business: in light shows and live performances.

These are just a few examples, and the use of lasers continues to expand as new technologies are developed.

What types of lasers are presented on the market

There are several types of lasers available on the market, including:

1. Gas lasers (such as CO2, helium-neon, and excimer lasers)

2. Solid-state lasers (such as Nd:YAG, ruby, and diode lasers)

3. Liquid lasers (such as dye lasers)

4. Semiconductor lasers (such as laser diodes)

5. Fiber lasers

Each type of laser has unique properties and, accordingly, is used for different purposes, such as cutting and welding, scientific research, medical treatment, and entertainment.

What are key laser suppliers?

There are many companies that supply lasers, including:

1. Coherent, Inc.

2. IPG Photonics Corporation

3. TRUMPF GmbH + Co. KG

4. Rofin-Sinar Technologies, Inc.

5. NKT Photonics A/S

6. Jenoptik AG

7. Newport Corporation

8. Mitsubishi Electric Corporation

9. Photonics Industries International, Inc.

10. Lumentum Holdings Inc.

These companies offer a wide range of laser products and solutions for various industries and applications, including medical, industrial, scientific, and military. It is important to note that this list is far from being complete. There are many other laser suppliers in the market.

Where gas laser are being used

Gas lasers are used in a wide range of applications and industries, including:

1. Industrial processing and manufacturing: for cutting, welding, drilling, and marking various materials.

2. Scientific, physics and chemistry research: in spectroscopy, interferometry, and in laser cooling experiments.

3. Medicine: in dermatology, ophthalmology, and dentistry for skin resurfacing, neoplasma removal, and other surgical and physiotherapy procedures.

4. Military and defense: in range-finding and targeting systems.

5. Entertainment: in laser light shows, where they produce bright, colorful beams of light.

Gas lasers have unique properties such as high power, wide range of wavelengths, and good beam quality, which make them ideal for these applications.

Where solid-state lasers are used

Solid-state lasers have a wide range of applications, such as

1. Industrial processing: for cutting, welding, marking, and engraving a variety of materials in the manufacturing industry.

2. Medical treatments: in dermatology, ophthalmology, and dentistry for hair removal, skin resurfacing, and other physiotherapeutic and surgical procedures.

3. Scientific research: in spectroscopy, interferometry, and laser cooling experiments in physics and chemistry research.

4. Military and defense: in range-finding and targeting systems.

5. Printing and scanning: in laser printers, scanners, and copiers to produce images and texts.

6. Telecommunications: in optical communication systems for transmitting information over long distances.

7. Metrology: in precision measurement and testing applications, such as coordinate measuring machines and laser interferometers.

Solid-state lasers are distinguished by compact sizes, high reliability, and low maintenance, which make them suitable for these applications.

What is the application of liquid lasers

Liquid lasers, also known as dye lasers, have several applications, including:

1. Scientific research: e.g., in spectroscopy, interferometry, and laser cooling experiments in physics and chemistry.

2. Medicine: in dermatology, ophthalmology, dentistry, and cosmetology for tattoo removal, skin resurfacing.

3. Printing and imaging: such as digital light processing (DLP) and laser displays.

4. Entertainment: in laser light shows, where they produce bright, colorful beams of light.

5. Art and design: in artistic installations and for laser engraving and cutting.

Unique properties of liquid lasers, such as tunable wavelengths, high brightness, and short pulse duration make them ideal for these applications. However, they also have some drawbacks, such as the need for continuous cooling, special handling and storage of the laser dyes.

Where semiconductor lasers are being used

Semiconductor lasers, also known as laser diodes, have a wide range of applications. They are used for:

1. Data storage: in CD, DVD, and Blu-ray players for reading and writing data on optical discs.

2. Optical communication: in fiber optic communication systems for transmitting information over long distances.

3. Bar-code scanning: in bar-code scanners for reading bar codes in retail and other industries.

4. Printing and imaging: in laser printers and copiers for printing and copying documents and images.

5. Medicine: in ophthalmology, dermatology, cosmetology for hair removal, skin resurfacing, and other cosmetic procedures.

6. Military and defense: in range-finding and targeting systems.

7. Industrial processing: for cutting, welding, marking, and engraving various materials in the manufacturing industry.

Semiconductor lasers are ideal for these applications due to their small sizes, low power consumption, and high efficiency.

Where fiber lasers are being used

High power, high beam quality, and low maintenance are features that make fiber lasers ideal for many industries, such as

1. Industrial processing: for cutting, welding, drilling, and marking various materials in the manufacturing industry.

2. Scientific research: in spectroscopy, interferometry, and laser cooling experiments in physics and chemistry research.

3. Medicine: in ophthalmology, dentistry, and dermatology for cosmetic procedures, such as hair removal and skin resurfacing.

4. Printing and imaging: in laser printing and engraving applications, such as printing on metal and plastic materials.

5. Military and defense: in range-finding and targeting systems.

6. Telecommunications: in fiber optic communication systems for transmitting information over long distances.

7. Metrology: in precision measurement and testing applications, such as coordinate measuring machines and laser interferometers.

What laser power range is presented on the market now

The laser power range available on the market varies greatly, depending on the type of laser and its application. The laser power range starts as low as a few milliwatts for laser pointers and bar-code scanners, and go up to many kilowatts for industrial cutting and welding machines.

1. Diode lasers: The power range of diode lasers is typically in the range of a few milliwatts to several watts.

2. Solid-state lasers: The power range of solid-state lasers varies from a few watts to kilowatts.

3. Fiber lasers: The power range of fiber lasers is typically in the range of a few watts to kilowatts.

4. Gas lasers: The power range of gas lasers varies from a few watts to several kilowatts.

5. Liquid lasers: The power range of liquid lasers varies from a few milliwatts to several hundred watts.

The exact power range of a laser system depends on its design, the materials used, and the cooling and pumping methods. The laser power range should be chosen based on the specific application requirements, including the material properties and the processing speed desired.

Tell us more about energy, pulse width and pulse duration for lasers

Energy, pulse width, and pulse duration are important parameters for characterizing laser performance.

1. Energy: The energy of a laser pulse is the amount of energy delivered by the laser in a single pulse. The energy of a laser pulse is typically measured in joules (J). High energy laser pulses can be used for cutting and welding, while low energy laser pulses are used for applications in spectroscopy and marking.

2. Pulse width: The laser pulse width is the duration of a single laser pulse. The pulse width is typically measured in nanoseconds (ns) or picoseconds (ps). The pulse width can range from a few nanoseconds to several microseconds, depending on the application and the type of laser used.

3. Pulse duration: The laser pulse duration is the total time that the laser emits light in a single pulse. This is different from the pulse width, which is the duration of the light output at its peak. The laser pulse duration can be much longer than the pulse width and is typically measured in nanoseconds or microseconds.

The selection of the appropriate laser parameters, including energy, pulse width, and pulse duration, depends on the specific application and the properties of the material being processed. The laser energy, pulse width, and pulse duration should be optimized to achieve the desired processing results while minimizing damage to the material or surrounding environment.

What global inventions were made using lasers

Lasers have played a significant role in many technological innovations and scientific discoveries over the past several decades. Here are a few examples of global inventions and advancements made using lasers:

1. Medical technology: Lasers have revolutionized medical procedures, such as LASIK eye surgery, cancer treatment, and cosmetic procedures, such as hair removal and skin resurfacing.

2. Fiber optic communication: Fiber optic communication systems, which use laser light to transmit information over long distances, have revolutionized the telecommunications industry.

3. Industrial processing including cutting, welding, and marking of a great variety of materials.

4. Scientific research and experiments, including spectroscopy, interferometry, and laser cooling.

5. Military and defense, such as range-finding and targeting systems.

6. Printing and imaging, such as laser printing and engraving.

7. Manufacturing to produce precise and accurate equipment and products.

These are just a few examples of the many global inventions and advancements made using lasers. Lasers have had a significant impact on a wide range of industries and have paved the way for many technological innovations and scientific discoveries.

Diode laser

2.1 -> 3.5 watt -> 5.6. watt – 8 -> 8.5 watt. More power & more cutting and engraving abilities

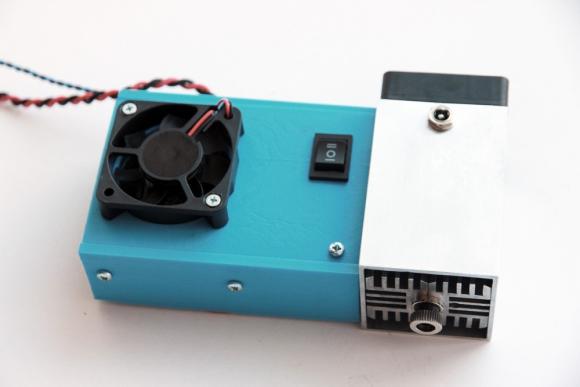

10 watt “Invincible” -> 10 watt Delux : has an air nozzle, bigger focusing ring, laser box instead of a laser control board.

10 watt Delux -> 10 watt Plus : has a TEC cooling with an external heatsink, air compressor.

8.5 watt -> 8.5 watt PRO: has a metal laser box ver 2.0 with MO2 and a smaller heatsink. (Additional accessories in the package)

10 watt “Invincible” -> 10 watt PRO: has a metal laser box ver 2.0 with MO2 and polished shining aluminum housing. (Additional accessories in the package)

10 watt Plus -> 10 watt PRO PLUS : has a metal laser box ver 2.0 with MO2, a ver 2.0 air nozzle, double TEC cooling with a turbine fan. (Additional accessories in the package)

15 watt DIY DUOS -> 15 watt DUOS has a more advanced electronics and metal enclosure for the laser and it has a double TEC cooling system

| Diode laser | 445 nm wavelength | Key abilities | Key features | Limitations | Key video footage | Endurance lasers model |

| 2.1 watt | Engraves on soft materials like wood, plywood, MDF, leather, acrylic, etc. Cuts thin soft materials 1-2 mm | Affordable laser module for any 3D printer / CNC router for laser engraving purposes. | Works only with soft materials | Watch | Open | |

| 3.5 watt | Engraves on stone. Cuts 2-3 mm of soft materials | Engraves on stone, rock, mirror, glass | Not powerful enough to cut thick wood/plywood | Watch | Open | |

| 5.6 watt | Engraves on painted metals. Cuts 2-3 mm of soft materials faster. | Engraves on painted metals. | Does not engrave pure metallic surfaces | Watch | Open | |

| 8 watt | Engraves on anodized aluminum and special laser marking metals. Cuts 3-4 mm of soft materials | Engraves on anodized aluminum | Does not cut more than 5 mm of wood /plywood with clean edges | Watch | Open | |

| 8.5 watt | Engraves on anodized aluminum and special laser marking metals. Cuts 3-4 mm of soft materials | Watch | Open | |||

| 10 watt | Engraves on all metallic surfaces with special engraving paste. Cuts 3-5 mm of soft materials | Universal tool for cutting and engraving | Requires an air assist for perfect wood/plywood cutting. Does not engrave metals in depth | Watch | Open | |

| 10 watt+ | Engraves on all metallic surfaces with special engraving paste. Cuts 3-8 mm of soft materials with accurate cutting edges. | Ultra-accurate laser cutting of a soft materials | Does not cut thicker than 8 mm of wood/plywood | Watch | Open | |

| 20 watt | Fast and accurate engraving on all metallic surfaces with special engraving paste. (for engraving purposes mostly) | Dual laser module for fast and accurate metal engraving | It does not engrave metals in depth. | Watch | Open | |

| 15 watt DUOS | Cutting thick and high-density wood and plywood cuts MDF and thick leather. | DUOS laser has 2 combined laser beams together | Processes all soft materials and engrave on all types of metal (with marking paste) | Watch | Open | |

| 8.5 watt PRO | Engraving on all materials. Cutting soft materials up to 5 mm | Has a laser box ver 2.0 with Mo2 PCB. Very light and portable. | Quite nosy due to turbine cooling | Watch | Open | |

| 10 watt PRO | Engraving on all materials. Cutting soft materials up to 5 mm | Has a laser box ver 2.0 with Mo2 PCB. Shining and ultra-stylish design | Has not air nozzle and air assist | Watch | ||

| 10 watt+ PRO | Engraving on all materials. Cutting soft materials up to 8 mm with clean edges | Has a laser box ver 2.0 with Mo2 PCB. Max power out of a diode laser. Ultra accurate laser cutting | Can not do the metal cutting | Watch | ||

| Diode array | 808 nm wavelength | Key abilities | Key features | Limitations | Key video footage | Endurance lasers model |

| 15 watt | Engraves on soft materials | High power concentration | Small focusing of a laser beam is not possible at the moment | Watch | Open | |

| 25 watt | Watch | |||||

| 30 watt | Watch | |||||

| 85 watt | Weed cutting. Not accurate laser engraving and laser cutting | High-power | Open | |||

| DPSS | 1064 nm wavelength | Key abilities | Key features | Limitations | Key video footage | Endurance lasers model |

| 10 watt | Deep metal cutting. Cuts up to 1 mm of a steel and stainless steel | Metal cutting and metal engraving | Is not good for cutting soft materials like wood, plywood, etc. | Watch | Open | |

| 20 watt | Faster metal engraving and cutting up to 1-2 of steel and stainless steel | – | n/a | |||

| 75 watt | Extremely fast metal engraving. Cutting up to 2-5 of steel and stainless steel, copper, brass, aluminum | – | R&D stage | |||

| DPSS | 532 nm wavelength | Key abilities | Key features | Limitations | Key video footage | Endurance lasers model |

| 4.5 watt | Better metal engraving and accurate glass engraving | Processes transparent glass. | n/a | Watch | Open | |

| Co2 | 10.6 um wavelength | Key abilities | Key features | Limitations | Key video footage | Endurance lasers model |

| 40 watt | Cuts 3-5 mm soft materials. Good for rubber engraving (seals and stamps) | Ability to cut soft materials quite quickly | Does not engrave on metal even with paste | – | Custom development | |

| 80 watt | Cuts 5-10 mm soft materials. Engrave on rock / stone. | Cuts white and transparent materials like glass and acrylic. Universal tool for engraving and cutting | Can not be used outside the engraving/cutting machine. | Watch | Custom development | |

| 150 watt | Cuts up to 15 mm of soft materials. Cuts metal up to 1.5 mm with an oxygen | – | Custom development | |||

| 300 watt | Metal cutting with an oxygen up to 3 mm, cuts acrylic up to 30 mm, plywood and wood up to 20 mm | Quite big and bulky. Is not good for engraving. | – | Custom development | ||

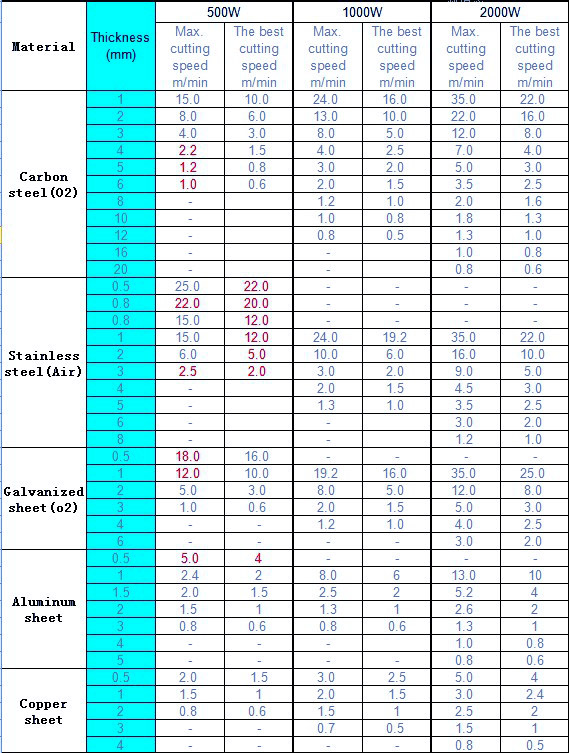

Metal cutting parameters with Co2 lasers: 500 watt / 1000 watt/ 2000 watt

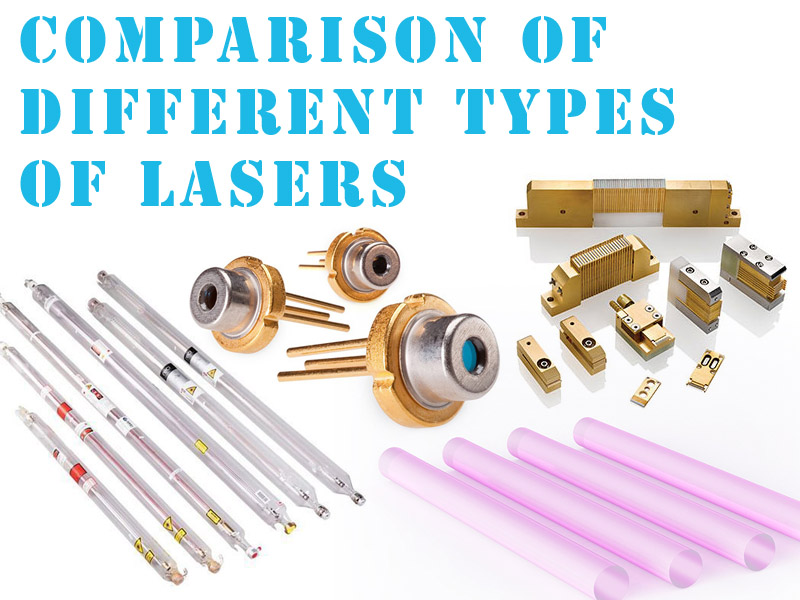

The key difference between diode, CO2 and fiber lasers.

Let’s start with diode lasers.

Diode lasers

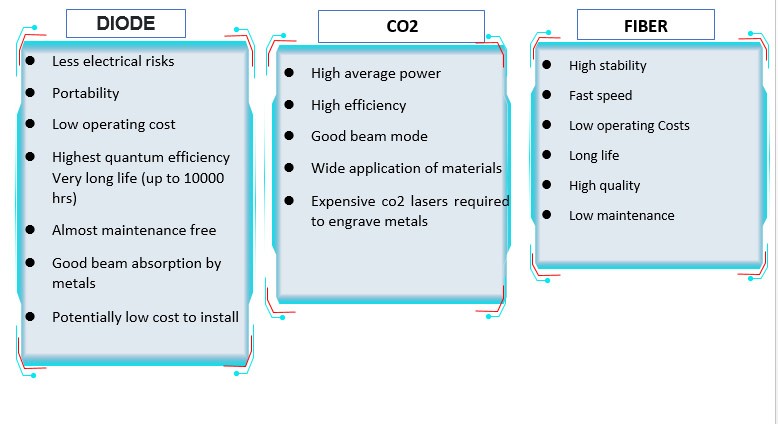

The basis of a solid-state diode laser (SSDL) is a laser diode. Laser diodes can have various values of the emission wavelength. Most of them have 405 nm – 808 nm. The laser diodes usually have TO3, TO5, TO9, TO18 housing.

What makes them different is their sizes.

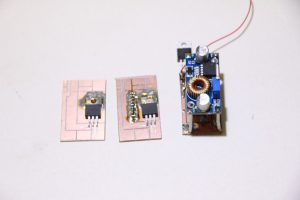

A laser diode needs a laser driver.

A good laser driver is a vital component for the laser lifetime.

These diodes are very sensitive to the initial voltage and current.

The power management system helps to control voltage jumps, current stabilizations, and prevent harm from the laser diode.

Every type of diode needs its type of driver. For example, the driver from NUBM44 or NUBM47 will not work for the M140 diode. A high-quality laser driver can stabilize current and maintain constant values of the current and voltage going directly to the diode.

Controlling the diode laser temperature is very important. The diode laser wavelength is also strongly influenced by temperature and the wavelength of the diode laser is affected by the driving current. Therefore, the varied power of the diode can cause a varying laser wavelength. High power usage for endurance lasers is at 70 degrees Celsius. What happens during high temperature is high power consumption and the temperature goes up, while laser power goes down. A laser diode’s maximum operating temperature is 70 degrees Celsius. Do not run at 70, but instead run at a maximum temperature of 60 degrees Celsius or below to prevent power loss during continuous usage. Endurance lasers include a temperature sensor for you when you order any endurance laser.

All of the Endurance protective housing for the diode is assisted with more durable heat sinks to draw excessive heat accumulation.

A fake laser will disappoint in temperature regulation. They work briefly and shortly become unusable and cannot engrave anything. The sellers of fake lasers will go out of their way to market their product but hide the fine details that matter. You can be attracted to an advertisement for a Chinese high-power laser but the high-power laser will not have true output power. Many innocent customers can be easily misled by fake lasers. Do your research and make a smart investment.

Endurance lasers have tried and true temperature control which plays a role in all of the factors mentioned above.

Another important thing is the cooling of the laser diode. As a rule, laser diodes are installed in copper modules like this.

But this copper module is yet unable to effectively give off the heat generated by the diode if the power of the diode exceeds 0.5 watts (500 mW).

It requires an additional heatsink.

The copper laser module can be inserted into a heatsink like this.

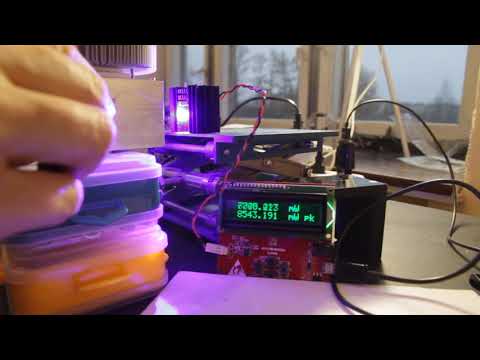

Testing and measuring laser power using a calorimeter

Special aluminum laser heatsink by Endurance production

But even inside a copper laser module inserted into a better heatsink, the diode can still generate too much heat, that is why additional air cooling with, let’s say, a regular fan of 40 x 40 mm or 50 x 50 mm in size, is needed to solve the problem.

Cooling of the laser diodes is very important. The cooler the module the longer the lifetime of the laser, the higher the laser power.

The cooler the laser diode the more powerful it is.

When all the basic components

1. Laser diode

2. Laser driver

3. Laser copper housing

4. Additional heatsink

are assembled together, it is necessary to choose an optimal focus mechanism for the laser.

LENSES

The lenses for lasers are vital to good operation. A focused laser beams light is formed using mirrors or lenses. Focusing is a key part of the diode laser’s proper operation. Diode lasers use several interchangeable optical lenses that allow for special usage such as G2, G7, G8 lenses.

Diode laser lenses are meant to work at particular ranges with your machine. They do not work like laser pointers and cannot shine the same way pointed across a room. You will not burn anything. Do not try this though because even if the laser power is very very low on a distance across a room, there is still some power being output and you may inadvertently put a hole in anything that crosses the beam of light.

Different lenses mean: Each lens has its optimal range of focus or focal point. Using the focusing ring on your diode to get the finest dot the range for using each of the lenses are as follows:

All lenses are made of glass. They have transmission, absorption, and reflection coefficients. A G7 will have more absorption or reflection and it will not output as much power as a G2

Most lasers can operate with 2 types of lenses:

A 3 element long focal lens

or high-quality G2 short focal lens.

The difference between these 2 types of lenses is the focal range. A 3 element lens can have the focus range of 2-10 cm while the focal range of the G2 lens is 2-10 mm (10 times less than the 3 element lens focal range).

The g2 lens is the most effective and more efficient than other lenses. The G2 lens is used for cutting and accurate engraving. The G2 lens also has the shortest laser beam spot and short focal length. For laser cutting, we recommend a short focal length.

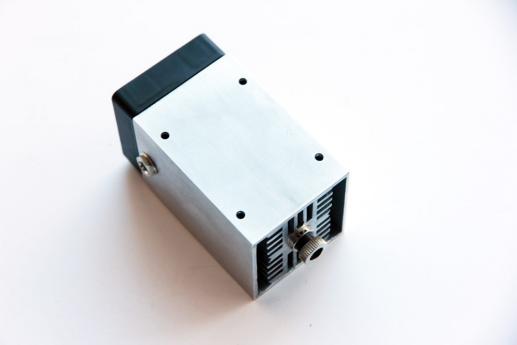

The final thing to do after the laser focusing mechanism selection is to encase the entire laser module.

The laser housing should be compatible with 3D printers and CNC machines otherwise the laser will not work with them. Endurance laser modules do not require additional mounting and fastening tools to be installed.

One may ask, what is so cool about diode lasers compared to fiber lasers and CO2 lasers.

The key advantage of a diode (solid-state) laser module is its small size and weight (about 200 grams or about ½’’). Its small size makes it possible to install the laser-like this almost on any 3D printer or CNC machine.

The diode laser does not require any additional power supply source (12V and 7-8 amps power is max what it needs). This is another important advantage of the diode laser.

The small size and compatibility of the Endurance diode lasers with most 3D printers or XY plotters make the diode lasers a great tool for laser enthusiasts, hobbyists, and makers.

Skeptics might say that CO2 40W laser tubes have the same price as 8 watt or 10 watt diode lasers.

But a high-quality CO2 tube with 40W-60W output will be more expensive rather than what people think considering a purchase on Aliexpress or eBay.

Laser control board with the laser module

3D perspective

Another disadvantage of these tubes is their fragility and big size. You cannot install any of them on a 3D printer or CNC machine.

CO2 tubes are compatible only with special plotters that also require special power drivers. Besides, it is important to bear in mind that the power consumption of a CO2 laser machine is much greater than that of a diode laser machine.

As for fiber lasers, they simply do not have separate modules that can be attached to a current chassis. A 10 watt – 20 watt fiber laser machine will probably cost something like 10-15K USD which is dozens of times higher than the price of a diode laser machine.

Of course, fiber laser machines have a lot of advantages in comparison with CO2 and diode laser machines.

A fiber laser is very powerful and a standard industrial fiber laser will have a significantly longer life span than other types of Co2 and diode lasers. The Fiber laser will permanently engrave on metals that other lasers cannot such as stainless steel, titanium, copper, aluminum, and other metals. On a Co2 laser, cutting is better on a wide application of materials over a fiber laser however engraving on metals requires expensive CO2 lasers. This is a piece of expensive industrial equipment, not affordable to beginners and intermediately experienced tech guys.

In conclusion, I’d like to mention that diode (solid-state) lasers have great potential and are a perfect solution for those who wish to upgrade and bring the extension to their 3D printers or CNC machines.

A lot of nice things such as photo-engravings and engraving on metal can be done with 8 watt, 10 watt lasers with 445 nm wavelength.

Absorption wavelength spectrum for different materials: glass, metal and others.