Endurance lasers present an industrial Co2 engraving and cutting machine

with a huge working area (6×5′) [2×1.7 m]. High velocity + ultra-high precision.

Endurance Lasers LLC offers a custom Co2 engraving/cutting machine that can operate (suitable for) with various Co2 tubes. At the moment the CO2 laser is one of the cheapest options and has a low specific cost per watt of radiation. There are 40-600 watt Co2 tubes available on the market now. Common CO2 tubes have a power ranging from 40W to 100W. The laser is powered by a high-voltage source of approximately 10 … 40 kV, depending on the power. The size of the tube depends on the laser power: the more powerful, the longer the tube, and the diameter also increases.

The good thing about Co2 tubes is that the beam quality is quite high so that it is easy to focus it in a small laser beam spot.

Imagine. Create. Enjoy!

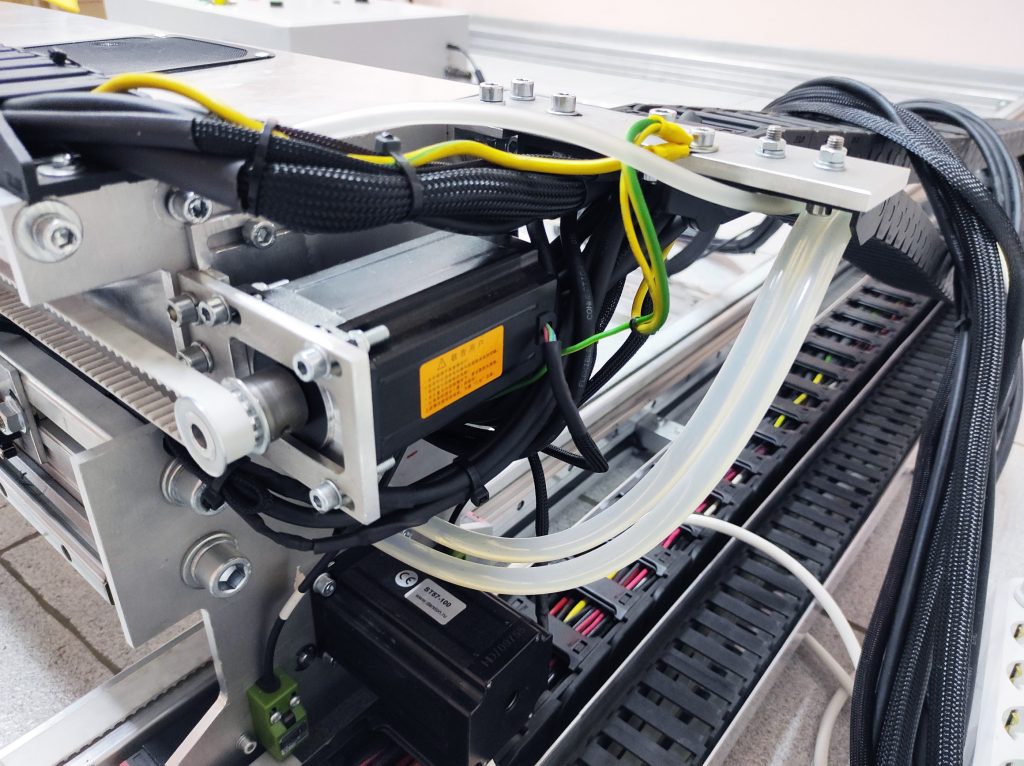

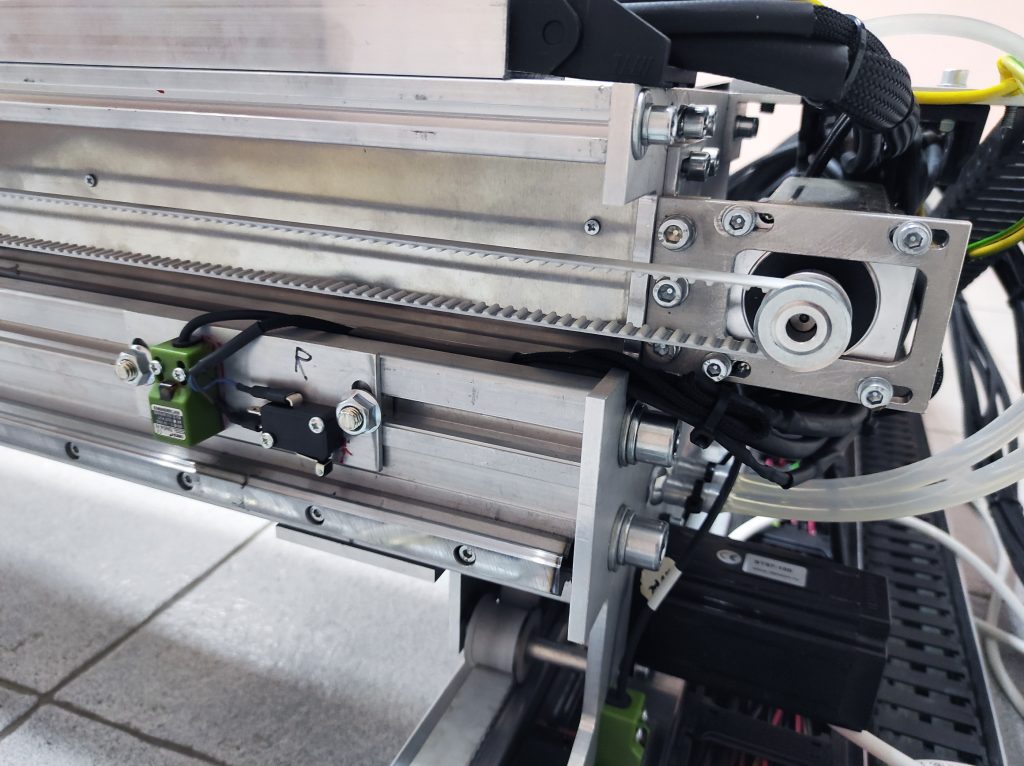

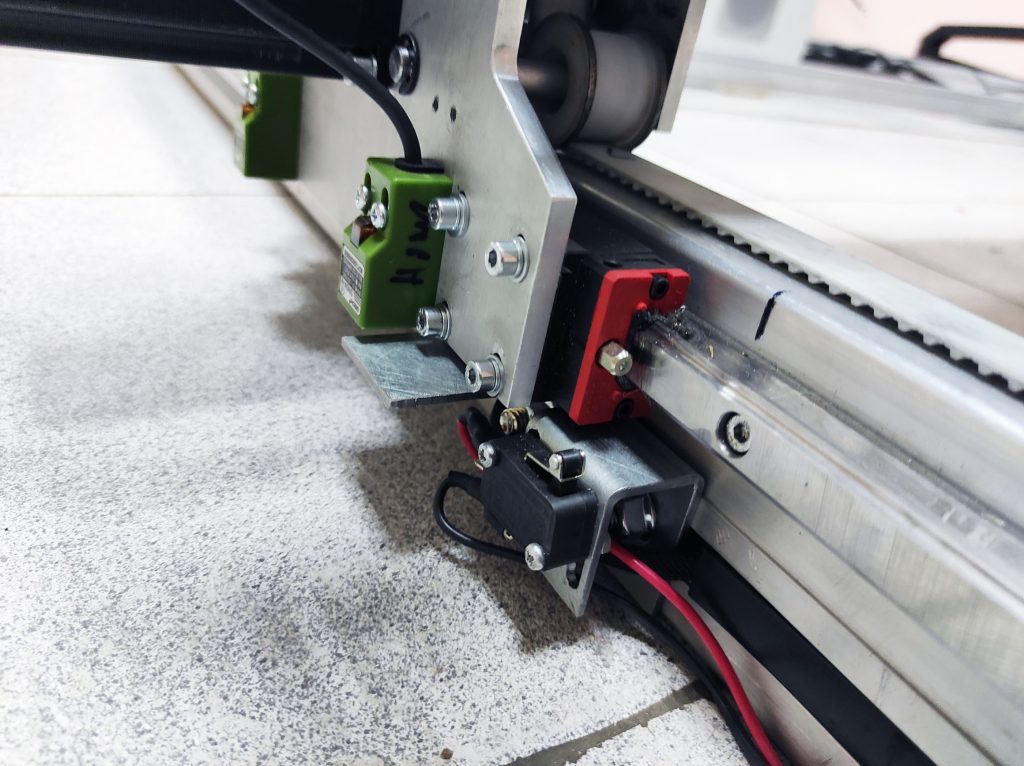

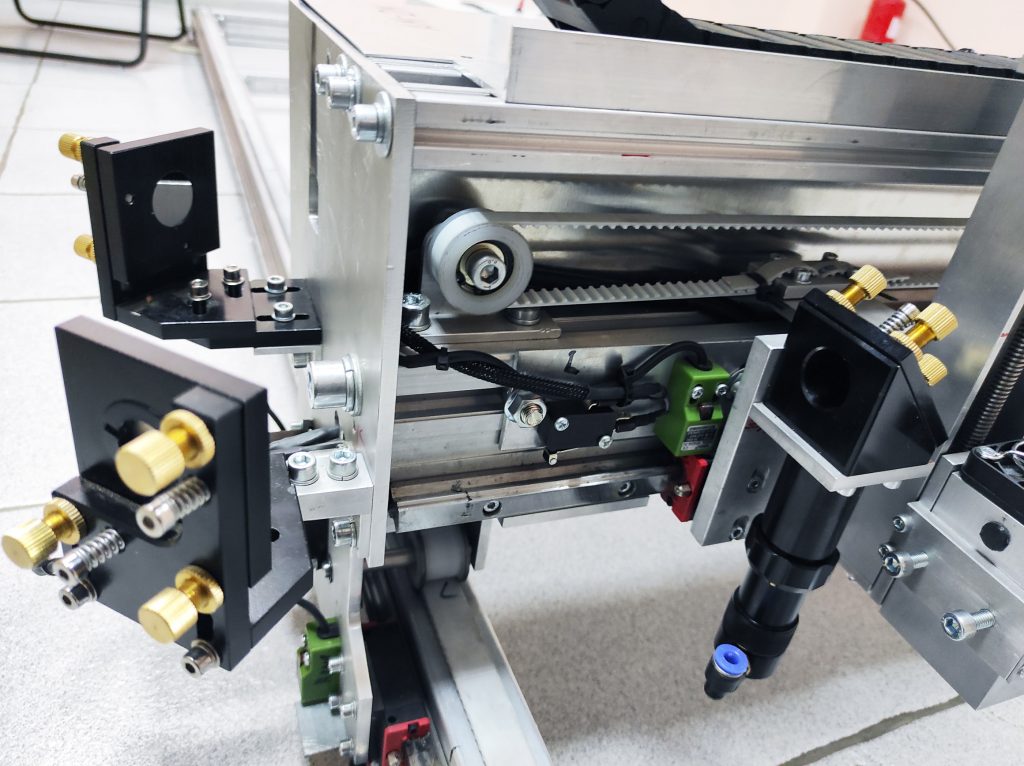

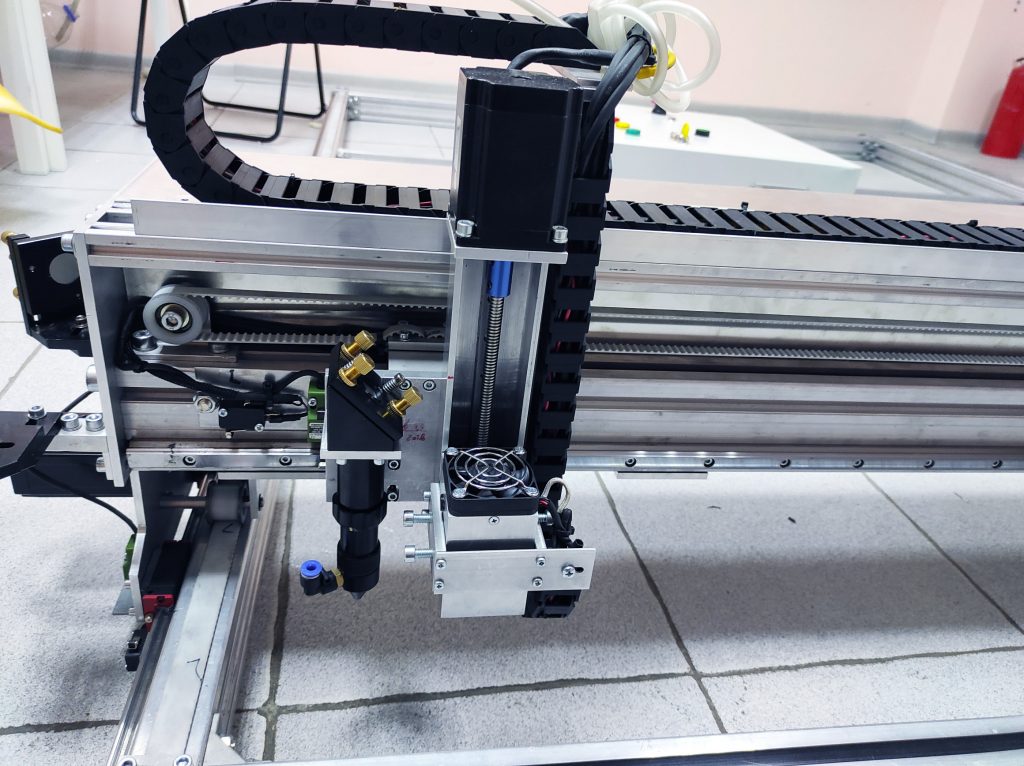

The machine itself has an aluminum frame with stainless steel guides and belts driven by stepper motors. In this type of frame, Nema23 stepper motors work fine. The work is carried out under the control of special controllers from the program (RdWorks) on the computer.

We use a high-quality stepper motor driver from Leadshine.

On an Endurance custom frame, we can install a spindle, a diode laser, and even a solid-state laser if needed.

Keep in mind that the laser radiation is potentially dangerous and it is necessary to operate the laser wearing special protective goggles (with at least OD>5) and it is better to have an enclosure as well.

Be careful when contacting the high-voltage part of the equipment. Be sure to connect the ground connection to the high-voltage part and to the machine body.

We also recommend using a fume extractor while laser cutting.

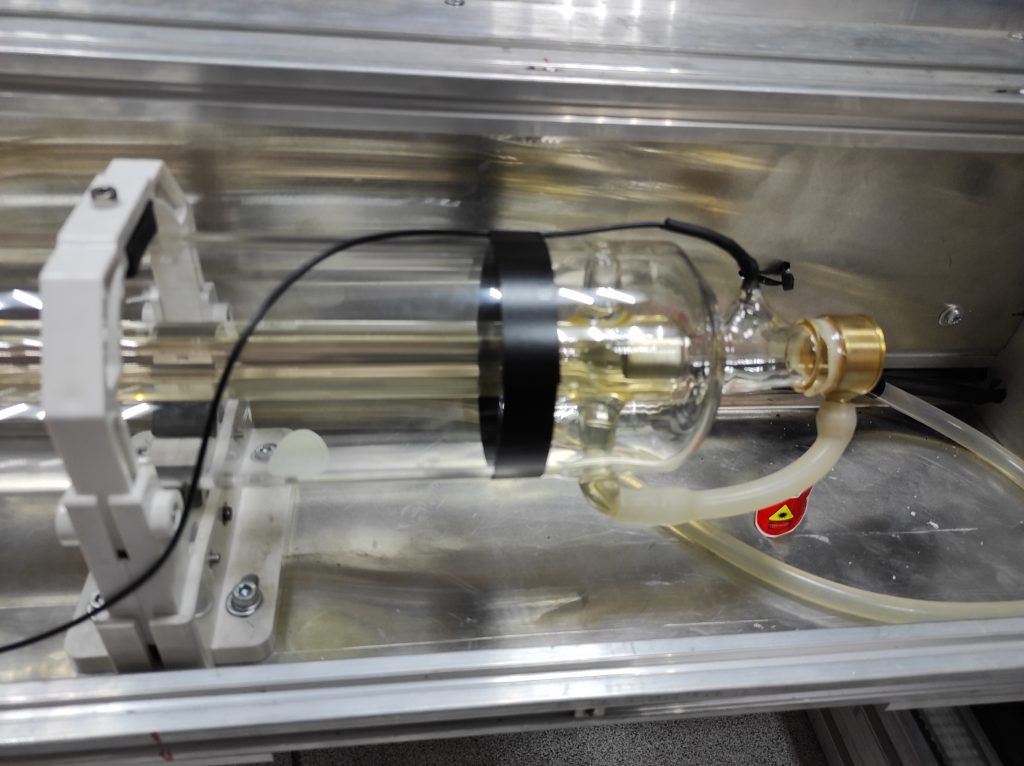

Keep in mind that to operate a Co2 laser you need a chiller – the device that cools down the laser tube itself. The temperature of the tube should be less than 30C.

That is why we recommend using 2 types of industrial chillers.

The wavelength of the Co2 laser is 10.6 uM while a diode laser has a wavelength of 445 nm which is 20 times less.

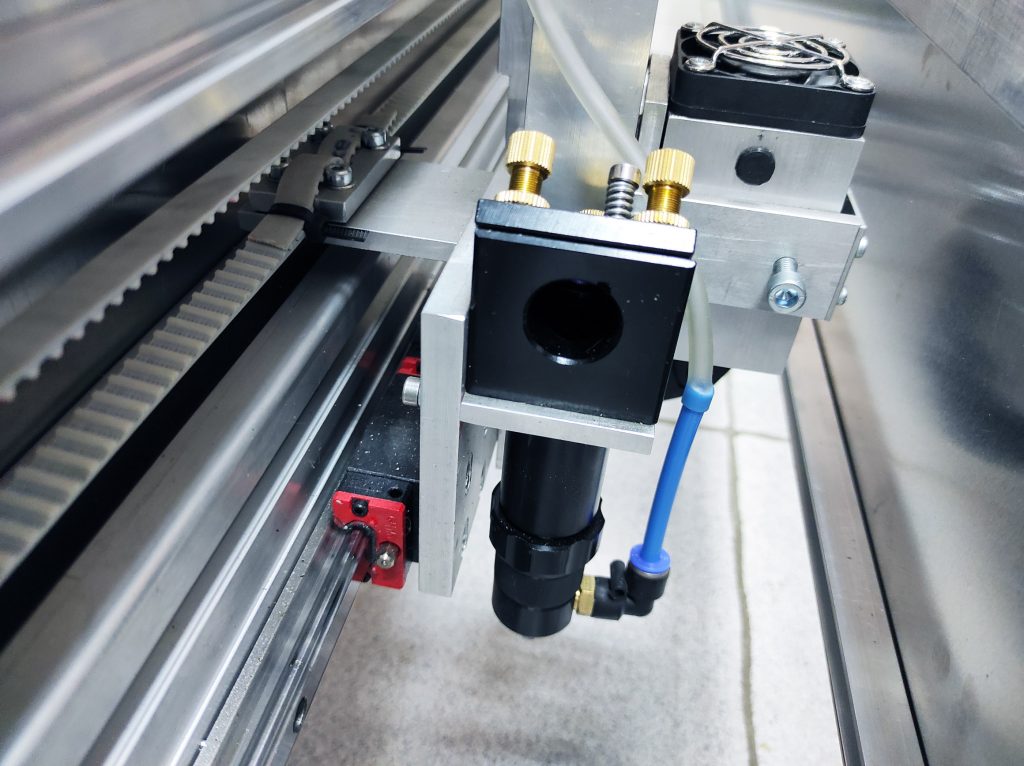

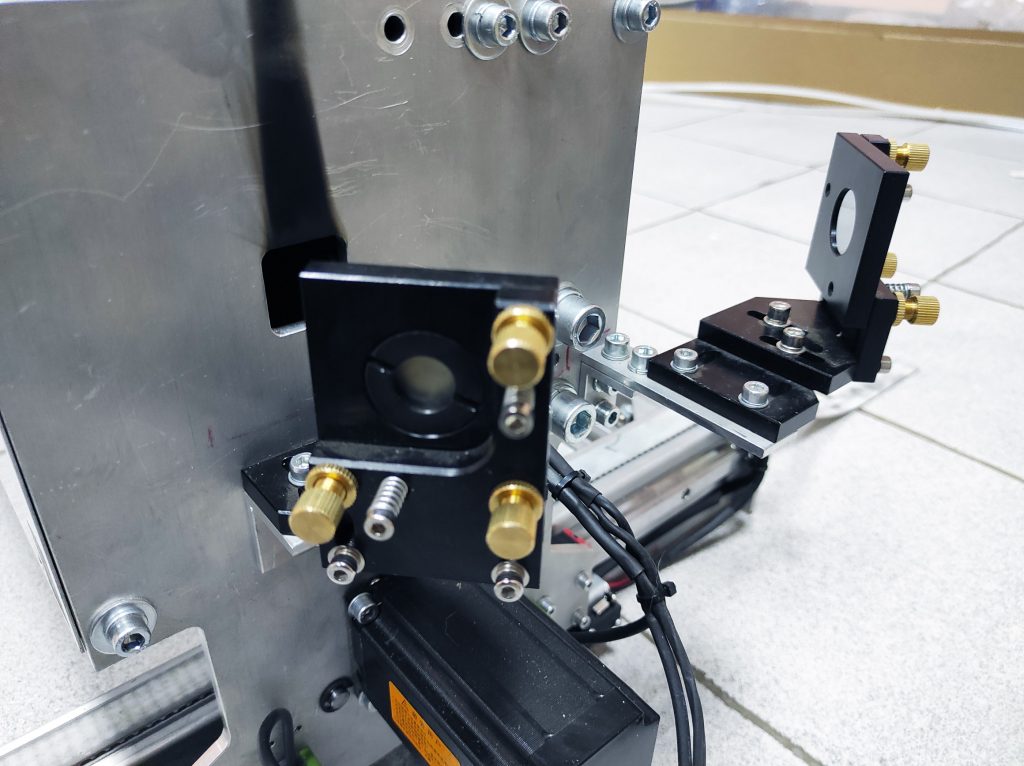

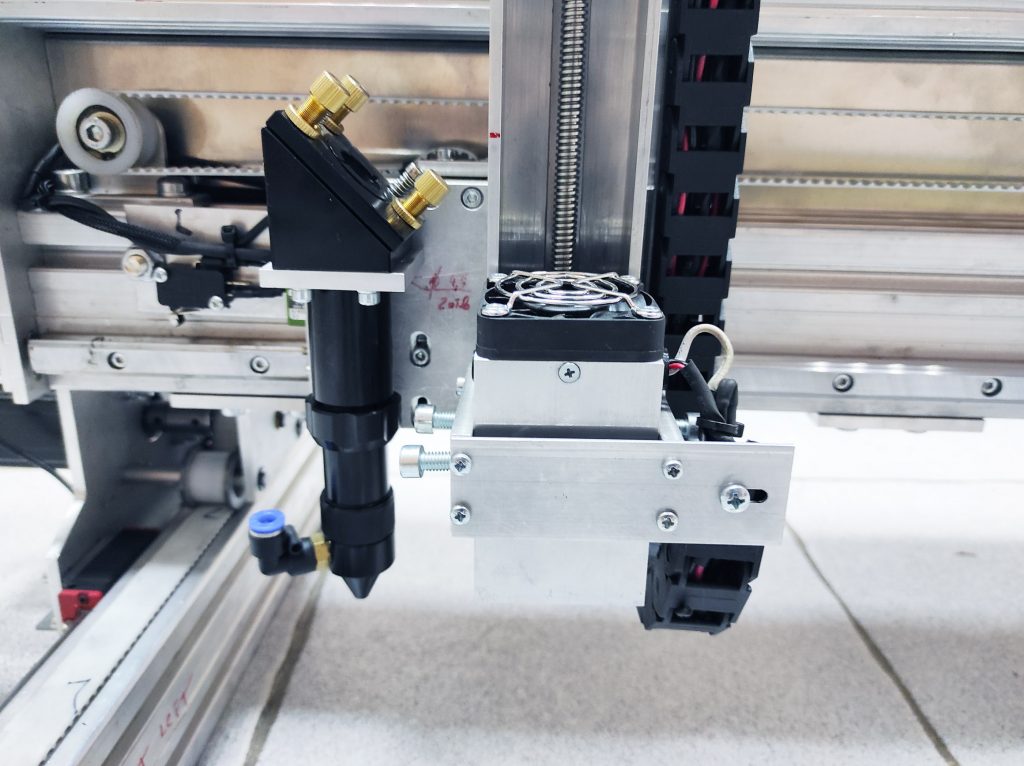

The laser cutting machine is a working area with a mechanism for moving mirrors and lenses.

The laser radiation comes out of the tube, hits a mirror mounted at 45°, and turns the beam 90° into the working area. The next mirror is fixed to the profile of the X-axis and moves along with this axis. It also rotates the beam by 90°. On the axis itself, a carriage with a special head (laser barrel, laser focusing head) is installed, in which, in addition to another mirror that turns the beam from the horizontal plane vertically down, a focusing lens is installed that collects the laser beam to a point. Thus, the laser radiation moves in the XY plane.

We also recommend using compressed air all the time when you do laser cutting. We used Hailea ACO-500 with 420 l / min and pressure of 0.05MPA, a higher pressure may be also used.

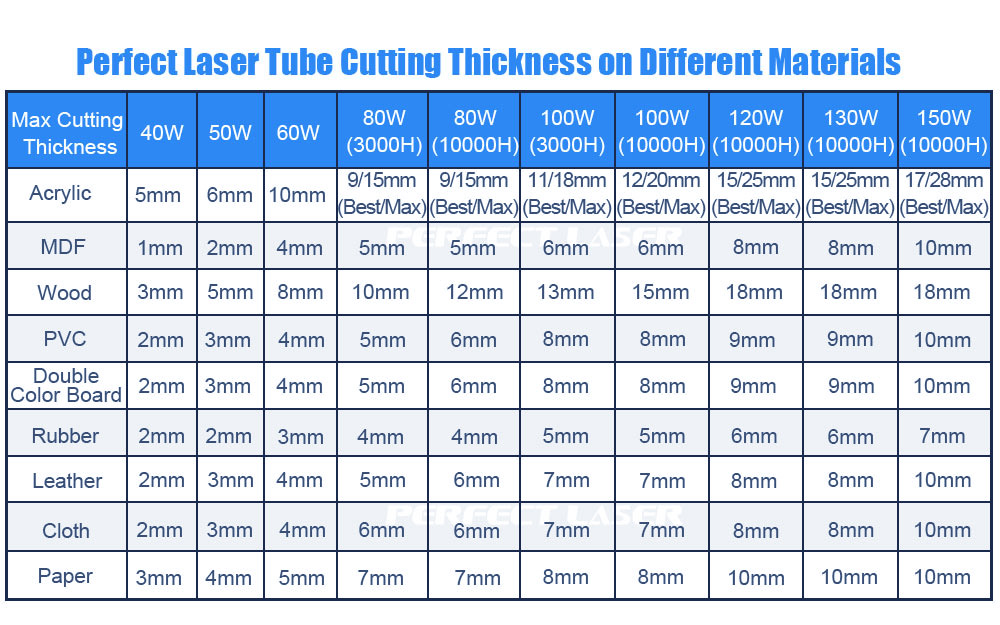

Keep in mind that most Co2 tubes have a lifetime of 3000-10000 hours so replace the Co2 tube once you see the power loss.

You can control our machine via USB or Wi-Fi.

First launch of the laser machine

Wood / plywood C02 Co2 laser cutting

We cut:

- 3 mm (1/8”) MDF

- 5 mm (3/8”) plywood

- 10 mm (5/12”) plywood

- 12 mm (1/2”) plywood

- 24 mm (1”) piece of wood

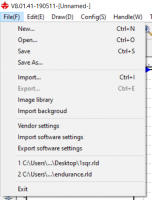

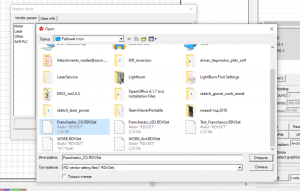

Running on RdWorks software

- Using the same power: 95%

- Laser cutting speed: 15 mm / sec

- 80 watt Co2 tube

- Hailea 500 watt ACO-500 420 l / min air compressor

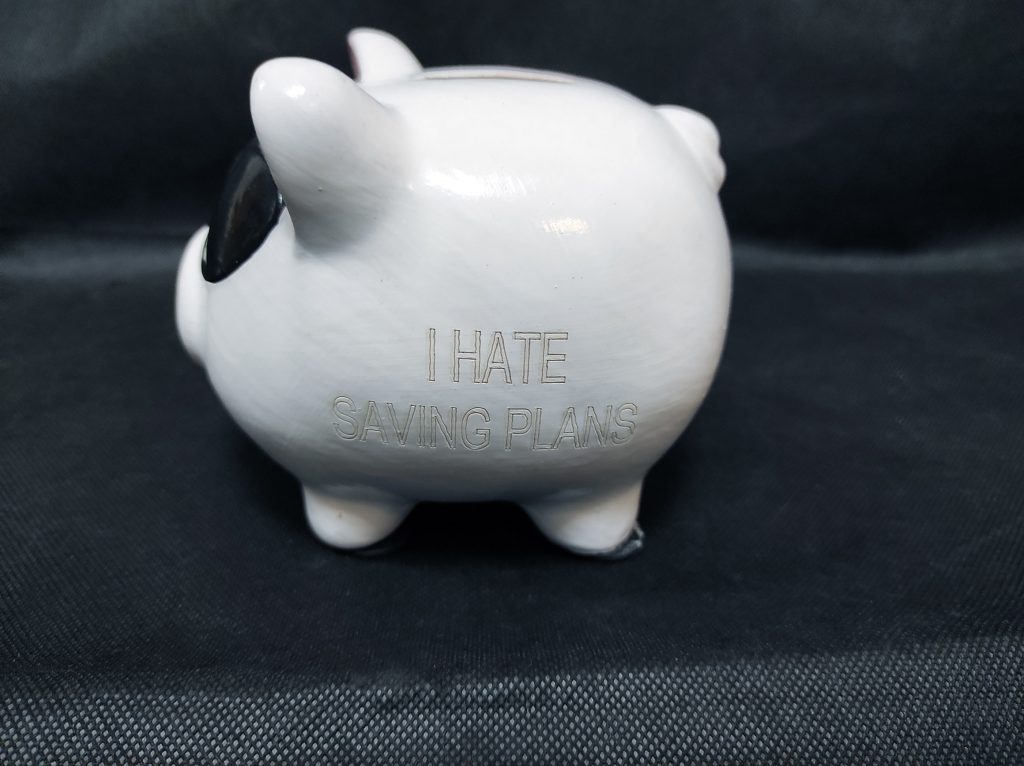

Metal engraving with a Co2 laser

Acrylic cutting speed can vary: 25-40mm / sec, power 95%

MDF engraving speed can vary: 200 mm / sec, power 15%

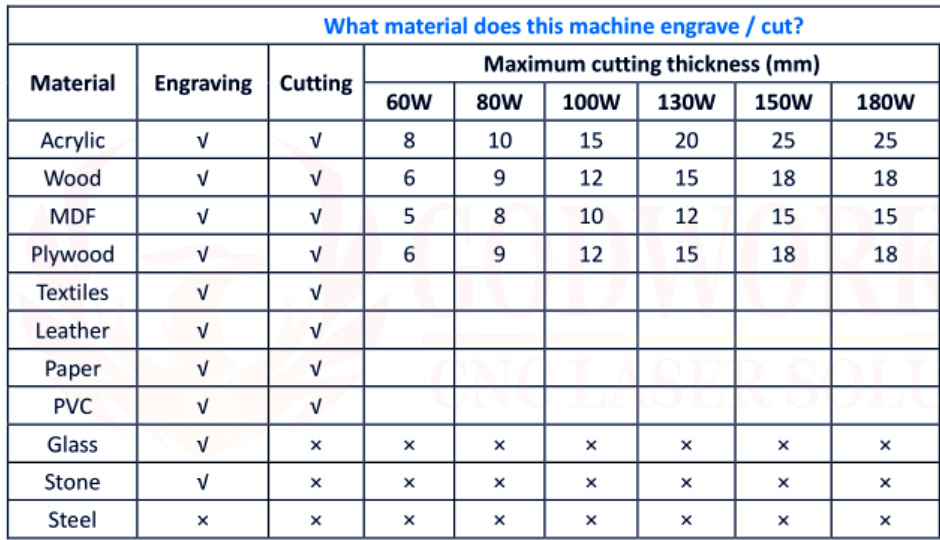

More cutting abilities with a Co2 laser

Tech specs of an Endurance 80 watt Co2 laser machine

| Name | Endurance Custom 80 watt Co2 machine | |

| Total size X x Y x Z | 2550 x 2370 x 500 | mm |

| Material | Aluminum Alloy | |

| Working size X x Y | 2035 x 1655 (6 x 5′) | mm |

| Z-axis height for a diode laser max | 100 | mm |

| Max Travel Speed (X / Y / Z) Optimal Travel Speed (X / Y / Z) | 50 15 | meters / min |

| Accuracy | 0.1 | mm |

| Motor Drivers (X / Y / Z) | Leadshine 552 | |

| Steps / mm (X / Y / Z) | ||

| Communication Interface | USB | |

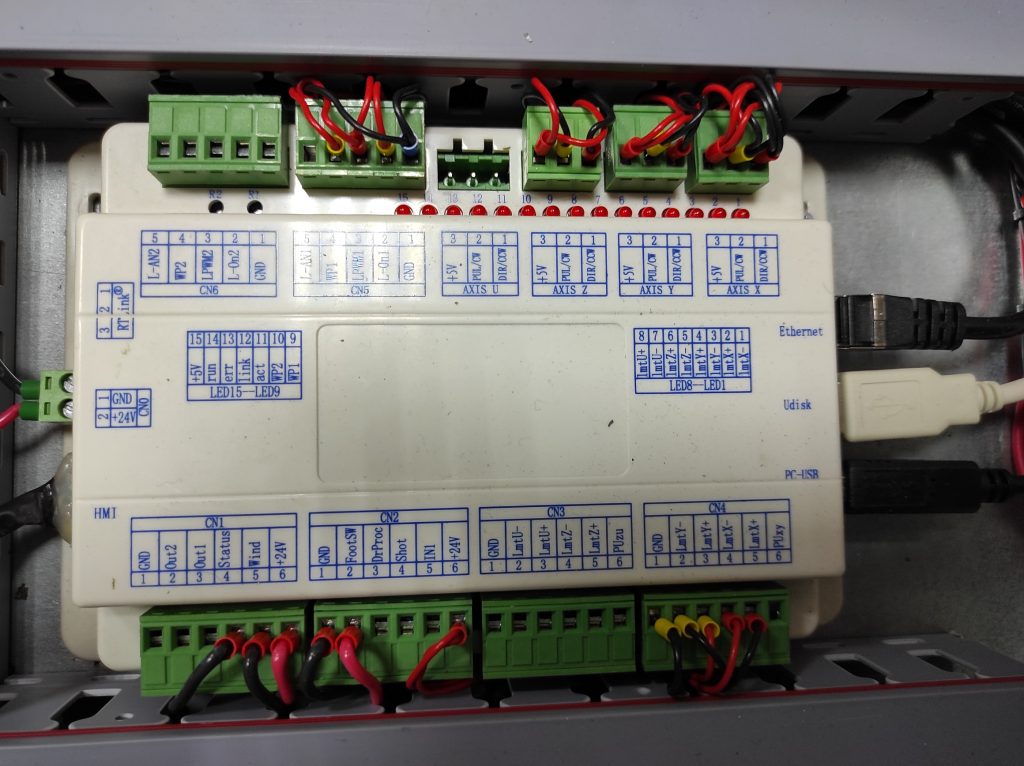

| Control Board | Ruida 6442G | |

| Firmware | ||

| Software Support | RdWorks / Lightburn (optional) Autocad / CorelDraw can be used with RdWorks plugin | |

| Supported OS | Windows 7/8/10 | |

| Laser | Endurance 10 watt (wavelength 445 nm) 80 watt Co2 (wavelength 10.6 um) | |

| Total power supply | watt | |

| Air assist | Air compressor Hailea ACO-500 1 x air nozzle for a Co2 | 420 L / min |

| OS | Win | |

| Warranty | 1 year | |

| Maintenance | Keep the frame and the laser clean | |

| Laser Box Size XYZ | 650 x 500 x 220 | mm |

| Emergency control of the working area | Software + Hardware | |

| Supply Voltage | 240 | V AC |

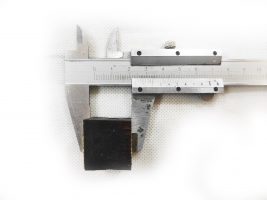

| Co2 laser-beam focus | 2-3 mm | |

| Co2 laser lens | 20 mm diameter / 100 mm focus | |

| Laser beam divergence | 3.1 | mRad |

| Laser beam spot | 0.3 | mm |

| Laser focal depth | 7.5 | mm |

- Laser lens package (optional)

Focus range in inch Focus range in mm Laser beam spot in mm Laser focal depth mm 2 50 0.155 3.75 2,5 60 0.186 4.5 3 75 0.2325 5 4 100 0.31 7.5 - Cooling chiller for Co2 tube is required (CW3000 / CW5200)

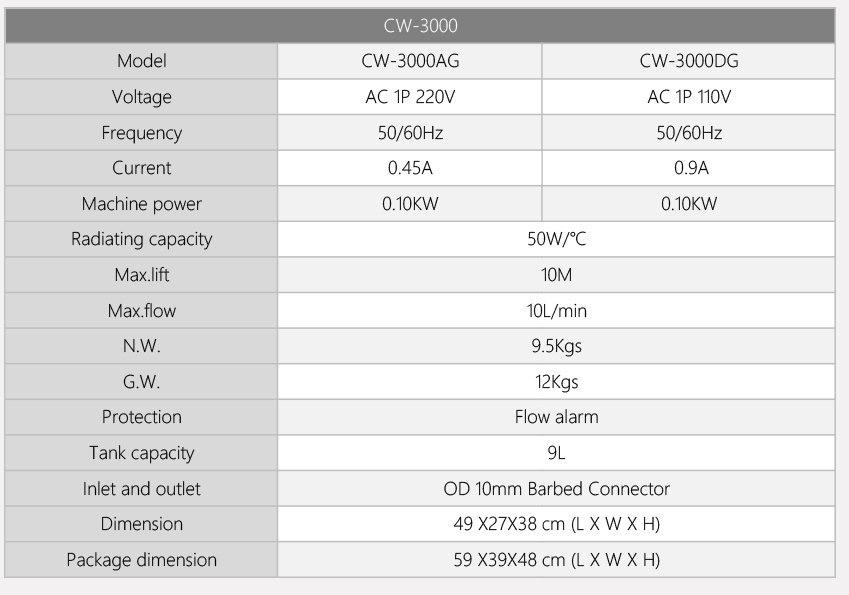

| CW3000 | CW5200 | ||||||||||||||||||

|

| ||||||||||||||||||

- A fume extractor can be added upon request

Components list

Laser components

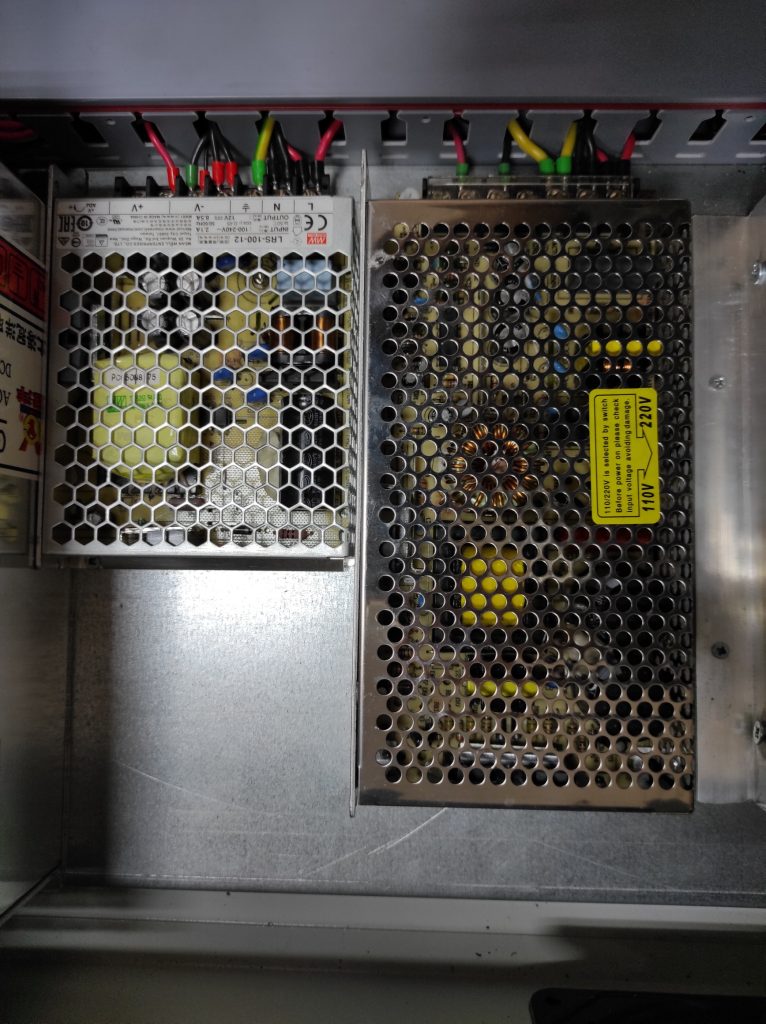

High voltage Co2 laser power supply

Holder for laser tubes with a diameter of 80mm x 2PCS

Mirrors d = 25mm x 3 PCS

80 Laser tube PURI PRR-1200

Focusing lens: Lens d = 20 mm, f = 63 mm

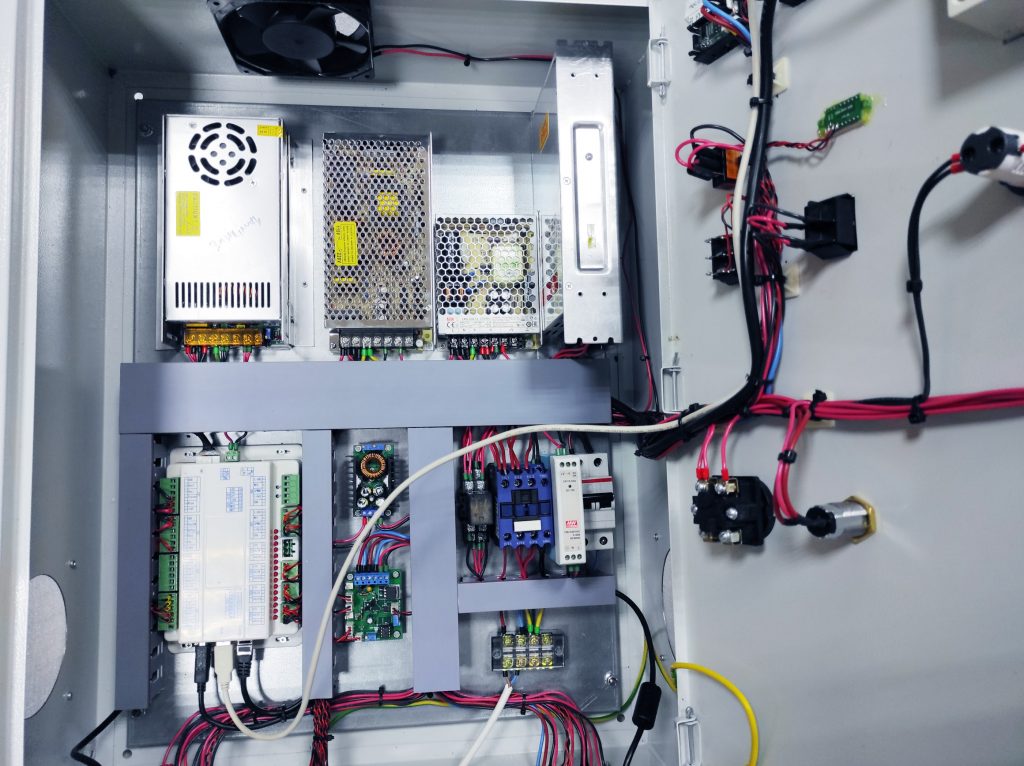

Electronics components

Power supply AC/DC 48V 12.5A x 2PCS (power for X1, X2, Y, Z axes)

Power supply AC/DC 24V 10A x 1PCS (Ruida power)

Power supply AC/DC 24V 0.42A x 1PCS (emergency end-stops)

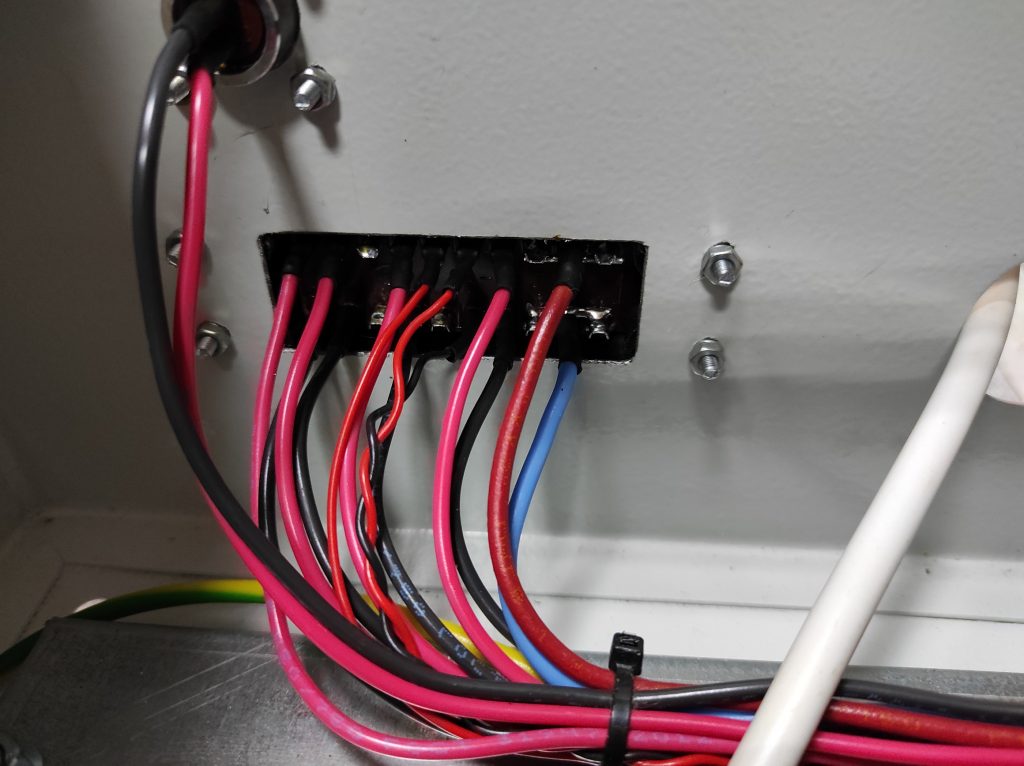

Electric opening switch 6A

DC/DC+ Mo2 (power + controller of a diode laser)

Security switch (on/off the machine)

Emergency stop

Control box (transportable)

Active fan cooling

Mechanical components

X axes:

Aluminum profile 40×80 – 2 x 2.5 meters

Profile guide 15 mm – 2x 2.5 meters

Belt 20 mm XL 5.08- 2×3 meters

Motors: Nema23 ST57-100x 2PCS

Y-axes:

Aluminum profile 40×80 – 2 x 2 meters

Profile guide 15 mm – 2x 2 meter

Belt 10 mm XL 5.08 – 4.5 meters

Motors: Nema23 ST57-100x 1PCS

Z axes:

Motors: Nema23 ST57-75 x 11PCS

Connector X with Y Aluminum profile 40×80 – 2 x 1.92 meters

Extra X with Y connectors 20×40 – 2 x 1.92 meters

Cutting abilities (material / thickness / speed / amount of repeats / laser power)

| MATERIAL (3mm) | SPEED (mm/sec) | POWER (%) |

|---|---|---|

| Acrylic | 15 | 70 |

| Card | 30-100 | 30-70 |

| Laser Plywood | 15-20 | 70 |

| MDF | 16-25 | 70 |

Co2 laser cutting speed for different laser power tubes (thickness | speed in mm per second)

| Thickness in mm | Thickness in inch | 40 watt | 60 watt | 80 watt | 100 watt | 130 watt | 150 watt | 180 watt | |

| mm/s | |||||||||

| Acrylic | 3 | 1/8 | 8 | 20 | 30 | 35 | 40 | 45 | 50 |

| 5 | 1/5 | 5 | 15 | 16 | 20 | 21 | 25 | 30 | |

| 8 | 1/3 | 4 | 5 | 10 | 12 | 12 | 15 | 20 | |

| 10 | 2/5 | 1 | 3 | 6 | 7 | 10 | 11 | 16 | |

| 15 | 3/5 | – | 1 | 3 | 4 | 5 | 7 | 9 | |

| 20 | 4/5 | – | – | 1 | 1,5 | 2 | 3 | 5 | |

| 30 | 1 1/6 | – | – | – | – | – | 1 | 1,5 | |

| MDF | 3 | 1/8 | 9 | 15 | 20 | 23 | 25 | 30 | 33 |

| 5 | 1/5 | 5 | 10 | 13 | 15 | 18 | 21 | 25 | |

| 10 | 2/5 | – | 3 | 5 | 7 | 9 | 12 | 14 | |

| 15 | 3/5 | – | – | 2 | 3 | 5 | 7 | 10 | |

| 20 | 4/5 | – | – | – | 1 | 1,5 | 2 | 3 | |

| Plywood | 2 | 1/12 | 15 | 25 | 35 | 40 | 45 | 55 | 65 |

| Wood | 3 | 1/8 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

| 5 | 1/5 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | |

| 10 | 2/5 | – | 4 | 8 | 12 | 15 | 20 | 25 | |

| 15 | 3/5 | – | – | 4 | 8 | 11 | 15 | 18 | |

| 20 | 4/5 | – | – | – | 1 | 2 | 2,5 | 3 | |

| Fabric | 1 layer | 40 | 60 | 100 | 200 | 300 | 400 | 500 | |

| Leather | 1 layer | 10 | 20 | 25 | 30 | 40 | 50 | 60 | |

| Paper | 1 layer | 80 | 120 | 20 | – | – | – | – | |

| Rubber | 4 | 1/6 | 15 | 25 | 30 | 35 | 40 | 45 | 50 |

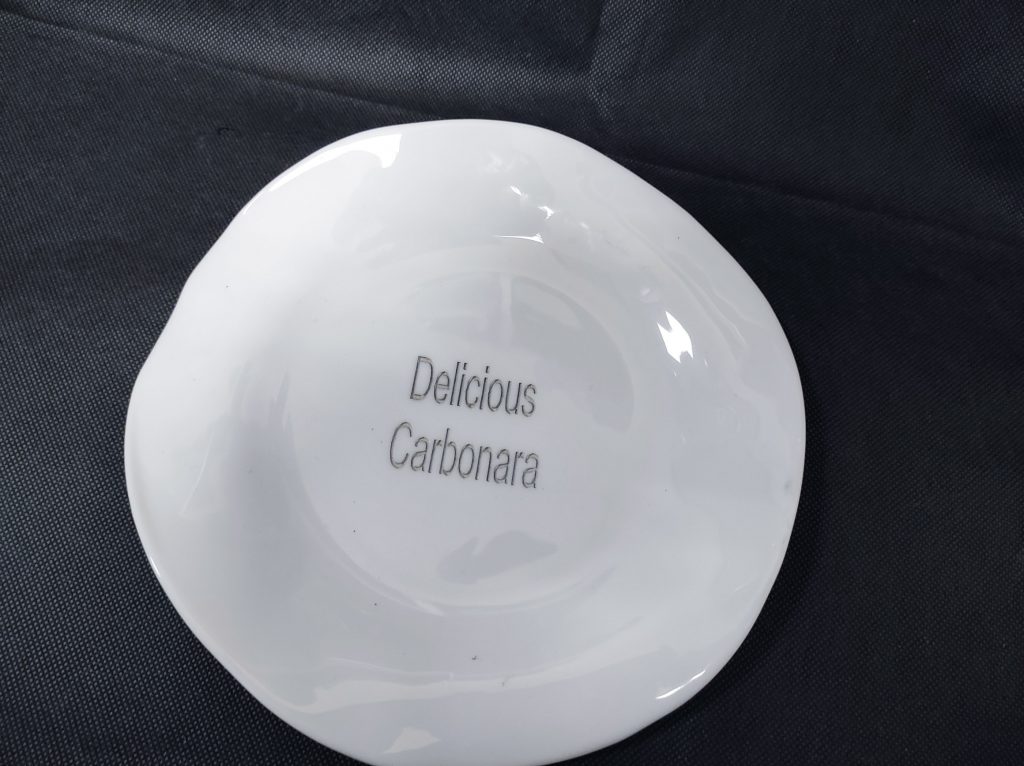

Engraving abilities

A starting point for the power setting when engraving is 30-35%.

A higher percentage will increase the power and produce a deeper engraving, while a lower percentage will decrease the power and produce a shallower engraving.

The depth of the engraving will also depend on the material which is being processed (softer materials can be etched away more easily than harder materials).

Laser power test stability

Final CNC frame tests

| CNC test check report | Electronics |

| Final test | Control board stability |

| Working size | Laser temperature |

| RdWorks | PWM |

| Max cutting speed | Focusing |

| Max engraving speed | Laser beam spot |

| Z-axis length | Motors test |

| End stops | Drivers test |

| Photoengraving | Firmware test |

| Home position | Resonance test |

| 100 repeats test | |

| MAX / MIN travel speed | Mechanical |

| Laser engraving parameters | Backlashes |

| X-axis travel speed | XY vibrations |

| Y-axis travel speed | Z-axis vibrations |

| The maximum workpiece height | Z-axis power |

| The maximum workpiece height | Stepper motors temperature |

| Machine weight |

Total costs and time consumption:

| Costs for components | Costs |

| Co2 laser + all accessories | 700 USD |

| Diode laser + driver + DC/DC | 600 USD |

| All Mechanical parts | 1300 USD |

| All Electronics parts | 1400 USD |

Total costs for components: 4000 USD

| Time consumption | Hours |

| Metalwork | 160 |

| Electronics | 160 |

| laser installation and aligning | 10 |

| Total testing | 20 |

The total price for an entire unit including air compressor and the chiller is 9500 USD (without the shipping costs)

Full components list (PDF)

RdWorks user manual

Users manual for software RDWorksV80.325318474

RDC644XG Controller User Manual

Changing modes in Ruida from Co2 into diode laser mode

Files >>> co2 vs diode on ruida

Different laser power options

30W / 40W / w60W CO2 Laser Tube

30W/40W/60W CO2 Laser is suitable for fine surface engraving. Design for hobbyists, crafters to cut thin materials (<3mm) and engrave fine quality pictures on a smooth surface.

80W/90W CO2 Laser Tube

90W CO2 Laser is suitable for laser marking, laser cutting, and laser engraving which is the ideal choice of a laser cut on thin plates include perspex, softwood, etc laser cloth cutting, and marble marking.

100W CO2 Laser Tube

100W CO2 Laser is suitable for leather carving and hollowing-out or embossing, cloth cutting, lampshade making, signs, marks and artwork processing and truly boasts excellent engraving and cutting performances.

120W/130W CO2 Laser Tube

120W/130W CO2 Laser is suitable for the cutting of die-cutting plates, thick acrylic plates, and so on. It is widely used in the packaging industry which uses large quantities of medium-density fiberboard and plywood cut by die-cutting machines. In addition to the packaging industry, this Laser is also popular in the signage industry with the prominent usage of perspex, light guiding plates and display screens.

150W/160W/180W CO2 High-Power Laser Tube

Our 150W – 180W CO2 Laser is capable of cutting thin metal plates.

Learn more about our custom frames >>>

Read more about lasers on All3DP >>>

How to upgrade your CNC or engraving machine for the work with a Co2 laser tube.

Comparison of a different types of lasers and different wavelength