A real story by Bob West

As I am getting old, the family are always having issues, trying to get me a present for my birthday.

2019 it was a DJI drone, which I managed to drown, which is a bit sad, and very costly as well.

Covid stuffed the birthday last year, so a bottle of Scotch had to do, but it was not 15-year-old single malt.

2021 came along another birthday, more Covid issues.

Suggested the present should be an engraver of some sort, so did some hunting around and settled on a cheapie 3018 Pro, with a 2.5watt laser. Purchased it on eBay for the grand total of AU$229.96, delivered to the front door. Knowing the quality of some units is an issue, I was prepared to give it a go, as I had plenty of time on my hands, having recently retired.

All you need to know before buying a laser or an engraving / cutting machine

Unpacked the box and checked all the parts, which seemed to be there, and proceeded to do the assembly. Did not have too many issues, and it did help when others had done YouTube videos of unboxing and assembly.

Got it all together and started testing the engraver.

Learn more about Endurance CNC 3018 >>>

A candle was the suggested software to use with the engraver, but many posts I saw by people were suggesting Easel was the better way to go. There is a free version and a pro version which you need to pay for. The free version does give you 30 days access to all the pro features, and then I think you get a few days’ month access to all the pro features at no cost. For the number of items I would do, that seemed fine.

Created a few designs in Easel, and got ready to give it a try.

Not really knowing what I was doing at this stage, I was a bit apprehensive watching the spindle spinning up to 8000rpm, and then moving down towards the MDF. Lucky for me I had done some more homework, and found a very helpful young fella on Youtube called James Dean, of James Dean Designs, who had done a tutorial on fitting a Z probe onto the 3018.

I made a few sample signs using MDF. The V cutters supplied with the machine did the job, and I did err on the side of caution and ran them at 200mm/min, which was a bit less than the speed suggested by the Inventables, who supply the Easel software.

As the machine is in my study, the noise went all through the house. The wife was pleased about the machine working, but said it was too loud!!

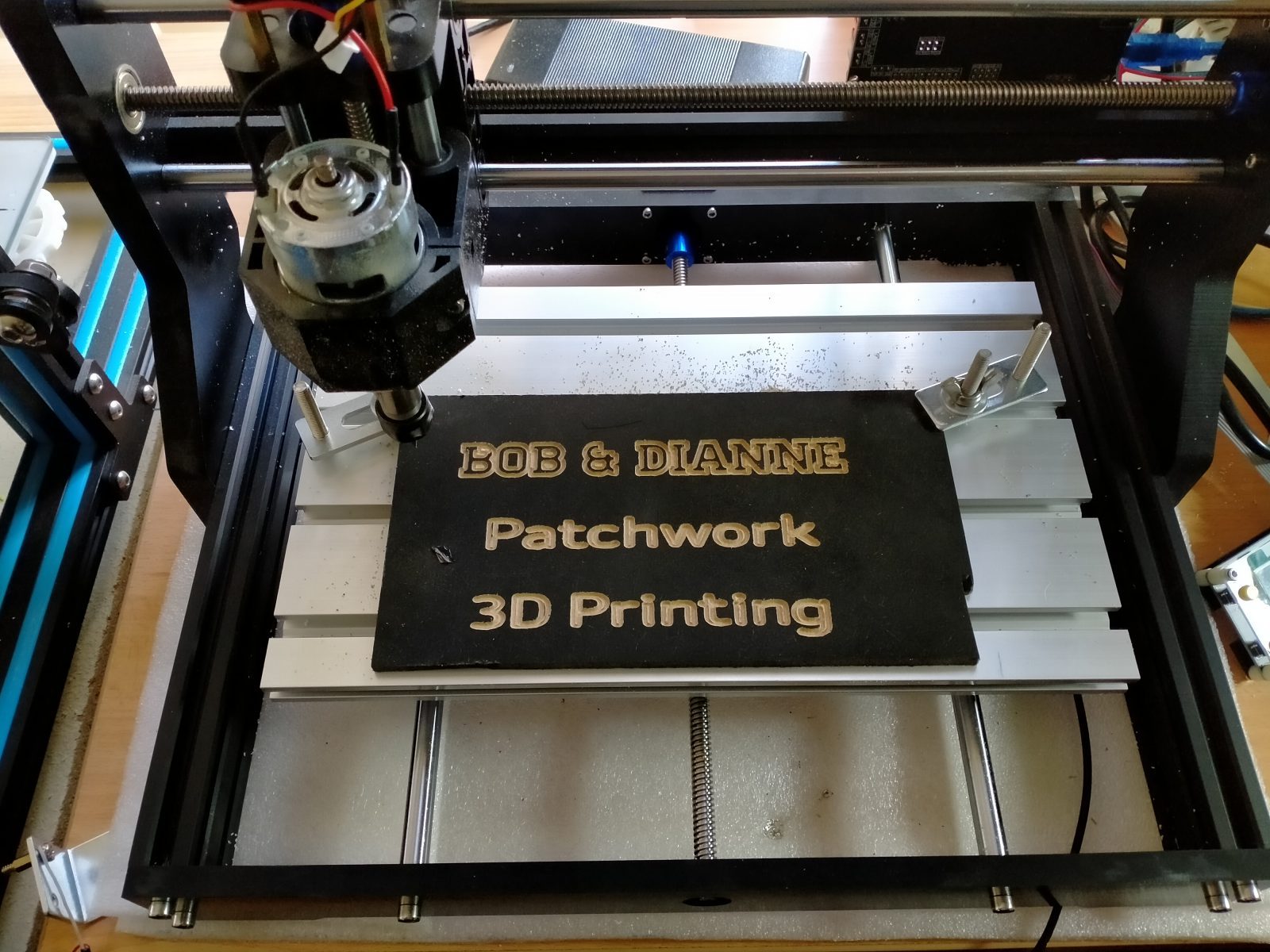

While the signs were OK, without any painting/staining they were a bit dull. I painted some MDF Black and then did the engraving, which turned out rather well.

Having had success with the MDF, I was keen to try engraving, and cutting acrylic, as I do make some templates for the wife’s patchwork she does, but they are 3D printed, and she would prefer acrylic.

I found a 3.175mm end mill in the Dremel box and had some 4mm acrylic, so thought I would give it a try.

Drew a pattern in Easel, loaded it up, and let it run. I thought the V cutters were noisy, but the end mill was twice as loud. The bad news is I had set it up to only cut .5mm each pass, trying not to break the tool, and had dropped the speed down to 150mm/min. It took ages, but it got there in the end.

While doing the acrylic, I found out the bed of the engraver runs out on the X-axis by about .6 to .7 of an mm, so will have to shim it, or make a spoil board as per the tutorial by James Dean, which would bring the work surface back to level, but I would lose some height on the Z-axis. Will look at it in the near future.

So far so good, it was now time to try out the laser.

I have owned a Creality CR10 for almost 3 years and had purchased their 500mw laser for it about 18 months ago. It gave me a chance to see what a small laser could do. This power laser is a bit limited, but I found it a good starting point. It could cut colored paper. How well it would cut did depend on the actual color of the paper. I used speeds around 450mm/min with the laser at 95% power. White paper was an issue, at 150mm/min and 100% power, would not even mark the paper. I could engrave patterns, text etc on wood, created using Laser Etch, with speeds of 150 to 200 mm/min, depending on how dark I wanted the engraving. Sometimes it needed 2 passes, based on the type of wood being used.

I went ahead and installed the 2.5watt laser. The instructions were not really clear when I assembled the engraver, and I found that I had to do some trial and error adjusting the location of the X-axis gantry, to enable me to get the maximum work area I could along the Y-axis. After watching a few Youtube videos, I began to use Inkscape to do drawings and downloaded the J tech Photonics laser plugin to create the G-codes. and switched over to Laser GRBL to control the machine. I was very pleased to get it all working, after expecting more problems.

LaserGRBL video guide

The difference between the old and new laser was impressive. It could be run at speeds up to 1500mm/min at 90% power, and engrave a decent image on colored paper, and white paper at a slightly lesser speed. Cutting was Ok at 800mm/min for standard 80gsm paper. A big improvement. My daughter makes handmade birthday cards etc and is keen for me to cut out various thickness card stock she can use making the cards, so she is happy.

As I expected, an issue arose with the unit. When doing Vector engraving of a closed graphic, square, hexagon, etc, the endpoint of the engraving did not finish at the start point, and it did not happen all the time. Eventually, I found the X-axis coupling was slipping on the threaded rod, even though I had tightened the grub screws very well. The issue persisted, so I approached the seller about it. They were very helpful and asked for a video and pictures of the problem, which I sent them. A day or so later, they advised a new coupling was being sent to me, which arrived about a week later.

All was well again after fitting the new coupling and I did a few small items over the next couple of months and had no problems.

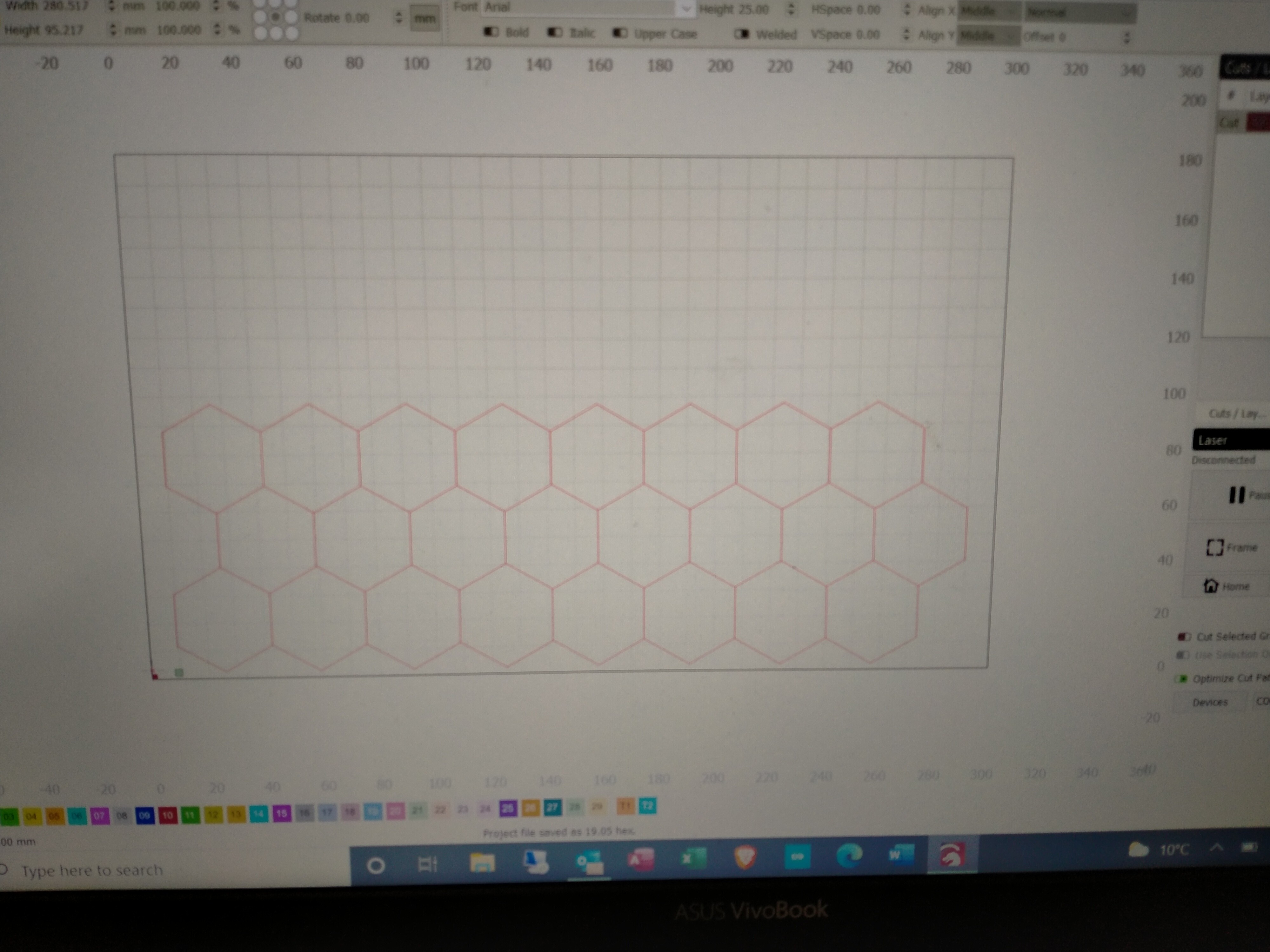

My wife gave me a job to cut out 2000 hexagons for her, for one of her projects. They were to be cut from standard Kodak Glossy photo paper.

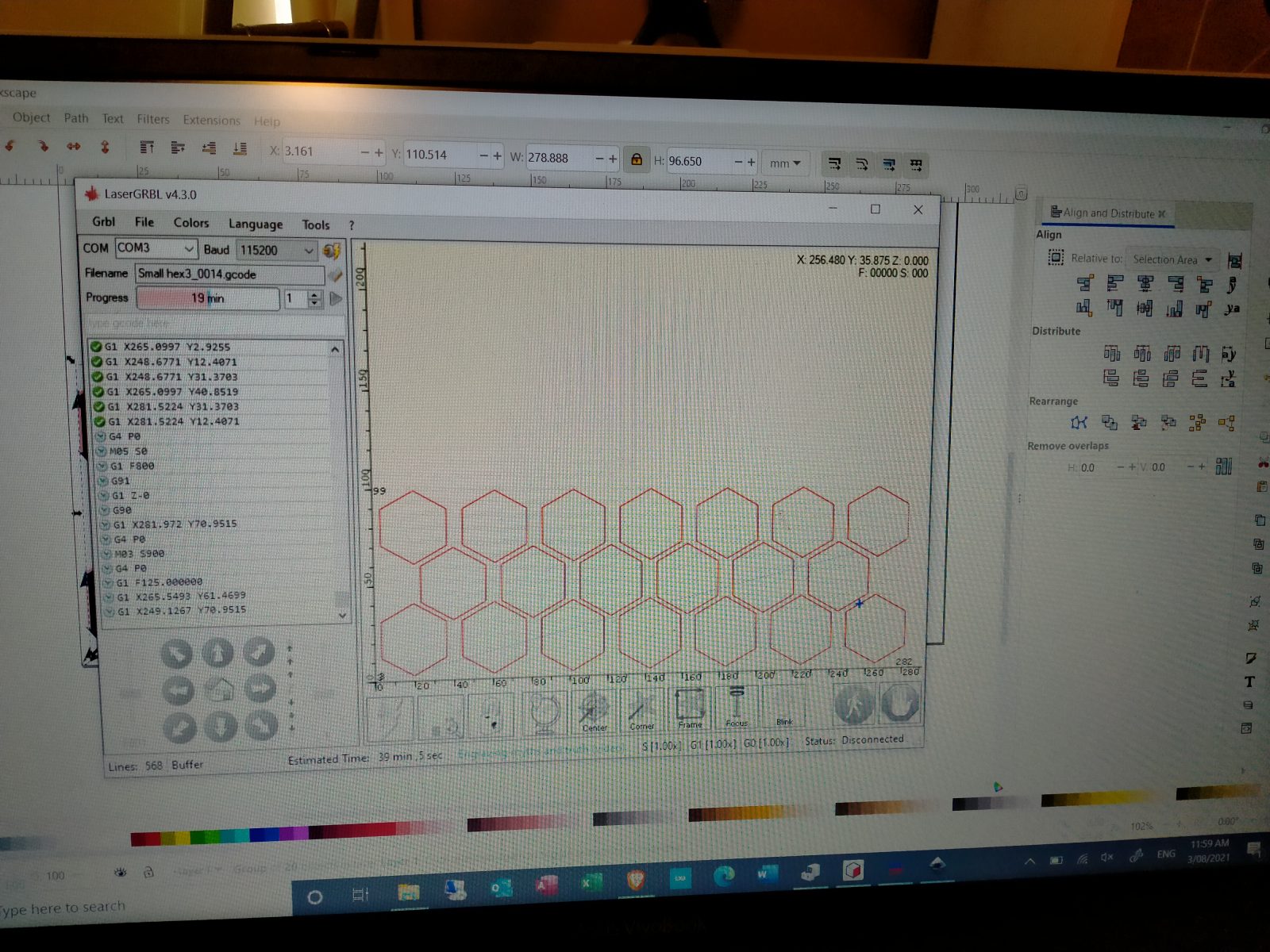

I set out 20 individual hexagons on a drawing in Inkscape. Tried to interconnect them and save cutting time, but could not find a way to do it. Created the Gcode and checked it in Laser GRBL, as it all looked good, hit the go button. Being unsure how it would cut the Glossy paper, I set it up to do 2 passes but found it would cut completely through on the first pass. Speed was 350mm/min at 90% power.

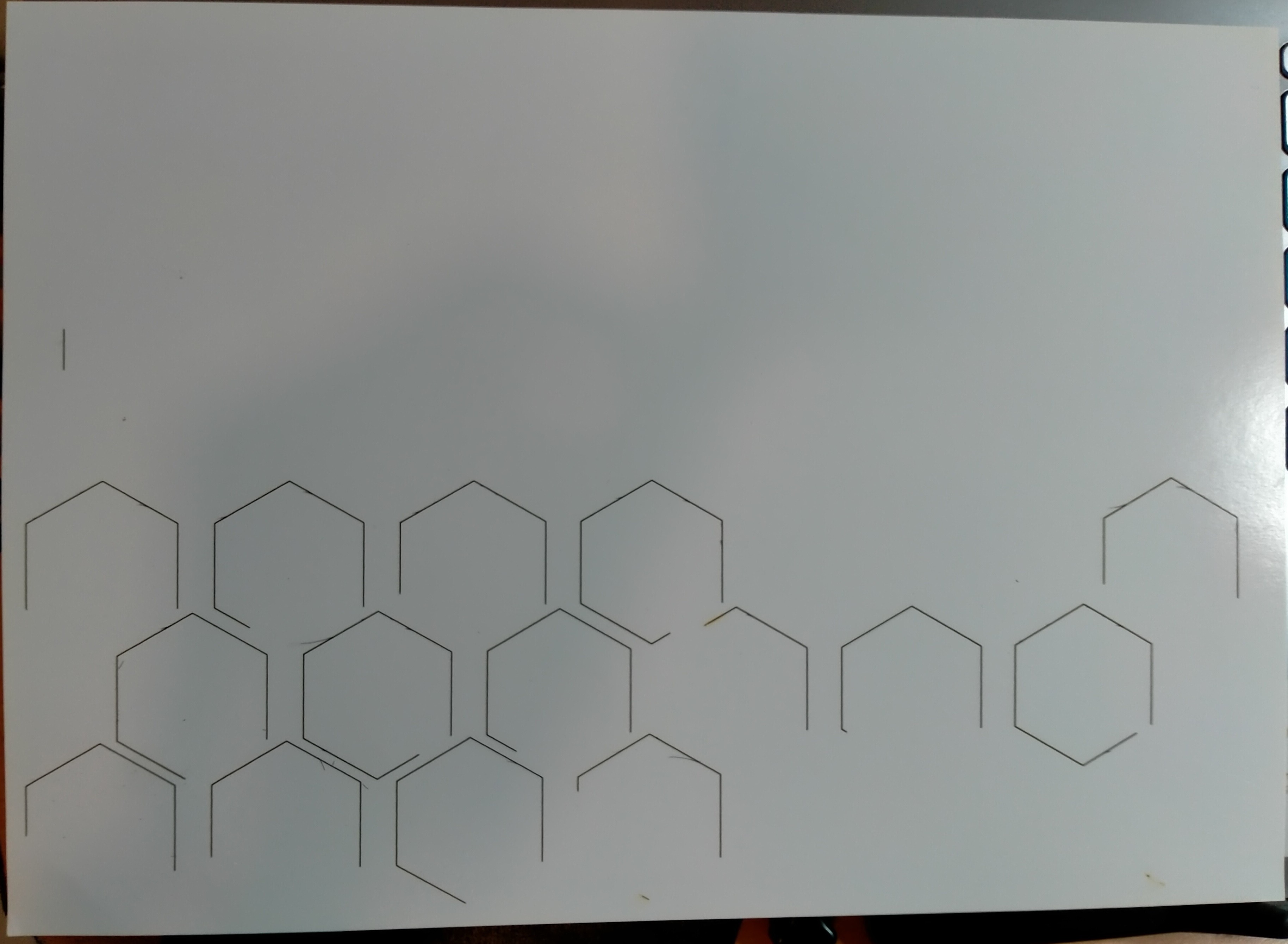

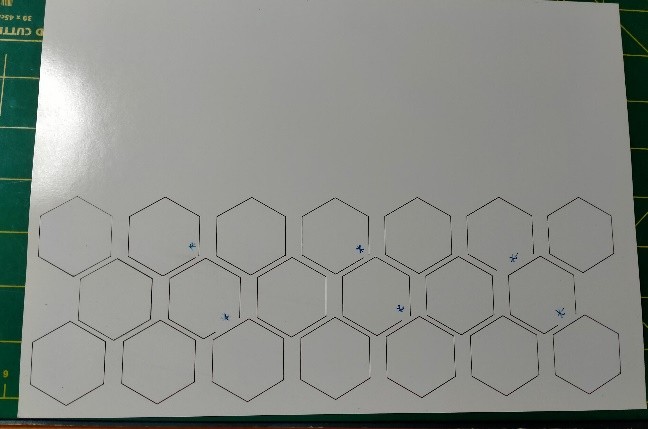

I could get 40 hexagons per A4 sheet, and after doing 2 sheets, without warning, the laser did not cut anything on some of the hexagons, and then, at a different location each time, it started to cut correctly.

Laser Engraving & cutter projects – photo and files – best ideas

I checked all my settings and Gcode but could find nothing wrong. Left it for the night and tried again the following day. Same issue, but not the same on every hexagon.

Some did not cut at all, others were just cut part of the way, as can be seen in the above picture. What should have happened is in the picture of the computer screen, showing the layout in Laser GRBL.

Learn more about other engraving software >>>

Anyway, back to the supplier again. I was unsure what warranty was on the unit. It had been 3 months or more since I purchased the it, so was surprised when I was told the laser would be replaced. As per the previous issue, had to send pictures and video of what was happening.

Laser number 2 arrived a couple of weeks later.

Installed it and cut more hexagons using the Gcode I had made previously. The replacement worked much better than the original laser. Found I could up the travel speed to 400mm/min, and it would still cut in 1 pass at 90% power. The fan on the new laser was quieter as well.

The next day, started to do some more cutting, and the same issue appeared again, although not as bad as the first time. Out of 20 hexagons, 6 were incomplete in some way, as shown in the picture below.

Again, contacted the seller and advised the problem had started again. As 2 lasers were having the same problem, I asked if it may be the control board that had the problem not the lasers. They suggested the 2nd unit may have been damaged in transit, so it would be replaced, again.

About 2 weeks later, laser number 3 arrived.

My Experience With Non-Branded Chinese Made Lasers. Fake laser modules! WARNING!

At the time of writing this, I am pleased to advise that this replacement is even better than number 2. Adjusted the speed up to 500mm/min, still at 90% power, and it looks like it may even be able to go faster. After cutting about 300 hexagons, it is still going strong. Once I keep the boss happy and cut another 1600 hexagons, I will see what else I can do, if the laser is still running.

I downloaded a trial version of Lightburn, with which I can draw or import Graphics and create Gcodes, similar to using Inkscape. Main difference is Lightburn can control the engraver, which I find useful.

I managed to re-draw my hexagons, and link them together, so instead of having 20 individual items to cut, it is now 1 big item, giving me 23 hexagons per cut. Lightburn also gives you a preview of what the cut will look like as well. Can check and make sure things are done in the correct order.

Engraving before cutting is a must.

Lightburn does not seem that hard to use, but I was having issues with the laser darting off in the wrong direction across the X-axis, and hit the side of the machine, every time I tried to start a program.

Back to Youtube and James Dean Designs, who had, among his other videos, a very informative tutorial for Lightburn. Problem solved. Change the setting for the start of the job to “Current Position” and it works a treat. I am not used to having a machine without limit switches. I learned that you have to set the laser at the starting position, which is the bottom left corner of the cut, not the home position unless the is where you set it up. Without limit switches in Lightburn, you cannot do a homing sequence, like the CR10, so maybe that is my next project, fit them to the 3018 Pro.

The bigger headache has been learning to use new software, that sometimes comes with limited documentation, so must rely on Youtube and the net to learn how to use them correctly.

As I am now on my 3rd no-name Chinese laser, when this last replacement does expire, I will have to make a decision. What will I replace it with?

From eager hobbyist to failed entrepreneur: Living in the world of Chinese Knockoffs

Do I buy another no-name Chinese one, or spend up and replace it with the better quality, more reliable, more expensive unit? I have had good after-sales service far, but it has taken 3 lasers to find one that, at the moment, works as it should. The seller I dealt with do not sell lasers only, so I would have to find another, and who knows how I would get treated if there were issues.

I may have to lean towards the more expensive laser when the time comes, as it would not take long to spend the same amount of money on no-name lasers, as it would to buy a decent brand, if they had to be replaced often, and this may happen to judge by my experience so far. After-sales service I presume would be better with a name brand as well.

As am only using the 3D printer and engraver as a hobby to keep the brain active in retirement, I am not looking at them to make money, although I have made and sold approx. $200.00 worth of 3D printed sewing templates to my wife’s sewing groups, and that may continue in a small way, especially if I can cut and engrave Acrylic.

In the early days of having the 3D printer, I even made feet for her sewing machine, as she required special sizes, that she could not buy. Made some Brownie points with that one !!

I am sure there are many opportunities to put the laser/engraver to good use, for those that would like to earn money with one. The local Sunday market will at have least one stall selling custom-made signs, done with either a laser or engraver. Have also seen personalized phone covers made on the spot with a laser. Craft shops have precut MDF shapes available, letters, numbers, animals etc, and I am sure money could be made offering a custom cutting service.

Many years ago, my wife was involved in making handmade leather photo albums. Lasers were not around then, but today, what couple would not want a custom-made, custom engraved leather photo album for their special day. The possibilities are endless for those with the drive to get started.

Again, as a hobby, I am looking forward to seeing what I can do in the way of birthday gifts etc, for the family and friends.

Annoyed the Nieces one birthday with a Labyrinth puzzle each, which I found on Thingiverse, and printed them. Put $20.00 in each one and they had to open them, without doing any damage. Think it took 1 week and they managed to do it.

Have even made a machine to sort the daughter’s M&M’s into their respective colors, as she does not like them mixed.

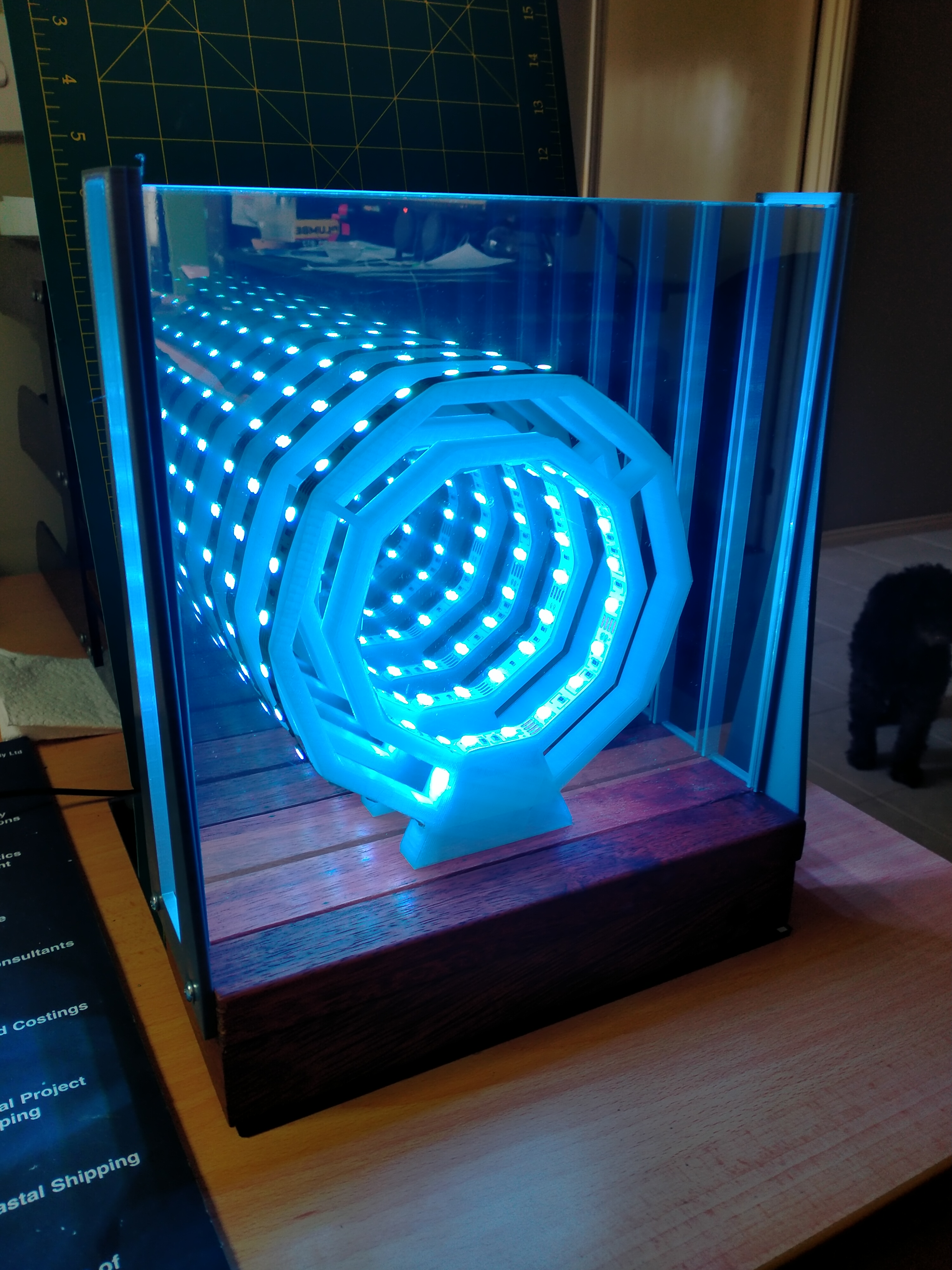

Bought 3 small boxes from the local hardware and made a lamp using LED’s and an Arduino. Would love to do more, and make custom boxes with various cutouts in the front for the lights. May be able to with the 2.5watt laser, but will have to see if it has enough power if it lasts long enough.

This digital LED clock was 3D printed and mounted in a standard Ikea picture box. Would like to redo it using timber, and machine it out on the engraver, possibly burn numbers in with the laser.

Red LED’s are the hours, green are the minutes and blue is for the seconds.

My latest creation is an infinity lamp, which was made

using a 3Dprinted mount for the LED’s, a mirror, and some tinted glass. There are also some 3D printed supports to hold the glass in place. Lights are remote control for changing color.

Having the engraver and the 3D printer certainly will keep me busy, seeing what new things I can come up with, or improve on what I have already done. I try not to make ornaments to sit on the shelf, but endeavor to make useful items for the family and friends.

As far as the 3Dprinter goes, it is bog-standard, and after 3 years, still works well. Have found no real reason to tinker with it. I have only just changed the print nozzle after getting a clog, and also found the Bowden tube had started to fatigue, so replaced it as well.

If it is not broken do not fix it !!!!!

Endurance Lasers provide the ultimate lasers with high-end assembling quality >>>