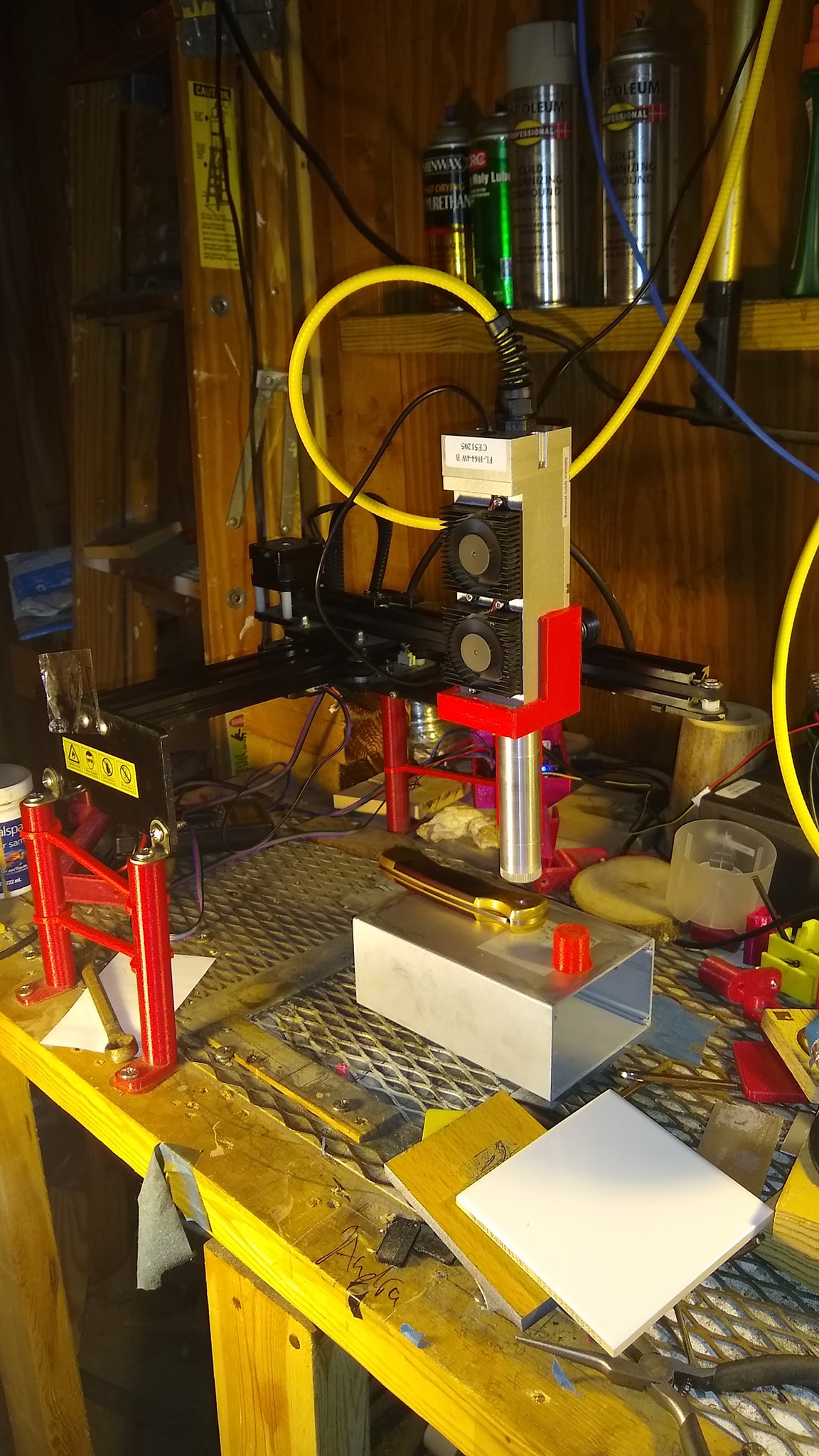

NEJE Laser Engravers are very popular machines but there are a few shortcomings in them to adapt correctly to Endurance DPSS Laser Engraving Modules. The major one is they leave the low-power laser engaged all the time with no way of controlling it.

The solution is to make your NEJE a quick change from Endurance DPSS Lasers to standard NEJE laser modules. This solution may be applied to other makes of laser engravers if needed.

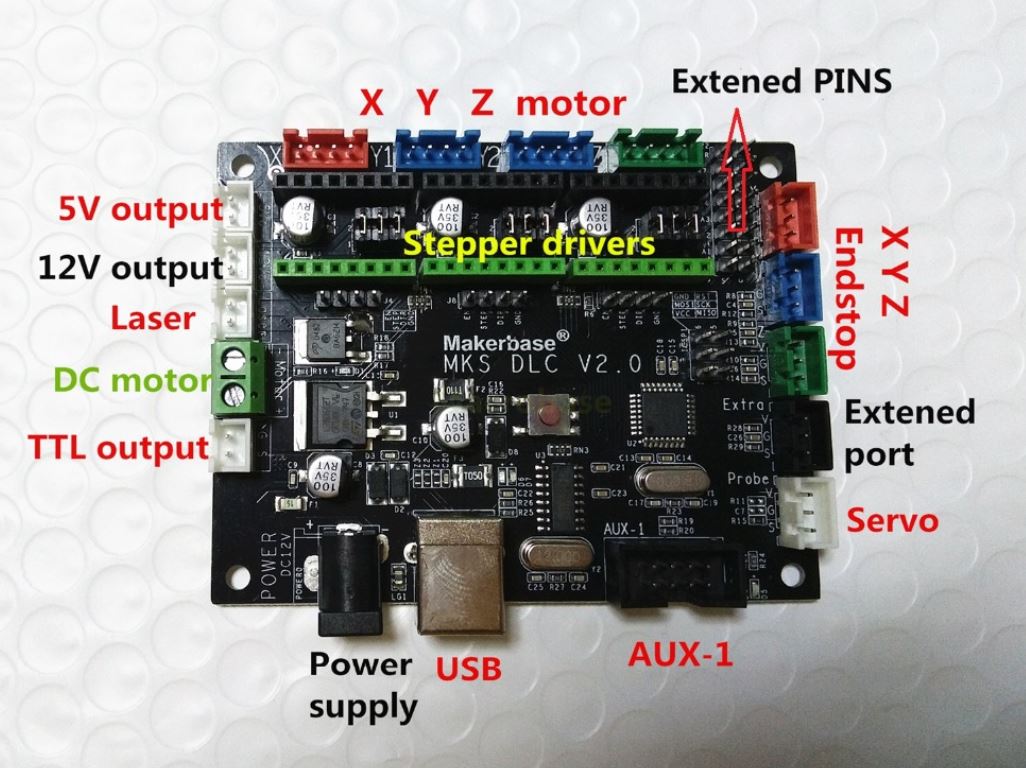

Step one is to order an MKS DLC V2.0 control board plus 8825 stepper drivers and stepper motor wires.

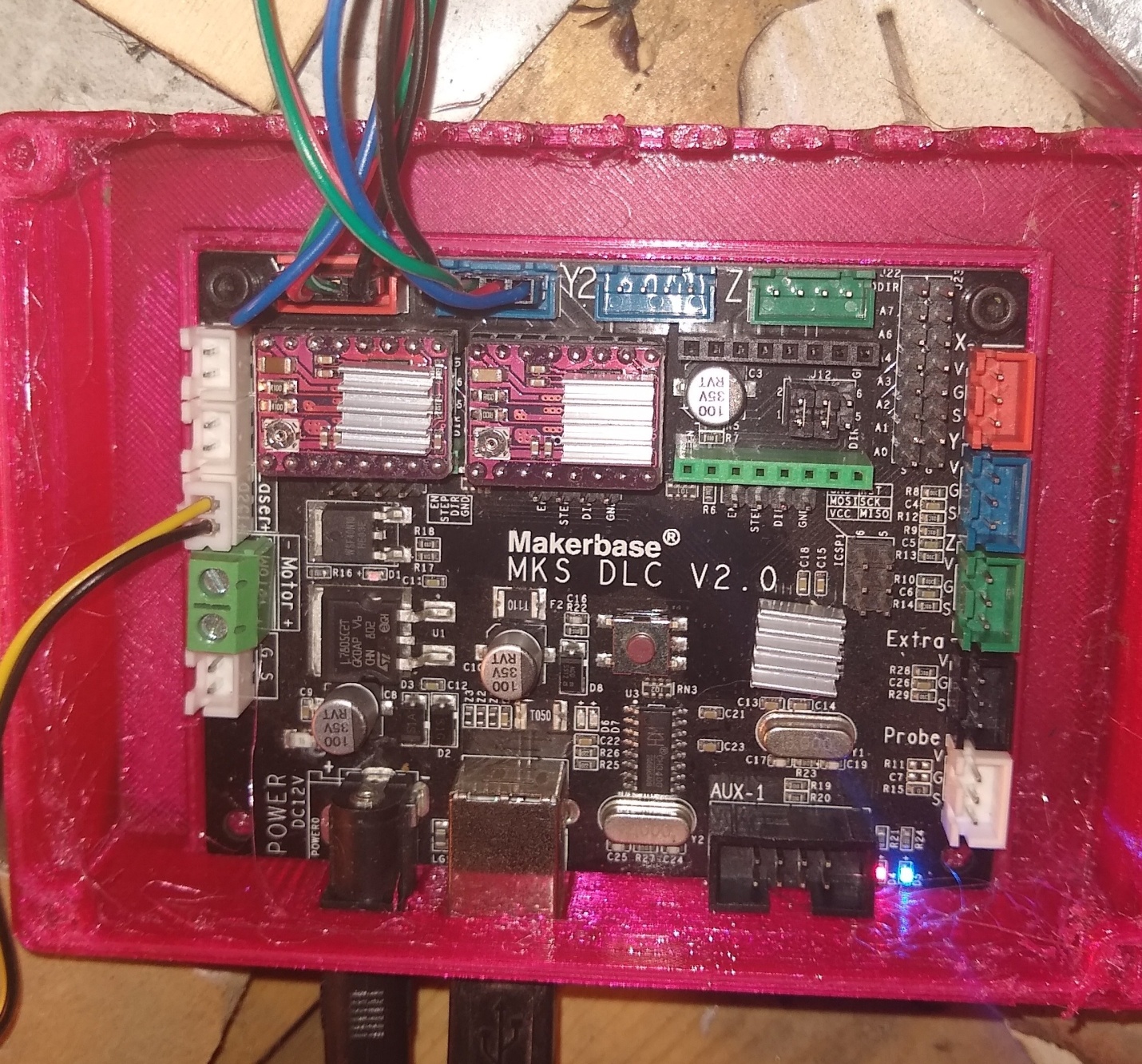

A case for the board you can purchase or 3d print.

https://www.thingiverse.com/thing:4649741 stl printable box.

Tools needed: “small nettle nose pliers or strong finger nails”, “a tiny flat screw driver” and “a voltmeter”.

Your power supply is just fine that you have for the NEJE.

Now since you have your new control board in hand let me guide you thru the process of preparing this for a successful installation.

On the board there are three sockets for X Y Y Z stepper drivers. Before you plug in the drivers you need to remove some of the jumpers that are nested under the three stepper drivers. With the board placed with power plug-in and USB facing you from right to left on X and Y Y stepper motor jumpers.

Remove the left jumper and center jumper on each of the two. On the Z stepper motor just remove the one jumper on the right side.

Next step is to plug in the two stepper motor drivers correctly. If using 8825 drivers the chip on the top of the stepper driver is facing the Z stepper slot on both. You only need to install the X and Y stepper drivers.

Next, apply the cooling fans on the stepper motors drivers in the control board.

Next is applying power to the board, checking and adjusting the voltages on the stepper motors.

With our voltmeter ground to the USB metal case and positive reading on the tiny little adjusting pod on top of each stepper motor driver, I read that voltage x 2 = current applied on stepper motors.

I have checked the heat on my stepper motors with a thermal camera. Even on a hot day they seemed only warm to the touch + 120 f. The original setting on the stepper motor drivers was 1.66 volts the heat generated on the stepper motors was 212 f Ouch!. I slowly work it down in voltages and on each change the thermals came down. I ended up with .75 volt and at warm motors at 110 f.

Now with stepper drivers voltage in a safe place at .75 volts dc you’re ready to hook up the stepper motor wires but you may need to cross the two center wires to make the system run correctly with NEJE stepper motors and your rotator device’s a stepper motor.

I cut the two center wire and cross-connected them using solder and electrical tape to insulate them from each other, a heat shrink tube would be nice also.

Now your wires are ready to be plugged into the MKS Control Board and the NEJE stepper motors.

On the control board there is a two pin output to the laser.

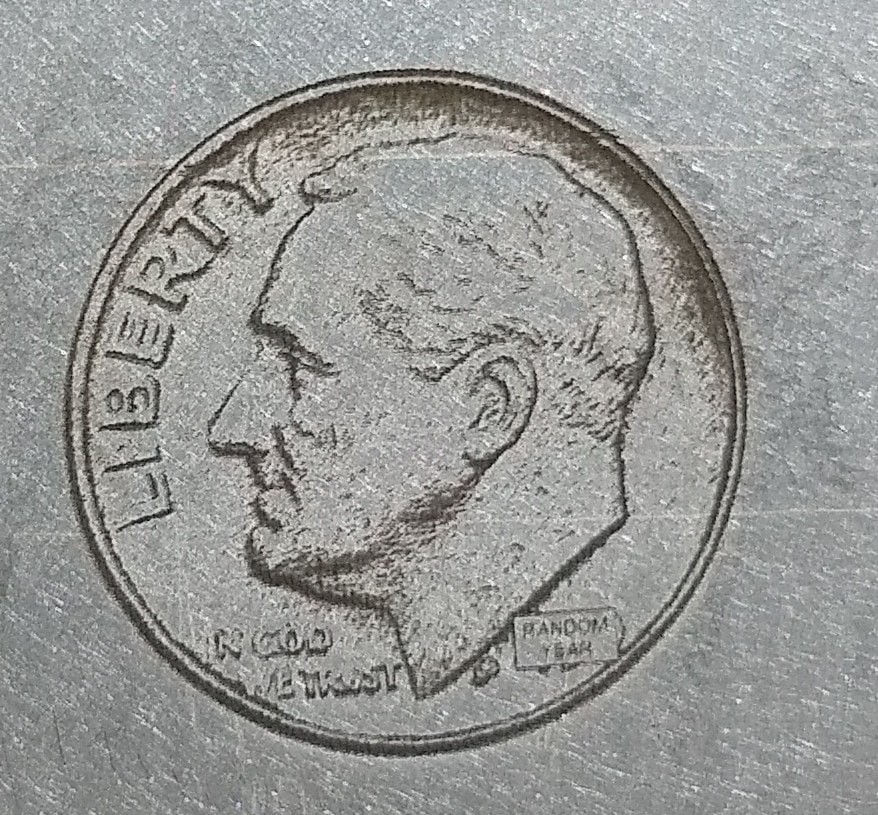

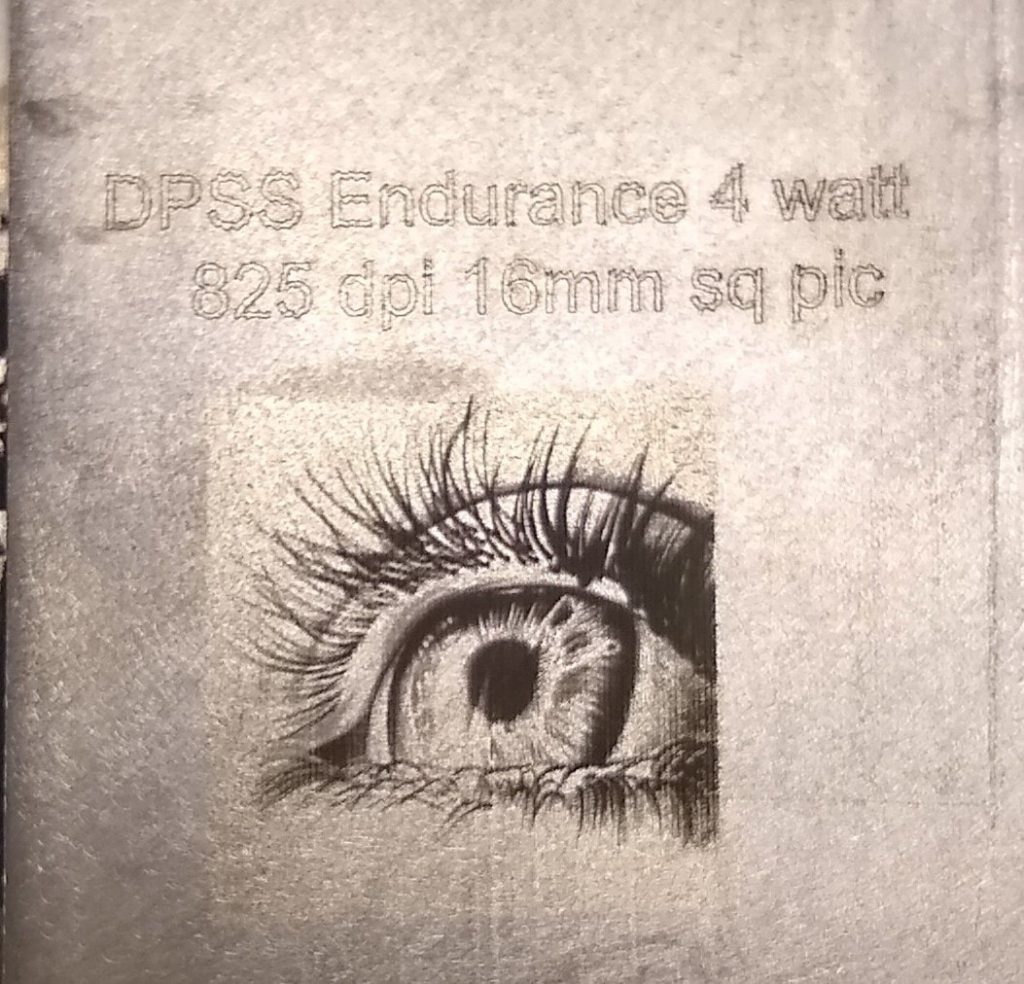

NEJE modified to do metals. I run the frame with a mks dlc v2.0 board . The Laser is a DPSS 4 Watt Endurance laser module. 725 dpi 3 Pass. It looked good on 2 pass I just want to go deeper.

Happy Laser Engraving with NEJE hardware powered via MKS DLC V2.0 .

Check http://www.laserwurks.com/

An important things you need to know about GRBL parameters, firmware settings

Endurance lasers: all about cutting and engraving abilities of diode, DPSS, fiber, Co2 lasers.