ABS 3D printing is one of the most popular types of 3D printing. It is strong, durable, and can be used to create a wide variety of objects. In this guide, we will discuss the uses of ABS material, basics of ABS 3D printing, including how to print with this filament and what settings to use. We will also talk about some of the best abs printers on the market. So whether you are a beginner or an experienced printer, this guide has something for everyone!

| PROS | CONS |

| It is a low-cost filament | Heavy warping |

| It prints well with less stringing and gives a smooth finish | Needs heated bed, heated chamber, and draft-free. |

| It is wear-resistant and impact-resistant is also good. | Produces a pungent odor while printing needs ventilation |

| It holds up under sunshine very well and is heat tolerant. | ABS Parts tend to shrink leading to dimensional inaccuracy |

Hardware requirements for ABS

- Heated Bed to temperatures of 95-110 c

- Build Surface Kapton Tape or ABS Slurry

- Extruder Temperature: 220-250 c

- Cooling part cooling fan not required.

Uses of ABS Material

ABS printing filament is a type of thermoplastic that is used in Fused Deposition Modeling (FDM) 3D printers. It is made up of acrylonitrile, butadiene, and styrene monomers, which are then polymerized to create ABS plastic. This material has a high resistance to impact and can be used for a variety of applications.

Here are 9 uses for ABS printing filament:

- Prototyping: ABS is often used for prototyping because it is strong and durable. It can be used to create models that will be subjected to stress or impact, such as car parts or medical devices.

- Manufacturing: ABS is also commonly used for manufacturing products that need to be strong and durable. It can be used to make products such as phone cases, eyeglasses, and children’s toys.

- Robotics: ABS is a popular material for robotics projects because it can withstand high temperatures and has a low coefficient of friction. This makes it ideal for creating robots that operate in difficult environments.

- Art: ABS is often used by artists for sculpting and modeling because it can be easily molded and has a high degree of detail.

- Food Applications: ABS is FDA approved for use in food contact applications. This makes it a popular choice for creating food containers, trays, and other kitchenware.

- Protected Packaging: ABS can be used to create packaging that is both strong and lightweight. It is also resistant to moisture, which makes it ideal for protecting sensitive items during transport.

- Lab Equipment: ABS is often used in laboratory equipment because it is non-toxic and heat resistant. It can be used to make products such as incubators, hot plates, and reaction vessels.

- Aerospace: It is frequently used in the aerospace industry because it has excellent mechanical properties and does not corrode in the presence of oxygen. This makes it ideal for use in aircraft parts and fuselages.

- Automotive: It is often used in automotive applications because it can withstand high temperatures and has a low coefficient of friction. It is commonly used to make car parts, such as dashboards and door panels.

There are many uses for ABS printing filament, making it a popular choice for both prototyping and manufacturing projects. It is strong, durable, and resistant to impact, making it perfect for a variety of applications.

3d Printed Projects Done with ABS

Here are five examples of 3D printing projects that have been printed using ABS:

A custom phone case with a built-in stand

This is one of the interesting projects that was done using ABS filament. It’s an open source project and it’s freely available on Thingiverse. With just a few twicks, you can be able to customize it based on your phone’s requirements. You can use 3D modeling software like SelfCAD to customize it and change other details like color and then use its in-built slicer to slice it and generate the G-code which is a file format understood by a 3D printer.

Check out more details about this project in Thingiverse.

A prosthetic hand designed for children

This is a useful project that was 3D printed using ABS material. It has a unique look and it was created for children who have no fingers to give them a comfortable grip strength. You can check out more details about the project in Thingiverse.

An air Freshener

This air freshener is useful in filtering the air around you and it makes your place smell good. It can be placed in the door and sealed with painters tape in order to avoid leakage.

You can check out more details about this interesting project on Myminifactory.

USB SD and MicroSD Holder

Are you tired of losing your USB, SD, or MicroSD cards? If so, you can 3d print this holder easily and use it to store your cards. This project can hold upto 8 wide USB sticks, 15 MicroSD cards, and 8 SD cards. It has holes to prevent the accumulation of dust. More than 467 people have downloaded the files and 3d printed this item and it has more than 34,000 likes.

You can download the files on Thingiverse.

Each of these projects turned out great and utilized the strengths of the ABS material perfectly! The Projects all had different goals, but each one was able to be completed successfully with the help of ABS. With its resistance to heat and durability, this material is perfect for a wide variety of applications!

Best 3d printers for ABS

There are a lot of 3D printers for ABS that are available. Here are some of the best printers for printing with ABS filament:

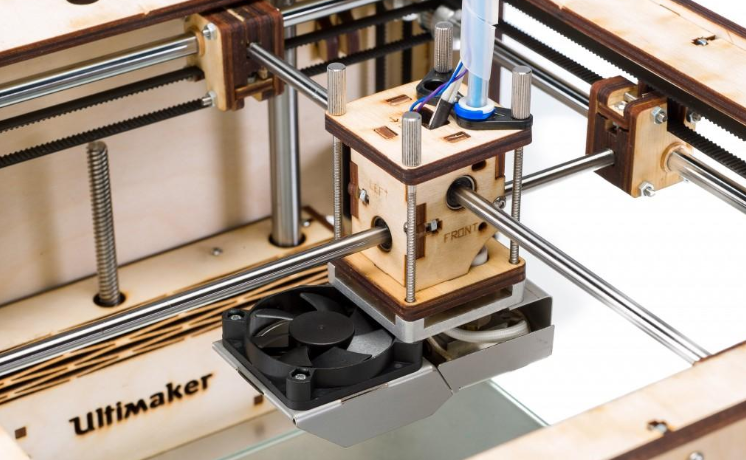

The Ultimaker Original

This is a great option for those looking for an affordable printer that can handle ABS filament. The printer has a heated build plate and fan cooling, ensuring that your prints come out correctly every time.

MakerBot Replicator+

MakerBot Replicator+ Image source:3Dbeginners

If you’re looking for a high-end option, this is definitely worth considering. This printer has a large build volume, as well as dual extruders and a heated build plate, making it perfect for printing with ABS filament. It also has Wi-Fi connectivity and an onboard camera, so you can keep an eye on your prints from anywhere.

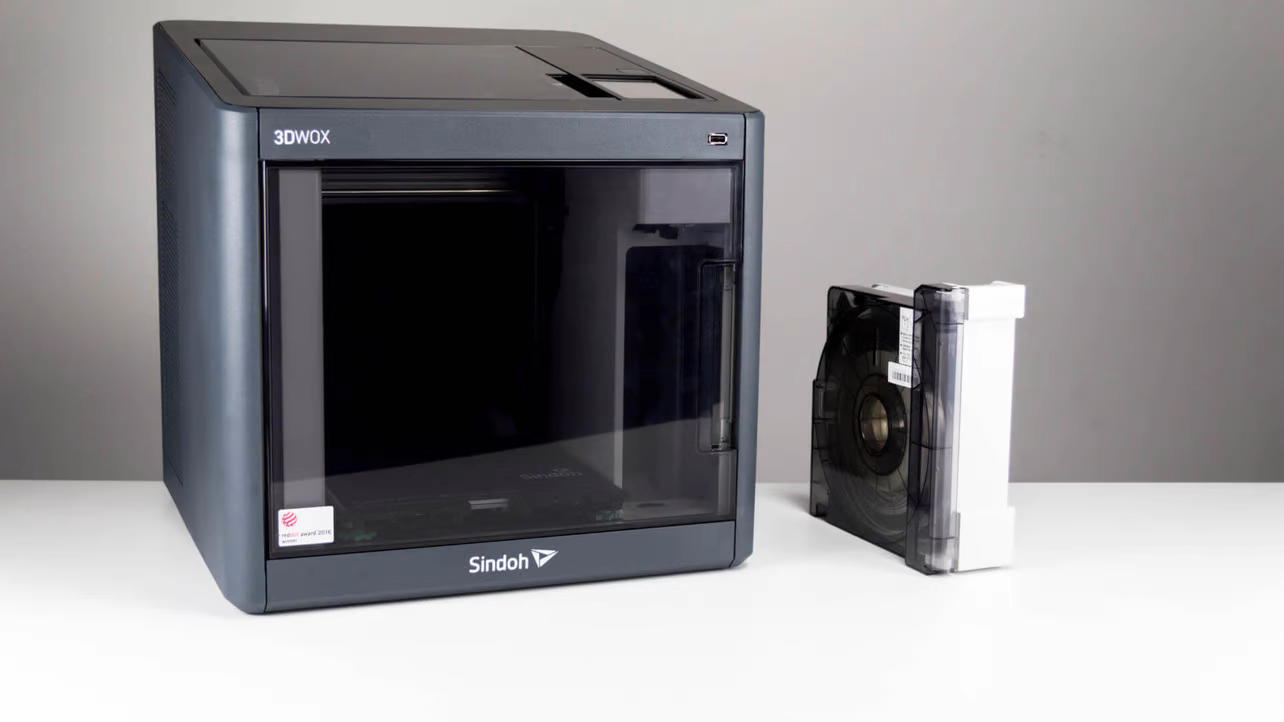

Sindoh DP200

Sindoh DP200 3D printer. Image source:All3dp

If you’re looking for a printer that’s designed specifically for ABS filament, the Sindoh DP200 is a great option. It has a heated build plate and dual extruders, ensuring perfect prints every time. Plus, it comes with an easy-to-use touchscreen interface, making it easy to navigate even if you’re not familiar with printers.

These are just a few of the best printers for printing with ABS filament. Be sure to do your own research to find the perfect printer for your needs.

PLA vs. ABS: What’s the Difference?

PLA and ABS are two of the most common types of filament used in Fused Deposition Modeling (FDM) printers. They are both thermoplastics, meaning that they melt and can be molded when heated, and they come in a variety of colors. However, there are some key differences between PLA and ABS that you should know before choosing which to use for your prints.

- Strength and Durability: The biggest difference between PLA and ABS is their strength and durability. PLA is generally weaker than ABS and is more prone to breaking or cracking under stress. ABS is stronger and more durable, making it a better choice for prints that will be handled or used outdoors.

- Biodegradability: PLA is biodegradable, while ABS is not. This means that PLA will decompose over time, while ABS will not though it’s recycable. If you are looking for a filament that is environmentally friendly, PLA is the better choice. And if you are looking for a filament that is recyclable then ABS is the best option.

- Printing temperature: Another difference between PLA and ABS is their printing temperature. PLA has a lower printing temperature than ABS, so it is a good choice for printers with limited heat capacity. ABS requires a higher printing temperature, so it is better suited for printers with more powerful heating systems.

Overall, PLA and ABS have some similarities but also key differences. When choosing which to use for your prints, be sure to consider the intended purpose of the print and the capabilities of your printer.

5 Tips for 3D Printing With ABS Material

When 3D printing with ABS filament, there are some key points you need to put into consideration. These includes:

- The first layer is very important when printing with ABS material. It should be well-adhered to the build platform in order to avoid warping.

- The heated build platform should always be on when printing with ABS, as it helps to prevent warping and also results in a higher quality print.

- Keep the filament dry, as wet ABS can cause problems during the printing process.

- Use a brim or raft on your prints to help them stick better to the bed and reduce warping.

- If you’re having trouble getting your prints to stick, try using a glue stick or hairspray on the bed surface.

- Try increasing your printer’s fan speed if you’re experiencing problems with curling or warping.

- If you’re printing small parts, use a fan to help cool the ABS as it prints. This will help reduce curling and warping.

- Don’t print with ABS in high humidity environments, as it can cause the material to warp and become brittle.

- Make sure your filament is free of moisture before you start printing. Abs prints can be ruined by even a small amount of moisture in the filament.

- Experiment with different print speeds and temperatures to find what works best for you. Each printer is unique, so you may have to adjust these settings to get the best results.

- Always use caution when using a knife or scissors near a heated print bed. ABS is soft and can be easily cut, so take care not to damage your print.

- Make sure your printer is calibrated correctly

- Clean your printer’s nozzle regularly.

- Finally, be patient! Printing with ABS can be tricky, but with a little practice, you’ll be able to create beautiful prints with this versatile material.

Do you have any tips of your own to share? Leave them in the comments below! We’d love to hear from you.

Questions and problem solving

Bed adhesion

My Best setup includes using Brims and Rafts.

Highly Favoring rafts and supports where needed.

ABS Slurry is made by dissolving small amounts ABS in Jar with acetone then it is brushed on the printer’s heated bed with a thin coating. One exception is AnyCubic Predators heated bed need no slurry or tape applied just keep it clean with acetone or rubbing alcohol. Its glass bed is micro-grooved whereas all filaments stick to it and most all release while cooling.

Print in a well-ventilated Area

Printing with ABS is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Avoid confined spaces and place your printer in a well-ventilated area to avoid these issues. Noted over the years some of the odor has been removed from ABS filaments but is still highly recommended to print in a well-ventilated area.

Venting the room by keeping a window open near your printer helps.

A small fan point out the window helps more if you don’t have an adequate ventilation system installed. I use also a networked video camera and close the room off to the rest of my house.

With the window open and an air condition home, I have turned off the AC vent. And because the window opens to bring in some breezes that large ABS prints to cool in unwanted ways. I encapsulated my Micro Make 3d delta printer with flexible corrugated plastic sheets and made a tiny window to check on the printing. I printed several attachments to slide the sheets into on the printer. Noted latest versions of Cura software has a new option for making a draft shield around your ABS print job.

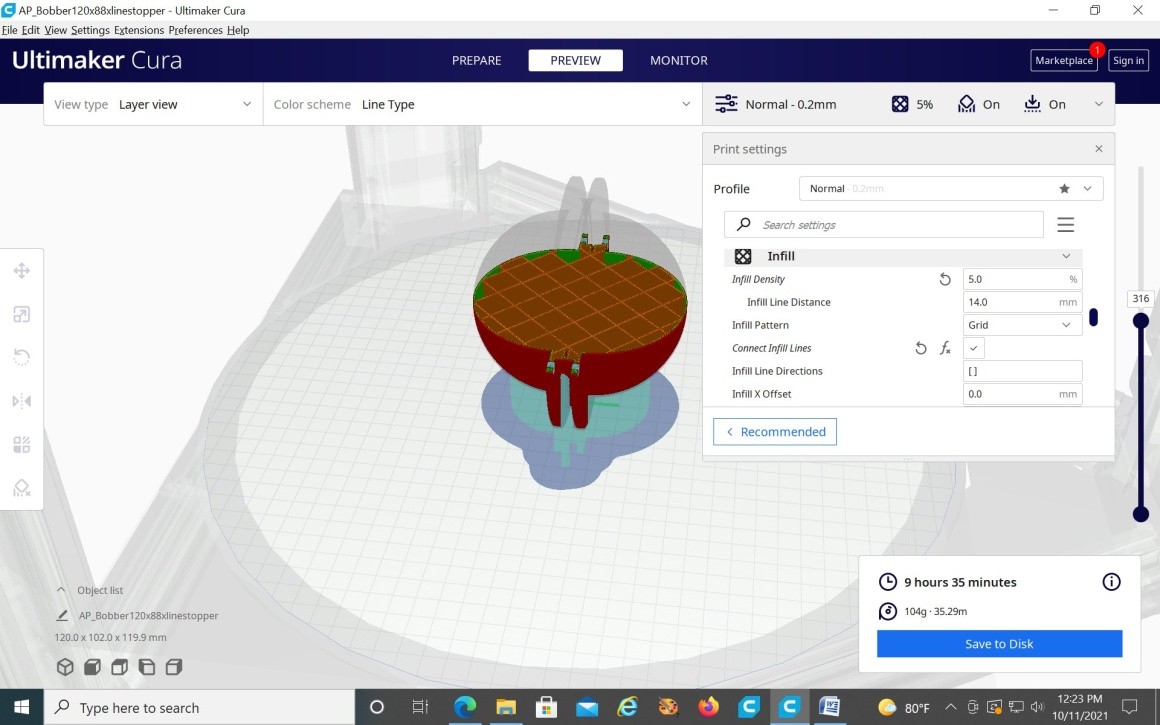

This bobber I designed is 140mm round ABS printed very well with supports and with incased 3d printer .04mm nozzles size. No fan cooling was used.

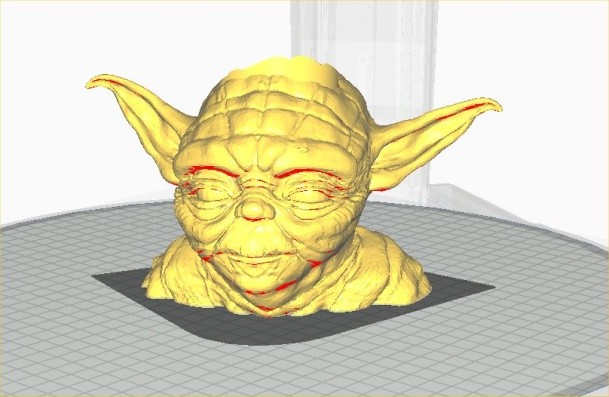

Yoda printed very nicely with ABS toys were downloaded from

Thingiverse – Digital Designs for Physical Objects

These made great gifts for friends with children into Star War’s movies

I have stored over 2600 files backed up on my network drives from the beginning of my printing.

I have used all Cura software from the start.

This picture is showing infill and raft and supports aiding in the printing were needed.

As you might notice in the picture how infill supports the curved area of the object to be printed as well as supports aid in outside areas were needed. Note supports the space between the support and what is supported is adjustable in the Cura software.

Please Note that in Cura and quite possibly any good version of 3d printing software there should be basic settings for ABS Filaments and some by brand name. Also on the spools, they come in you will find bed heat and filament temps you can use with the product.

Once you are put your object in software and configure it for your printer in Cura you can select the type filament and on the right upper you can dropdown box and select expert for adding in settings and fine-tuning for best results in 3d prints. Also if you change nozzle sizes there is a place for you to add into the program that information and it will adapt default settings for its use. Such as speed setting the larger the nozzle the faster you can print but you will degrade the finish and quality of your printed objects. Most standard 3d nozzles are of .04 mm and it give really great results. I have switched to a .05mm nozzle because I was printing with fiber and wood inside of filaments. This small increase of nozzle size still giving great accurate prints with a bit smoother finishes.

Finish enhancement with ABS by using Acetone Fumes for a short period of time. This will cause the ABS skin to flow and smooth out in a very short time. You need a container big enough to suspend your object in the air with a little acetone on the bottom it will evaporate and the fumes will cause the skin of the object to be liquefied and flow over the layer and smooth them out.

This happens rather fast so don’t forget your item or you will ending up with ABS paint for later uses.

Happy 3d Printing it’s a fun exciting hobby to have.

My Name is Bruce Benson and sharing in this article my ABS experience with two Delta style 3d printers. I have been 3d printing for over six years now and design and print using ABS were needed is wonderful.