CDs&DVDs as raw material for CNC

How to use and what to do with your old CD and DVD discs

By the year 1995, while trying to maintain sales, against the internet, Greek newspapers and magazines started giving away presents along with each issue. The most frequent gifts were movies or music on DVD or CD, respectively. Many people used to purchase every issue just for the gift instead of the content!…

Most of the discs in my warehouse come from those years!…

I will try to describe how those old CDs and also their packaging can be used as raw material for various handicrafts, with the help of CNC Router and Laser.

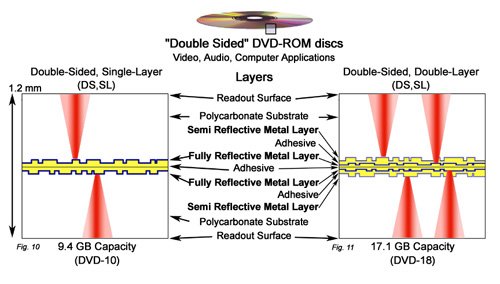

CD / DVD anatomy

The material of the disks

CDs and DVDs are made of polycarbonate/Lexan and a thin aluminum foil. Depending on the type of the disk the aluminum foil appears in different color tints.

Wanting to cut them, it is better to use a CNC Router. Polycarbonate can be cut with a CO2 laser but the cut is not clean, it discolors and catches fire easily. The window of the laser cutter is made of polycarbonate because polycarbonate strongly absorbs infrared radiation.

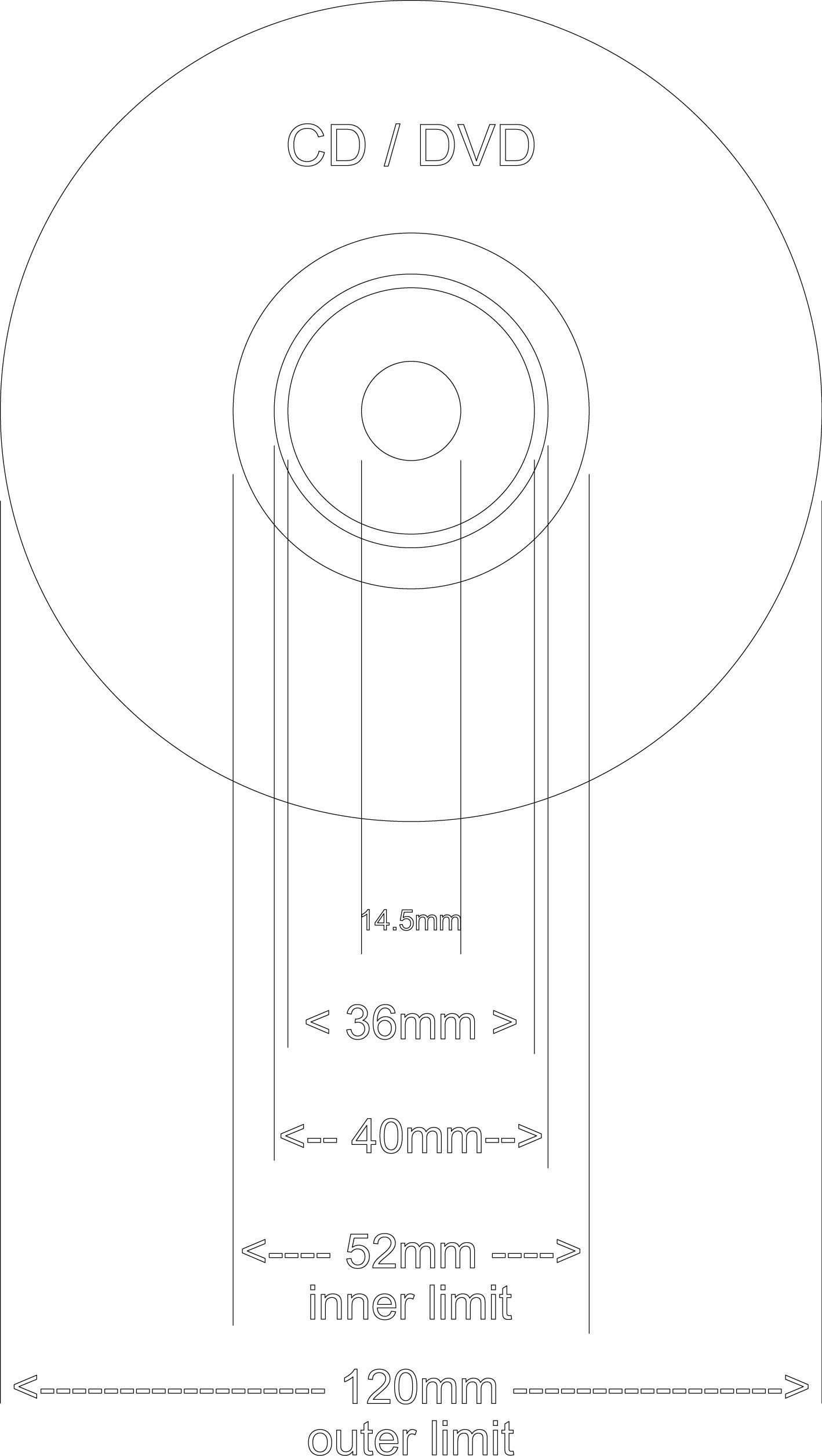

Dimensions of the disk

Between the outer (120mm) and the inner (52mm) limits is the material we can use. In every CD and DVD exists a shallow “lip” (36mm to 40mm from the center) at the bottom of the disk. 14,5mm is the diameter of the hole at the center of the disk. The thickness of the disk is 1,2mm . These data are very useful in order to make a jig for the wasteboard of our CNC.

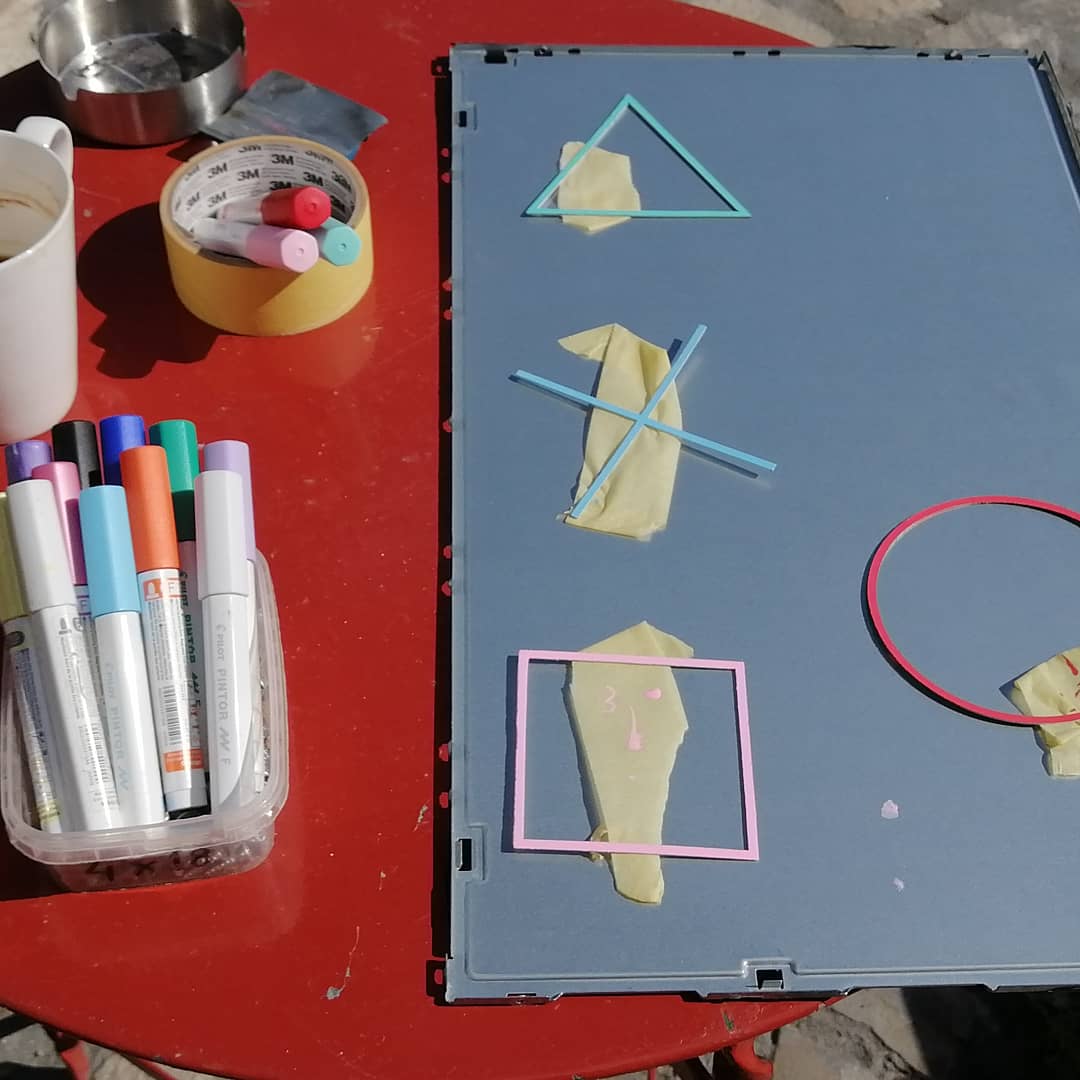

CD / DVD case anatomy

Material of the case

CD and DVD cases are made from polypropylene or polystyrene. The cut of this type of material can be performed both with a CO2 laser and a diode laser to produce a clean non-discolored cut with a slightly raised edge near the point of ablation. Laser engraving and laser marking of polypropylene are possible using a CO2 or diode laser.

PolyPropylene catches fire Like PolyStyrene, it melts, and the melted drops continue to burn and turn into rock-hard drips and pebbles.

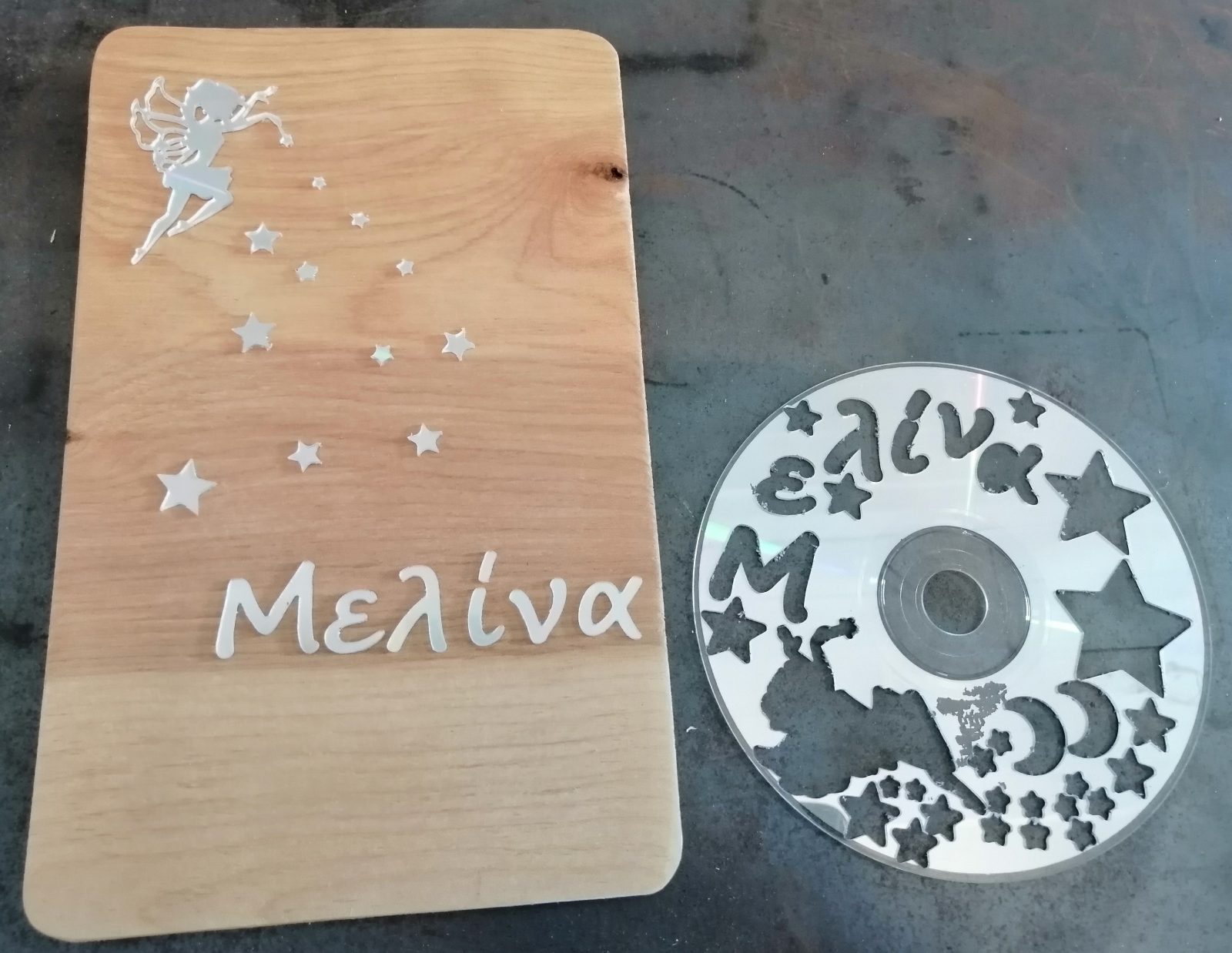

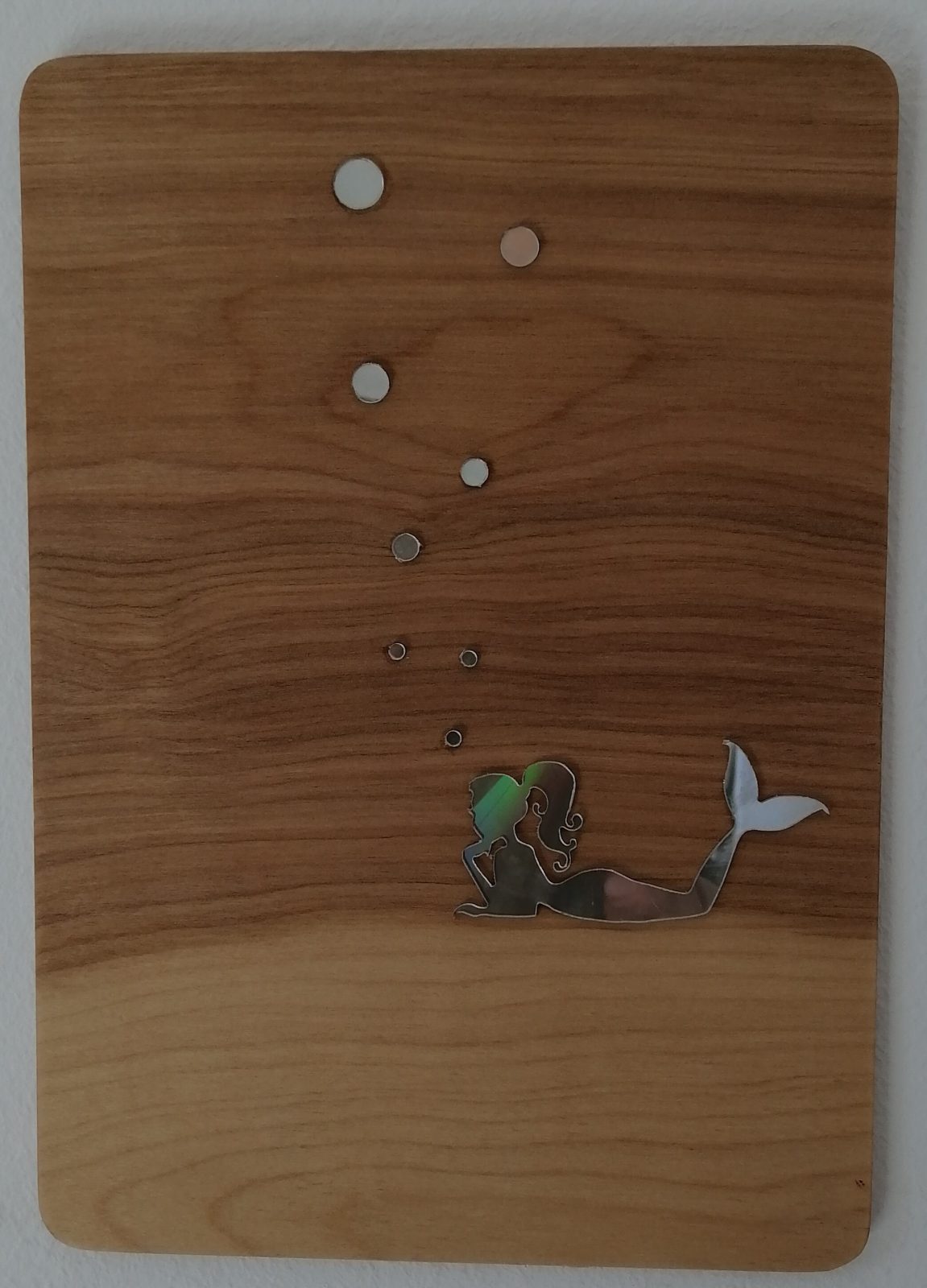

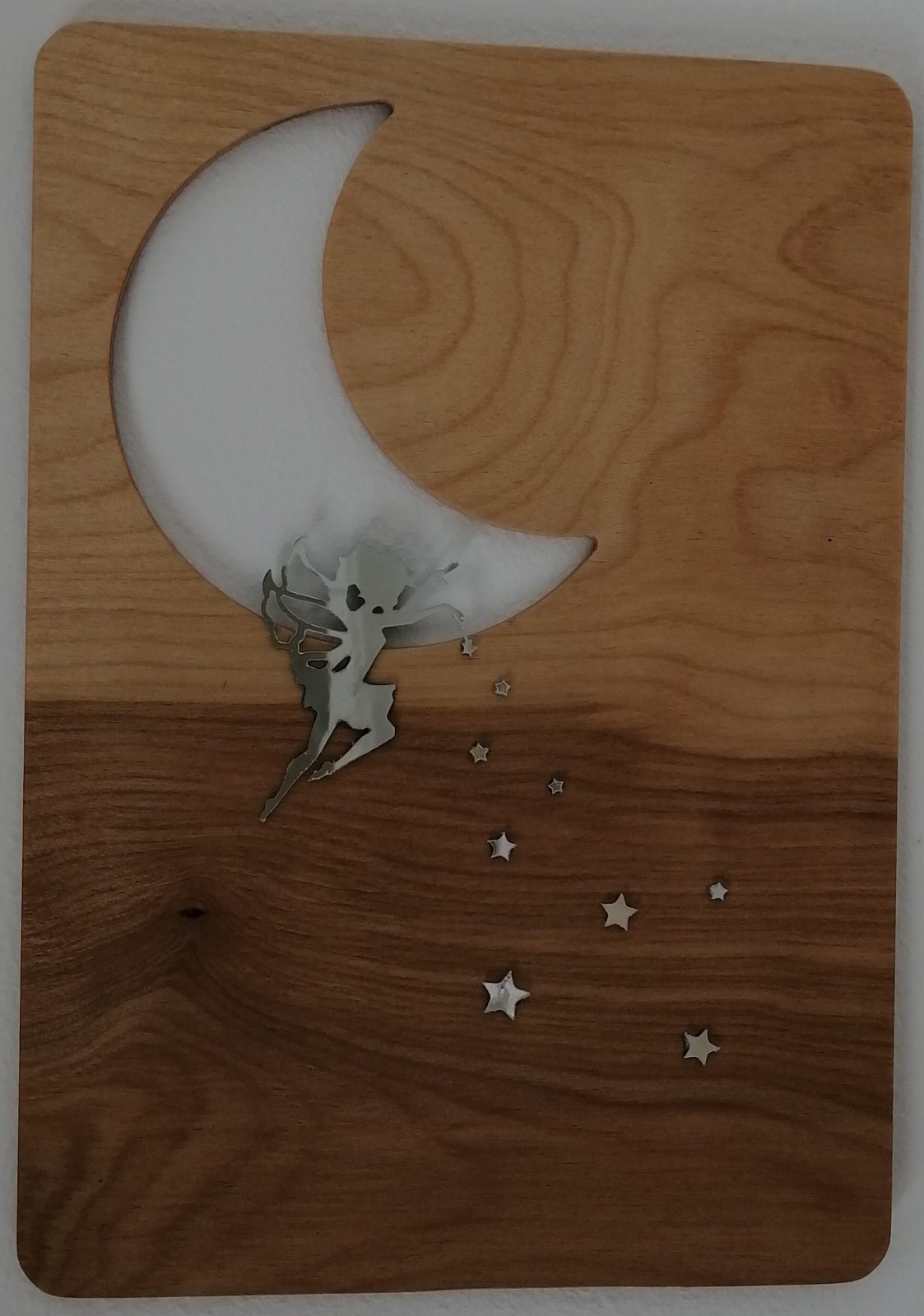

At the following photos we can see an idea of using the material of a DVD case in order to make inlays for a project.

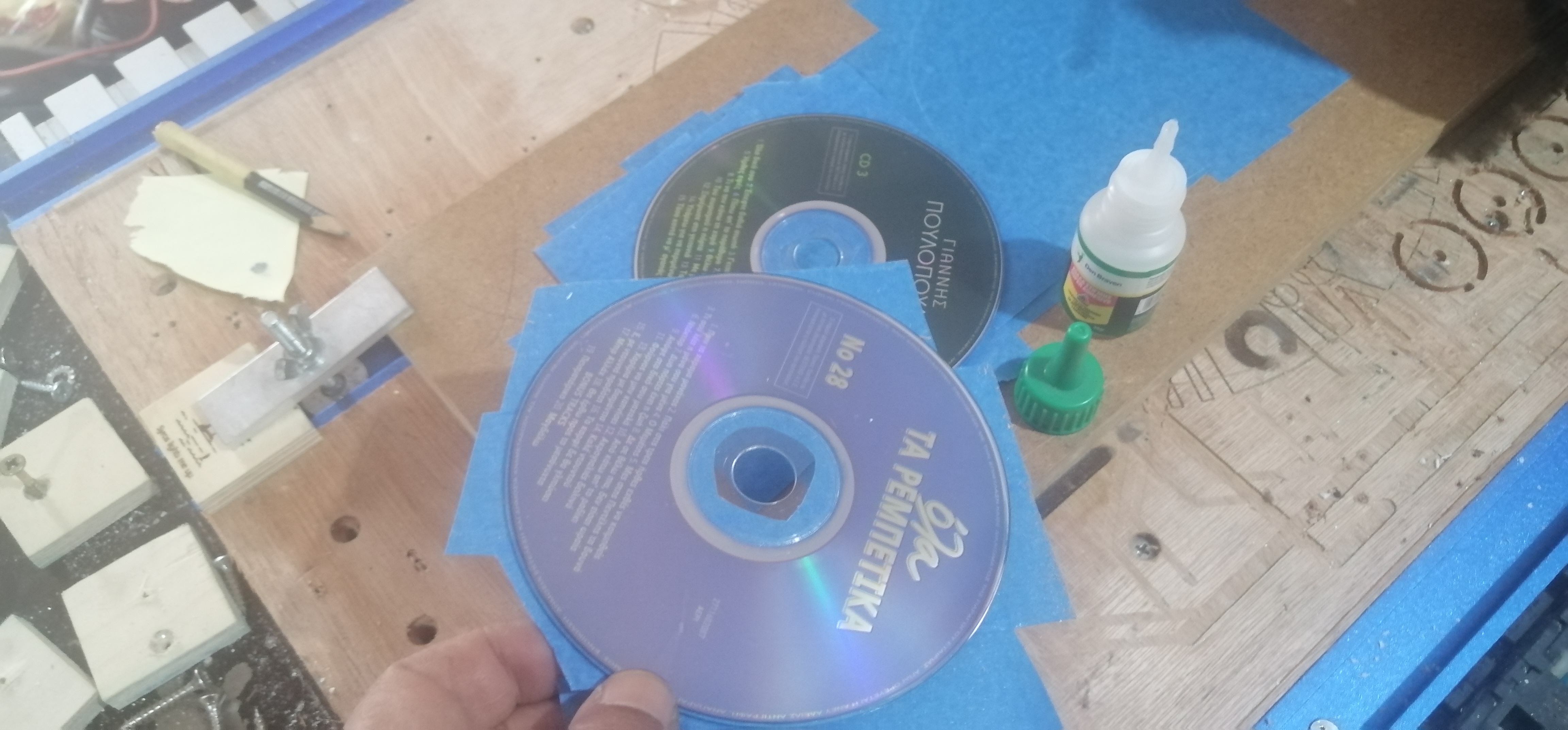

Preparing to cut the disks

As we have said before the best result for the cut, we will have it with the router.

Due to the CD shape, it will be very helpful to make a jig having in mind the dimensions provided before.

The bit that we used is a cheap 3,175x1x3 single flute. The pocket hole, where the small “lip” at the bottom of the material, will be nested has 2mm depth.

We used for the jig MDF stained with spray varnish. Due to the fact that we will use the method of tape and CA glue for securing the CD on the jig, we want a material with a surface on which the tape can stick well.

As we can see in the picture above, removing the tape from the center hole (14,5mm) will help to align the disk to the jig

For the cut, we used the following settings

bit : 3,175x1x3 single flute

spindle speed: 12500 RPM

feed rate: 1600 mm/min (or faster, if your machine can handle it…)

pass depth : 0,5mm

Due to the printed side of the disk, it is better to place it with the aluminum foil facing down.

The result after the cut:

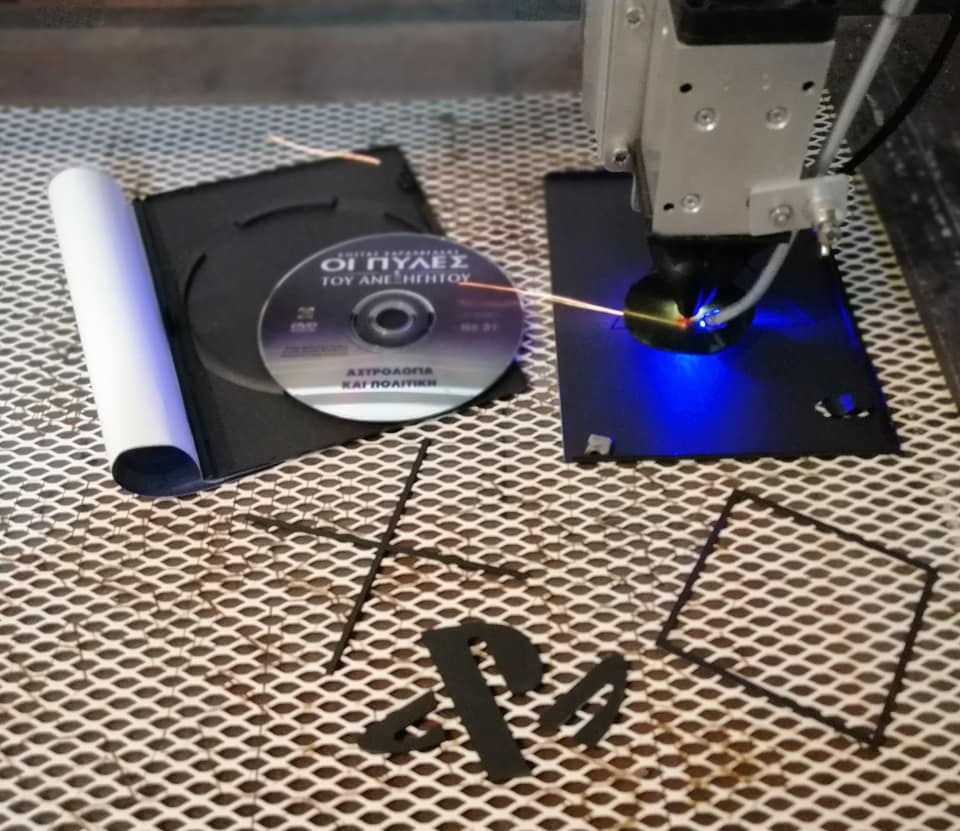

Having cut the disks, we can place the material to the CNC Laser in order to make an egraving.

Using an Endurance 10W “invincible” , the setting we used were :

Fill, Cross Hatch 45 degrees, 0.0mm stepover

power: 10%

feed rate: 1000 mm/min

A diode laser cannot engrave the transparent material. We will engrave the disk from the printed side. The laser will remove the color and the thin aluminum foil.

We could say that the process is similar with the engraving method on painted transparent acrylic.

https://endurancelasers.com/engraving-transparent-acrylic-with-a-diode-laser-applying-color/

The engravings can also be painted from the back, at the following picture we used green permanent marker

at the following pictures you can see some more CD cutting ideas

Thanks for your time!

Michail Gedeon

Another example of DVD disk laser cutting and laser engraving by Bruce Benson

THE 1.2MM LASER CUTTING CHALLENGE

The day before I was looking for a new exciting medium to engrave images on. I came up with my huge collection of DVDs and CDs that I used to use for storage of and backup of Movie DVDs and installing images of windows operating systems and others.

Since the advance of hard drives USB and easy uses of these for putting your favorite DVD movies on and no need to find the disk all these copy DVDs and music CD are just laying in my office. So Knowing that CD and DVD are engraved Via 405 nm lasers and reading is with light reflection from a red laser reader why not do some engraving on them. I did this and the results are fantastic. My next thought was what if I could get enough squares of the DVD or CD disk and put them all in a frame and engrave on it. How would that be fantastic? Next, I searched out cutting DVD and CD on the internet and saw some videos on methods of cutting these disks using typical scissors and sheet metal shears. They involved freezing the disk and heating the disk in boiling water. Not one was with a laser cutting machine.

As you can see these disks are made to engrave on and reflex the light all in one. Polycarbonate is a very hard material and will not withstand shock without fracturing. I have impacted a few with my pellet gun and the explode liken to a plate of thin glass hit by a rock. The metals used in the disk is very thin foil-like some silver some gold some aluminum depending on manufactures.

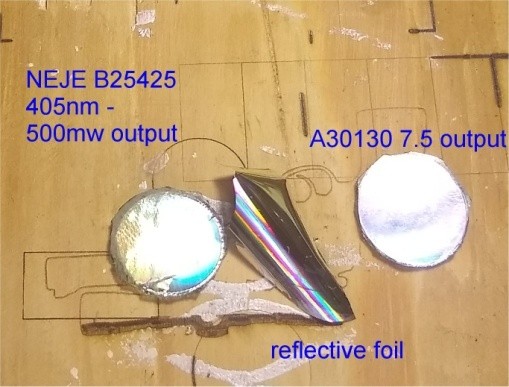

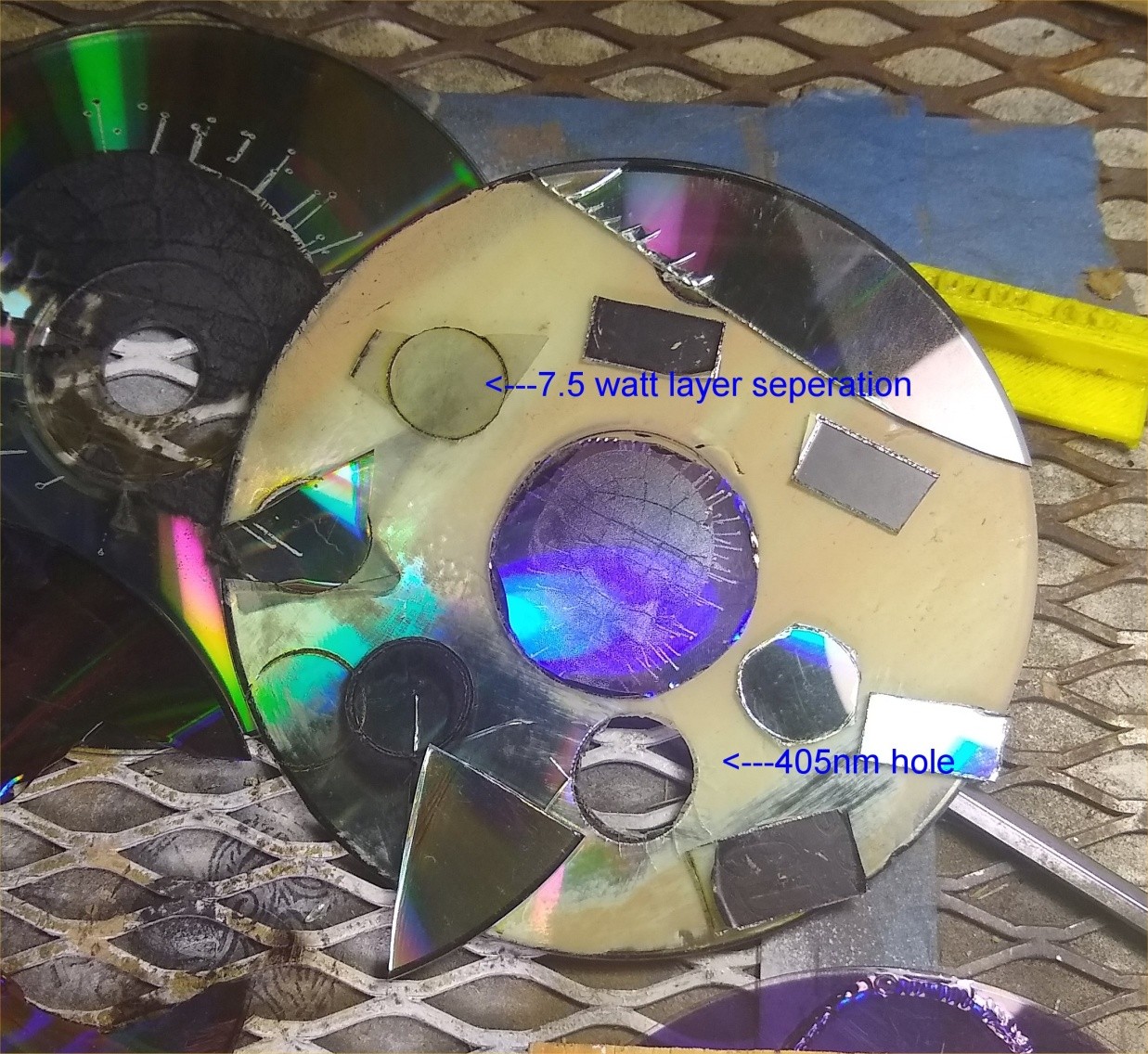

So that was my challenge of the day with my multiple collections of laser modules I chose to start with the and its 7.5 watt beam with a focal point of .1 mm. I did paint the backside with Chalkboard black paint I did this for all tests. This laser did manage to give breakaway parts of DVDs and cd but with much fracturing involved not so clean and no drop-out parts. I tried with a variety of settings and speeds as slow as 2m/s that created too much heat even at 10 & 20% power settings. Some attepts cause the layers of the DVD to separate completely leaving foils exposed.

Next after hours of working with the higher powered, it was time to switch laser modules to the finer focusing 405 nm Laser Module 500 mw .01 mm focus.

I ended up doing several passes and finding in lightburn speed setting of .4 to.6 mm sec power at 100% multiple passes did not overheat the disk. It cut fine line thru the foil layers but as with the other there were no drop-out parts but they broke out much cleaner because the fractures in the polycarbonate layers were finer than with the larger beam blue laser.

As for now, I can only wish that manufacture would make squares of DVD or CD-ROM material for our laser engravers wanting to display custom cutting edge all most 3d image viewing.