Once you have designed your model in a 3D modeling software and it’s time now to 3D print, you will need a 3D printing material to use in your 3D printer in order to print it. There are a lot of different 3D printing materials on the market these days. It can be tough to decide which one is right for your project. 3D printer filaments come in different types and your filament choice might depend on the object that you are trying to build. In this article, we provide a list of our top 13 filament picks and their key characgteristics! Follow along!

Best 3D Printing Filament of 2022

ABS

ABS is one of the best 3D printer filament that comes in the first position in the list of the 3D printer filaments of 2022. It is popular as it is strong and durable.

| PROS | CONS |

| Strong | Low flexibility |

| Durability | Toxic fumes are expelled and require a mandatory enclosure. |

| Heat resistance | Cannot withstand heat and will melt at high temperatures. |

| Clean finish | Non-biodegradable plastic |

| Impact resistance |

Technical details |

| Strength: Medium Flexibility: Low Durability: Medium |

| Print difficulty: Medium |

| Printing temperature: 180°C to 230°C |

| Print bed temperature: Not required |

| Shrinkage/warping: High |

| Soluble: Yes |

| Food safety: Yes |

Key Features

- Durability and Strength: Strong and durable material

- Biodegradability: Not biodegradable, however, it is recyclable.

- Resistance to heat: not as heat resistant as other materials and it can warp at high temperatures.

- Britability: It is not brittle, rather it is ductile.

- Melting point: 220 degrees C.

- Toxicity: non-toxic and environmentally friendly

- Where it is used:create objects that will be handled frequently or that need to withstand wear and tear. ABS is also non-toxic, making it a safe choice for home use.

- Downside: One downside of ABS is that it can warp when exposed to heat. This can cause problems in 3d printing, particularly when using a 3d printer with an open bed design. To solve this, you need to make sure your 3d printer has a heated build plate to help reduce warping. Another issue is the tendency to shrink as it cools. This can lead to dimensional accuracy issues, so take care when 3D printing with ABS and ensure that you cool it unformly.

AMPHORA

Amphora is a 3D printing filament made from renewable resources. It is produced using a patented process that converts plant-based materials into filament.

| PROS | CONS |

| Impact strength | Heat bed and nozzle temperature must be set precisely. |

| Flexible | High printing temperature |

| Heat resistance | |

| Impact resistance | |

| Produces smooth surface finish. |

| Technical details |

| Strength: Medium Flexibility: High Durability: Medium |

| Print difficulty: Low |

| Printing temperature: 240 to 270 °C |

| Print bed temperature: 70 °C |

| Shrinkage/warping: Medium |

| Soluble: No |

| Food safety: Yes |

Key Features of Amphora

- Durability and Strength: very strong and durable, and it has excellent toughness making it ideal for use in functional parts and end-use products.

- Biodegradability: biodegradable and has a low environmental impact.

- Resistance to heat: not as heat resistant as other materials and it can warp at high temperatures.

- Britability: filament is more brittle than other materials and can break more easily.

- Melting point: 300 degrees C.

- Toxicity: It is non-toxic and the parts 3d printed with this filament are food safe and comply with FDA regulations for contact with food products.

- Where it is used: Can be used in the medical field, especially in the 3D printing of prosthetic body parts and also it’s useful in the manufacturing of aircraft parts, car parts, and other consumer goods.

- Downside: more expensive than most of the other 3d printing filaments.

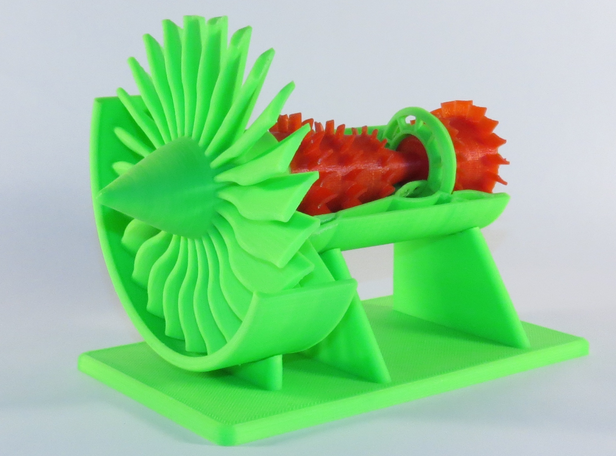

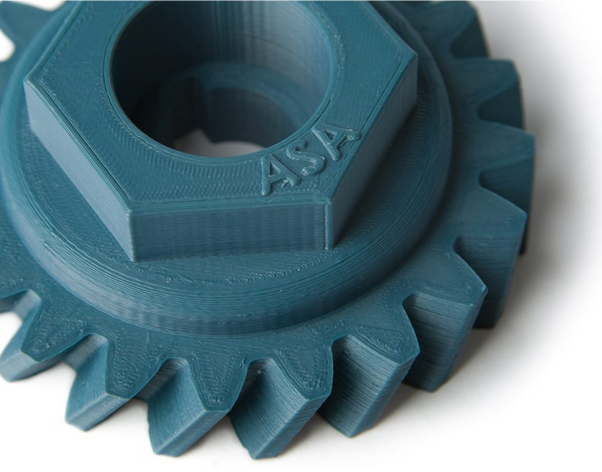

ASA

ASA 3D printing filament is a material that is quickly gaining in popularity. It is made from acrylonitrile styrene acrylate, and it has many benefits that make it an excellent choice for 3D printing.

| PROS | CONS |

| Temperature resistance | Poor layer adhesion can occur if there is no equipment set up like heated chamber with no cooling |

| Tough | |

| Absorbs ultraviolet light (UV resistant) | |

| Can be left outdoors | |

| Polish-able with acetone vapor | |

| Chemical resistance | |

| Flexibility |

| Technical details |

| Strength: Medium Flexibility: Low Durability: High |

| Print difficulty: Medium |

| Printing temperature: 235°C to 255°C |

| Print bed temperature: 90°C to 110°C |

| Shrinkage/warping: Medium |

| Soluble: Yes |

| Food safety: Not recommended |

Key Features:

- Durability and Strength:strong and durable. It also has high tensile strength and low elongation at break, meaning that it can hold up against stress and wear.

- Biodegradability: It is biodegradable.

- Resistance to heat: ASA has a high resistance to weathering.

- Britability: not as brittle as some other 3D printing materials, making it less likely to shatter or break when handled incorrectly.

- Melting point: It has a low melting point of between 250 to 260 degrees C.

- Toxicity: It is also non-toxic, making it a safe choice for home users as well as businesses.

- Where it is used: Applied where strength and resilience are important, outdoor applications, and it is also used in prototyping and in products that require a high level of aesthetics.

- Downside: Amphora is more expensive than most of the other 3d printing filaments.

BRASS PLA

BRASS PLA is a type of 3d printing material that consists of brass and PLA. BRASS PLA is available for purchase on the internet and in stores that sell filament for a printer. It is a great choice for people who want to create high-quality prints with beautiful gold colors.

| PROS | CONS |

| Feels dense | Not very good self support |

| Genuine look of brass | Abrasive to nozzle |

| Numerous finishing options | Cannot withstand or impact or stress |

| Technical details |

| Strength: High Flexibility: Low Durability: High |

| Print difficulty: High |

| Printing temperature: 195 to 220°C |

| Print bed temperature: Not required |

| Shrinkage/warping: Minimal |

| Soluble: No |

| Food safety: Not recommended |

Key Features:

- Durability and Strength: It is strong and durable.

- Biodegradability: It is bio-degradable.

- Resistance to heat: It has low heat resistance.

- Britability: It is brittle but rigid.

- Melting point: It has a low melting point of between 190 to 220 degrees C.

- Toxicity: Because it’s also made of PLA, Brass PLA is not toxic.

- Where it is used: BRASS PLA can be used to print 3D objects that require high strength, such as figurines, jewelry, ornaments, and outdoor applications.

- Downside: It has poor bridging characteristics. Because it has a high density, supporting bridges and overhangs may be a challenge hence it requires one to add more supporting structures.

BRONZE PLA

Bronze PLA is a great 3D printer filament to use for printing small parts and prototypes.

| PROS | CONS |

| Visually appealing | Rigid and brittle |

| Numerous finishing options | Can wear down nozzle |

| Does not have tendency to warp | Combined with abrasive particles |

| Nice heavy feeling |

| Technical details |

| Strength: High Flexibility: Low Durability: High |

| Print difficulty: High |

| Printing temperature: 195 to 220°C |

| Print bed temperature: Not required |

| Shrinkage/warping: Minimal |

| Soluble: No |

| Food safety: Not recommended |

Key Features:

- Durability and Strength: It’s strong and durable.

- Biodegradability: It has biodegradable

- Resistance to heat: It has low heat resistance, but it has a high resistance to corrosion and wears.

- Britability: It is very brittle.

- Melting point: It has a melting point of 160 degrees.

- Toxicity: It is not toxic as it contains PLA which is made from corn starch, yucca, and potato.

- Where it is used: It’s useful when printing beautiful prints for jewelry and figurines because of its nice metallic look. It can also be used in 3d printing drones and robots.

- Downside: Because they come with real bronze particles, they are more expensive than the general PLA. Also, because it is very brittle, it needs to be handled with care.

CARBON FIBER

Carbon fiber filament is a great material to work with and it comes in our list of the best 3D printer filaments.

| PROS | CONS |

| Dimensions have accuracy | Abrasive |

| Light weight | Wear and tear on the printer nozzle |

| Strong | Can require modification of a steel nozzle to avoid affecting machine |

| Prone to clogging |

| Technical details |

| Strength: High Flexibility: Low Durability: Medium |

| Print difficulty: Medium |

| Printing temperature: 195°C to 240°C |

| Print bed temperature: Not required |

| Shrinkage/warping: Minimal |

| Soluble: Yes |

| Food safety: Not recommended |

Key Features:

- Durability and Strength: Carbon fiber is incredibly strong and durable, making it perfect for high-stress applications.

- Biodegradability:

- Resistance to heat: It is resistant to heat and corrosion, making it ideal for use in harsh environments. It also has a very low thermal expansion coefficient, meaning that it does not expand or contract with changes in temperature.

- Britability:

- Melting point:

- Toxicity: The fumes it generates when 3D printing is very toxic and dangerous, hence care must be taken.

- Where it is used: It is useful in making parts for aircraft and aerospace, vehicles, drones, electrical appliances, as well as in making decorative items.

- Downside: When working with carbon fiber filament, you need to take some precautions to avoid injuries. Always wear gloves when handling the filament, and avoid breathing in the fumes it emits. Carbon fiber filament can also be dangerous if ingested, so always keep it away from children and pets.

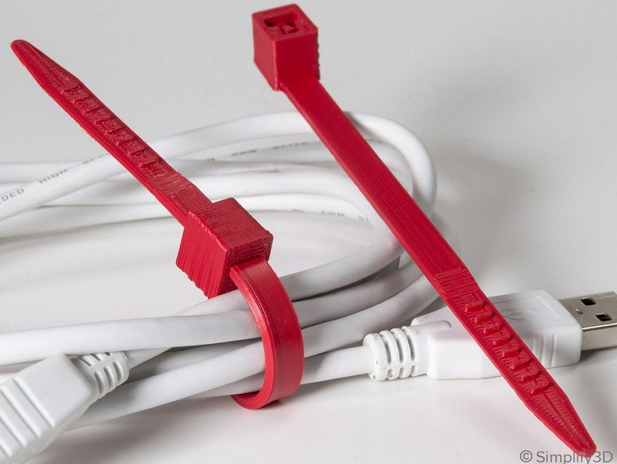

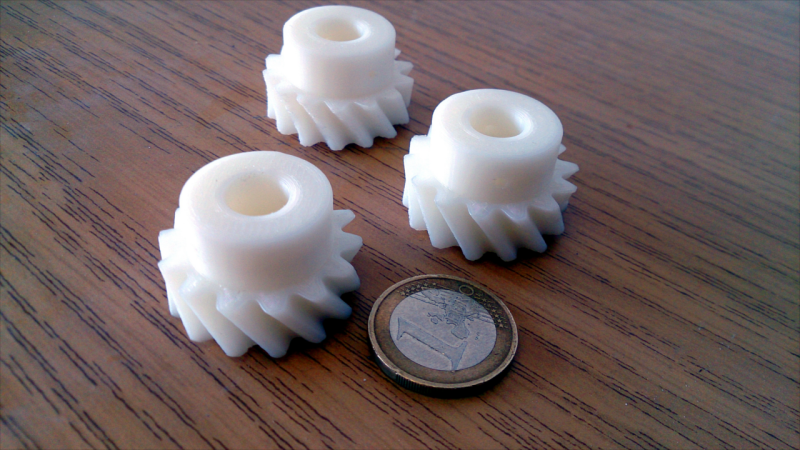

Nylon

This filament is a great choice for general-purpose printing. It has high tensile strength and is resistant to abrasion. Its key features are described below.

| PROS | CONS |

| Impact resistant, | Abrasive during extrusion, |

| Heating chamber not necessary | Wear and tear of nozzle, |

| Lightweight | Frequent clogging occurs |

| Does not warp like normal nylon | Requires additional hardware such as hardened nozzle, humidity controlled storage, heat dispenser |

| Flexible | |

| Rigidity & strength. |

| Technical details |

| Strength: High Flexibility:High Durability: High |

| Print difficulty: Medium |

| Printing temp: 225°C to 265 °C |

| Print bed temp: 70°C to 90 °C |

| Shrinkage/warping: Medium |

| Soluble: Yes |

| Food safety: Yes |

Key Features:

- Durability and Strength: It’s strong and durable.

- Biodegradability: It is non-biodegradable.

- Resistance to heat: It is heat resistant. Nylon is also resistant to oil and Alkali.

- Britability: It is not brittle and has no snapping effect. It can also bend without breaking.

- Melting point: It has a very low melting point of under 181 degrees C.

- Toxicity: It’s one of the most toxic 3D filaments, hence it’s advisable to use it with care.

- Where it is used: It is used in making decorative items, prototypes, and functional parts like gears.

- Downside: It is moisture sensitive and needs to be kept in a cool dry place. Nylon also comes with a shelf-life of only 12 months.

CONDUCTIVE PLA

Source: All3DP

WHAT IS CONDUCTIVE PLA?

A conductive filament that won’t replace a full circuit board, but they can be used to create a range of small items such as tiny LED, sensors and even touch sensitive items and more.

| Technical details |

| Strength: Medium Flexibility: Medium Durability: Low |

| Print difficulty: Low |

| Printing temp: 215 °C to 230°C |

| Print bed temp: 50°C to 60°C |

| Shrinkage/warping: Medium |

| Soluble: No |

| Food safety: Not recommended |

COPPER PLA

Source: 3DJake International

WHAT IS COPPER PLA?

A metal filled filament infused with PLA that can print beautifully. The characteristics of copper are mimicked very well. An incredible finish can be made with sanding and polishing to give a visually appealing and realistic texture.

| Technical details |

| Strength: High Flexibility: Low Durability: Low |

| Print difficulty: Low |

| Printing temp: 190°C to 220 °C |

| Print bed temp: 55°C to 60 °C |

| Shrinkage/warping: Low |

| Soluble: No |

| Food safety: Not recommended |

FLEXIBLE TPE

Source: allthat3d.com

WHAT IS FLEXIBLE TPE?

A flexible thermoplastic elastomer that is designed to stretch. This material is one of the most smooth, rubbery, and durable materials available. The bend-ability make it ideal for a variety of applications such as wearable items.

| Technical details |

| Strength: Medium Flexibility: High Durability: High |

| Print difficulty: High |

| Printing temp: 210°C to 260 °C |

| Print bed temp: 85°C to 110 °C |

| Shrinkage/warping: Medium |

| Soluble: Yes |

| Food safety: Yes |

GLOW IN THE DARK

Source: Pinshape 3D Printing Blog | Tutorials, Contests & Downloads

A luminous filament that allows prints to glow in the dark. This composite of glowing powder absorb light energy and then release the glowing color in another color of light like neon green. To make it glow extra bright, make walls extra thick. It glows very bright with a black light.

| Technical details |

| Strength: Medium Flexibility: High Durability: Medium |

| Print difficulty: Medium |

| Printing temp: 190°C to 220 °C |

| Print bed temp: 40°C to 60 °C |

| Shrinkage/warping: Low |

| Soluble: No |

| Food safety: Not recommended |

HIPS

Source: Fabb-It 3D Druckservice

WHAT IS HIPS?

A light, stiff and low cost filament with dimensional stability. This material is easy to print and makes for good costumes and props. This filament is similar to ABS and can be a better support material compared to other filaments.

| HIPS PROPERTIES |

| Strength: Medium Flexibility: Medium Durability: High |

| Print difficulty: Medium |

| Printing temp: 230°C to 245 °C |

| Print bed temp: 100°C to 115 °C |

| Shrinkage/warping: Medium |

| Soluble: Yes |

| Food safety: Yes |

MAGNETIC IRON PLA

Source: Project 3D Printers

WHAT IS MAGNETIC IRON PLA?

The properties are PLA and with magnetic particles infused to create a highly durable filament. The prints have a rusty texture that imitates real iron. The base of PLA and metallic combination require a hardened nozzle. It behaves similarly to real iron and it react to magnetic fields.

| Technical details |

| Strength: High Flexibility: Not flexible Durability: High |

| Print difficulty: Medium |

| Printing temp: 195 °C to 220°C |

| Print bed temp: 60 °C |

| Shrinkage/warping: Minimal |

| Soluble: No |

| Food safety: Not recommended |

MARBLE PLA

Source: All3DP

WHAT IS MARBLE PLA?

A unique infusion consisting of PLA and marble particles that make a distinct marble like appearance. This material is easy to print and produces fine details with swirls and veins that appear well on sculptures and replicas.

| Technical details |

| Strength: Flexibility: Low Durability: Medium |

| Print difficulty: Low |

| Printing temp: 190°C to 220 °C |

| Print bed temp: 50°C to 100 °C |

| Shrinkage/warping: Low |

| Soluble: Yes |

| Food safety: Not recommended |

PET

Source: 3dwithus.com

WHAT IS PET?

A commonly used thermoplastic that’s waterproof and recyclable. This material is used in water bottles, food containers due to its dimensional stability and chemical resistance. PET is also suitable for electronic applications such as lamp housings, light frames and other applications that need heat resistance.

| Technical details |

| Strength: High Flexibility: Low Durability: High |

| Print difficulty: Low |

| Printing temp: 160 °C to 210°C |

| Print bed temp: 70 °C to 80°C |

| Shrinkage/warping: Low |

| Soluble: No |

| Food safety: Yes |

CLEANING FILAMENT

Special polymer designed for nozzle cleaning and pushing carbonized plastic and particles out. When used proactively to maintain, it will not damage the nozzle.

| PROS | CONS |

| Cannot unlock full clogs | Extend the life of your extruder, |

| Additional processes needed for full clogs | Non abrasive, |

| Removes residue, | |

| Removes filament contaminants |

HIPS (HIGH IMPACT POLYSTYRENE)

HIPS is a low cost and easy to print filament. It can be found in television parts, computer housing, toys and it’s food safe. It has dimension stability and acts as an excellent support material.

| PROS | CONS |

| Easy to print | Odor |

| Handles overhangs well | High printing temperature |

| Great for support material | Warping can occur without heating bed or not completely cooled off |

| Dimension stability |

PETG

PETG filament is a type of filament that is made from PET (polyethylene terephthalate) and glycol. PETG filament is a great material choice for both experienced and novice users.

| PROS | CONS |

| Flexible | Flexible but Brittle (if bending) |

| Strength | Thin strings can arise at overhangs |

| Heat-resistance | |

| Liquid/chemical resistance | |

| Withstands impacts better than PLA |

| Technical details |

| Strength: Medium Flexibility: Medium Durability: High |

| Print difficulty: Low |

| Printing temp: 220°C to 240°C |

| Print bed temp: 75°C to 90°C |

| Shrinkage/warping: Low |

| Soluble: Yes |

| Food safety: Yes |

Key Features:

- Durability and Strength: It is stronger and has a high tensile strength, which means that it is durable and can withstand a lot of wear and tear.

- Biodegradability: It is non-biodegradable though it is 100% recyclable.

- Resistance to heat: It’s intermediate as compared to PLA and ABS.

- Britability: It is less brittle than PLA.

- Melting point: PETG has a melting point of 260 degrees C.

- Toxicity: It is non-toxic, making it a safer option for printing with than some other filaments.

- Where it is used: It can be used to print a wide variety of objects, including toys, tools, and household items. It is also used to print objects that will come into contact with food as it is food-safe.

- Downside: The major challenge with PETG filament is that it is no UV-resistant. When it’s exposed to UV light it weakens. It is also difficult to obtain a clean finish when printing with PETG.

PETT

PETT filament is a new type of filament that has been gaining popularity in the last few years. It is made out of PETT, which is a type of plastic that is very strong and durable. PETT filament also prints very smoothly, which makes it a good option for detailed prints.

| PROS | CONS |

| flexibility | Uses slow speeds for better printing |

| does not warp easily | Heated printing bed needed |

| not brittle | prone to clogging |

| Technical details |

| Strength: High Flexibility: Medium Durability: Medium |

| Print difficulty: Medium |

| Printing temp: 210 °C to 230°C |

| Print bed temp: Around 45°C |

| Shrinkage/warping: Low |

| Soluble: Yes |

| Food safety: Yes |

Key Features:

- Durability and Strength: PETT filament is very strong and can hold up well under pressure. This makes it a good choice for projects that require durability.

- Biodegradability: PETT is made of renewable materials and it is biodegradable in industrial plants.

- Resistance to heat: It is heat resistant.

- Britability: It is relatively brittle.

- Melting point: It has a melting point of above 250 degrees C.

- Toxicity: It is non-toxic as it is made of food-safe material.

- Where it is used: It is a good choice for printing items like kitchen utensils and dishes.

- Downside: PETT filament is very fragile and you can choose this filament if you would like your final product to be less brittle.

PLA

PLA 3D printer filament is a type of filament that is made out of polylactic acid.

| PROS | CONS |

| Strong | Softens at low temperatures (heat tolerance is low) |

| Durable, | Brittle(if bending) |

| Food safe | Not chemical/water resistant |

| Easy to work with |

| Technical details |

| Strength: Medium Flexibility: Low Durability: Medium |

| Print difficulty: Low |

| Printing temp: 190°C to 230°C |

| Print bed temp: 60°C to 80°C |

| Shrinkage/warping: Low |

| Soluble: No |

| Food safety: Yes |

Key Features:

- Durability and Strength: PLA is strong and it has impressive tensile strength.

- Biodegradability: It is not biodegradable, rather it is compostable.

- Resistance to heat: PLA has low heat resistance.

- Britability: It is relatively brittle. It can crack in some special circumstances.

- Melting point: PLA has a melting point of between 170 to 180 degrees C.

- Toxicity: It is non-toxic.

- Where it is used: Useful in the food and medical industries. For example in 3d printing disposable tableware, straws and containers, Cups and lids, etc.

- Downside: It is not suitable for use in parts that can be subjected to high temperatures as it has its glass transition temperature is low (111 to 145 degrees Farenheight.)

Wood Filament

Wood filament allows one to print objects that feel and look exactly like wood. They are not exactly wood but sometimes it can be PLA added wood fibres and this makes it resemble wood but the temperature has to be low as compared to that of PLA.

| PROS | CONS |

| Authentic feel and smell of wood | Lacks strength, and durability. |

| Sanding can achieve different effects | Wears the nozzle and extruder can be clogged |

| Flexibility |

Key Features:

- Durability and Strength: Though wood is strong, the final product of Wood filament is brittle and it can also easily wear out.

- Biodegradability: It is 100% biodegradable.

- Resistance to heat: It is not heat resistant.

- Britability: It is brittle and inflexible.

- Melting point: Around 140-150 degrees C.

- Toxicity: It is non-toxic.

- Where it is used: Useful in display and design items.

- Downside: Wood filament can easily catch fire as it is flammable. It is also stringy and you will need to do some post-processing to fix this after printing.

POLYCARBONATE

Source: afinia.com

WHAT IS POLYCARBONATE?

Considered as the strongest consumer filament out on the market with a wide applications for mechanical and electrical parts. This material has high tensile strength and temperature resistance. It’s also flexible and it can be bent without shattering. It requires a high temperature hot end and long minimum layer time.

| Technical details |

| Strength: High Flexibility: High Durability: High |

| Print difficulty: Medium |

| Printing temp: 220°C to 310°C |

| Print bed temp: 85°C to 120°C |

| Shrinkage/warping: Low |

| Soluble: No |

| Food safety: Yes |

POLYPROPYLENE (PP)

Source:3Dnatives

WHAT IS POLYROPYLENE?

A long-lasting strong and lightweight filament that’s considered to have near perfect layer adhesion. It has great flexibility that wont wear and tear easily. It is great for anything that need to contain liquid and resist chemicals.

| Technical details |

| Strength: Low Flexibility: High Durability: High |

| Print difficulty: Medium |

| Printing temp: 220°C to 250°C |

| Print bed temp: 85°C to 100°C |

| Shrinkage/warping: High |

| Soluble: Yes |

| Food safety: Yes |

More about 3D printer filament overview

NASA Astronaut Barry (Butch) Wilmore holds a ratchet wrench created in 2014 with the 3D printer aboard the International Space Station using a design file transmitted from the ground.

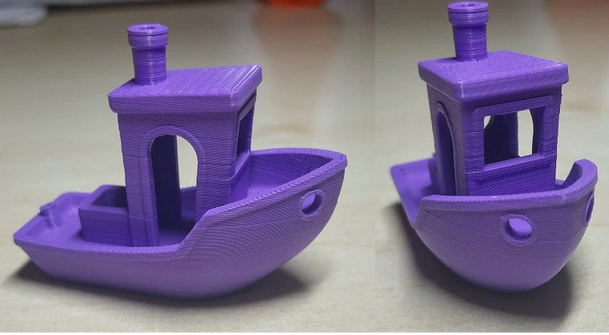

These items are a few of what I have designed and printed with my 3d printers.

I the coronavirus mask I changed how the straps and how the filter is installed. The fishing floats are of my father’s design. But I had to change how the string is held inside because of the limits of what it could print. Saturn fishing bobber. https://www.ebay.com/itm/334042034802 This was made in the 1970’s.

The blades on drowning are ABS I designed the hubs and added blades using Matterhackers software. The tiny Seek thermal camera is encased in flexible plastic I designed this because it slipped and fell into 3parts. The bobbers are ABS. The mask is made flexible.

https://www.thingiverse.com/ is a great place to find things for your 3d printer.