Lever your print bed

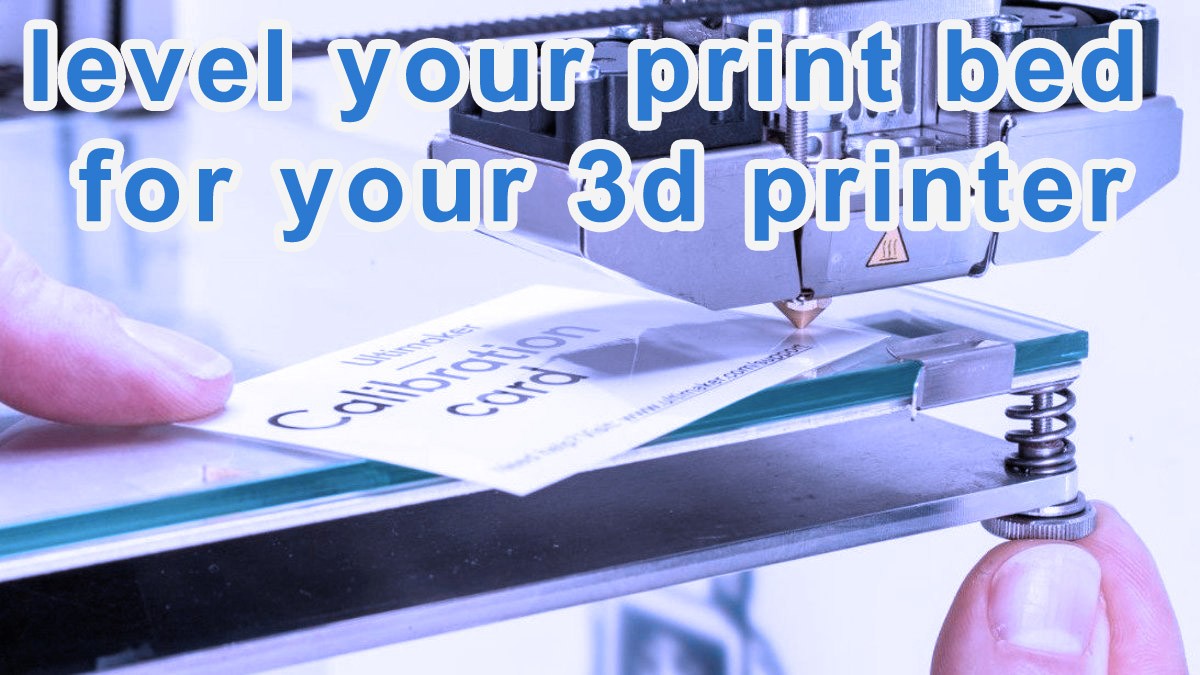

3D printer bed leveling Ender 3 PRO

Level your bed, without doubt, this will be the first reply most people who are new to 3d printing will receive when they venture to a forum to ask for help.

It doesn’t matter what issues you have, this seems to be the standard greeting from many ‘established 3d printing’ forum users, and quite often isn’t helpful.

I’m not saying that the person replying isn’t being helpful, they are probably trying to be, it’s that the statement isn’t helpful in its self, there just isn’t enough information in the statement.

So let’s look at the statement, level your bed, what does it mean? The word level is being wrongly used to replace the word tram, your printer mostly doesn’t care if its level, it only matters that it is trammed correctly.

Having your bed trammed correctly means that the print nozzle (as long as the z axis isnt moved) is the same distance from the bed where ever it is in the X and Y positions, so front left is the same as back right, center and anywhere else on the build plate.

How to Level Your 3D Printer Bed Nozzle Height Calibration for the Best Printing

So how do you tram your bed?

Well, there are a few methods, the one I prefer is to use a cheap set of feeler gauges, feeler gauges are a precision tool designed to measure small distances less than 1mm, most cheap sets will go down to something like 0.05mm, I use the 0.1mm gauge. But before we get to that do you know if your machine is square?

What do I mean by square? What I mean is have you checked that the machine is built correctly and that all the mechanical parts that make the frame are at their correct angles?

This needs a tool, luckily it’s a cheap tool! Remember as a child getting school supplies, you would get a measuring set with a compass, rubber, pencil, ruler, and a couple of triangles that seemed a bit pointless? Here’s the point of those!

On those triangles is a 90-degree angle, it’s the only angle that’s the same on both triangles, these are perfect to check the frame of your printer for squareness, most importantly (especially on creality ender 3 type machines) check the X-axis, these can droop on one side due to the fact that they only have one side being driven by the Z-axis.

Creality Ender 3 – easy way to level your print bed

I won’t go into details about that specific machine, there are already a lot of articles about the process for that issue, this article is about getting past the bed leveling gatekeeper!

So now the machine is square we can check for the tram, firstly you need to do this with the heat bed and nozzle up to printing temperature, why? Simple, as things get hotter they expan, they may also warp slightly, so the way things are set when cold might not be the way they stay when they heat up.

You can use paper or feeler gauges to set this, it’s entirely up to you, I prefer feeler gauges, being that they are precision metal instruments, which makes the process easily repeatable to very close accuracy. Start a print and let the machine start laying plastic, don’t worry about how this looks it’s just to get the printer to its Z 0 height. Once this happens, turn the machine off and back on again, then go through the printer’s menu and turn the heat back on, while you are waiting for the heat to stabilize again remove any plastic that may have been laid onto the bed.

Position your nozzle

Now position your nozzle over your first adjustment point (this should have an adjustment wheel so you can move the bed up and down, make a note of which way is up and which way is down!)

What your looking to do is have a little resistance when you move the feeler gauge (or paper) between the nozzle and heat bed. Once you have that, move to the next adjuster with the nozzle positioned above, repeat the adjustment on this position so the resistance feels the same

Once you have that position done move on to the next position repeat the process and if you have it move to the fourth position. Unfortunately, we aren’t done! Repeat the process a few times, moving each position alters the others slightly, so you may find that the first position now sits too tight to the nozzle, this is nothing to worry about, just repeat the process until all positions are the same.

That’s it, your bed is now tram (level), but your prints still won’t stick? That’s because you don’t have enough squish on the first layer! Just because the bed is tram doesn’t mean your prints will magically adhere to the print bed.

Time to get out the glue stick or hair spray?

Time to get out the glue stick or hair spray? No! There are two more things to do, firstly clean the heat bed, use warm water with a little dish soap, don’t forget to rinse, then dry with a lint-free cloth.

Now we need a bed leveling test print, this will allow you to fine-tune your bed level and set your squish so that your prints adhere to your heat bed without using anything to stick it down. Just take your time with this, small changes at a time, and remember which way to turn your adjusters!

So here it is, next time you have an issue with your prints and you need help, go through this method before you go to a forum for help so you can say with confidence in your opening comment, my bed is tram, clean and my squish is set.

The best method for 3D printer bed leveling – a complete video lesson

Hopefully, this will help avoid the standard replies of level your bed!

My name is peter Humphreys, I’ve been 3D printing and tinkering with 3D printers since 2012, I’m currently working as workshop manager and lead engineer for the uk’s leading diamond tooling company.

I’ve previously worked in the automotive industry, energy industry and have designed, built and piloted Rob’s.