Contents

- Specification for PETG Filament

- Basic Requirements for a 3D Printer for PETG

- Dobot Mooz 3D 3-in-1 Printer

- Anet A4

- Geeetech A30

- Laser cleaning machine TST-LC50

- Geeetech Prusa i3 Pro x

- Laser cutting and engraving machine TST-1610 100W

- Geeetech Delta Rostock Mini G2 Pro

- Comgrow Comgo Z1

- Uses of PETG Filament

- Tips for 3D Printing With PETG Filament

- Tip #01: Use a heated build platform

- Tip #02: Use a good quality printer nozzle

- Tip #03: Use a low bed adhesion material

- Tip #04: Use an Enclosure

- Tip #05: Use a purge tower

- Tip #06: Use an all-metal hotend

- Tip #07: Use a High-Quality PETG Filament

- Tip #08: Increase the Print Speed

- Tip #09: Keep the Extruder Head Clean

- Common Challenges When 3D Printing With PETG Filament

- Important PETG Settings

- 5 Best 3D Models Printed with PETG

PETG is one of the most popular 3D printing filaments on the market. It’s strong, durable, and prints with a beautiful finish. It is available in both opaque and transparent varieties, which makes it perfect for printing a wide range of objects. In this comprehensive guide, we shall discuss on uses of PETG, give you step-by-step instructions on how to print with this filament as well as tips on how to avoid common problems. Let’s get started!

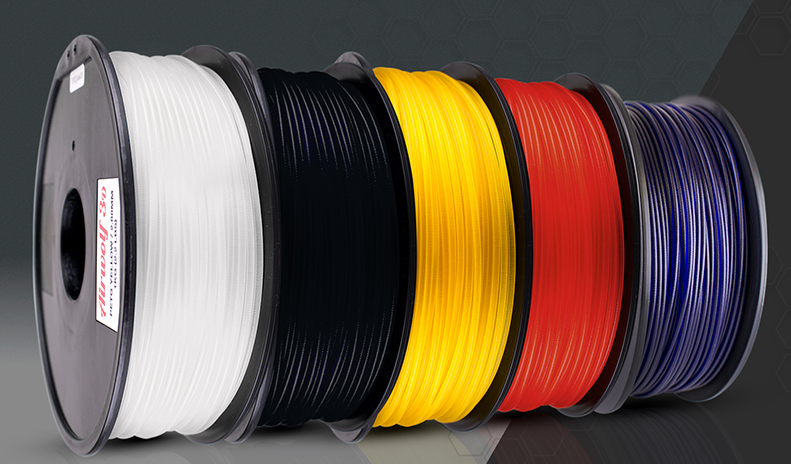

Specification for PETG Filament

Key Features.

| Strength |

|

|---|---|

| Resistance |

|

| Cost | Low |

| Temperatures |

|

| Thermoforming |

|

| Clarity | Good |

| Eco |

|

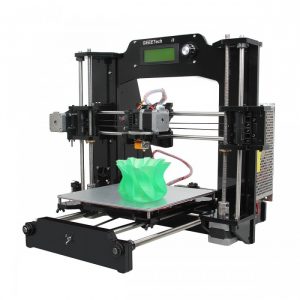

Basic Requirements for a 3D Printer for PETG

When you are looking to purchase any 3D printer, there are a few things you need to consider before making your final decision. One important factor is what type of filament the printer supports. PETG is strong and durable and it’s often used in many areas. If you are looking to print using this filament, you will need a printer that can handle it well. In this section, we will go over some of the basic requirements for 3D printer printing in PETG.

- The first requirement is that it must have a well-functioning heated build plate. This is because PETG has a high melting point and requires a higher temperature to melt properly. Without a heated build plate, it will not stick to the build surface and your prints will be very weak.

- The extruder must be able to reach high temperatures quickly. Again, this is because of its high melting point. Most standard extruders cannot reach the necessary temperatures and will need to be upgraded.

- Finally, should have a properly functioning fan to cool the filament as it is extruded. This is because PETG can warp and deform easily when it is not cooled properly. Without a properly-working fan, your prints will likely be very deformed and unusable.

These are just a few of the basic requirements for a 3D printer printing in PETG. With the proper printer and settings, you can produce high-quality prints.

Uses of PETG Filament

Here are some of the most common uses for PETG:

- Prototyping: PETG filament is ideal for creating prototypes because it is strong and durable. This makes it perfect for testing the strength and durability of a design before committing to a final product made from a more expensive material.

- Creating 3D designs for Display and Presentations: It can be used to create models of all shapes and sizes. Its strength and durability make it perfect for creating models that will be used in presentations or displays.

- Home Décor: PETG can be used to create a wide variety of home décor items, from simple ornaments to complex furniture. Its strength and durability make it perfect for use in high-traffic areas.

- Crafts: It is perfect for crafting a wide variety of items, from jewelry to toys.

- Clothing: PETG can be used to create clothing accessories, such as hats, bags, and full garments.

There are many other uses for PETG, including but not limited to medical implants, automotive parts, and food packaging.

Tips for 3D Printing With PETG Filament

3D printing with clear PETG. Image source:All3dp

Here are some tips to help you get the best results from your PETG prints:

Tip #01: Use a heated build platform

A heated build platform is essential when printing with PETG. The temperature of the build platform should be maintained at around 110 degrees Celsius. If the platform is not heated, it will cool too quickly and will form droplets that can cause problems with the print quality.

Tip #02: Use a good quality printer nozzle

PETG filament can be quite abrasive, so it’s important to use a good quality printer nozzle. If you are using a standard brass nozzle, it will wear out quickly and may need to be replaced often. A stainless steel nozzle is a better choice.

Tip #03: Use a low bed adhesion material

PETG can be quite slippery, so it’s important to use a low bed adhesion material such as hairspray or PVA glue when printing on a glass build platform. This will help to keep the print stick to the platform and prevent it from slipping during the print process.

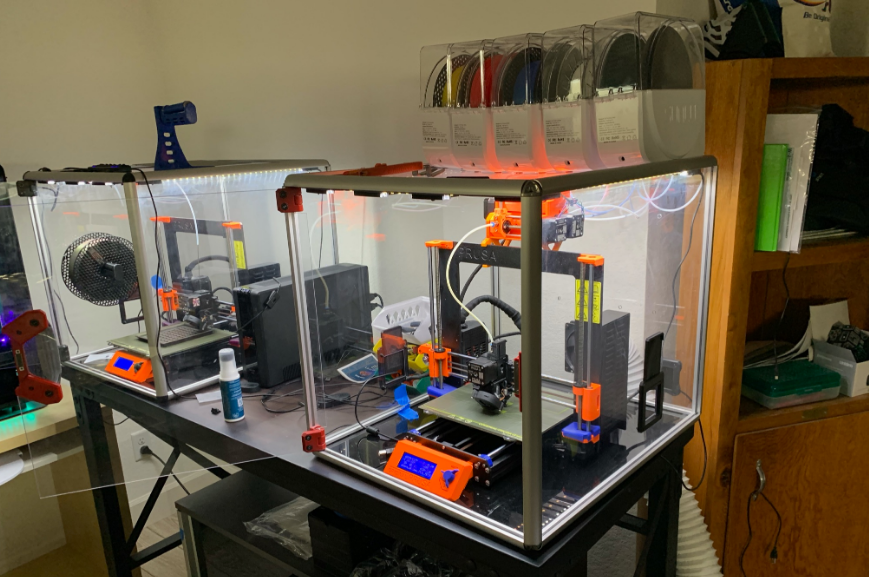

Tip #04: Use an Enclosure

3D printers with enclosure. Image source:Prusa forum

PETG prints best in an enclosed environment. An enclosure helps to maintain the temperature of the build platform and prevents drafts from cooling it down too quickly.

Tip #05: Use a purge tower

A purge tower is a great way to reduce the amount that is wasted during the printing process. A purge tower is simply a short section of tubing that is attached to the extruder head and routed back to the spool. When you start a print, it will be purged through the purge tower and into the waste bin. This reduces wastage and helps to keep your filament costs down.

Tip #06: Use an all-metal hotend

An all-metal hotend is essential when printing with PETG. The metal construction helps to dissipate heat faster and prevents clogging of the nozzle.

Tip #07: Use a High-Quality PETG Filament

It’s important to use a high-quality PETG when printing with this material. A good quality will produce better results and is less likely to cause problems during the printing process.

Tip #08: Increase the Print Speed

PETG prints best at a high print speed. Increasing the print speed will help to reduce the chances of clogging or jamming the nozzle.

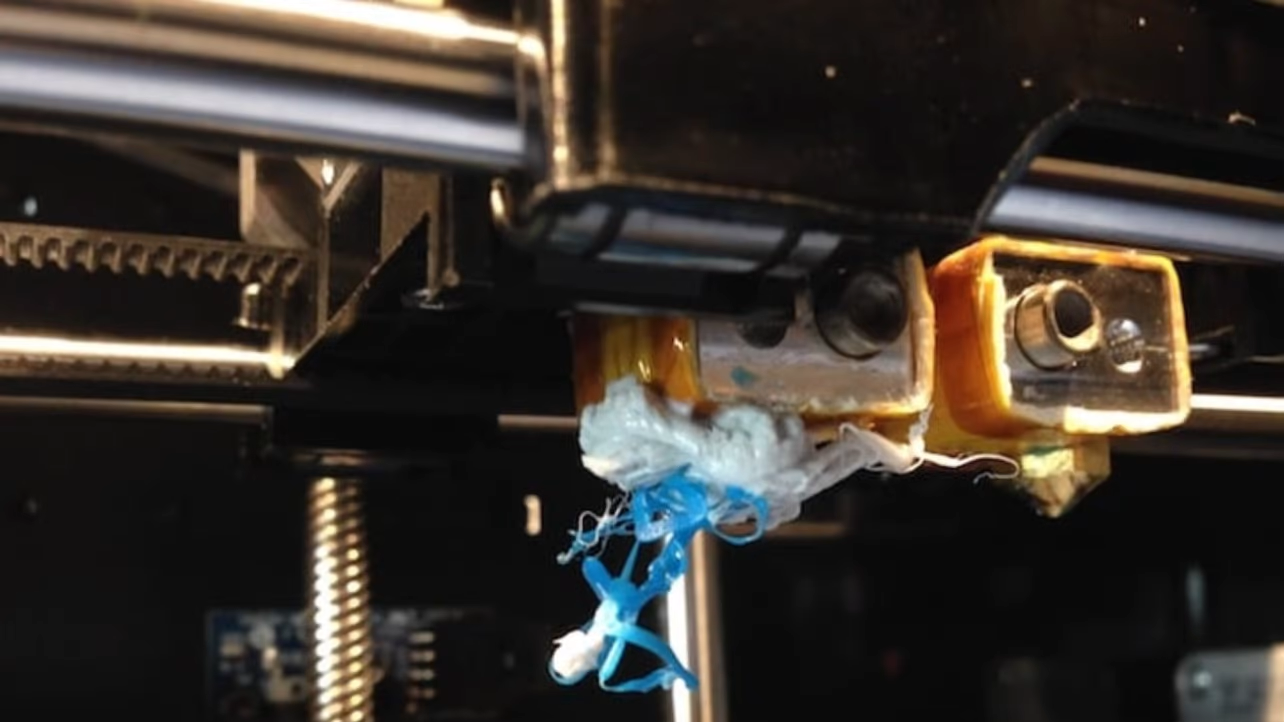

Tip #09: Keep the Extruder Head Clean

It’s important to keep the extruder head clean when printing with PETG. Clogged nozzles can cause problems with the print quality and may even damage your printer. Regularly cleaning your extruder head will help to ensure that it performs well.

Common Challenges When 3D Printing With PETG Filament

PETG is a great option for those looking to print with a material that has both strength and flexibility. However, there are some common challenges that can occur during 3D printing. These includes:

#01: Not sticking to the build plate

Sample of a 3D object not sticking to the bed. Image source: Simplify3d

One of the most common problems with PETG is that it doesn’t stick to the build plate very well. This can be caused by a variety of factors, including a dirty or greasy build plate, low bed temperature, incorrect bed leveling, and even problems with the printer’s hot end.

Solution: The best solution for this problem is usually to clean the build plate thoroughly and adjust the bed temperature and/or bed level as necessary.

#02: Warping or Deforming

Another common problem is warping or deformation. This can be caused by a number of factors, including high printing temperatures, low ambient humidity, and unsupported overhangs.

Solution: The best solution is usually to adjust the printing temperature and/or ambient humidity as necessary.

#03: Clogging the hot end

PETG sometimes clogs the hot end of the printer if it’s not cooled down properly. This can be caused by high printing temperatures, low ambient humidity, or even poor ventilation.

Solution: Adjust the printing temperature and/or ambient humidity as necessary, and make sure that the printer has good ventilation.

#04: The filament is sticking to itself

Sometimes it can stick to itself, which can cause problems with feeding and/or printing. This can be caused by low bed temperature, incorrect bed leveling, or even problems with the printer’s hot end.

Solution: The best solution for this problem is usually to adjust the bed temperature and/or bed level as necessary.

#05: The filament Shrinking or Expanding

Another common problem with PETG is shrinkage or expansion. This can be caused by extremely high printing temperatures, low ambient humidity, and unsupported overhangs.

Solution: Adjust the printing temperature and/or ambient humidity as necessary.

#06: Not Coming out of the Printer Correctly

Filament not coming out properly. Image source:All3dp

This is a common challenge that occurs when printing with this material. This is usually caused by a dirty or greasy build plate, low bed temperature, incorrect bed leveling, and even problems with the printer’s hot end.

Solution: The best solution for this problem is usually to clean the build plate thoroughly and adjust the bed temperature and/or bed level as necessary.

#07: Breaking or Snapping

PETG usually breaks or snaps Easily.

Solution: Just like other challenges, to fix this issue, you will need to adjust the printing temperature and/or ambient humidity as necessary, and to make sure that the printer has good ventilation.

#08 Poor adhesion between layers

Another common problem that can occur when printing with PETG filament. This can often lead to prints that are prone to peeling or delamination.

Solution: Always use an enclosure, reduce layer height, and increase temperature.

These are just a few of the common problems that can occur when printing with PETG. By understanding these challenges, you can take steps to avoid them and produce higher-quality prints.

Important PETG Settings

In order to get the best results from your PETG prints, you need to adjust your settings accordingly. Some of the common PETG settings include:

1) Temperature

PETG has a recommended print temperature range of 210-240°C. However, depending on your printer and environment, you may need to adjust the temperature setting.

For example, if your printer has a heated build platform, you may need to increase the temperature to 220-235°C in order to prevent warping. Conversely, if your printer does not have a heated build platform, you may need to decrease the temperature to 205-210°C in order to avoid excessive cooling and reduce shrinkage.

2) Speed

The recommended printing speed is around 30-60 mm/s. However, you may need to adjust the speed setting depending on your printer and environment. For example, if you are printing in a high humidity environment, you may need to decrease the printing speed to 25-35 mm/s in order to avoid excessive drooling. Conversely, if you are printing in a low humidity environment, you may be able to increase the printing speed to 50-60 mm/s without causing problems.

3) Retraction

PETG typically does not require any retraction. However, if your printer is having trouble with oozing or stringing, you can try increasing the retraction distance slightly. You should also increase the retraction speed to ensure that the it is properly retracted.

4) Calibrating the 3D Printer Correctly

Calibrating a 3D printer. Image source:Instructables

You will want to make sure that your printer is calibrated correctly. PETG is a very unforgiving material, so any discrepancies in print quality will be amplified. If you are not confident in your ability to calibrate your printer correctly, you can check out our article on how to calibrate your 3D printer properly and it will walk you through the process.

With these common PETG printing settings in mind, you should be able to produce high-quality prints with your PETG material.

Other Tips:

- Make sure that you are using a high-quality material, such as Proto-Pasta PETG. Cheap ones may not have the same properties as higher quality, and may not print correctly.

- If your printer has a fan shroud, make sure that it is installed correctly and is blowing air onto the print surface. This will help to prevent warping and improve the print quality.

- If you are experiencing problems with curling or lifting of the corners of your prints, try increasing the printing temperature by five degrees and see if that helps.

There are a lot of projects that have been done with PETG. In this section, we’ll show you five of them that you can 3D print too.

5 Best 3D Models Printed with PETG

1. iPhone Gear Case

This 3D-printed iPhone gear case is made from PETG and is designed to protect your phone from scratches. The case has a raised lip around the edge of the screen, which helps to keep the glass from shattering if it’s dropped.

Link to get Files: QuentinT via Thingiverse

2) Cat Drinking Pod

An interesting drinking pond that can take soda bottles. You don’t need to monitor it as the level is kept constant by the pond. Because PETG is food safe, this is the best design that you can print for feeding your cat.

Link to Get Files: Johk via Thingiverse

3) Goose Keychair

An interesting keychain was designed and 3D printed in PETG and PLA. The design is easier to print and it doesn’t need any support material.

Link to Get Files: Gynni via Thingiverse.

4) Wrist Brace

This wrist brace is made entirely from PETG filament and is designed to help people who have injuries in their hands. Before placing it in the hands, it is heated first. Though it’s safe and flexible, it’s recommended to consult with your physiotherapist before using it.

Link to get the files: PiuLAB via Thingiverse

5) Refrigerator Can Holder

This refrigerator can holder can support 10*300ml cans. You place the cans on the front then they roll back and forth from backward to the front. This ensures that you will always be taking the coldest one. It doesn’t waste space and it’s ideal for small refrigerators.

Link to get the files: MR2C280 via Thingiverse

Conclusion

PETG is indeed a great filament to use for 3D printing. It has many benefits over others. In this guide, we have walked you through the basics including settings, common problems, and solutions. We hope that this guide is of great help to you and you will be able to print with PETG like a pro!