Air assist for diode lasers – a real customer experience

Adding a DIY ait assist on Endurance 10 watt “Invincible” laser

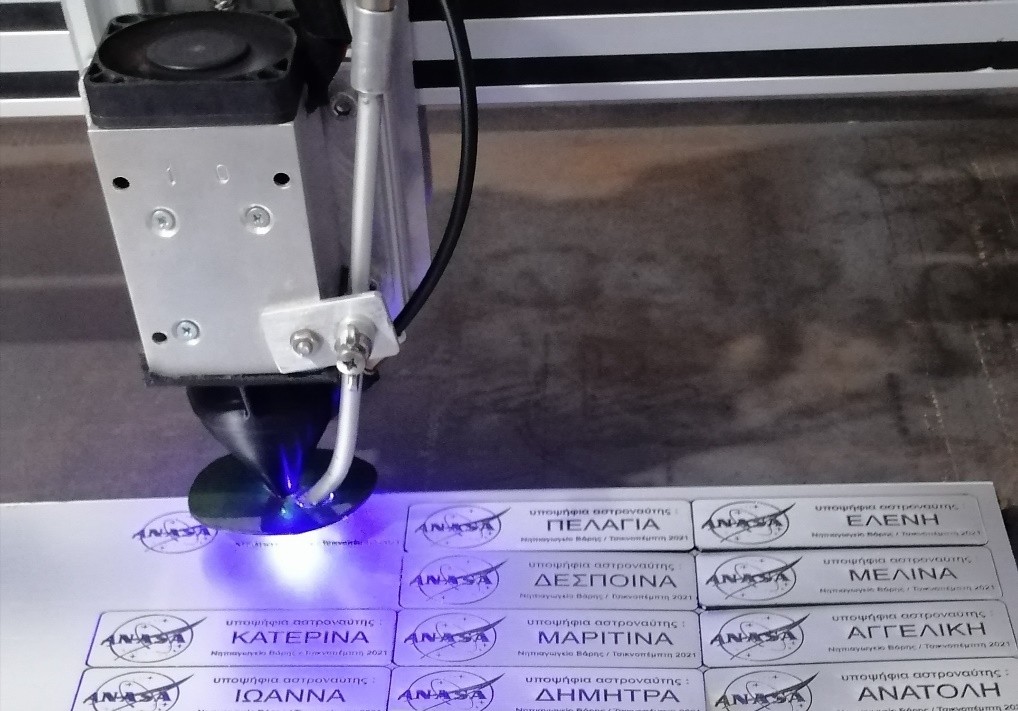

The addition of an air nozzle to a laser module is a must in order to have clean engravings and clean and fast cuttings for the majority of materials. From my little experience, it is only the NWT method, and maybe some types of plastics that are better not to use an air nozzle.

Over time I have used several DIY designs of air nozzles for my laser modules. I will make a try to present each design and share the results, with an open-source spirit in mind!

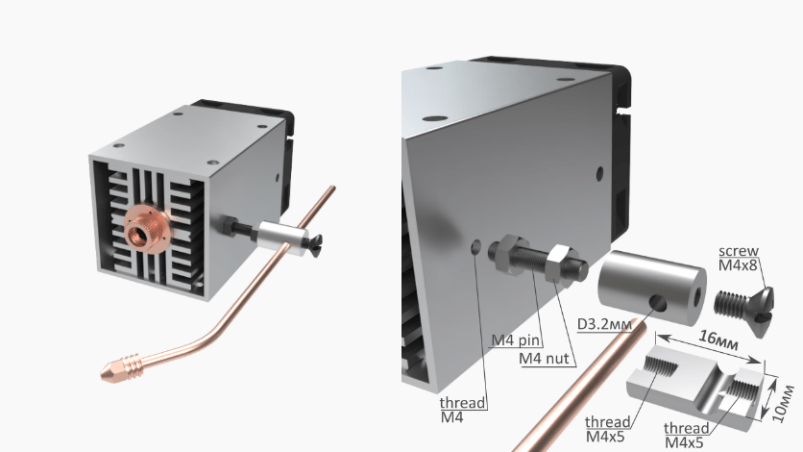

An Endurance laser air nozzle: ver.1.0 (fully open-source)

The open-source design from Endurance lasers is the one I use mostly

I had the opportunity over time to experiment with some variations of the specific design, depending each time with the materials I had handy…

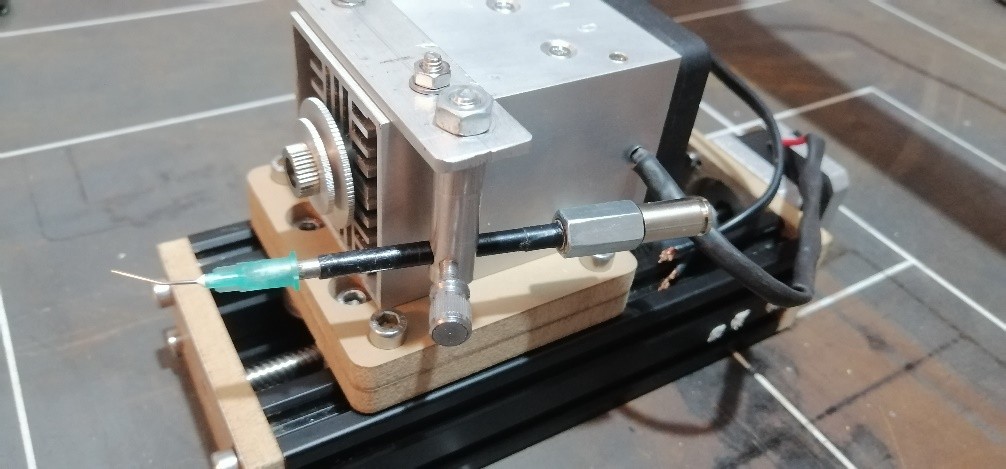

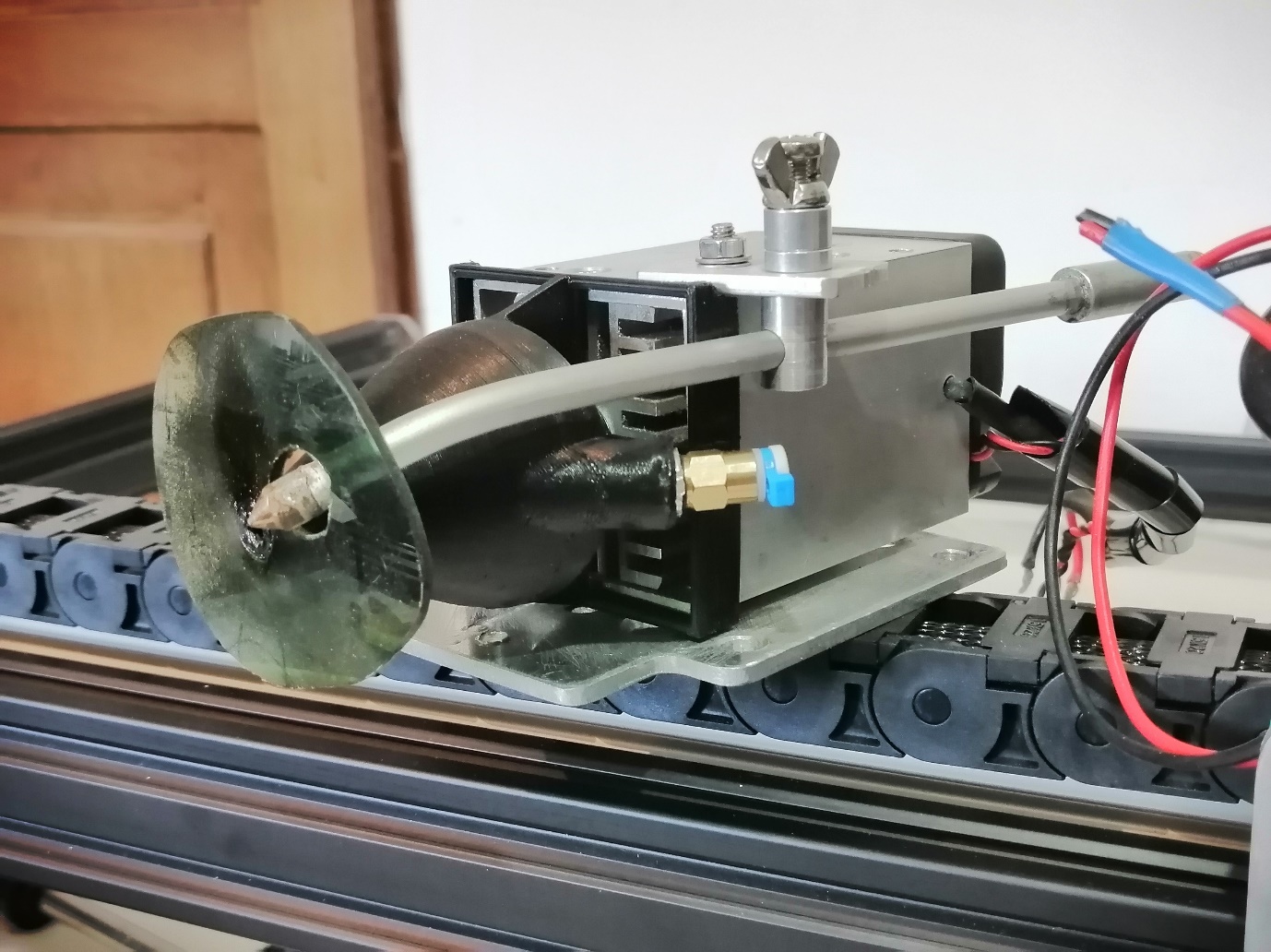

Using a syringe needle instead of a 3d printer’s nozzle. The rod is inox covered with black plastic (from trash) The long nut, at the other side of the needle, helps to screw the quick connector for the 4mm high-pressure air pipe.

Using an air compressor

You can notice in the photo the water bubbles coming out from the copper pipe due to the fact that my air compressor is running without a water trap…

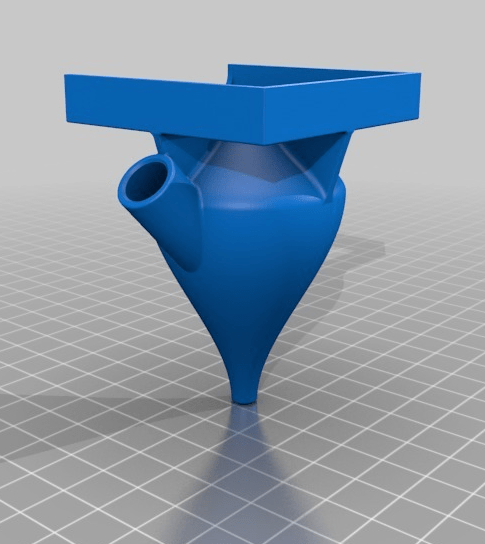

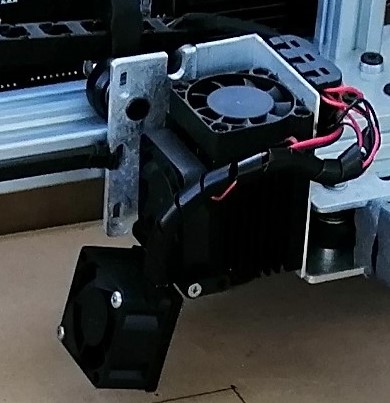

3D printed air assist

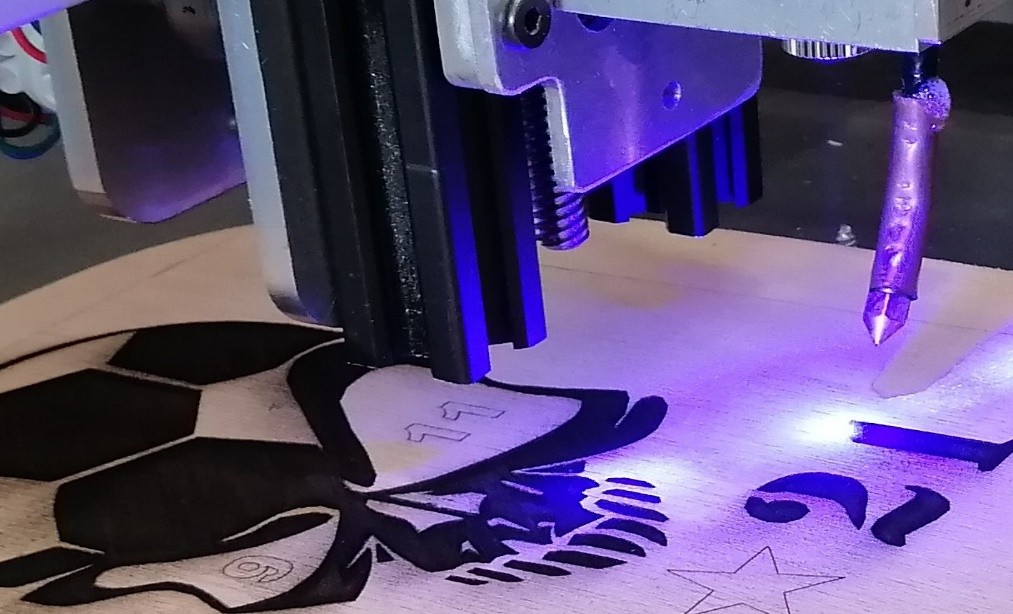

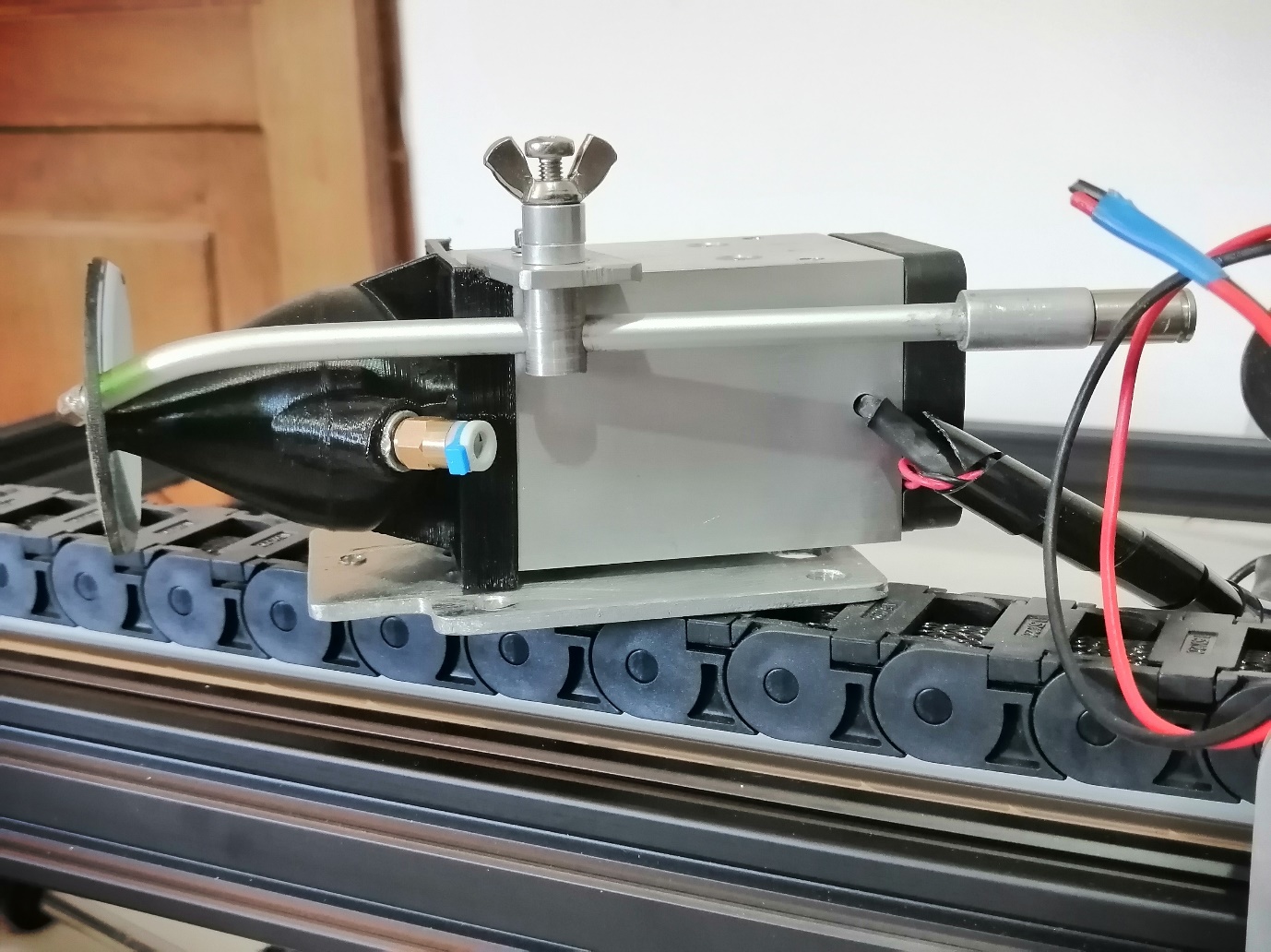

Looking for 3d printed designs on Thingiverse, thing:3652414 from Datulab Tech drew my attention.

It is not only the design I like, that remembers me of an upside-down dome of a mosque, but also its functionality. The specific design despite that it is working as an air assist, it protects also the laser beam from the smoke that is generated from the engraving or the cutting process. Keeping the beam clean of smoke helps a lot to the cuttings and also protects the lens of the laser.

Using a 3 layer lens the specific design worked very well for my needs. The problem was when I wanted to change the lens and decrease the zoom height. So, I printed some more copies of this design by stopping the printing at the desired height, depending on the type of the lens.

Getting started with Endurance lasers and certain limitations

Also, I added an extra air nozzle (Endurance laser air nozzle: ver.1.0) blowing high-pressure air to the beam spot and a half-cut pair of protective goggles for the laser to restrict the radiation.

6V air pump and syringe needle

The 6V air pump had been salvaged from a dead electronic blood pressure device. The small motor is very loud and has a lot of vibrations. The syringe needle helps to increase the air pressure of the pump. The whole system is just better than nothing!

Works good with the engravings but it doesn’t help a lot with cuttings…

DC fan

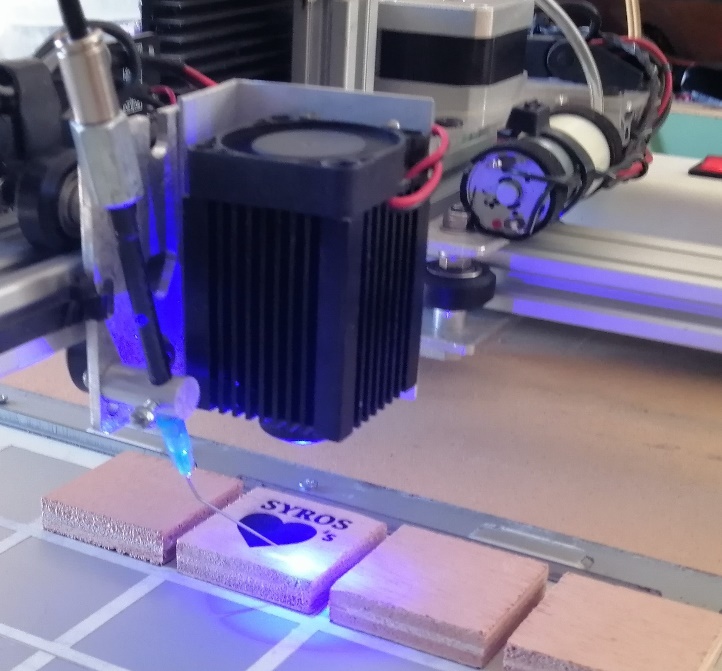

The benefit of using a DC fan mounted with a 3d printed hinge on the laser module is that the laser beam will be clean from smoke. The specific setup will help just a bit with cuttings…

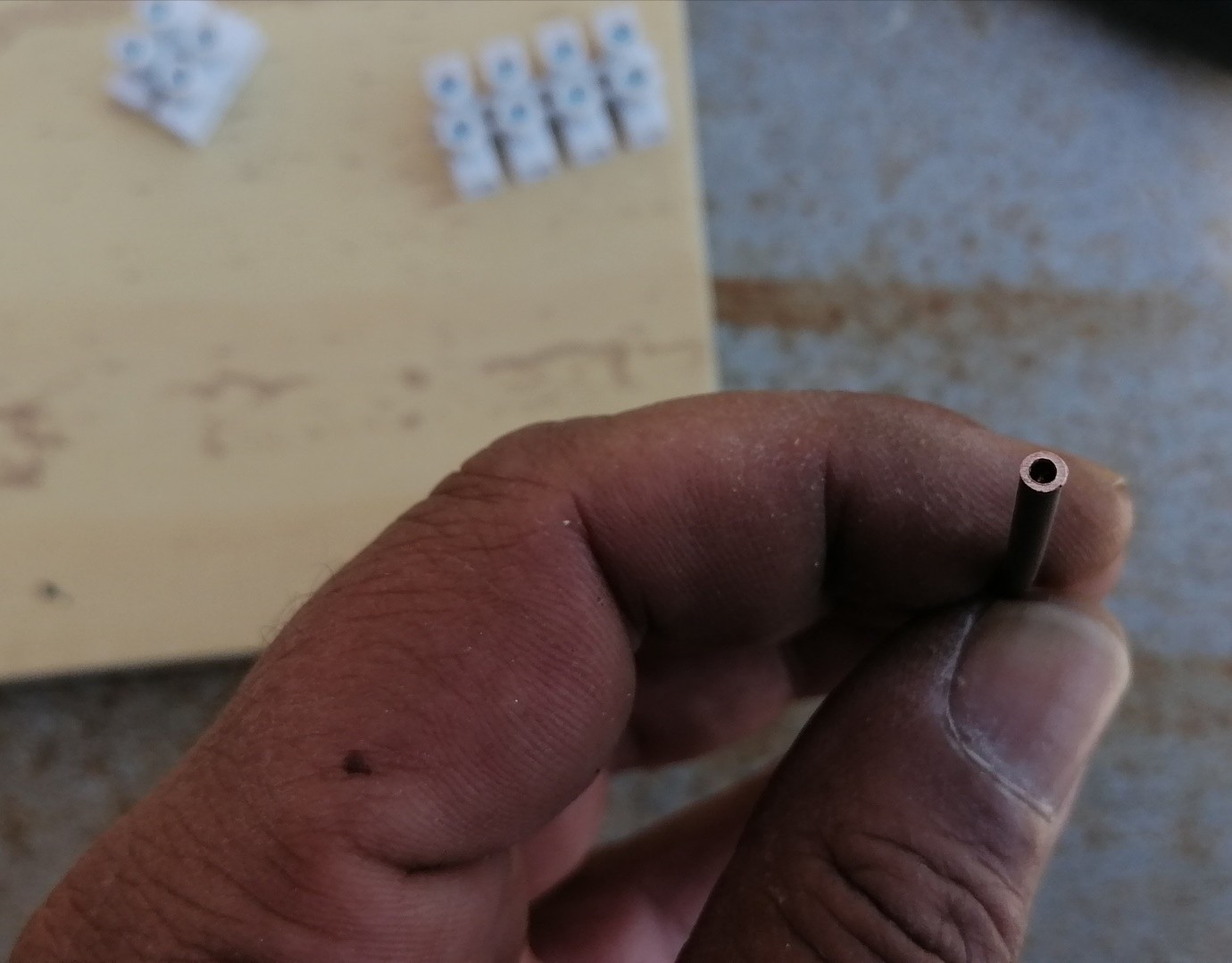

Trash to treasure design

Walking lately to the scrapyard of a crab collector, my eyes stuck to this copper wire and pipe pile …

It was then that I had the idea which is demonstrated in the following pictures

The specific copper pipe has an outer circumference of about 2mm and an inner of about 1mm. It can be nested tightly inside a high-pressure 4mm pipe, by applying some heat to the plastic pipe (using boiled water, a heat gun or a lighter) and hooking it up to an air compressor.

The connector strip has been mounted temporally with two-sided tape to the aluminum shell of the laser, till to decides where to drill and thread a hole. Then an M3 screw will be used to secure the fixture on the laser module, passing throw the small hole at the middle of the connector strip.

Thanks for your reading my story!

Michail Gedeon