A lot of people are looking for an efficient laser engraving/marking tool.

In this post, we will explain all you need to know about laser metal engraving and the difference between making and etching.

Now you do not need a new machine – you can simply install the laser emitter on your existing 3D printer / CNC router or XY plotter and be able to engrave / mark / etch at home or at your workshop.

Etching vs engraving

Let’s get started.

Thermal conductivity, metal melting temperature, laser pulses.

First of all, you need to know that metals have a high temperature of melting and require high energy pulses to vaporize metal. So actual engraving/marking can be applied if your laser has a pulse mode with the good energy of a single pulse.

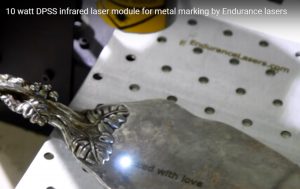

Once the laser pulse hits the metal it creases a bright flash.

Like this.

Most metals have a melting temperature of 1000C+ (see the appendix table below)

That actually requires high-energy pulses and some average power. In Endurance, we offer 4 watt DPSS laser module that is capable to do laser engraving / marking.

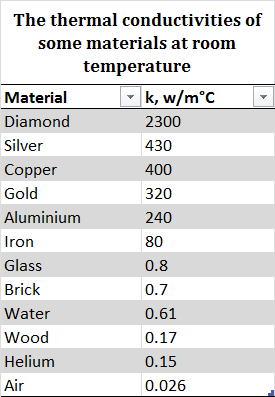

Also, metals have high-temperature conductivity that requires a lot of power as well.

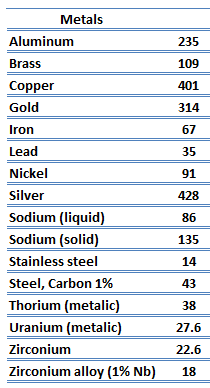

As you see metals have 100-500 times more heat conductivity than wood, water, or glass.

That means that the temperature spreads inside the metal very quickly.

Copper, silver, gold and aluminum have the max thermal conductivity that is why most heatsinks are made out of aluminum or copper.

To get metal engraving /marking jobs done you need high ultra-short and high energy pulses.

Pulse width can vary 1-150 ns

Pulse energy should be at least 10 uJ

and the average power of the laser should be at least 4 watts.

(that is not necessary but according to our R&D those parameters work the best for fast and accurate metal engraving / marking)

However, to get a metal etching you do not need laser pulses and you may do that with 5-15 watt laser power.

Metal etching is a bit different process and does not need pulses at all. It is more like a chemical reaction adding another element on top. Usually, it is an oxide of the original material.

Most laser marking machines do not have a lot of power (most of them have 20-50 watt average power output) but they do have pretty good energy in a short laser pulse (5-150 ns).

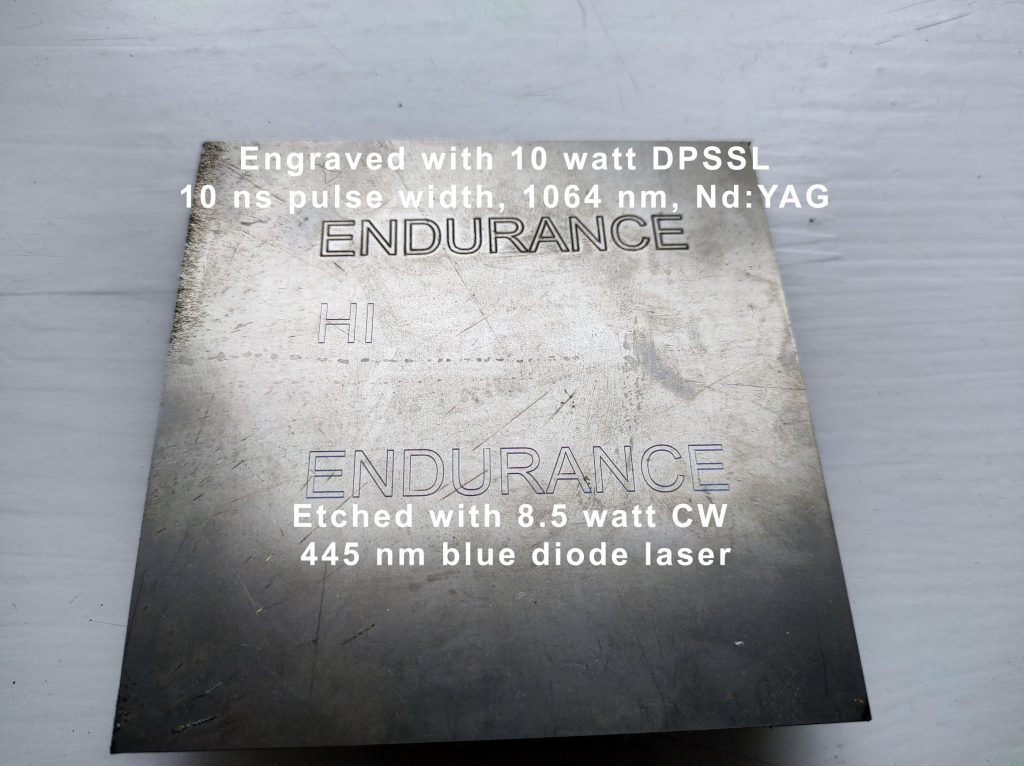

Laser engraving/laser marking is the actual process that removes (vaporize) part of metal from its surface.

High energy pulse heats up the metal creating a hot plasma. That plasma flies away leaving an empty space on its surface.

That allows getting in-depth laser engraving and you can watch the video of the process below

Some people consider etching the same as marking and engraving but there is a key difference between engraving/marking and the etching process.

Once you etch the metal – you create an oxide file (oxidation). That oxide film can be thin and not very stable, Usually, it can be removed with acetone or using a solvent.

Usually, metal engraved or marked will remain a lifetime on the material.

Accurate laser engraving / marking

For example, you can etch on titanium and stainless steel with low CW power diode lasers. You may that those metals with 5-10 watt CW power output but you can not etch aluminum.

Some metals can be etched with a special engraving paste-like thermal grease, Dry Lube Moly, or Cermark engraving paste.

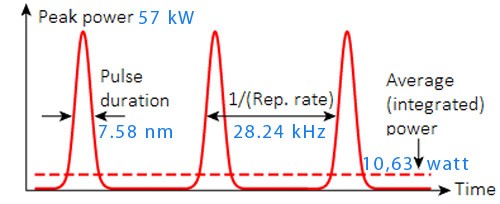

In this video, you see short pulses of laser engraving/marking.

Pulse width is about 7-9 ns and the average laser power is about 10 watt however laser pulse is about 40 uJ

In this video, you may see how Dry Lube Moly can be used in a laser etching process

However with 15 watt diode (DUOS) laser you can etch without any paste on titanium, steel, stainless steel

Another important thing is that metals have different wavelength reflections and absorption spectrums.

Absorption wavelength spectrum for different materials: glass, metal and others.

Diode lasers and DPSS laser can be installed almost on any 3D printer / CNC machine or engraving plotter.

A 10-watt DPSS laser module is installed on a CNC router.

However, the fastest speed of engraving can be reached if the laser is installed on a galvoscanner (galvo)

Usually, industrial laser metal marking takes a few seconds to make a company name or a logo

An interesting fact is that with different types of lases you may do a color metal engraving (called tint colors)

The basic theory is that different laser pulses (energy), different power can create different colors on metallic surfaces.

Usually, those laser markers are very expensive and require adjustable energy pulses and adjustable laser power.

What you can do with different laser types

| Power | |||

| Diode lasers | <5 watt | 5-10 watt | 10-15 watt |

| Stainless steel | – | etching | etching |

| Steel | – | – | etching |

| Copper | – | with thermal grease / dry lube moly | with thermal grease / dry lube moly |

| Brass | with thermal grease / dry lube moly | with thermal grease / dry lube moly | |

| Titanium | etching | etching | etching |

| Anodized aluminum | – | etching | etching |

| Painted aluminum | Removing paint | Removing paint | Removing paint |

| Polished aluminum | – | – | – |

| Power | |||

| Co2 laser | <40 watt | 40-80 watt | 80-150 watt |

| Stainless steel | – | etching | etching |

| Steel | – | etching | etching |

| Copper | – | with thermal grease / dry lube moly | with thermal grease / dry lube moly |

| Brass | – | with thermal grease / dry lube moly | with thermal grease / dry lube moly |

| Titanium | etching | etching | etching |

| Anodized aluminum | – | etching | etching |

| Painted aluminum | Removing paint | Removing paint | Removing paint |

| Polished aluminum | – | – | – |

| Power | |||

| DPSS/Fiber laser | 4-10 watt | 10-30 watt | 30-50 watt |

| Stainless steel | engraving/marking | engraving/marking | engraving/marking |

| Steel | engraving/marking | engraving/marking | engraving/marking |

| Copper | engraving/marking | engraving/marking | engraving/marking |

| Brass | engraving/marking | engraving/marking | engraving/marking |

| Titanium | engraving/marking | engraving/marking | engraving/marking |

| Anodized aluminum | engraving/marking | engraving/marking | engraving/marking |

| Painted aluminum | engraving/marking | engraving/marking | engraving/marking |

| Polished aluminum | engraving/marking | engraving/marking | engraving/marking |

Conclusion

It is obvious the with lasers you can do an effective laser engraving / marking / etching.

Diode lasers and Co2 laser can do metal etching and DPSS and fiber lasers can do metal engraving / marking

If you have any more questions – you are welcome to ask in our Livechat!

Appendix: Metal melting temperature

METAL | MELTING POINT | |

| (oC) | (oF) | |

| Admiralty Brass | 900 – 940 | 1650 – 1720 |

| Aluminum | 660 | 1220 |

| Aluminum Alloy | 463 – 671 | 865 – 1240 |

| Aluminum Bronze | 600 – 655 | 1190 – 1215 |

| Babbitt | 249 | 480 |

| Beryllium | 1285 | 2345 |

| Beryllium Copper | 865 – 955 | 1587 – 1750 |

| Bismuth | 271.4 | 520.5 |

| Brass, Red | 1000 | 1832 |

| Brass, Yellow | 930 | 1710 |

| Cadmium | 321 | 610 |

| Chromium | 1860 | 3380 |

| Cobalt | 1495 | 2723 |

| Copper | 1084 | 1983 |

| Gold, 24K Pure | 1063 | 1945 |

| Hastelloy C | 1320 – 1350 | 2410 – 2460 |

| Inconel | 1390 – 1425 | 2540 – 2600 |

| Incoloy | 1390 – 1425 | 2540 – 2600 |

| Iron, Wrought | 1482 – 1593 | 2700 – 2900 |

| Iron, Gray Cast | 1127 – 1204 | 2060 – 2200 |

| Iron, Ductile | 1149 | 2100 |

| Lead | 327.5 | 621 |

| Magnesium | 650 | 1200 |

| Magnesium Alloy | 349 – 649 | 660 – 1200 |

| Manganese | 1244 | 2271 |

| Manganese bronze | 865 – 890 | 1590 – 1630 |

| Mercury | -38.86 | -37.95 |

| Molybdenum | 2620 | 4750 |

| Monel | 1300 – 1350 | 2370 – 2460 |

| Nickel | 1453 | 2647 |

| Niobium (Columbium) | 2470 | 4473 |

| Palladium | 1555 | 2831 |

| Phosphorus | 44 | 111 |

| Platinum | 1770 | 3220 |

| Red Brass | 990 – 1025 | 1810 – 1880 |

| Rhenium | 3186 | 5767 |

| Rhodium | 1965 | 3569 |

| Selenium | 217 | 423 |

| Silicon | 1411 | 2572 |

| Silver, Pure | 961 | 1761 |

| Silver, Sterling | 893 | 1640 |

| Carbon Steel | 1425 – 1540 | 2600 – 2800 |

| Stainless Steel | 1510 | 2750 |

| Tantalum | 2980 | 5400 |

| Thorium | 1750 | 3180 |

| Tin | 232 | 449.4 |

| Titanium | 1670 | 3040 |

| Tungsten | 3400 | 6150 |

| Yellow Brass | 905 – 932 | 1660 – 1710 |

| Zinc | 419.5 | 787 |

Learn more about wiring the laser to CNC machine and different 3D printers