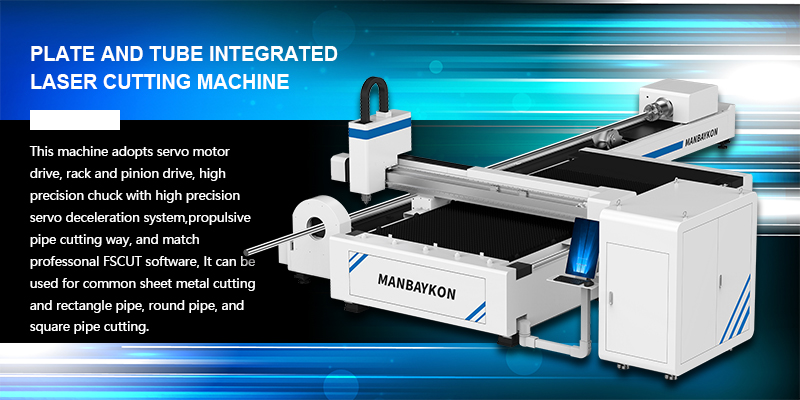

| Equipment Type | MK-3015C |

| Laser Wavelength | 1064nm |

| Impulse Frequency | 1-300HZ |

| Minimum Linewidth | 0.15mm |

| Board Process Area | 3000mmx1500mm |

| Board Thickness | 0.2-15mm |

| Tube Diameter | 10-220mm |

| Tube Length | 6000mm |

| Pipe Wall Thickness | 0.2-5mm |

| Power | 380V/50HZ/100A |

| X, Y, Z-Axis Geometric Positioning Accuracy | ±0.03mm |

| Repeat Positioning Accuracy | ±0.02mm |

| Cooling Method | Water cooling |

Learn more about this machine >>>

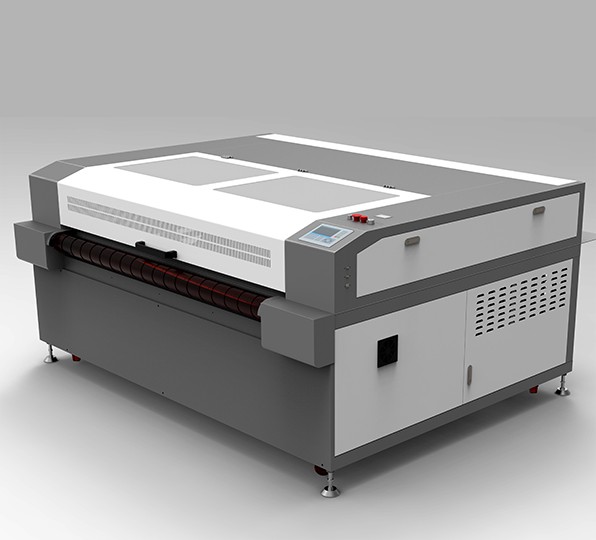

Auto-Feeding Laser Machine

Redsail auto-feeding laser machine is an excellent option and effective solution for clients demanding large-scale cutting of cloth rolls and other soft materials in that cutting machine can improve the working efficiency.

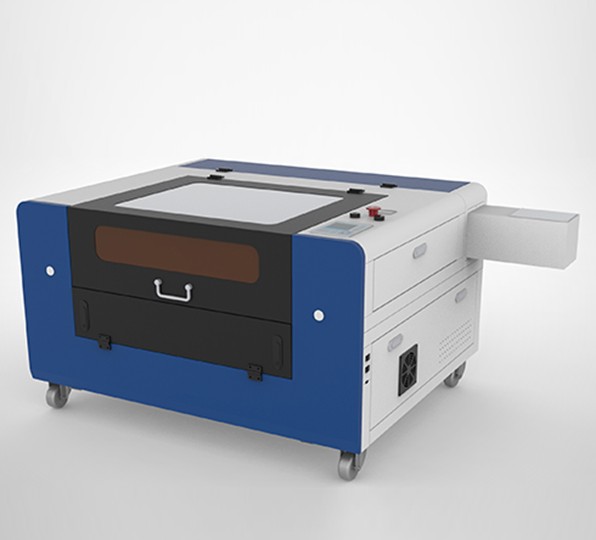

Laser engraver

Redsail Laser Engraver is a kind of Laser Engraving Machine System equipped with Co2 laser Tube. It is used to engrave on wood, bamboo, plexiglass, crystal, leather, rubber, marble, ceramics and glass, among others. It is the most suitable and the preferred choice of equipment in industries such as advertisement, gifts, shoes, toys and etc.

The Co2 Laser power of Redsail Laser Engraver is from 50W to 100W.

Co2 laser cutter

Redsail Laser Cutting Machine work with Co2 Laser, it is used for cutting wooden plate, acrylic, paper, plastic, rubber and other no-metal materials for complex shape. Redsail low-cost Laser Cutter is useful in many products such as airplane models, advertisements, decorations, article gifts, toys, and face guards of machines.

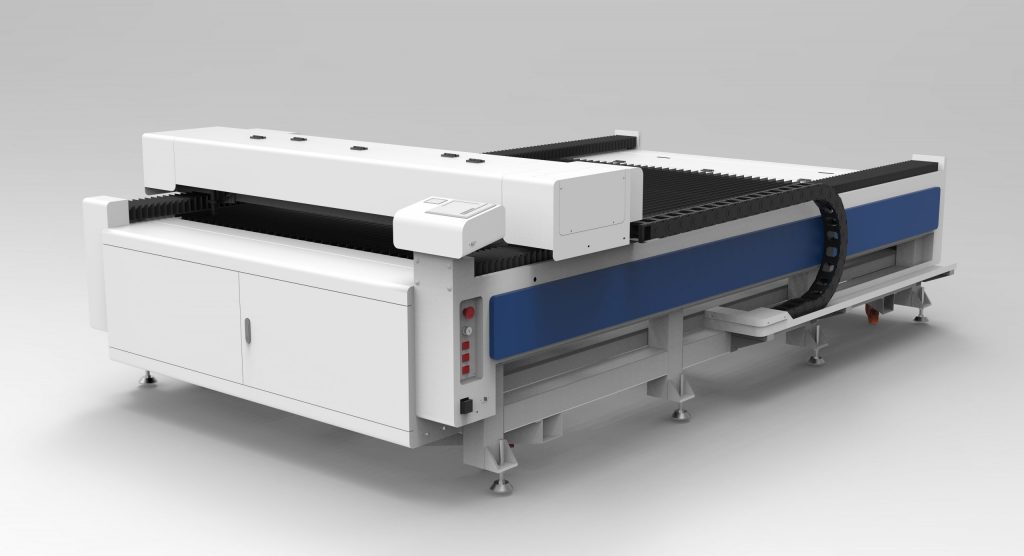

Flatbed Laser cutting machine

Redsail flatbed laser cutting machine works with high power Co2 laser tube, with the function of cutting and engraving. Laser tube moves following the design of files, without power wasting, keeping machine work with same power on each position of the working table. It gives better engraving and cutting results.

Learn more about Redsail machine >>>

Carton Aluminium Metal Cnc Laser Metal Cutting Machine 380v 1000W

| Product Name: | Fiber Cnc Laser Metal Cutting Machine | Cutting Thickness: | 0-30mm |

|---|---|---|---|

| Cnc Or Not: | Cnc | Graphic Format Supported: | PLT,DXF,AI,BMP,DST |

| Laser Power: | 1000W | Warranty: | 2 Years |

| Color: | White & Blue | Power Supply: | 220V±10%/10A,380v/50hz/60hz/60A,380V/50HZ |

| High Light: | 380v Cnc Laser Metal Cutting Machine, 1000W Cnc Laser Metal Cutting Machine, DXF Fiber Cnc Laser Cutting Machine | ||

Product Description

Carton Aluminium Metal Cnc Laser Metal Cutting Machine 380v 1000W

1000 W Carton Aluminium Metal Cutter Industrial Fiber Cnc Laser Cutting Machine

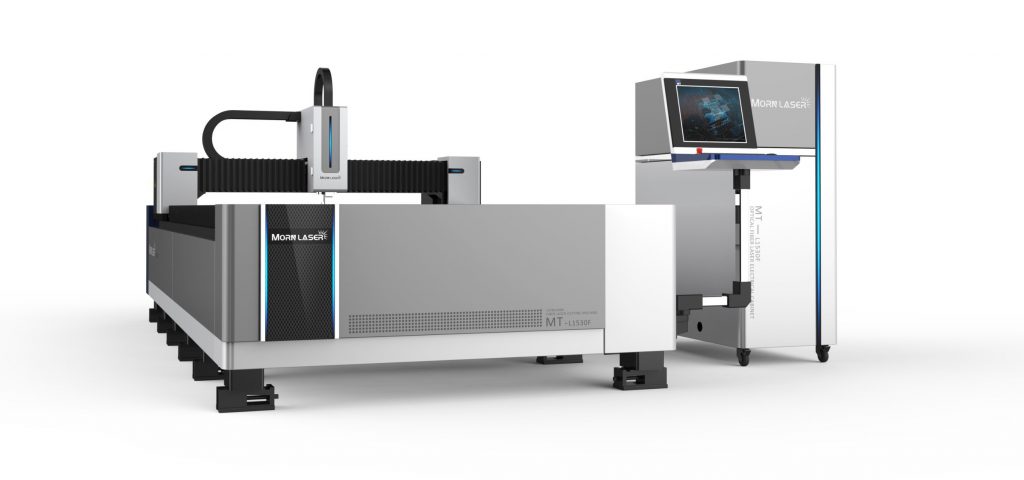

Machine overview

The fiber laser cutting machine is to focuses the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, so as to achieve the purpose of cutting.

Machine Data

| NAME | LASER CUTTING MACHINE |

| MODEL | HN-1530-1000W |

| Maximum running speed | 90m/min |

| Laser wavelength | 1080 nm |

| Minimum cutting line width | 0.1mm |

| Rated output power | 50–1000W |

| X, Y-axis positioning accuracy | ≤±0.015㎜ |

| Repeated positioning accuracy of the worktable | ≤±0.015㎜ |

| Maximum load of the worktable | 500KG |

| Effective processing area | 1500*3000mm, |

| Z-axis travel | 120mm |

| Area | 4.5*2.5*1.5m |

| Machine power | 12KW |

| Chiller | 2kw |

| Power supply | 380v±10% |

| Red light positioning | provide |

380V Max Raycus Source Raytools Cnc Laser Cutting Machine 1500x3000Mm

| Cooling Mode: | Water Cooling With Water Chiller Hanli | Cutting Thickness: | 0-2.5cm |

|---|---|---|---|

| Graphic Format Supported: | DXF, AI | Control Software: | Cypcut |

| Cutting Area: | 1500×3000 Mm | Color: | White & Gray |

| Function: | Cutting Metal Materials | Laser Power: | 1000W |

| High Light: | Raytools Cnc Laser Cutting Machine , 1500x3000Mm Cnc Laser Cutting Machine , 380V Cnc Laser Cutting Machine | ||

Product Description

1500 X 3000 Mm 380 V Max Raycus Source ray tools Cnc Laser Cutting Machine

Machine overview

A fiber laser cutting machine is a laser cutting machine using fiber laser as the light source.

Machine Data

| Crossbeam | Aluminum profile beam |

| Laser | 1000W |

| Cutting head | Au3tech |

| Control System | Au3tech |

| Guide | IKIO |

| Rack | IKIO |

| Reducer | Oriental Plant |

| X axis servo motor | WEICHI |

| Y axis servo motor | WEICHI |

| Z axis servo motor | WEICHI |

| Chiller | HK |

| Electrical control | CHINT |

| Proportional valve | SMC+CKD |

| Computer | Industrial PC |

| Sheet metal appearance | Independent research and development |

| Other standard configuration | Protective glass |

| Focusing lens | |

| Collimator | |

| Copper mouth, protective lens | |

| Toolbox | |

| Protective glasses |

Learn more about laser machines >>>

1kw 2 Kw 3 Kw 3015 380V Fiber Cnc Laser Cutting Machine Support CAD

| Product Name: | Fiber Cnc Laser Cutting Machine | Warranty: | More Than 12 Months |

|---|---|---|---|

| Cutting Area: | 3000*1500 MM | After-Sales Service Provided: | On-Line Or Videos |

| Color: | Customized | Power Supply: | 380V/50HZ/60HZ/60A |

| Type: | Fiber Laser Cutting | Function: | Cutting Metal Materials, stainless Carton Steel |

| High Light: | 380V Steel Metal Cutter, 3Kw CNC Laser Cutting Machine, CAD CNC Laser Cutting Machine | ||

Product Description

1kw 2 Kw 3 Kw 3015 380V Fiber Cnc Laser Cutting Machine Support CAD

Machine overview

Fiber laser metal cutting machine. integration of fiber laser and digital controlling, which represents the advanced technology of laser cutting. This machine adopts an imported manipulator, laser beam guiding device is fully integrated in robot arm which combines the advantage of stable laser and moving robot arm.it can realize arbitrary and special curves processing in 3D space.Fiber laser metal cutting machine, Easy to operate, higher automation, less cycle time ensure the machine’s fast-moving, high precision and reliability

Machine Data

| Model | HN-3015 |

| Working area | 3000mm x 1500mm |

| Laser type | Fiber laser |

| Rated laser power (optional) | 1000W |

| Traditional system | Gantry double drive structure |

| Lubrication system | Fully automatic |

| Maximum speed | 100m/min |

| Maximum acceleration | 1.0G |

| positioning accuracy | ±0.01mm/1000mm |

| Repeated positioning accuracy | ±0.03mm/1000mm |

| Support for graphic formats | CAD, DXF(etc) |

| work environment | 0-40 ℃, humidity ≤ 80%, no condensation |

| Total power | 20KW |

| Power demand | Three-phase 380V / 50Hz / 60Hz |

| Outline size | 4450mm x 2450mm x 1800mm |

| Total weight approximately | 4000KG |

Application

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet(tube),Mild Steel Plate(tube),Alloy Steel Plate,Spring Steel Sheet(tube),Iron Plate(tube),Galvanized Iron(tube),Galvanized Sheet,Aluminum Plate(tube),Copper Sheet(tube),Brass Sheet,Bronze Plate,Gold Plate,Silver Plate(tube),Metal Plate,Tubes and Pipes,etc.

Fiber Laser Cutting Machine is widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Learn more about this machine >>>

DMC5040LW new type double heads vertical and horizontal machining center

this machine can work through vertical type and horizontal type working way. Its Main feature:1). More function, higher productivity; 2). Save your work shop’s room, the small workshop can also use it; 3). Save your money, the price of this machine is far lower than the price of two set machining center. 4).because of new machine, and so it has good market potential, you resale it easier.

| Item | Model | DMC5040 | |

| Turntable

| Working table | 500*500mm | |

| T slot | 3X18H7 | ||

| Load capacity | 350KGS | ||

| Type | vertical type | horizontal type | |

| Travel | X/Y/Z moving range | 500/500/650mm | 500/650/500mm |

| Distance from the centerline of the central axis to the centerline of the worktable | -200~300mm | 100-750mm | |

| Distance from spindle head to the worktable | 90-740mm | 75~575mm | |

| Spindle | Spindle taper | BT40 | |

| Spindle power | 5.5KW/7.5KW | ||

| Speed range of spindle | 6000RPM/8000RPM(option) | ||

| Tool magazine | Tool shank | BT40 | |

| Speed of change tool | 2 Sec | ||

| Tool magazine capacity | 20 tools (disc type) | ||

| Accuracy | Positioning accuracy | 0.01mm | |

| Repeated Positioning accuracy | 0.006mm | ||

| other | N.W | 8000kgs | |

| unit price | CNC system | KND (option) | |

Learn more about this machine >>>

CK35LATC turn-mill CNC lathe machine

CK35LATC type cutter CNC turning and milling slant bed CNC lathe, with the advanced level of international similar products as the target, which is designed and developed by our company. The Lathe has a horizontal CNC tool holder and a powered spindle with a tool magazine. The conventional horizontal tool holder can be equipped with conventional tools for turning. The power spindle can be equipped with BT30 common tools for milling and drilling. Tool magazine can install 6/8 tools, thus could meet machining needs.

| Item | Content | Unit | Specification |

| Ability | Max. swing over bed | mm | Φ350 |

| Max. swing over slide | mm | Φ190 | |

| Max. Cutting diameter | mm | Φ320 | |

| Max. turning length | mm | 300 | |

| Drive spindle | Spindle end flange | No | A2-6 |

| Thru-hole diameter | mm | Φ56 | |

| Main motor power | KW | 5.5/7.5 or 3.7/5.5 | |

| Spindle speed range | r/min | 45-4500 | |

| Spindle max. output torque | N.m | 24 | |

| Feed | X/Y/Z axis feed rate(Y axis is power milling head feed) | M/min | 24/18/30 |

| X-axis max. travel | mm | 600 | |

| Z-axis max. travel | mm | 350 | |

| Y-axis travel | mm | 120-370 | |

| X/Z axis servo motor | Nm | 7.5/7.5 | |

| Power spindle ︵ C Axis ︶ | Spindle type | BT30 belt type | |

| Pull nail form | BT30-45° | ||

| Rotating speed | 3000r/min(Rigid tapping) | ||

| Torque | Nm | 15 | |

| Power | kW | 1.2 | |

| Loose force | N | 9000 | |

| Tool magazine type | BT30-06/BT30-08 | ||

| Tool change time | s | 0.5 | |

| Power spindle swing head ︵ A axis ︶ | Stroke | degree | 0°-90° |

| Minimum index unit | degree | 0.001° | |

| Rotating speed | r/min | 33.3 | |

| Segmentation accuracy | ±15 Angular second | ||

| Repeatability | ±2 Angular second | ||

| Rotary torque | Nm | 600 | |

| Power | kW | 0.75 | |

| Tool holder | Tool holder type | horizontal | |

| Tool holder positions | position | 8 | |

| Turning tool specifications | mm | 25×25 | |

| Maximum boring bar diameter | mm | Φ16 | |

| Other | Lathe length | mm | 2550 |

| lathe(length x width x height) | mm | 2550*2150*2200 | |

| Machine weight | t | 3 | |

| CNC system | FANUC 0i TF |

GMC1090G High-speed mini CNC gantry machining center

The gantry machining lathe is a kind of gantry frame type machining center with a fixed beam and removable workbench. On the basics of strong rigidity and good stability of traditional gantry, it absorbs the advanced design concept. By using the methods of the finite element to analyze mechanics, and distribute the rebar and mass reasonably, it can make the whole lathe’s rigidity strong and make static precision and dynamic performance stable and reliable.

| Item | Unit | GMC1090G |

| Worktable size | mm | 900×1000 |

| T slot size | mm | 4-22 -100 |

| Max. load | kg | 1000 |

| X travel | mm | 900 |

| Y travel | mm | 1000 |

| Z travel | mm | 650 |

| Distance from spindle nose to table | mm | 50-650 |

| Distance between two column | mm | 1100 |

| Spindle speed | r/min | 15000 |

| Spindle tapper | Hvct(Electric Spindle, Motor Spindle),BT30 | |

| Motor power | kw | 5.5 |

| X/Y rapid travel speed | m/min | 30 |

| Z rapid travel speed | m/min | 20 |

| Cutting feed | mm/min | 5-15000 |

| Guideway | X/Y/Z linear guideway | |

| X/Y/Z Positioning accuracy | mm | 0.012 |

| X/Y/Z Re-positioning accuracy | mm | 0.006 |

| Tool magazine | 20 | |

| Max. diameter/ length | mm | Φ30/ Φ80 |

| Tool max. weight | kg | 8 |

| Machine N.W | t | 7 |

| L*W*H | mm | 2500x3000x2500 |

Learn more about this machine >>>

OPTIFLEX

The OptiFlex is a high-performance, large-format CO2 laser cutting and engraving system. This is the most popular and versatile machine in Kern’s product line.

OPTIFLEX STANDARD FEATURES

The following features come standard with the OptiFlex CO2 Laser:

- USA-Made Laser Source

- HyperDual Servo Motion Package

- Blower Package/Vacuum Table

- High-Performance Computer and LCD Monitor

- 2.5” S-Focus Optics Assembly

- Laser Tool Kit

- Closed Loop Chiller

- KCAM Laser Software

- CorelDRAW Graphics Suite

- UL Certified Electrical Panel

- Steel Chassis

- 2 Days of In-House Training at Kern

OPTIFLEX OPTIONAL FEATURES

The following features are optional add-ons to the OptiFlex CO2 Laser:

- Metal cutting option

- K-Vision camera registration

- Rotary device

- Fume extraction unit

- 1.5”, 5” and 7.5” FL optic assemblies

- PhotoGRAV Software

- On-site installation and training

LC1390N Laser Cutting Machine

Technical Parameters

| Laser – Type | Sealed CO2 laser tube |

| Laser power | 80W 100W 130W 150W 200W (optional) |

| Cutting Area | 1300mm x 900mm |

| Whole Machine Size | 1820* 1310* 1070mm |

| Cutting Speed | 0 – 24,000mm/min |

| Resetting Positioning Accuracy | ±0.05mm |

| Working Voltage | AC 110 -220V±10%, 50-60Hz |

| Gross Power | <1,500W |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Work Table | 18cm lift platform |

| Driving System | stepper |

| Cooling Mode | water-cooling and protection system |

| Auxiliary Equipments | Exhaust-fans, air-exhaust pipe |

| Controlling Software | DSP control system |

| Compatible Software | CorelDraw AutoCAD Photoshop |

STORM600 CO2 Laser Cutting Machine

Technical Parameters

| Laser – Type | Sealed CO2 laser tube |

| Laser Power | 40w 60w |

| Engraving Area | 600mm x 400mm |

| Worktable | Manual up-down table |

| Whole Machine Size | 950mm x 740mm x 450mm |

| Engraving Speed | 0-48,000mm/min |

| Resetting Positioning Accuracy | ±0.05mm |

| Working Voltage | AC 110-220V ±10%, 50-60Hz |

| Gross Power | <1000w |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Graphic Format Supported | BMP, PLT, DST, DXP, and AI |

| Driving System | stepper |

| Cooling Mode | Water-cooling and protection system |

| Auxiliary Equipments | Exhaust-fans, air-exhaust pipe |

| Controlling Software | DSP control system |

| Compatible Software | CorelDraw AutoCAD Photoshop |

LC1390 Laser Cutting Machine

Technical Parameters

| Laser – Type | Sealed CO2 laser tube |

| Laser Power | 80w |

| Cutting Area | 1300mm x 900mm |

| Whole Machine Size | 1820* 1310* 1070mm |

| Cutting Speed | 0 – 24,000mm/min |

| Resetting Positioning Accuracy | ±0.05mm |

| Working Voltage | AC 110 -220V±10%, 50-60Hz |

| Gross Power | <1,500W |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Minimum Shaping Character | English 1x1mm |

| Work Table | 18cm lift platform |

| Driving System | stepper |

| Cooling Mode | water-cooling and protection system |

| Auxiliary Equipments | Exhaust-fans, air-exhaust pipe |

| Controlling Software | DSP control system |

| Compatible Software | CorelDraw AutoCAD Photoshop |

Learn more about lasers

CO2 Laser machines review. TOP-26 Co2 machines – best picks!

All you need to know before buying a laser or an engraving / cutting machine

Comparison of a different types of lasers and different wavelength