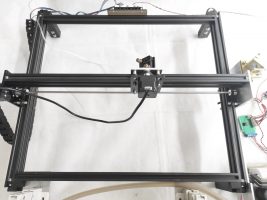

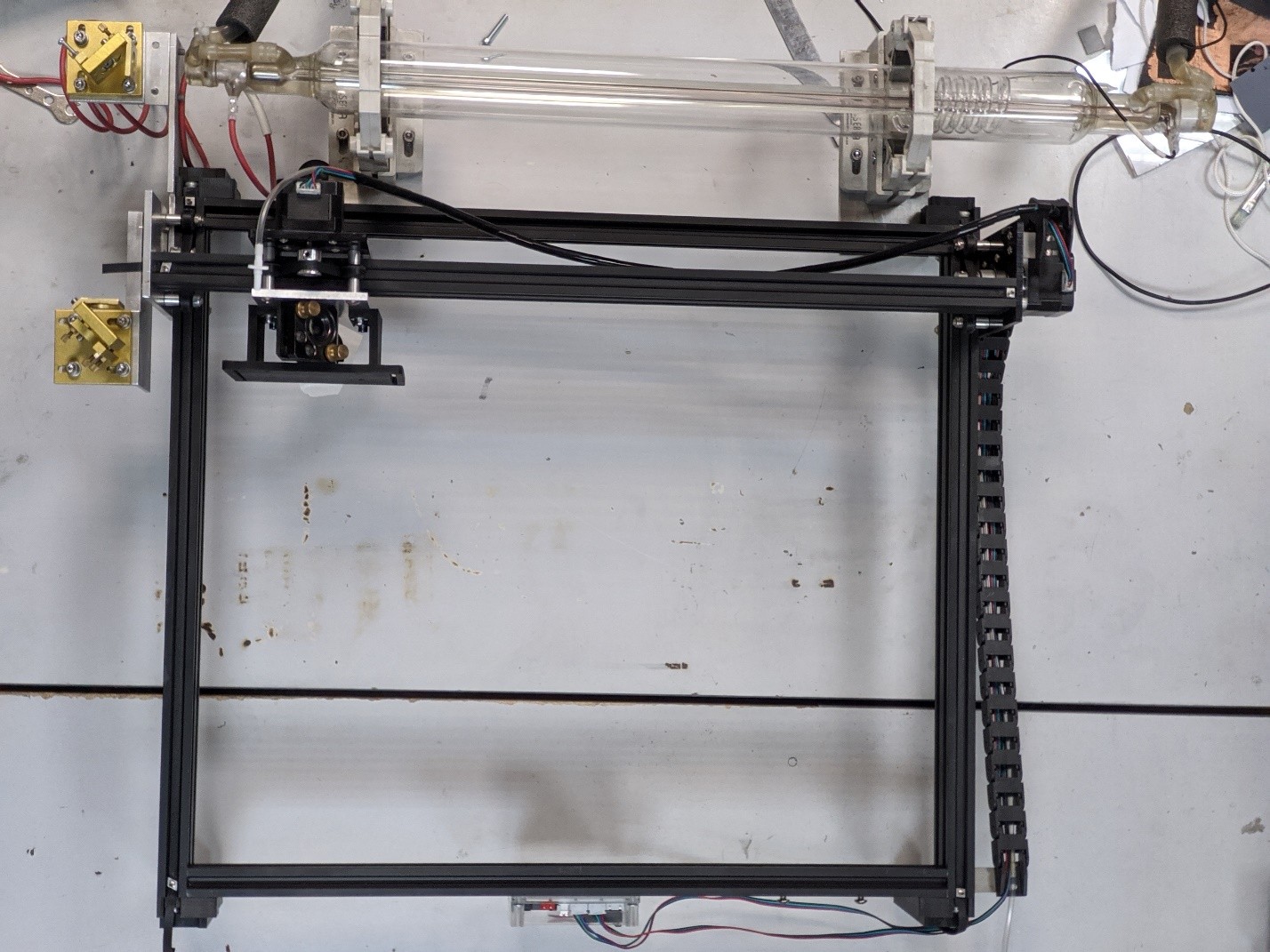

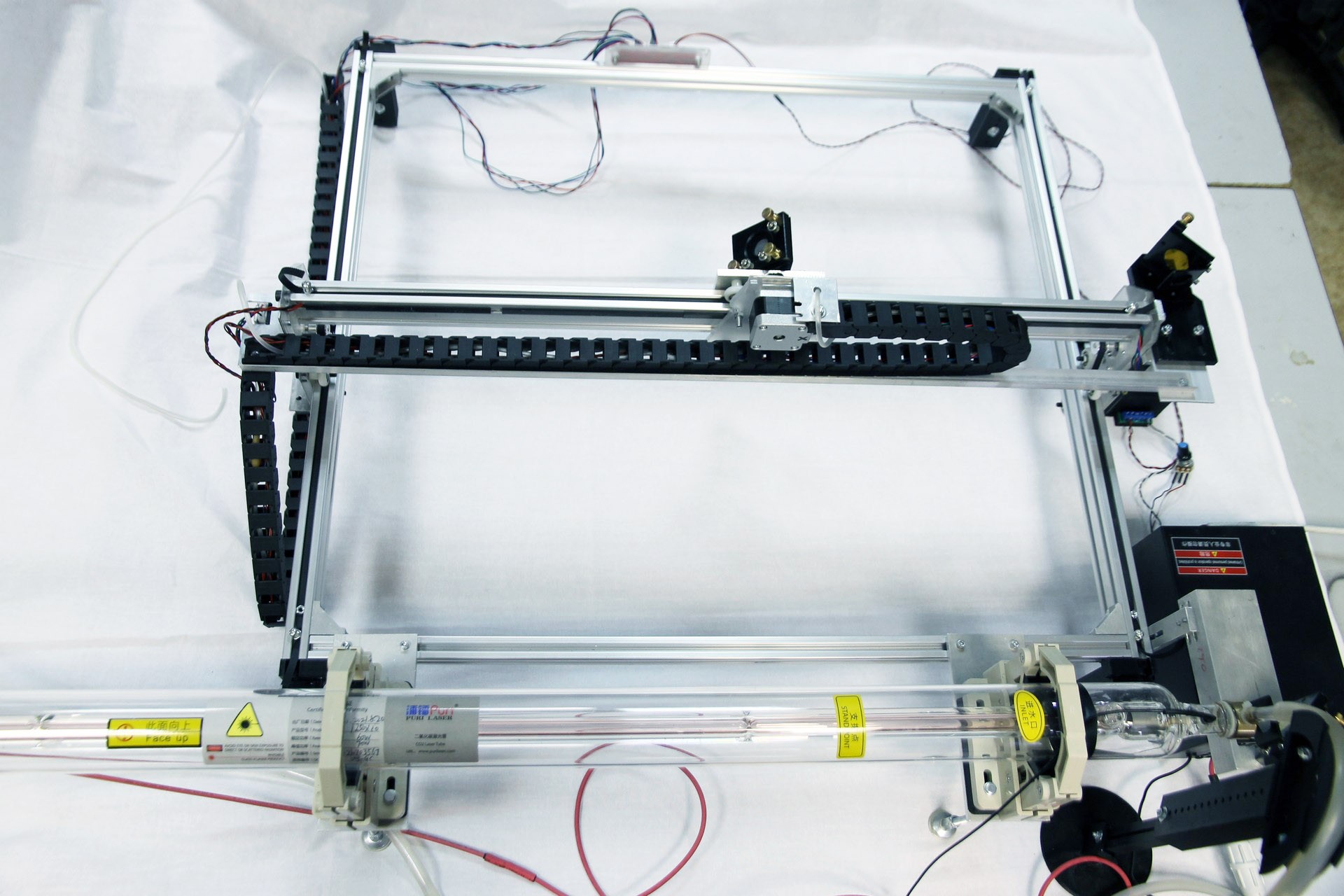

A Co2 DIY laser upgrade kit – 40 / 80 / 150 watt power output. Add a laser cutting and laser engraving abilities to your existing frame.

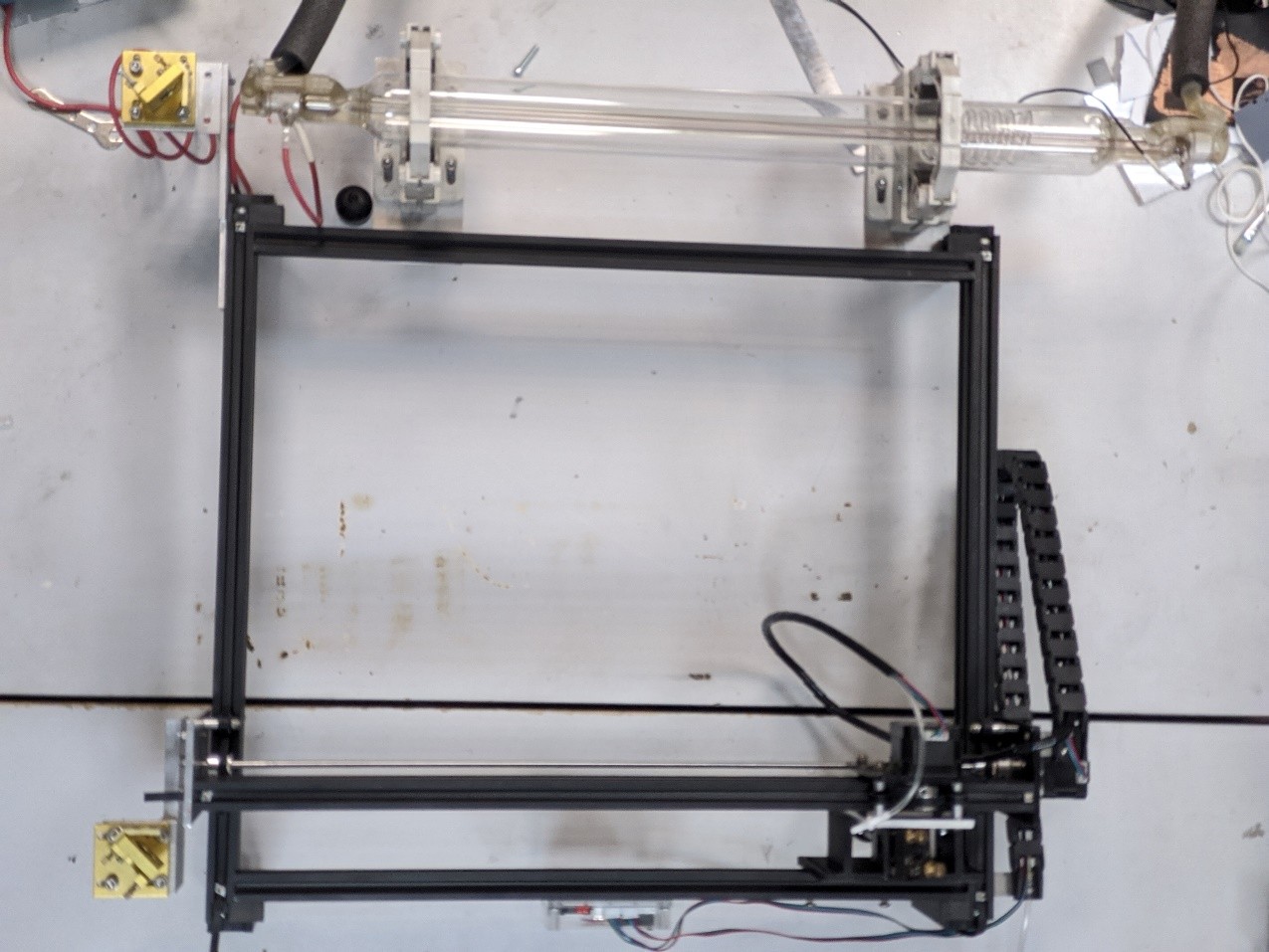

Upgrade your existing engraving frame with an Endurance Co2 upgrade kit.

Compatible with: Eleksmaker, Ortur, CNCC Laseraxe, WainLux, Neje, SainSmart (Genmitsu), Acan and other GRBL compatible frames.

To upgrade any 3D printer / CNC frame / engraving machine with a Co2 tube you need to follow a few simple procedures.

- You need to get all Co2 components ready.

- You need to setup a tube (fix it tightly).

- Add mirrors.

- Install the focusing lens into the nozzle.

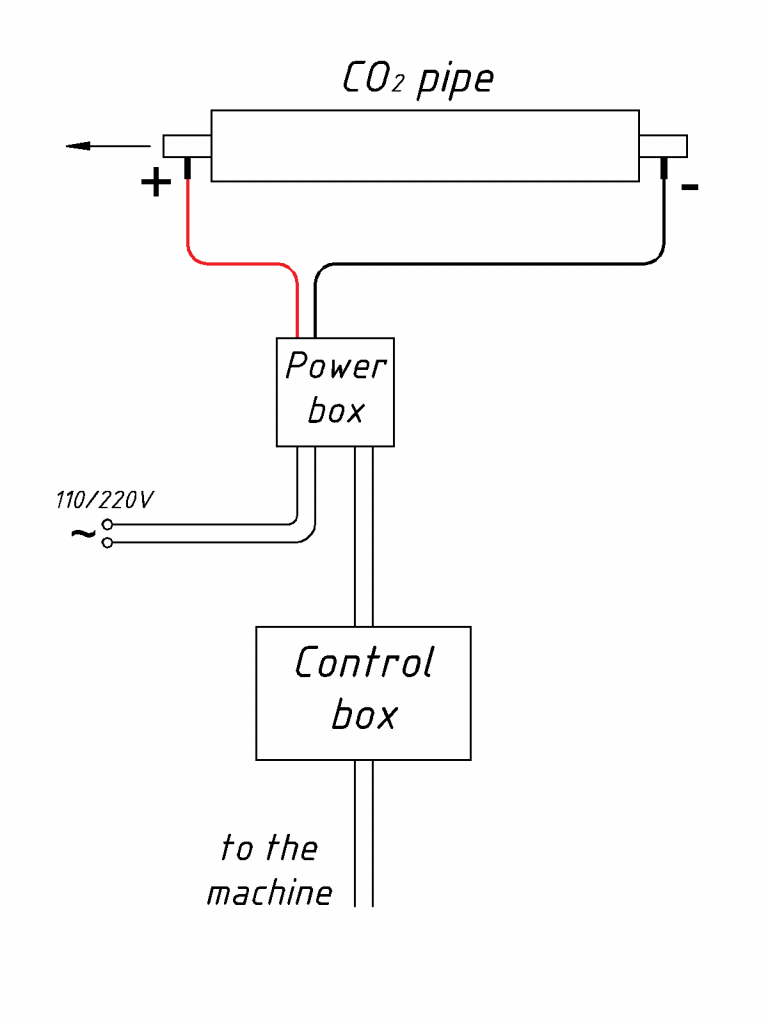

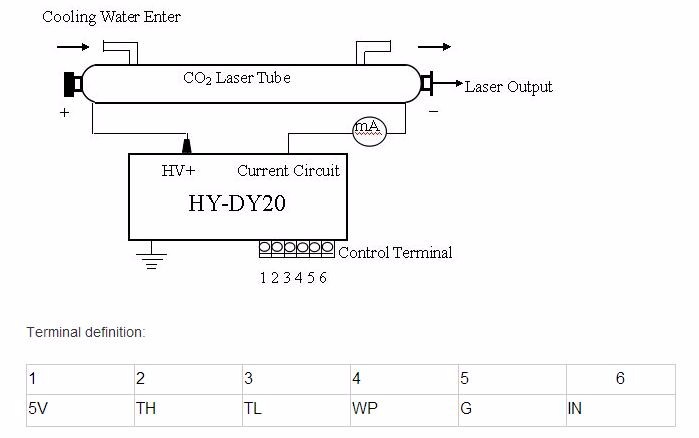

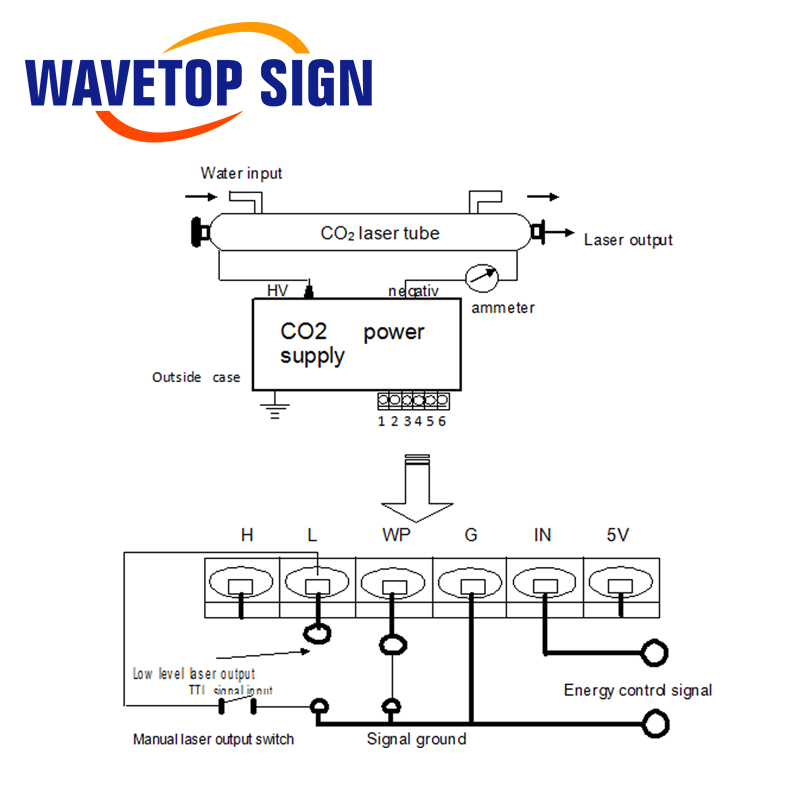

- Connect all electronics to the GRBL board and a power supply.

- Align mirrors to make sure that the laser beam goes through the focusing lens.

- Add an air compressor.

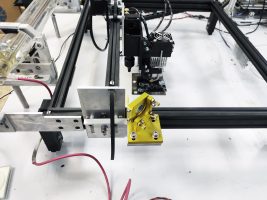

Adding 15 watt (15000 mw) DIY DUOS on the frame

What Endurance lasers deliver in our upgrade kit :

:

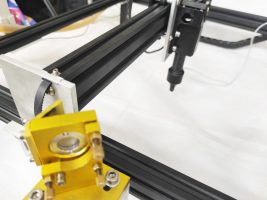

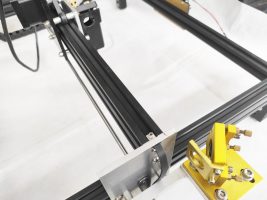

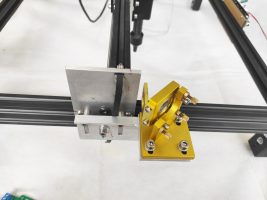

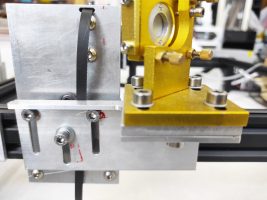

- Mounts and brackets for:

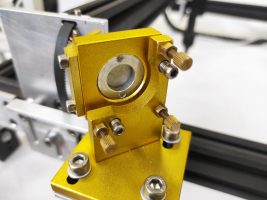

- Mirrors

- Co2 Tube

- A focusing lens with an air nozzle

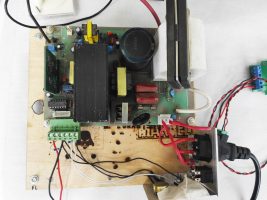

- Electronics box.

- Including high-voltage power supply

- Converter for GRBL board

- Short pulses board for the alignment process

- A detailed guide and full tech support about installation and wiring

If you have more questions – ask in our LiveChat

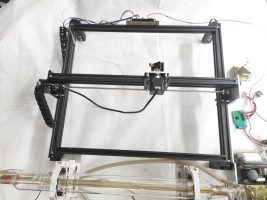

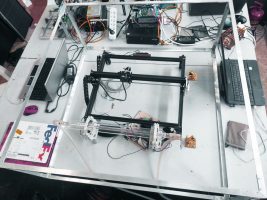

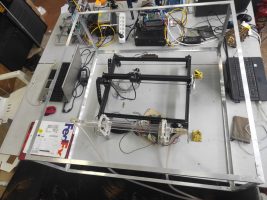

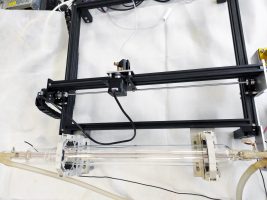

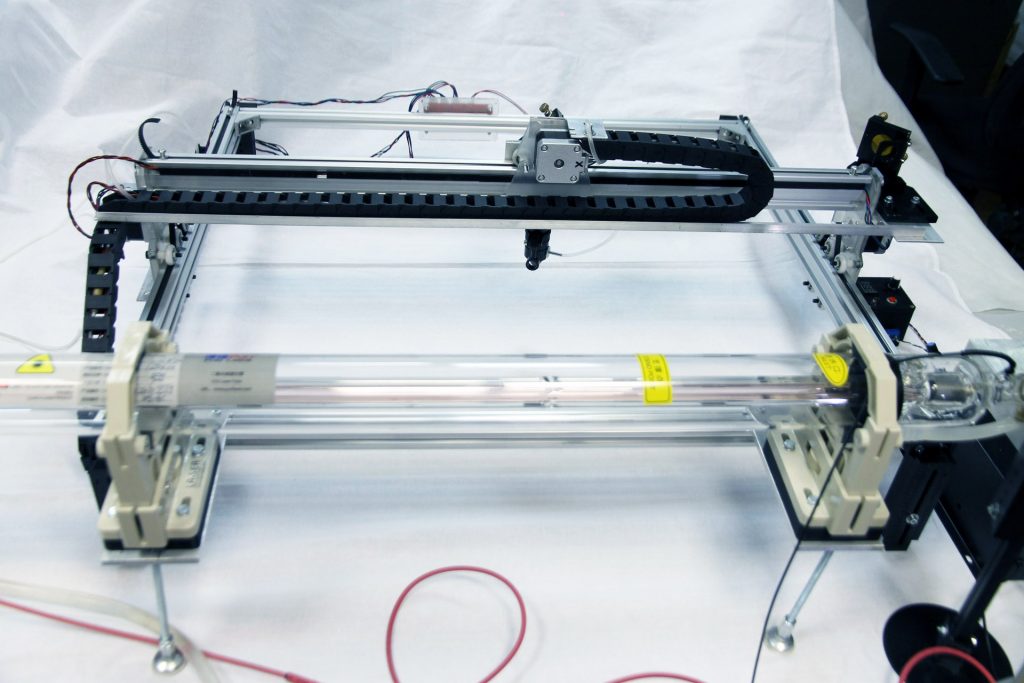

Installing a Co2 tube on LE5040 engraving machine

Replacing a diode laser with a Co2 tube

Laser cutting / engraving table (speed, power, loops)

| Material | Speed, mm / min | Power, % | Extras |

| Plywood 3mm (3/16”) | 350 | 100 | + air assist |

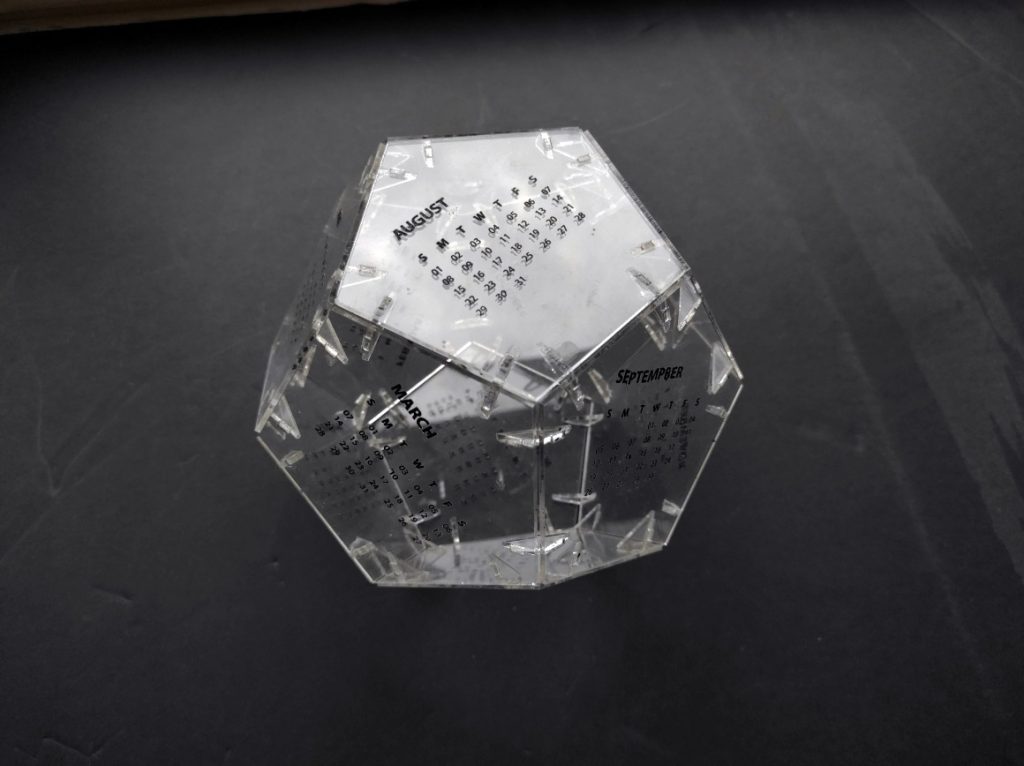

| Acrylic 3 mm (3/16”) : Cut Engraving | 380 10000 | 100 20 | + air assist + fume extractor |

| Acrylic 6 mm (1/4”) Cut Engraving | 300 8000 | 100 45 | + air assist + fume extractor |

| Glass Engraving Paint removal | 10000 | 25 | 0.1 mm line frequency |

| acrylic 4 mm painted in black | 500 | 100 | + air assist + fume extractor |

Our first launch of an Endurance 40 watt Co2 upgrade kit (LE5040 SainSmarkt engraving machine was upgraded with a Co2 tube)

Photoengraving on painted (black) glass

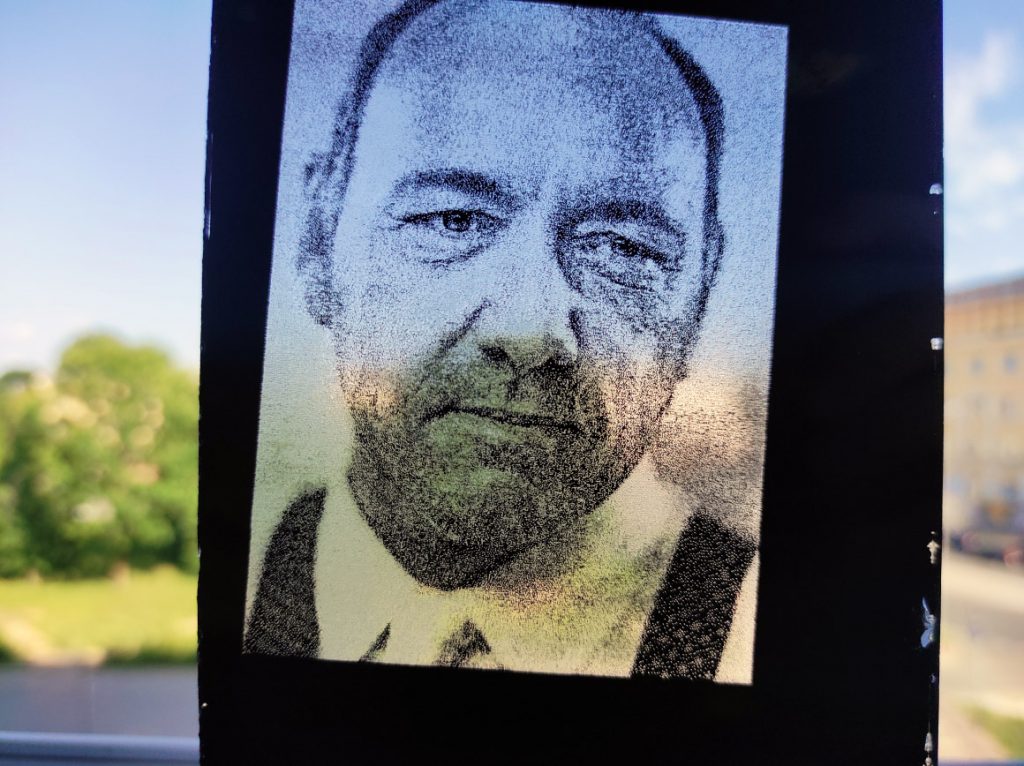

Photoengraving on a transparent acrylic (Michael Douglas)

Laser-cut (3 mm birth plywood)

g-code examples (download free g-code for GRBL 1.1H firmware)

Laser-cut (3 mm transparent acrylic)

Download free g-code of chess

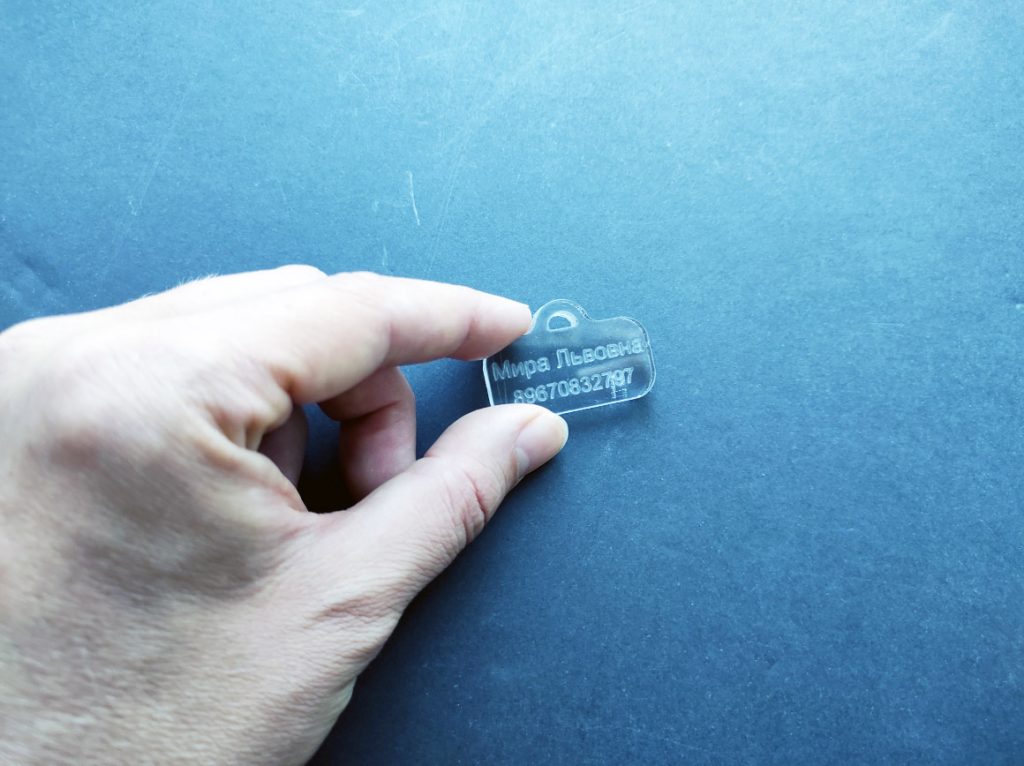

6 mm transparent acrylic (plexiglass) a DIY dog’s tag

Engraving on transparent glass (beer mugs)

Get all parts that you need to make your Co2 machine.

Upgrade your frame with 40 watt Co2 tube. Convert your frame into Co2 laser cutter/engraver.

What do we need to make the first launch of the machine:

- Co2 tube

- High voltage power supply

- Water pump

- Water tubes

- mA ammeter

- Switch

- Potentiometer

- Mirrors

- Focusing lens

- Co2 nozzle

- Thermometer

- Some wires and aluminum sheets.

What we ship in the package.

- High voltage power supply for a Co2 tube

- Water TEC cooler (Peltier) for Co2 tube

- Silicone water tubes.

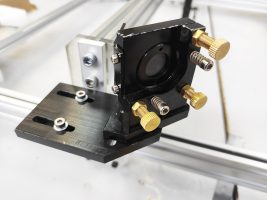

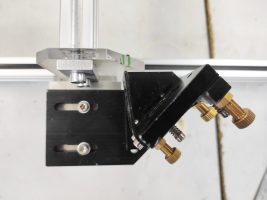

- Mirrors + focusing lens with an air nozzle.

- Holders for mirrors + mounts.

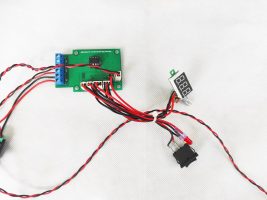

- Dynamic PWM box.

- Co2 tube holder + mounts

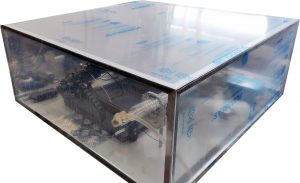

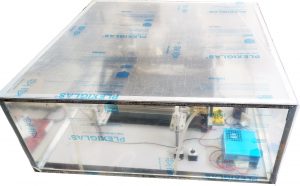

- Aluminum frame (for protective enclosure)

An Endurance DIY Co2 laser kit for upgrading your CNC / 3D Printer / engraving machine.

What else do you need:

- 40 watt Co2 tube [necessary].

- Air compressor (0.05-0.1MPA with 70-200 L / min capacity) [optional].

- Acrylic / plexiglass plates to cover the frame [necessary].

- Fume extractor [optional].

Laser engraving test – Comparing Beamo Flux with an Endurance DIY – checking engraving “waves”

That is it to get started.

Co2 tube – make sure it has no damages. Glass is very fragile and has to make sure it is in a good condition

A high voltage power supply is needed to blast the Co2 tube. Make sure that you need a high-voltage power supply especially for the Co2 tube wattage you have.

Water pump – you may use a car washer pump to get started.

Water tubes – since the water will be under high pressure you need to make sure that is can be connected tightly and we recommend using silicone wires.

mA ammeter is needed to be able to setup proper current. Keep in mind that since you have a very high voltage then the current is setup in mA, which is 1^-3

Switch – is needed to be able to turn on/off the laser, sometimes you can have a more complex system

Potentiometer – is needed to be able to set up needed current, usually, a potentiometer should be in kOhm.

Once you setup all systems you would need to deliver the laser power and focus it at the end, therefore, you need some special Co2 mirrors and well as a focusing lens.

Schematic parameters:

| Length | 700mm (±10) |

|---|---|

| Diameter | 50mm |

| Power | 40W |

| Wavelength | 10.6μm |

| Laser Beam Diameter | 3mm |

| Length | 1250mm (±30mm) |

|---|---|

| Diameter | 80mm |

| Power | 80W (Peak power 90W) |

| Wavelength | 10.6μm |

| Laser Beam Diameter | 5mm |

| Length | 1650mm (±30mm) |

|---|---|

| Diameter | 80mm |

| Power | 150W (Peak power 160W) |

| Wavelength | 10.6μm |

| Laser Beam Diameter | 8mm |

Power parameters:

Current: 15 – 20 mA

Voltage: 21-25 kV

Measurements:

Water temperature < 30C

Laser components for 40/80/150/300 watt unit

| 40 watt | 80 watt |

| Co2 40 watt tube | Co2 tube EFR F2 80 watt (6000 hours) |

| Tube holder | Tube holder |

| Power source for 40 watt | Power supply 80 watt ES80 |

| Optics | Optics |

| Lens 12 mm ZnSe | Mirror holder 25 mm |

| Mirror 20mm Мо | Laser head for mirror 25 mm + lens 20 mm |

| Head for 12 + 20 mm | Mirror 25 mm |

| Mirror holder | Lens 20 mm |

| Water pump | Chiller CW-3000 |

| Compressor | Fume extractor ventilation 550 watt |

| Potentiometer | Compressor |

| Milliammeter | Potentiometer |

| Wires | Milliammeter |

| Stream measurement | Wires |

| Tubes | Tubes |

| Tube | Tube |

| Fitting for a head | Fitting for a head |

| 150 watt | 150 watt |

| Tube RECI W6 150 watt (10000 hours) | Tube RECI W6 150 watt (10000 hours) |

| Co2 tube holder | Co2 tube holder |

| Power supply for 150 watt Z150 | Power supply for 150 watt Z150 |

| Optics | Optics |

| Mirror holder 25 mm | Mirror holder 30 mm |

| Laser head for mirror 25 mm + lens 20 mm | Laser head for mirror 30 mm + lens 25 mm |

| Mirror 25 mm | Mirror 30 mm |

| Lens 20 mm | Lens 25 mm |

| Chiller CW-5200 | Chiller CW-5200 |

| Fume extractor ventilation 550 watt | Fume extractor ventilation 550 watt |

| Compressor 012 | Compressor 012 |

| Potentiometer | Potentiometer |

| Milliammeter | Milliammeter |

| Wires | Wires |

| Tubes | Tubes |

| Tube | Tube |

| Fitting for a heads | Fitting for a heads |

| 300 watt | 300 watt |

| C 300 watt SLW TS300 | C 300 watt SLW TS300 |

| Power source 150 watt * 2 | Power source 150 watt * 2 |

| Optics | Optics |

| Mirror holder 30 mm | Mirror holder 30 mm |

| Head mirror 30 mm lens 25 mm | Head mirror 30 mm lens 25 mm with height regulation |

| Mirror 30 m | Height sensor |

| Lens 25 mm | Motor 42HS03 + driver DM542 |

| Chiller CW-5200 | Mirror 30 mm |

| Fume extractor ventilation 750 watt | Lens 25 mm |

| Compressor 016 | Chiller CW-5200 |

| Potentiometer | Fume extractor ventilation 750 watt |

| Milliammeter | Compressor 016 |

| Wires | Potentiometer |

| Tubes | Milliammeter |

| Tube | Wires |

| Fitting for a head | Tubes |

| Tube |

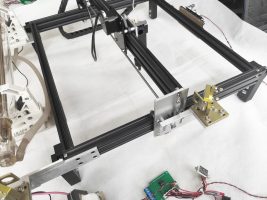

Assembling, tuning, and installation process

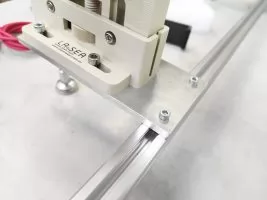

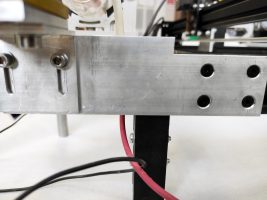

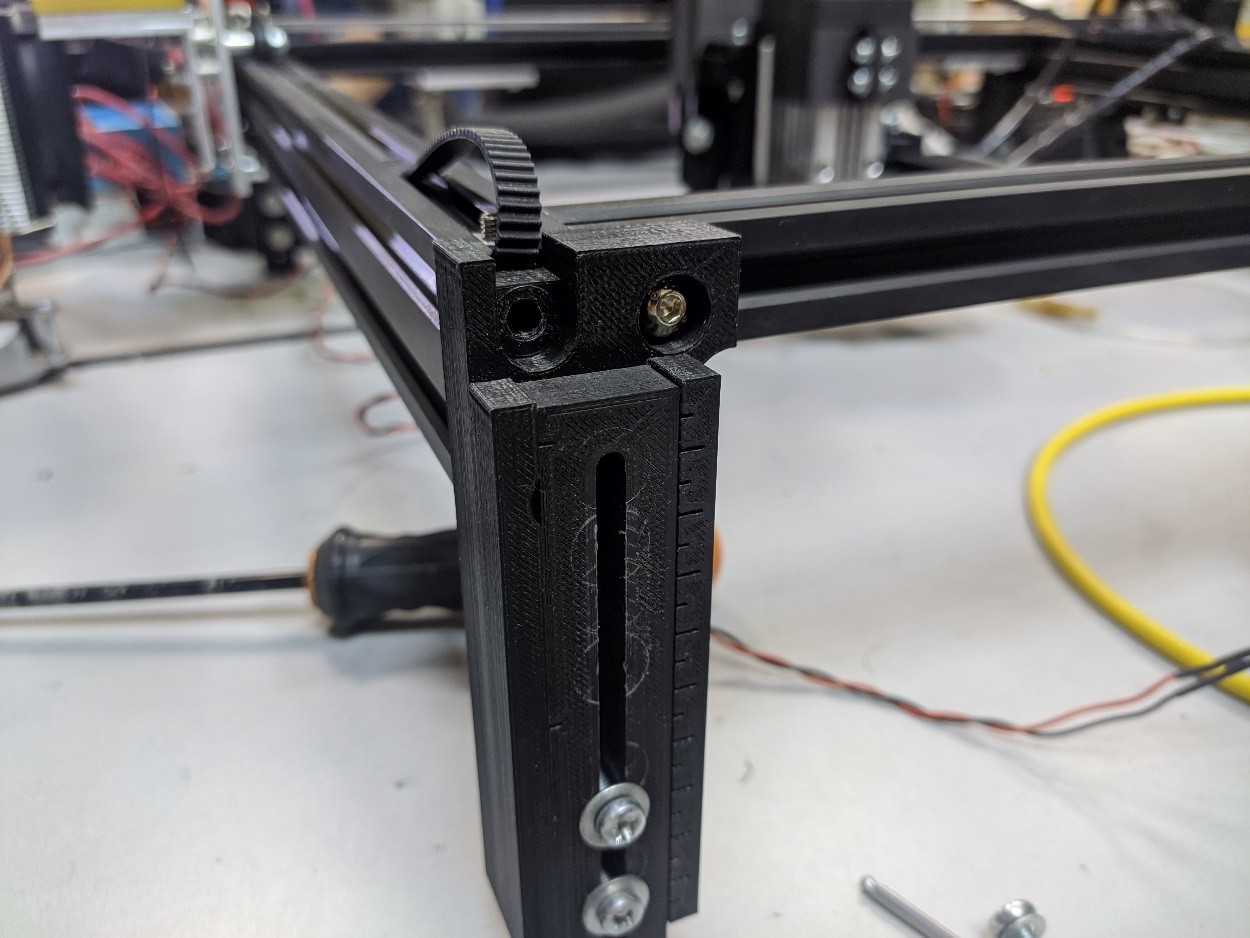

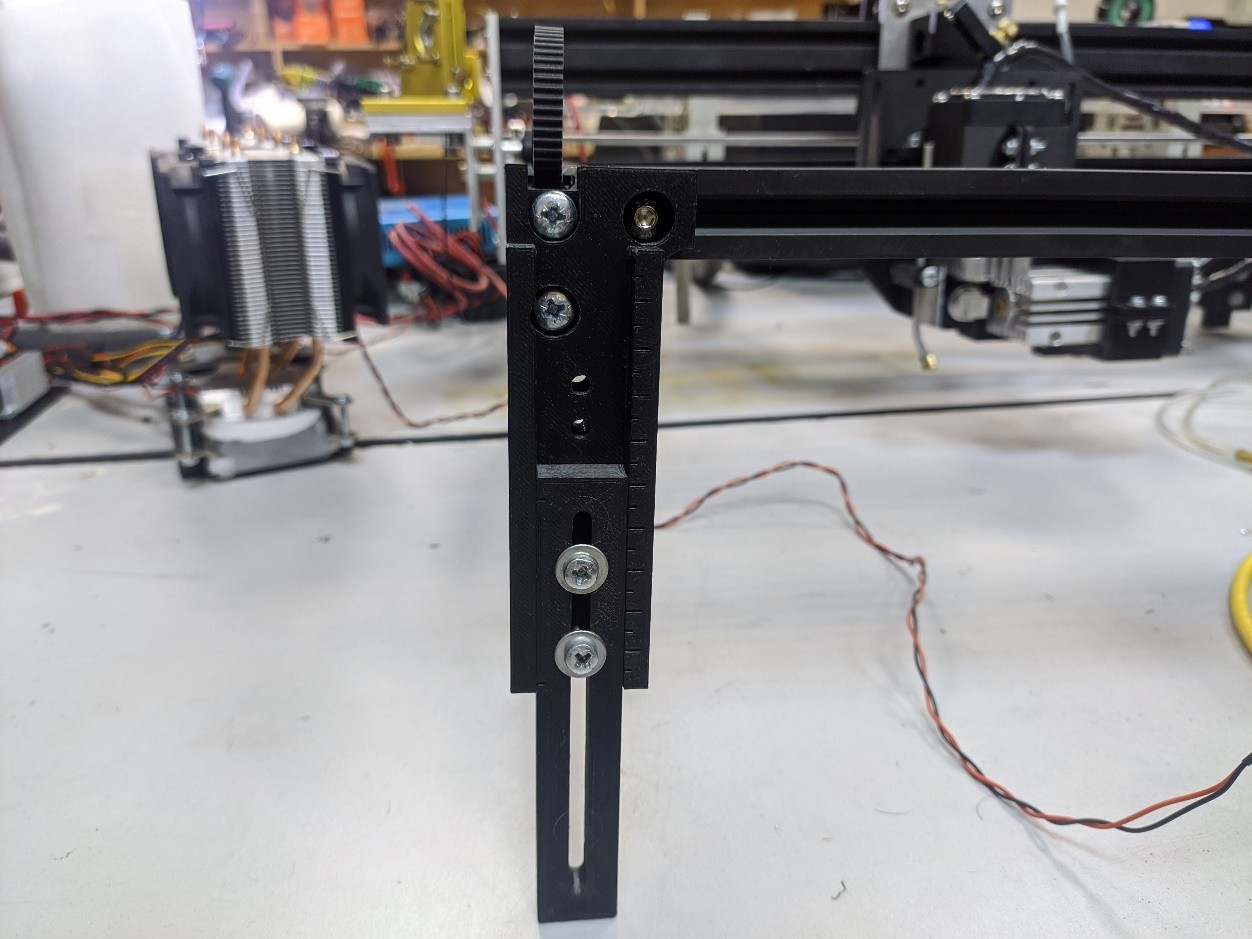

Installing the legs

To install the legs on the machine, you will need:

- Directly the leg.

- 2 screws for a screwdriver

- 1 screw for a 6гранный-face wrench

- Special nut

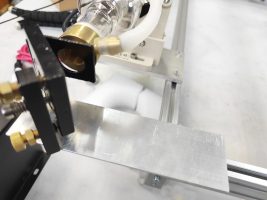

Install the hex screw in the upper right hole. And we screw a nut on it a little as in the photo.

We place the nut in the chute of the machine and tighten the hex screw. Now we are doing this so hard that we can still move the machine leg along.

We place the leg as shown in the photo. So that the holes on it match the holes on the machine.

Tighten the remaining 2 screws. Then tighten the hex screw.

Repeat steps 1.1-1.4 for the remaining legs of the machine. After that, you need to install the legs that support the laser tube.

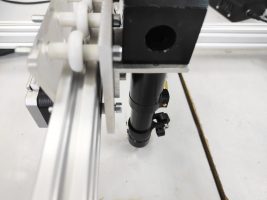

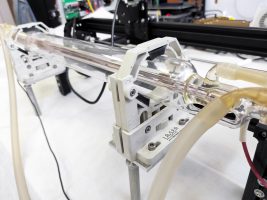

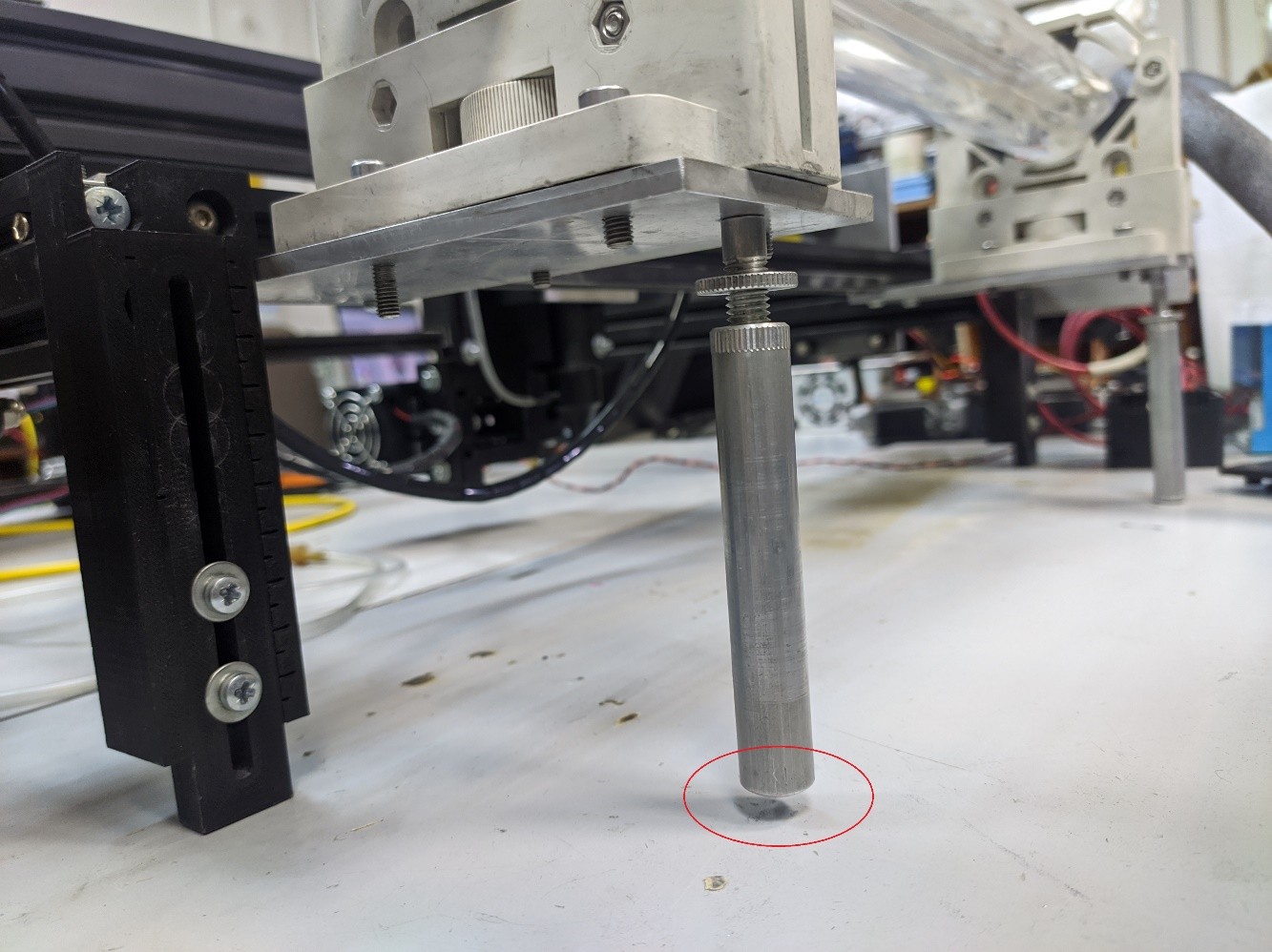

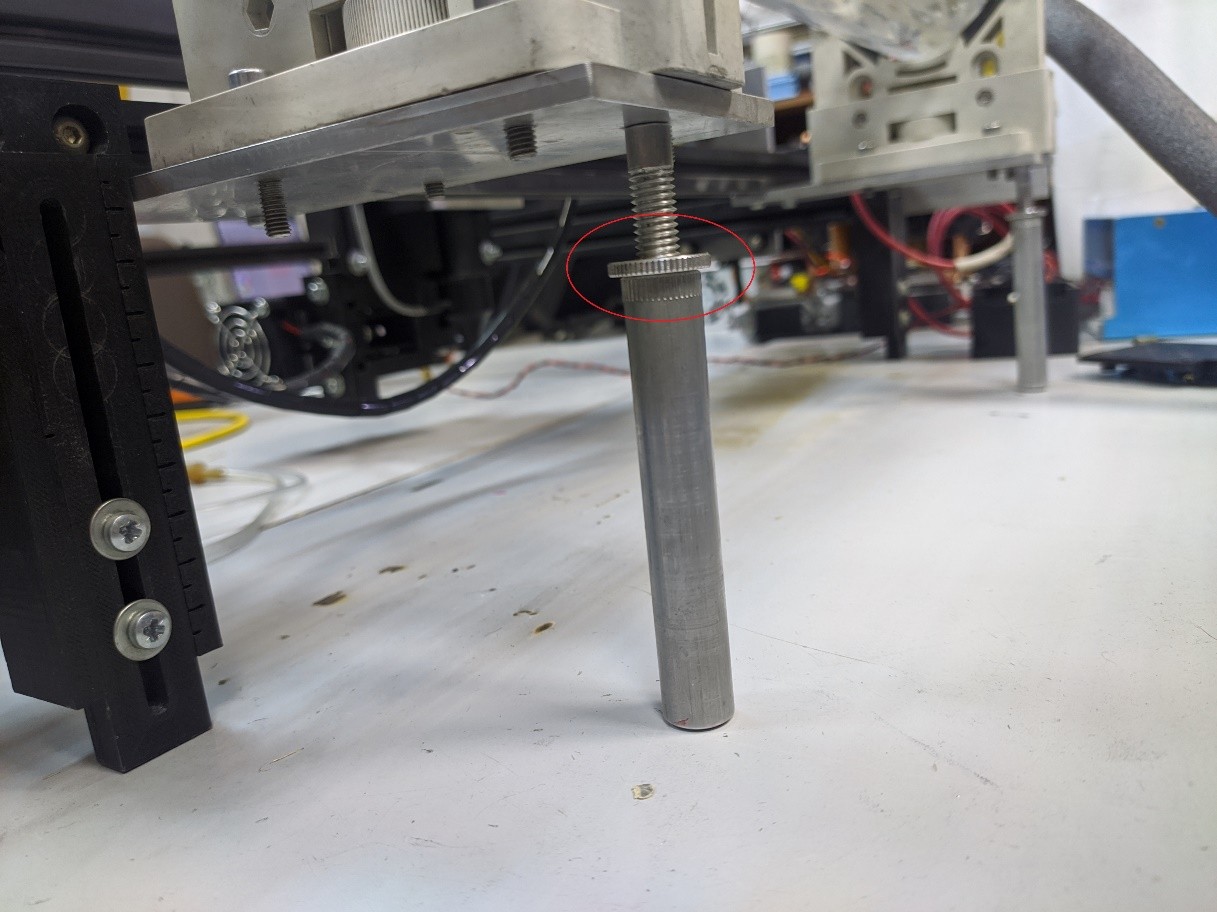

The legs that hold the tube are as follows.

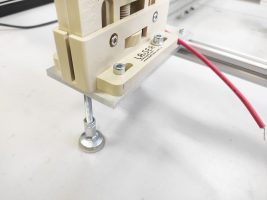

After that, we screw it into the hole at the bottom of the base of the tube. You can see it in the photo below.

After installation, it is possible that the legs will not be short. And will not support the tube (will not rest on the surface) just like in the photo. Or vice versa, they will be too long.

Then you will need to slightly unscrew or tighten it accordingly.

then-clamp with a contouring nut

When all the legs are set, you can move on to the next step.

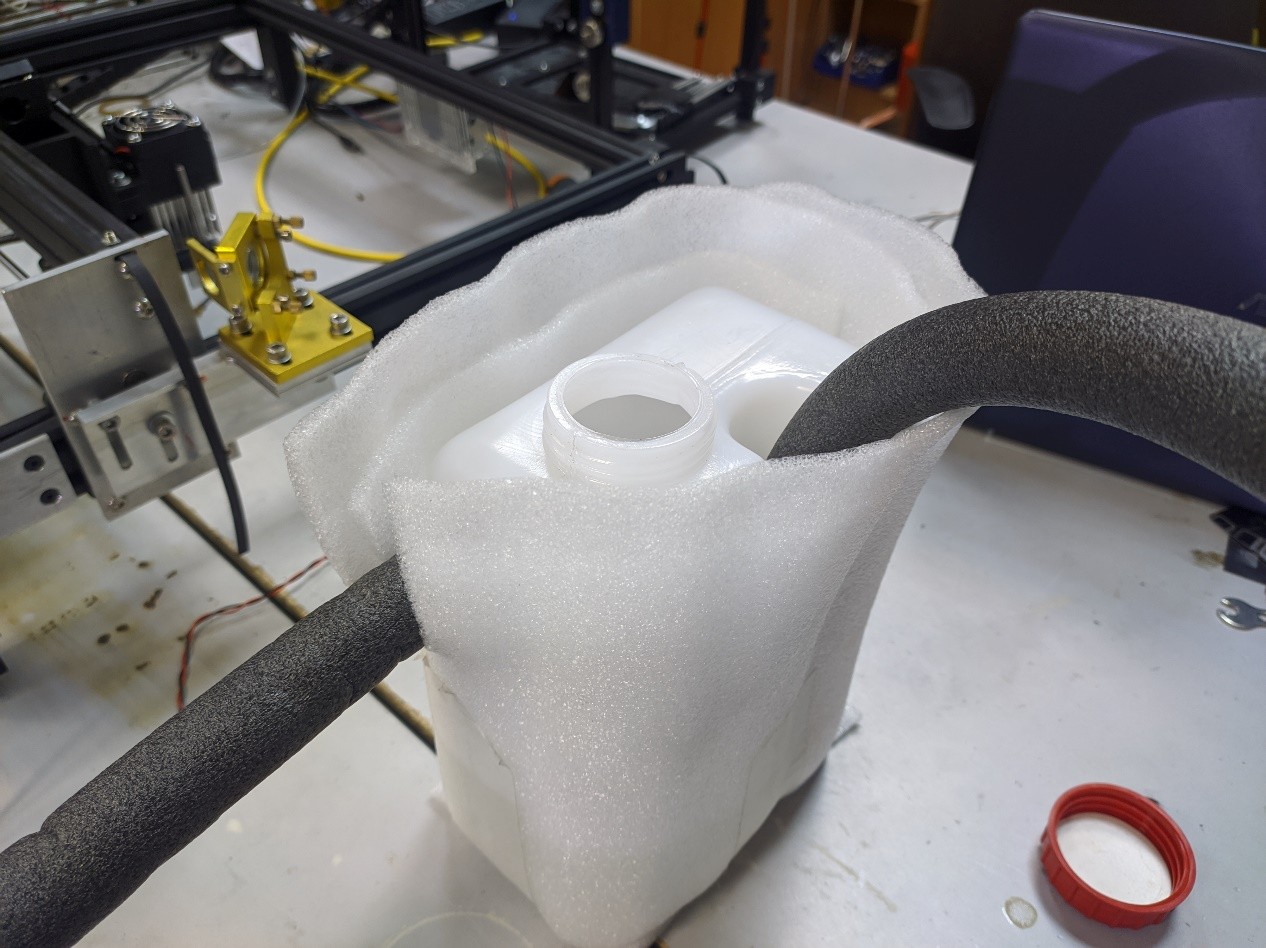

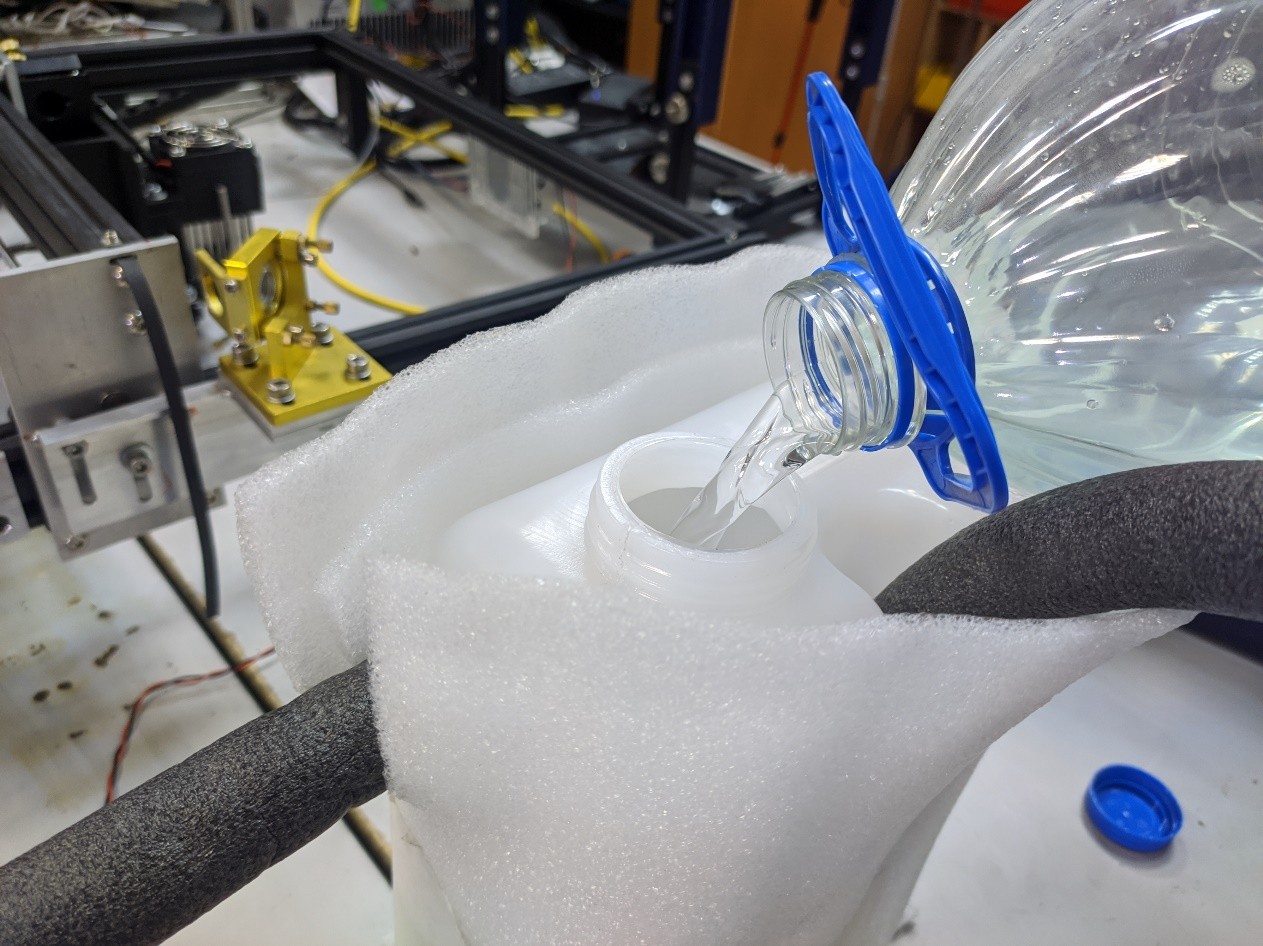

Fill in the water

Only DISTILLED WATER should be used as the cooling liquid.

You will need approximately 2 liters OF DISTILLED WATER.

Opening the lid

Fill in the water

Closing the lid

After pouring water, make sure that the water hoses are free of creases before turning on the pump. When the pump is turned on, when there is a hole on the hose, the load on the pump increases significantly. And the flow of water, and accordingly the cooling of the laser worsens.

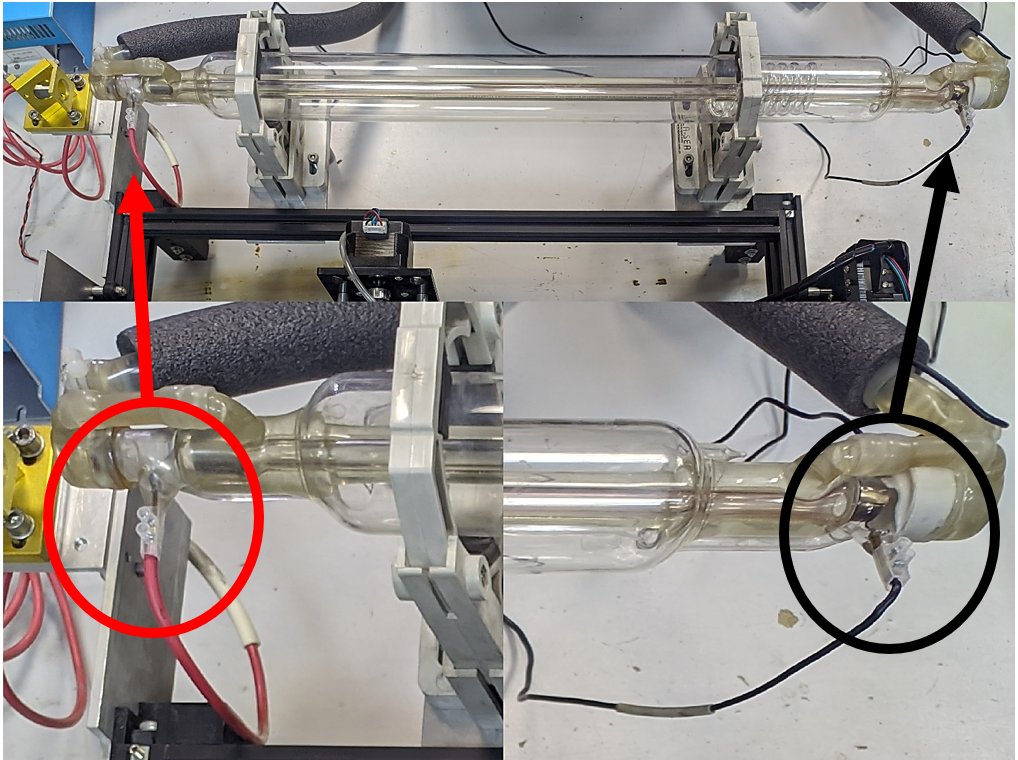

Connecting the power supply.

When the water is filled in and the machine is stable on the table – you can switch to switching on the power supply. But before that, make sure that the wires from the laser tube do not fly off during the delivery process. In the photo below, you can see how they should be connected.

If all the wires are in place, you can plug them in. First, we need to connect to the electricity:

- Power supply for the laser ignition unit

- Блок питания TEC Power Supply unit

- Power supply unit for 12V line

After a few seconds, you will see the water begin to fill the laser tube. It is important that there is a minimum number of air bubbles left in it.

Also, after connecting the power supply, the water temperature will gradually decrease. When it enters the range of 15-25 degrees Celsius – you can start testing.

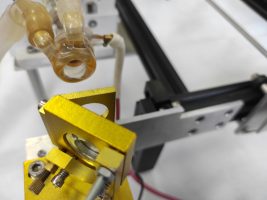

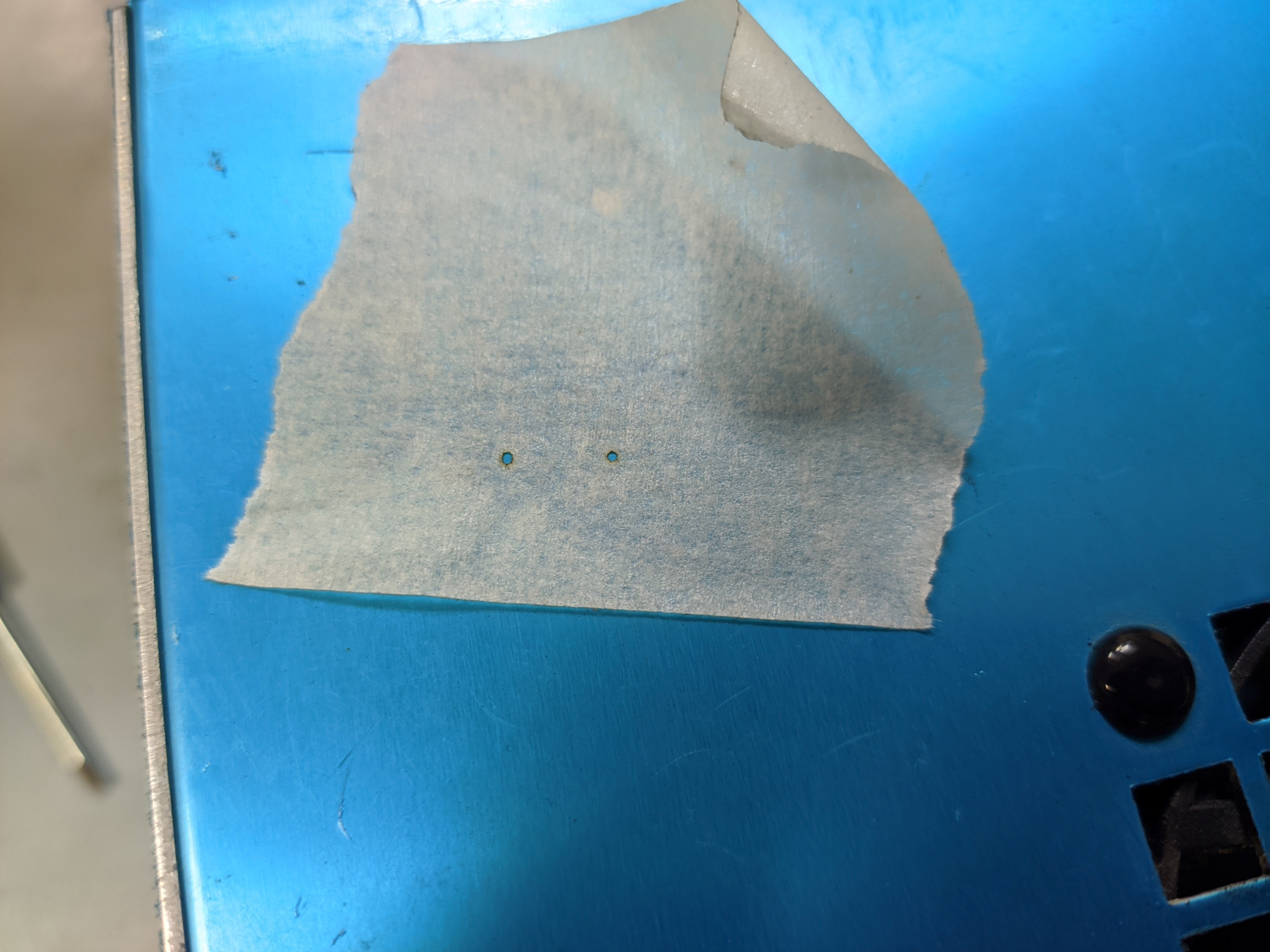

We check the alignment of mirrors.

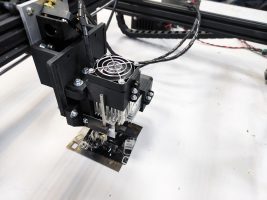

The optical system of the machine is arranged as follows. The laser beam coming out of the tube is reflected from the mirror system and enters the nozzle with a focusing lens. All mirrors must be positioned so that when the carriage moves around the machine, the laser beam always hits the center of the nozzle.

The mirror alignment process is quite complex. Therefore, it is better not to touch them again, so as not to confuse the exact setting.

Before shipping, everything was set up and tightly clamped so that nothing would get lost during the delivery process. But there is still a chance of misalignment. Therefore, before you start working, you should make sure that everything is in order.

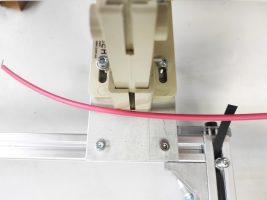

To check, you will need paper tape.

We cut off a small piece of tape, and glue it to the nozzle as shown in the photo.

Move the caret to the left top position

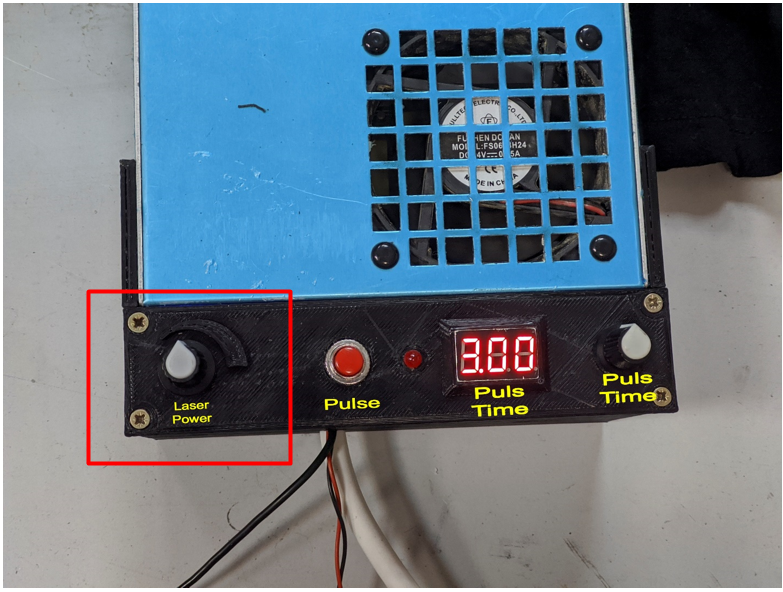

We set the power to about 50%. The pulse time is also increased by 50 milliseconds.

Now make sure that there is nothing in the path of the laser-click on the red button. There will be a short pulse and a hole will remain on the tape.

We peel off the tape, but do not throw it away!

Repeat these steps by moving the caret to the lower-right corner.

Then compare the 2 spots (from the left one upper position and lower right position).

On the left – a spot with a violation of alignment, on the right – everything is normal

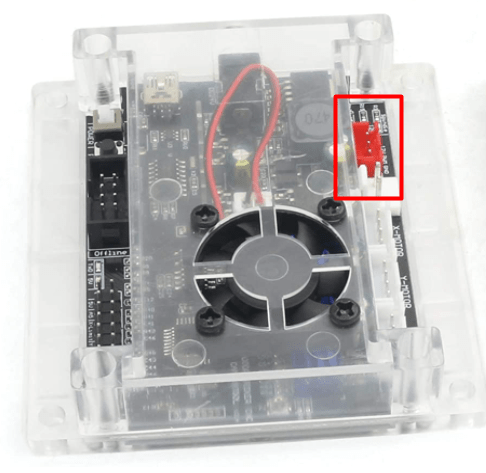

Connecting it to the board

When everything is checked, we connect the laser to the machine board. If you use a CO2 laser, connect the wires from the ignition unit to the red connector on the board (PWM)

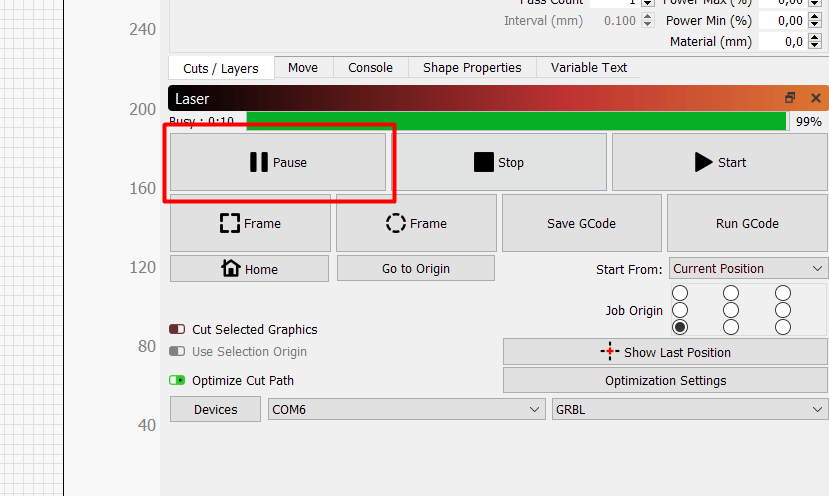

Monitor the temperature

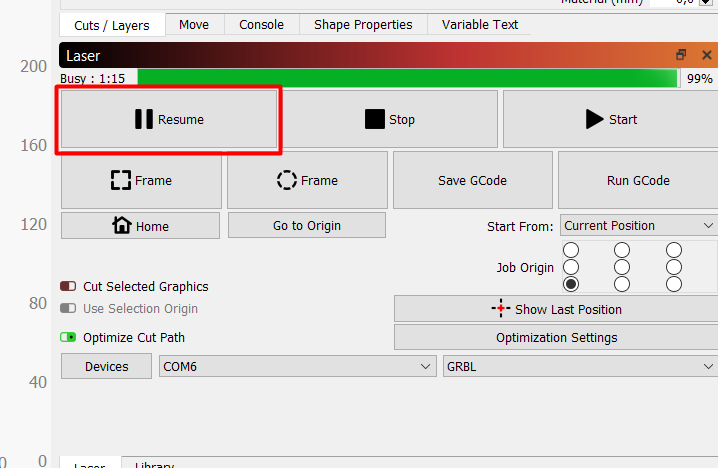

During the operation of the machine, it is extremely important to monitor its temperature. Itа should be in the range of 15-25 degrees Celsius. When approaching the upper limit, you must pause the process in the LightBurn programLightBurn.

When the temperature drops – you can continue the process.

If you want to increase the efficiency of the cooling system, you can replace its tank. To a larger capacity.

Safety precautions

It is worth starting cutting only after careful preparation and checking of the ventilation system. Many materials, when cut with a laser, evaporate substances harmful to the body. Therefore, carry out the work in a box.

Also, do not forget that you should exercise maximum caution when manipulating in the working space of the laser. In contact with the skin, the laser leaves serious burns.

Don’t forget about using glasses.

Work in LightBurn.

You can use our program instructions, or any other. However, we only distinguish that the power adjustment is made not in the program, but on the laser ignition unit.

How to upgrade your CNC or engraving machine for the work with a Co22 laser tube.

:

: