Here some examples that our customers did something wrong with the lasers…

Most common problem is that users start to screw potentiometers in a different direction, ultimately it kills the laser diodes itself.

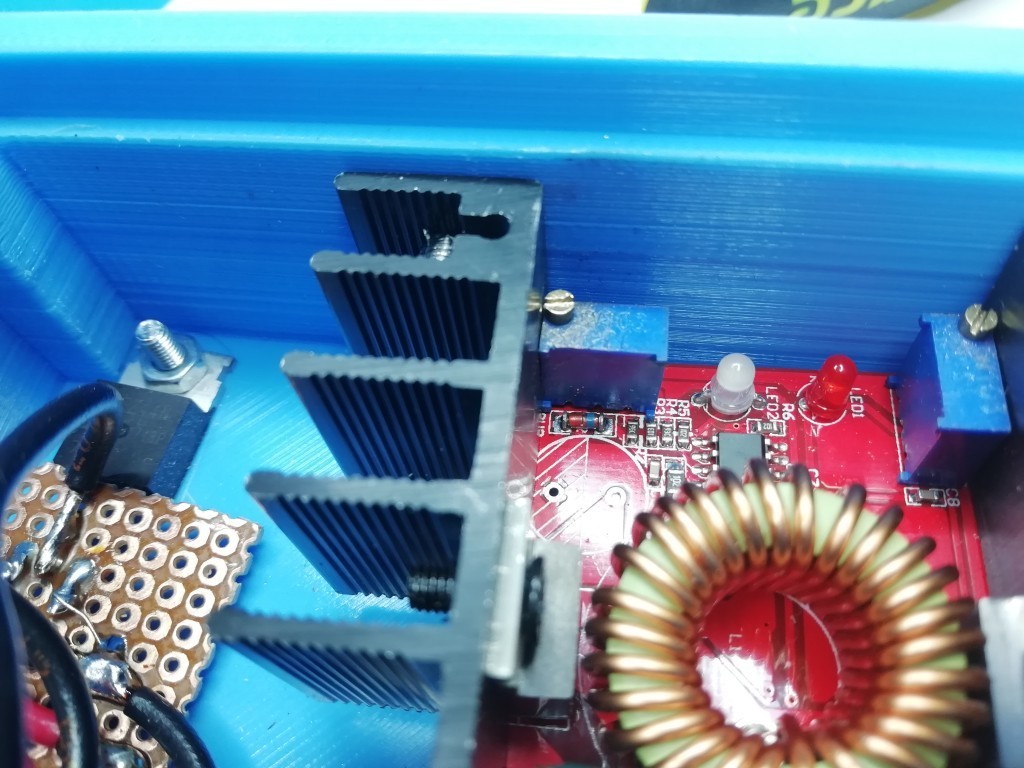

Another common problem is a burned zener diode.

Also we had some cases with buttons

1 – Twisted a lot. One of the lasers in the cliff 2 shine. The current is normal. The button is odd (different contact resistances from 0.05 to 0.1 ohm. This gives different currents in different modes and when switching to and fro. There are no problems with electrics.

2 – Laser break. There is no problem with ds.

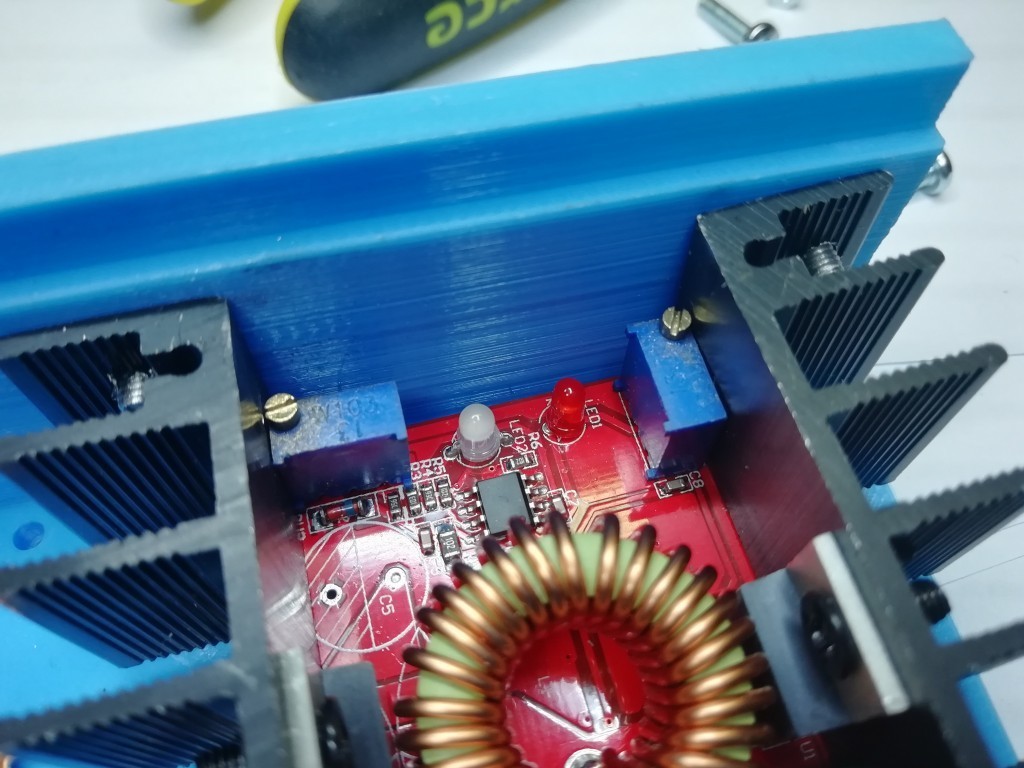

(laser was disassembled)

3 – Some small DC/DC had a different current when turned on, while checking the work returned to normal. I found out about the button after this kit. Electrics are fine. The laser shines well.

4 – A zener diode (stabilitron) burned out here. After a tap on ds 8 volts were unscrewed. There are no problems with the electrician. Here I think the laser has died. Of all that he has the smallest current. Check the laser. There are no problems with the box.

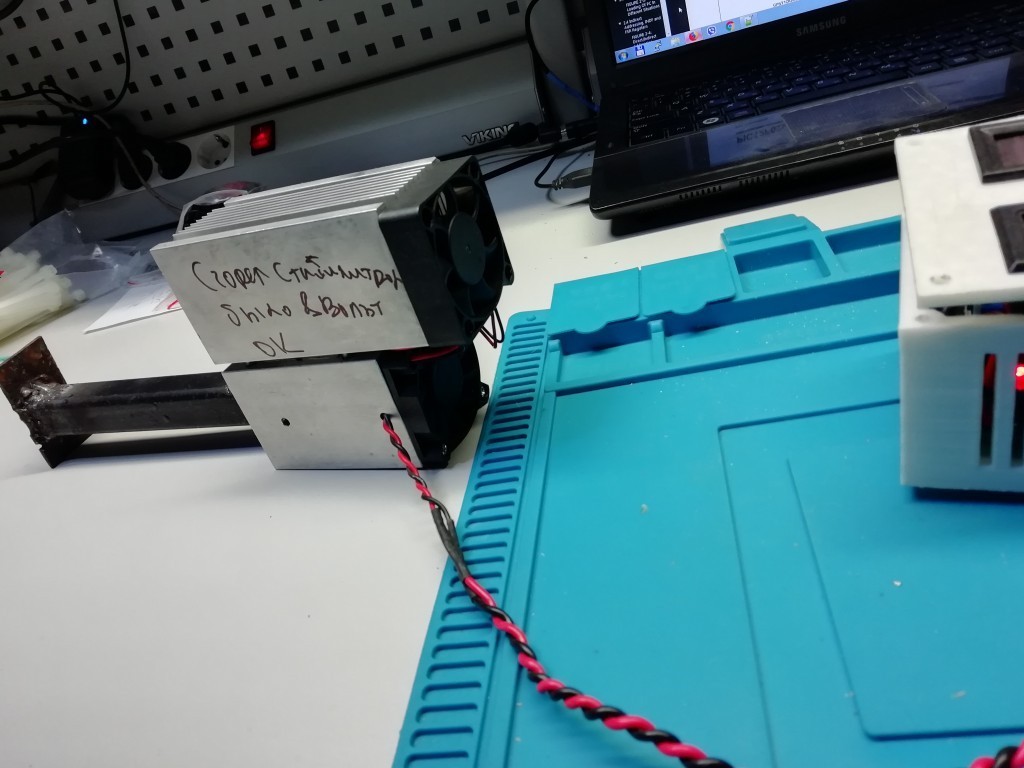

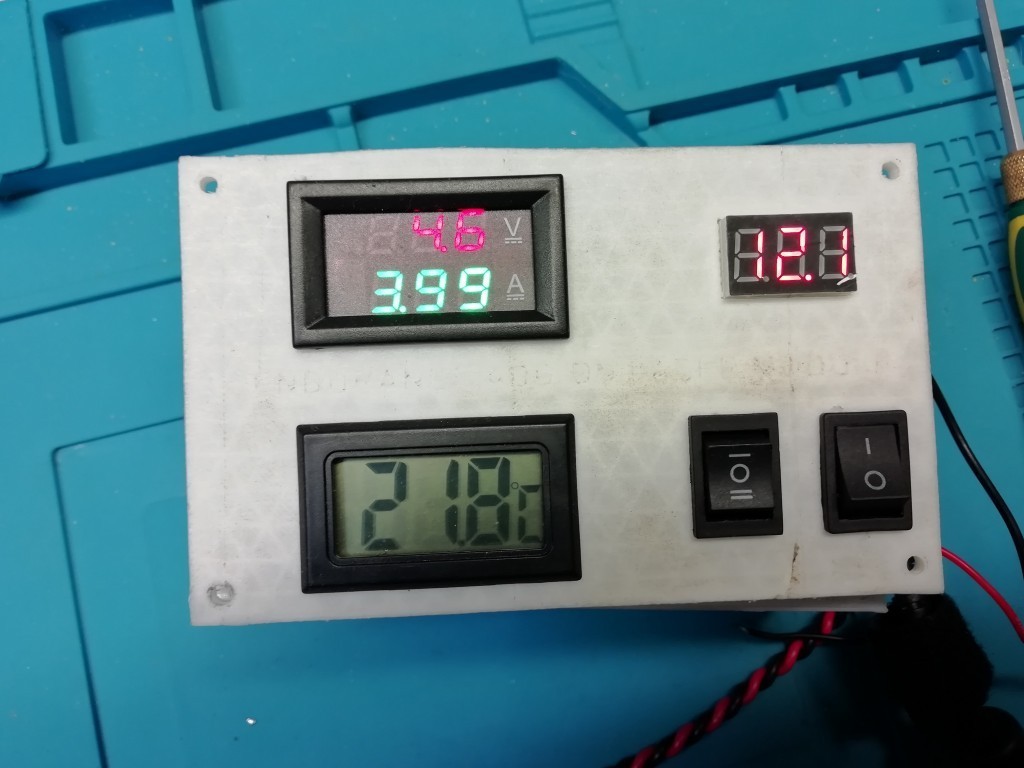

How did we test?

We drove in all modes of Full-TTL 0-100 for 15 minutes. Oscilloscope observed what is happening with DC. Indirectly measured button contact resistance. Included DC at once in the full power mode for the load. Measurements made both on the wires from the diode and on the terminals of the DC.

After proper setting of 4-th case

What do we have as a result?

1 – A very important moment is the problem with the button. It was hard to think, but it really is a weak link.

2 – Users are spinning all that is spinning and this problem is more serious than the first. We consider when designing MO2 how to minimize the consequences of this item as much as possible.

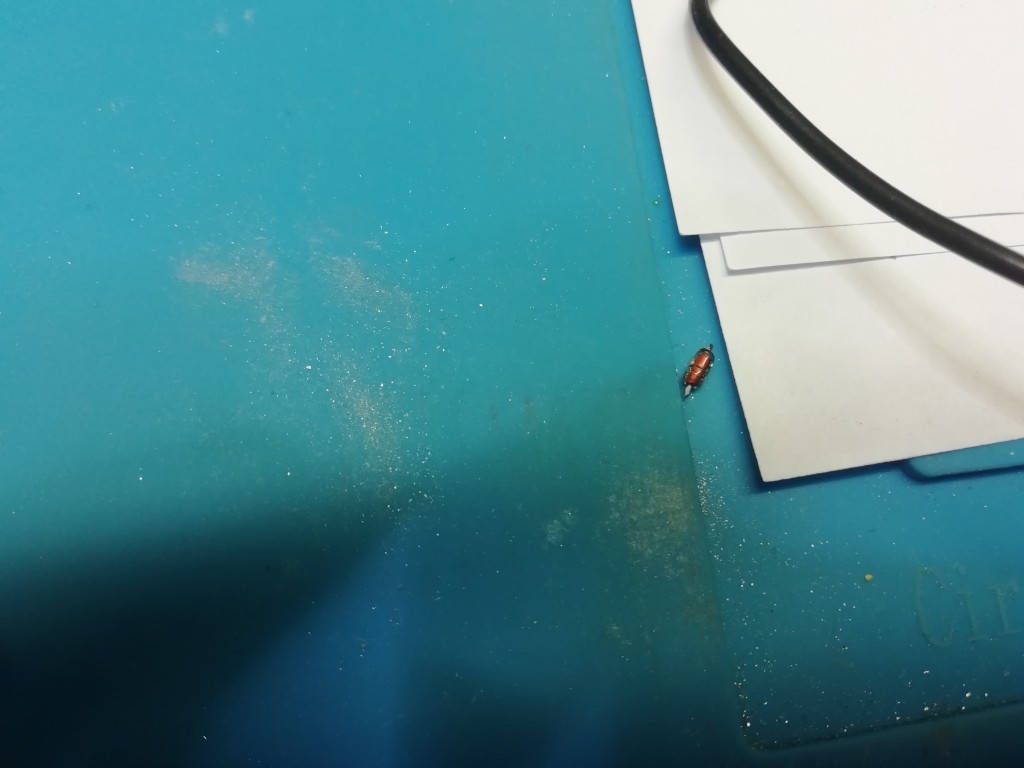

The image of a burned/ damaged laser diode