While traveling in the train to Berlin on Maker Faire to show my lasers and meet Thomas Sebastian and Florian Kelsch (our 2 big supporters) and bringing a few packages to our EU customers I decided to write a story about our further improvements that we are working on right now.

Electronics department

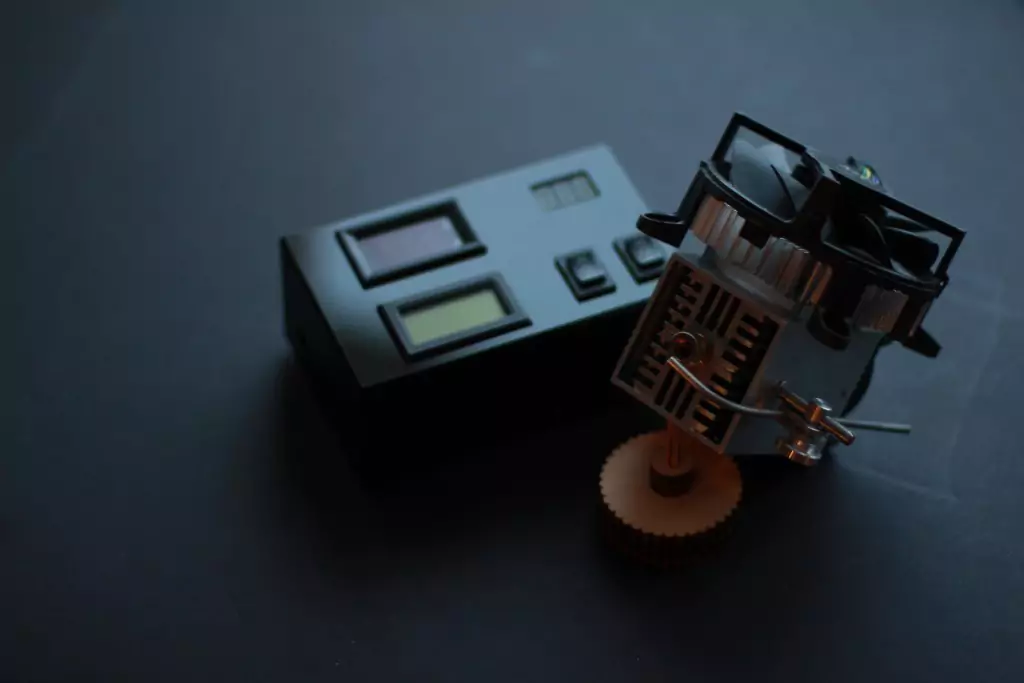

The most expected is our Endurance MO2 PCB to control the laser.

There will be a lot of useful features on this board.

We finalize a key development for FAP800 Coherent.

We have fiber optics and lens but we had difficulties with laser driver since it required 2V 50A power supply and therefore we needed a special driver to turn on/off the laser being able to commutate 2V 50A.

Another non-laser solution we were working on is an eyesight stimulation device.

The basic idea is to stimulate eyesight using fiber + regular 3 LEDS (red, green, blue)

Our new development is a Co2 laser module with fiber optics (PIR fiber). This is quite an early stage development. In general, it would require high precision equipment to focus Co2 radiation and then get it into the PIR fiber.

Experiments department

Our experiment department is been working on a few other experiments.

Creating a PCB using our lasers + photoresist

Engraving using 20 (double beam) / 30 (triple beam) laser.

Laser cutting with the most powerful Hailea compressor installed on our 10 watt+ laser.

Metalwork department

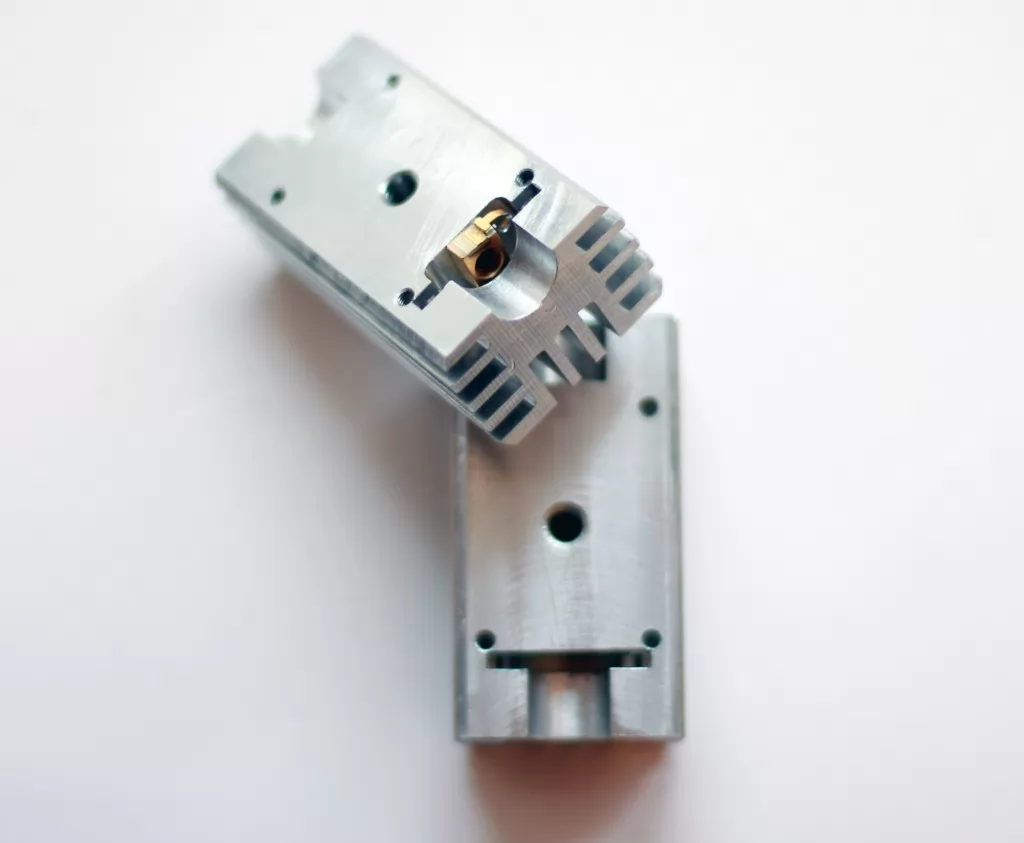

We plan to make a new aluminum casing for our lasers a little bit more advanced design + logo marking on acrylic. Very likely that we will announce a new version for 10+ /20-watt laser modules. We will call it “Pro”.

It is very likely that we will start making a universal aluminum casing for all lasers and the same laser heatsinks with a slight difference.

We also plan to make a new design for 10 watt+ heatsink following Graham Ham idea of better cooling. The basic idea is to use 2 TEC cooling plates instead of 1. And make a laser diode heatsink more solid.

Protective shield

We found out that many customers would like an additional safety while the laser is working so we plan to add an additional safety box. This box will be 5-7 cm height and will allow you to operate the laser.

New universal mounting brackets

Now we will offer to our customers 5-6 different plates for comfortable laser mounting to any 3D printer or CNC machine. We believe that it will close one of the most challenging questions is how to mount the laser.

We reached the limitation with 2-3 laser beam focusing on one spot. The key problem is that it is very hard to focus 2-3 laser beams in one spot and almost impossible to focus more than that. That is why we decided to build a closed enclosure that will allow to focus 5 laser beams in one spot following the design of Henrik.

Fume extractor

We know that many of our customers make fume extractor while laser cutting so we decided to make something similar.

It will be an acrylic enclosure with a tube allowing the fume extraction.

And the last one is to make a universal heatsink for all laser diodes: TO5, TO9, T18, TO38, C-mount, H-mount, T-mount.

Aluminum laser box

We plan making a new laser box our of aluminum for a “Pro” version. The laser box will be the same but it will be made out of a nice aluminum.

Better appearance

Painting and adding protection on an aluminum housing will be made starting from July 2019.

Small laser units

Small heatsinks will be made for smaller 3D printers and CNC machines.

Assembling department

In our assembling department, we also have a lot of things that are going on.

- Polishing the aluminum housing.

So, all the aluminum housings will be nicely polished before shipment.

- Laser stress test check.

We plan to run the laser for at least 1 hour just before the shipment.

- Rubber or silicone for fixing the optics.

The was a case when some lens are quite loose so we decided to add some rubber or silicone to make them fixed tightly.

- More efficient and beautiful air nozzle installed inside the heatsink.

The good thing about air nozzle made out of copper is that copper is quite flexible and you may bend it in different directions. We plan to add nicer nozzles like from 3D printer brass nozzles.

- Installing an additional protective shield

Now all lasers will be equipped with a protective shield as an option.

- Accurate marking

We will improve the technology of adding signs on aluminum housing.

- Adding M3 & M4 screws in the package.

We will add some M3 and M4 screws in the package so that all our customers will have less problems with mounting and hooking the laser.

- Adding a piece of paper with date, time of testing, signature of a person and setup voltage, current and power of the laser

This is an additional step we want to follow to make sure that each laser was tested accurately before shipment. Now a responsible person will add all details into the laser check list.

- Adding warranty signs

We will add warranty stickers and warranty signs for each laser.

- Adding bigger focusing ring to all lasers.

As you know we add bigger focusing ring for 10 watt+ laser only , now we will add it to all lasers.

- Adding a key to lock and unlock the laser

We want to follow international laws and limitations about using the lasers that is why we decided to add a key for each laser module, It means that there will be a key which allows to run the laser.

- Fan protective shield

Our rans that are installed on top of the laser module require and additional shield protection.

- Setting up the focus with a mirror camera

This is a planned thing we want to do before shipment the laser with a regular 3 element lens. The idea is to setup focus and add an info about focusing range. That will allow a user to start using the laser right away with knowing the range from the laser to the surface.

- Making a new 10 watt+ with a big external heatsink

We plan to make a new experimented 10 watt+ laser module with quite a big external heatsink. This will allow to cool the laser much more efficiently.

- Making a new 10 watt+ with a powerful fan turbines.

While adding a new bigger heatsink we plan to add a bigger turbine to cool the laser diode.

So, that was a brief Endurance plan what we plan to do an improve in our technology in the nearest future.