In this article we will explore the way of the best and the most efficient laser mold removal from a white paper.

Problem statement : it is necessary to find out at what optimal parameters of the 3 watt Endurance 355 nm UV laser can remove mold from paper without losing its quality.

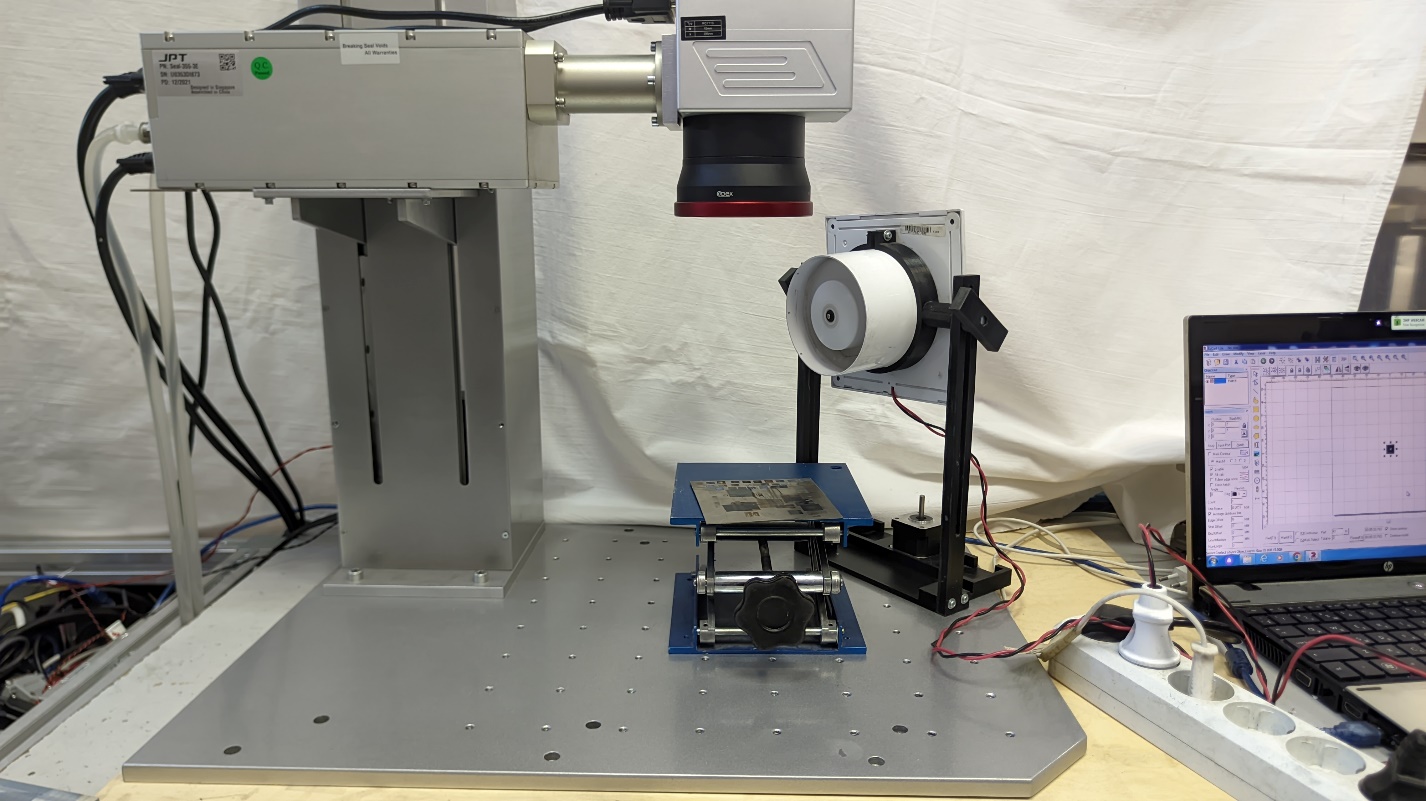

To complete the task, we use Endurance UV laser machine 355 nm wavelength with an average power of 3 watts. The pulse duration at 30 kHz is less than 18 ns . The laser operates in the frequency range from 20 kHz to 150 kHz. To maintain the operating temperature of the laser (25 °C), a water cooling system is used.

RC 7110 galvanometer with a lens “ SL -355-110-160- D 10- LP ” installed on it, having a focal length of 160 mm and a working area of 110 mm by 110 mm.

The machine is also equipped with a larger axis, with which you can raise and lower the laser at a speed of 1.5-6 mm / s. The travel range is 443 mm.

The machine is controlled using the EzCad program .

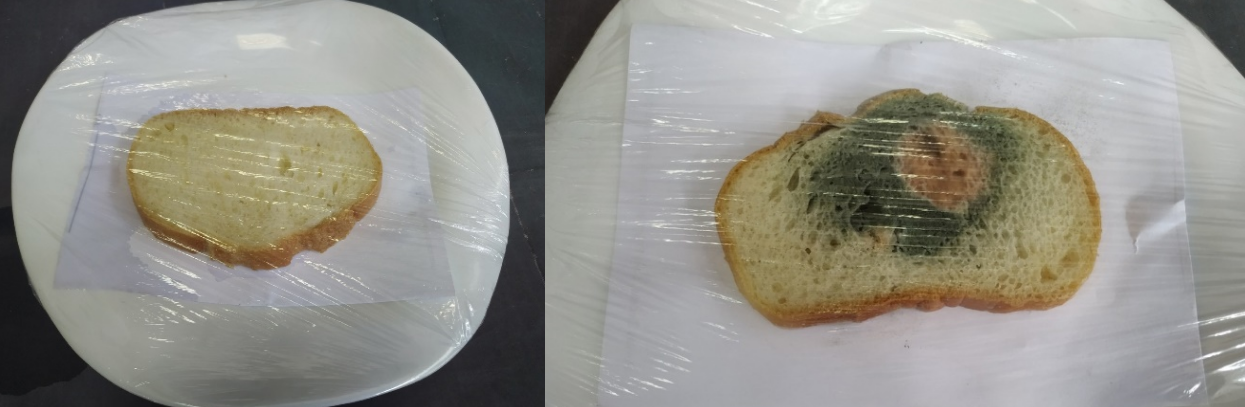

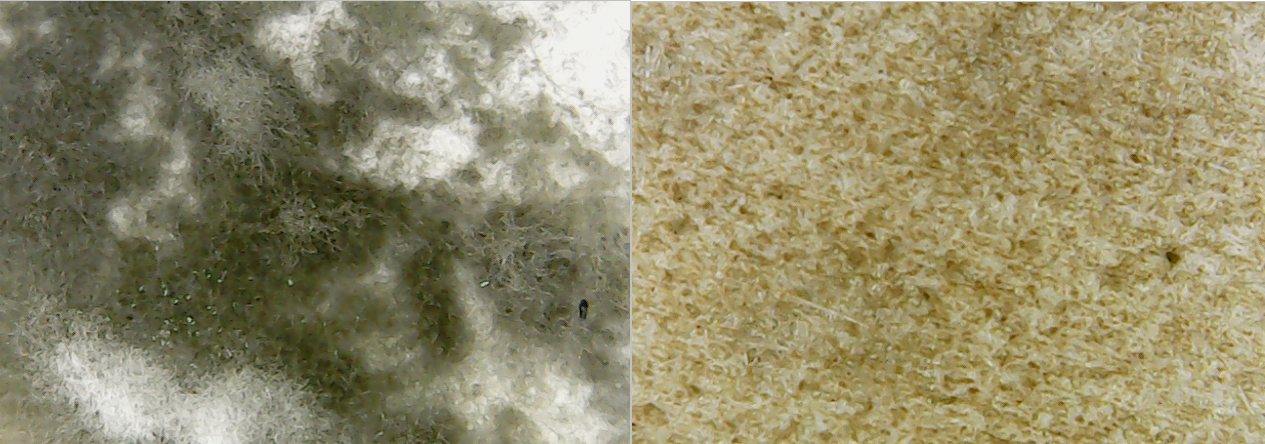

Previously, for the experiment, mold was grown on paper with the help of bread. To do this, they took a plate, then wetting the paper a little with water, put it on a plate, put bread on top of the paper, also wetting it. Next, the entire plate was covered with cling film, after which they put it in a dark, warm place. Within a week, mold began to form on the bread (Fig. 1).

Figure 1 shows the type of bread at the beginning of the experiment on the left, the type of bread after 7 days is shown on the right.

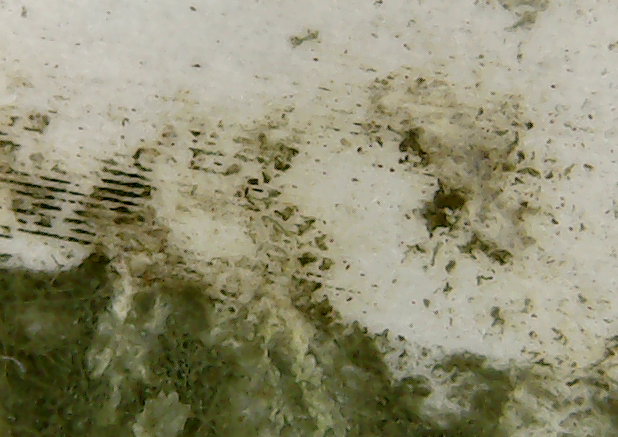

After 7 days, the paper was pulled out and the condition of the mold was recorded (Fig. 2).

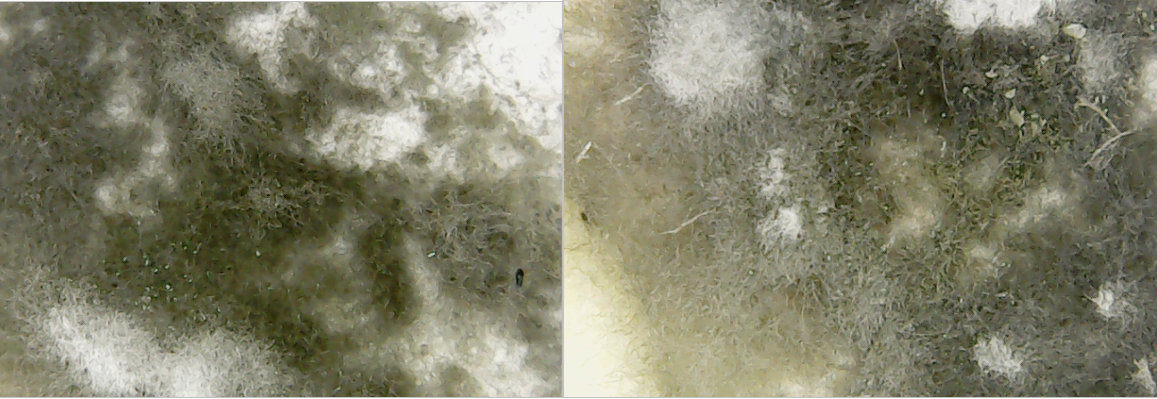

In the same way, the condition of the mold was established on both sides using a microscope (Fig. 3).

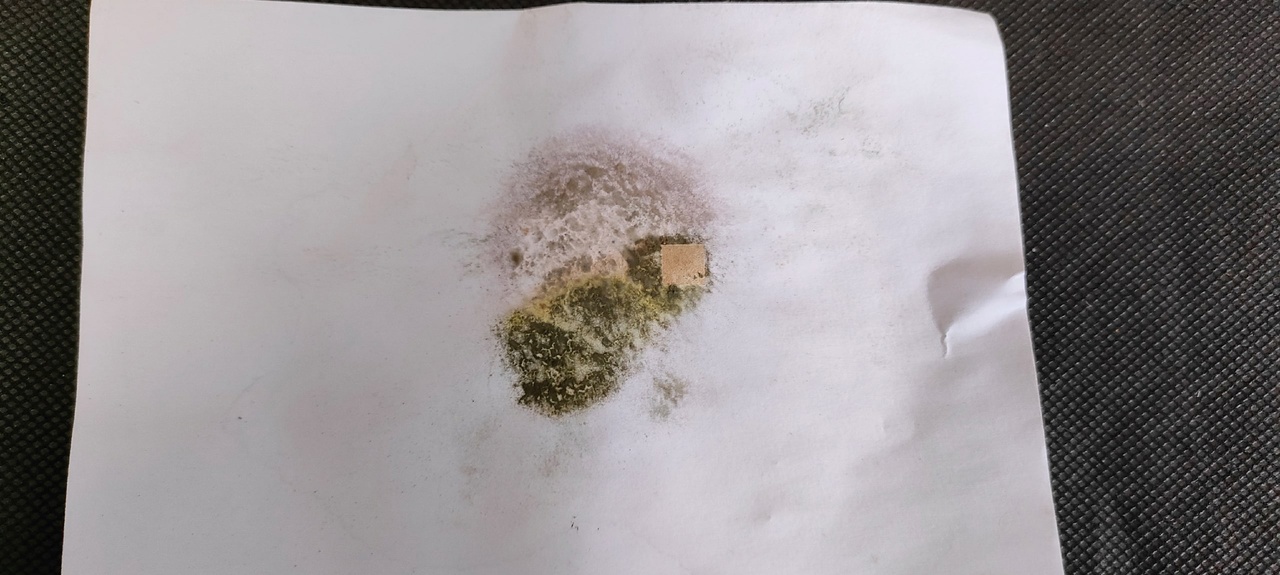

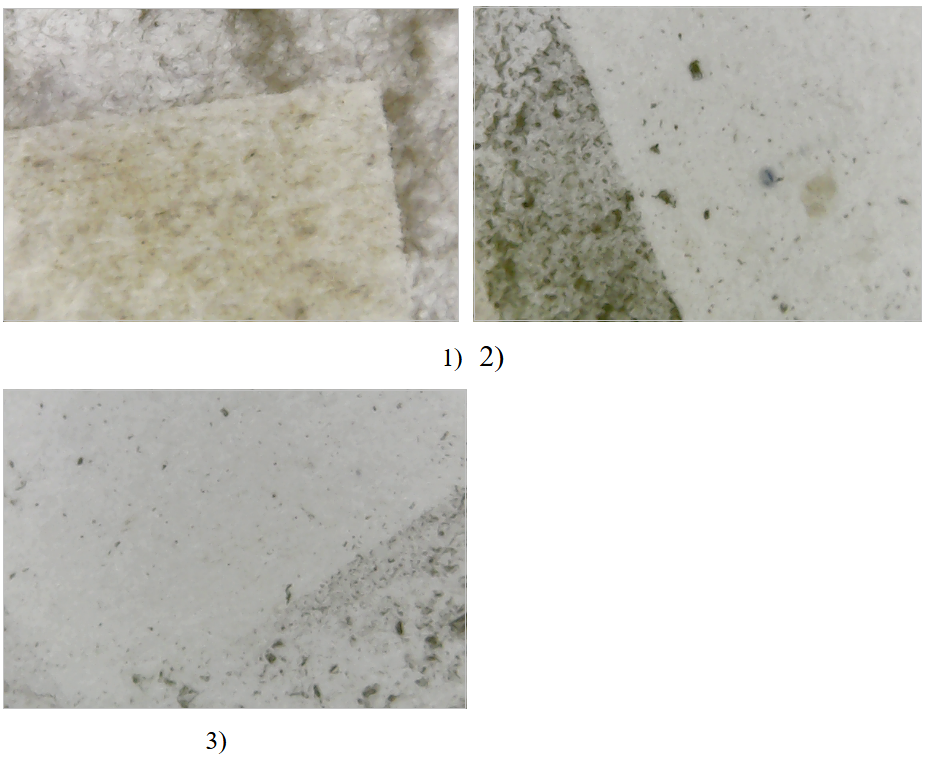

To remove mold (Fig. 2), the optimal laser parameters were selected: the number of passes 1, the passage speed 500 mm/s, the pulse frequency 20 kHz, the pulse duration 10 μs (Fig. 4).

Based on figure 4, it can be seen that after removing the mold, a yellow stain remains.

One of the best mold removal results was obtained with the following parameters: number of paper passes 12, pass speed 1000 mm/s, pulse frequency 100 kHz, pulse duration 5 µs (Fig. 1).

Figure 7 shows that it was not possible to completely remove all the mold, so the decision was made to increase the laser power. The new parameters are respectively: number of passes 12, passage speed 1000 mm/s, pulse frequency 90 kHz, pulse duration 5 µs (Fig. 3).

At different degrees of mold penetration with the same parameters, a different result is obtained.

In Figure 9, the mold is not completely removed, the integrity of the paper is preserved.

Conclusion: Using the Endurance 3 watt UV laser 355 nm laser cannot completely remove all mold but it can remove 90-95%. At low laser power, the mold is not completely removed, and when you try to increase the power, damage to the paper appears.

We will keep working and making experiments in our Endurance Lab.