All you need to know about running the Endurance MakeBlock XY with an Endurance 5.5-5.6 watt diode laser.

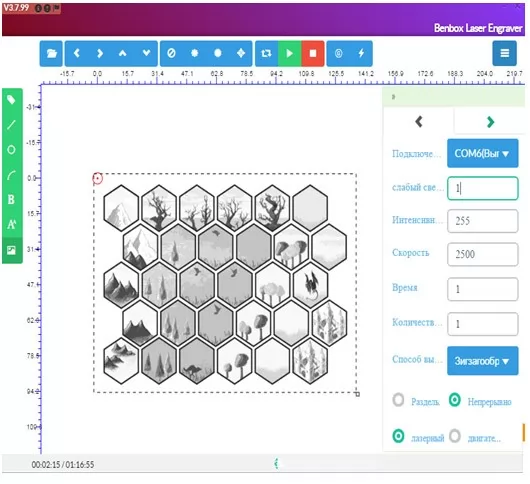

This article is about the peculiarities of the BenBox and Endurance MakeBlock XY 5.5- 5.6 watt laser engraver operation. Basic parameters for the BenBox program operation: Weak, light, Intensity, Speed, Timе, Number. To engrave grey tones (greyscale) it is important to correctly set the engraving parameters first.

Basic parameters for the BenBox program operation:

• Weak light

• Intensity

• Speed

• Time

• Number

Benbox settings affect engraving and cutting results.

Weak light – is the setting of the lightest spot on the image.

Intensity – is the setting of the darkest spot on the image.

Speed – is the setting of the travel speed along the X-axis.

Time – is the laser exposure duration per one spot.

Number – is the setting of the laser repeats.

Parameters and intervals

Weak light – {0; 255}

Intensity – {0; 255}

Speed – {1; 2500}

Time – {1; 10000}

Number – {1; 1000}

The Number parameter is not processed correctly in some program versions.

BenBox enables to work both with vector and raster images.

Programs for the work with Endurance MakeBlock and image processing:

Visit our download center >>>

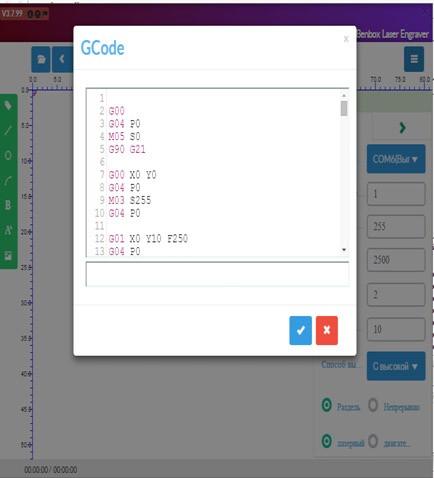

All of them work with the G-code.

G-code downloading

To engrave gray tones it is enough to upload an image and click “play”.

It is important to correctly set the engraving parameters first.

The following parameters are recommended to engrave an image with 8-16 shades of gray on wood or plywood using a

5.6 W Endurance laser:

Weak light – 50

Intensity – 200

Speed – 1000

Time – 1

Number – 1

These parameters allow reproducing of the shades and making a beautiful image.

To laser cut plywood with the Endurance MakeBlock 5 – 5.6 watt engraver we recommend the following values:

plywood 2 mm thickness

speed – 200-250, number of repeats – 1

3 mm thickness

speed – 150-200 mm / min, number of repeats – 2-3

4 mm thickness

speed – 150-200 mm / min, number of repeats – 3-5

5 mm thickness

speed – 150-200 mm / min, number of repeats – 5-15

For laser cutting black acrylic with the Endurance MakeBlock 5.6 W engraver we recommend the following values:

black acrylic 3 mm thickness

speed – 200-250 mm / min, number of repeats – 1-2

5 mm thickness

speed – 200-250 mm / min, number of repeats – 3-4

8 mm thickness

speed – 150-200 mm / min, number of repeats – 5-10

These parameters are optimal in terms of quality and speed of cutting.

By quality, we mean accurate cutting edges (without charring or melting).

By speed – an acceptable time to get the result.

Endurance lasers: all about cutting and engraving abilities of diode, DPSS, fiber, Co2 lasers.

How to make an image ready for laser cutting watch on our YouTube channel

These parameters are experimental and depend on the temperature, humidity, and the material itself.

Endurance lasers: all about cutting and engraving abilities of diode, DPSS, fiber, Co2 lasers.

Learn more about the Endurance MakeBlock

If you have any questions or concerns, please share them with us in our LiveChat!