A laser leather engraving – all you need to know.

Аny crafter would like to make high-quality patterns for their products, easily cut out intricate patterns and small leather details without spoiling the material, so Endurance semiconductor (diode) lasers will help you in your work. Endurance recommends semiconductor (diode) lasers with an output power of 3.5 watt laser power output and higher. The use of lasers with higher power will significantly reduce the time of cutting or engraving and will allow cutting thicker samples.

All About Leather Lasering (laser engraving)

About leather manual engraving, in short

Every leathercrafter, a professional or a hobbyist, knows what a painstaking process is leather engraving. Those who had or just touched an engraved leather item could not but admire the beauty of the work done. But very few know how manual engraving is done in practice.

The first step is leather moisturizing either with special compositions or with impromptu mixtures, such as shaving foam, for example, if you have nothing else at hand. The next step is pattering the leather surface. For this, you will need tracing paper with the image you need to transfer to the leather and a tool to do it such as an empty ballpoint pen or a special saw-tooth roller marker with which you will trace the lines of the drawing on the tracing paper put onto the face side of your leather workpiece. In this manner, you will have an imprint of your drawing on the leather surface. After this, you can set to engraving. The processed piece of leather should stay moist at that. Various tools are used for leather engraving: a swivel knife for leather cutting, a set of stamps for grounding, bodkins to make holes.

Leather engraving is a rather complicated and time-consuming process. Any mistake can spoil the look of the item. For high-quality work, you need special tools for different purposes. But there is one tool to combine and substitute them all. This is the laser.

Laser engraving. A vast advantages and no drawbacks.

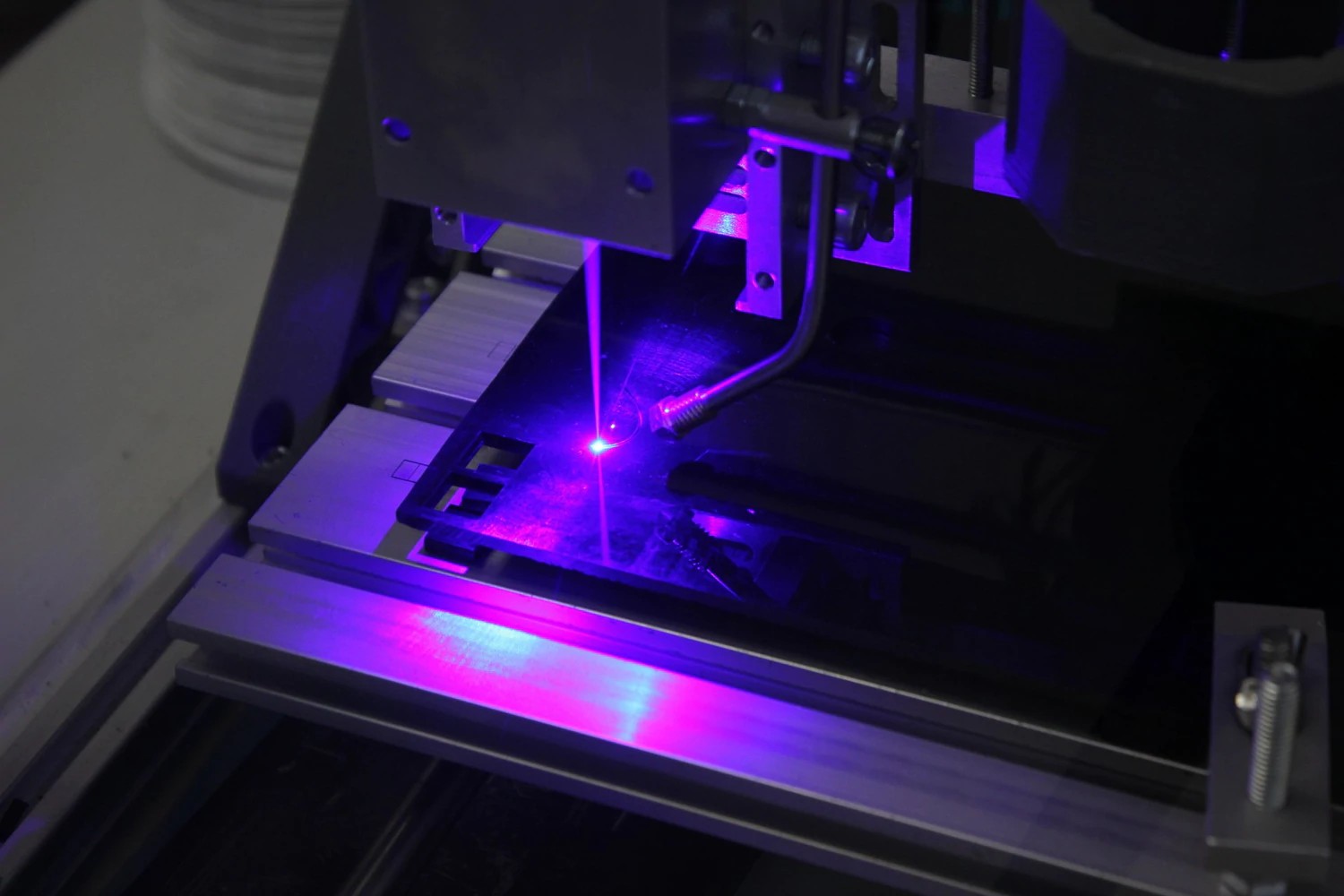

Today leather engraving with a laser engraver is rather popular and in high demand. No wonder! Laser machines suitable for leather engraving and cutting are easy to find, use, and maintain. They don’t need much room and even low-powerful machines can perform a great many operations and tasks.

The laser engraver is able to make an embossed pattern on a leather surface independent of its thickness. As for leather cutting, more powerful machines do it faster, but even low-powerful ones can do it too. Solid-state (diode) lasers with a 3,5 watt (3500 mw) output power and speed of 100mm/min. can make a relief of 0,3mm deep with just one pass independent of the leather type: elk side, chevro, suede. More powerful devices such as 10W DPSS easily cut leather up to 2mm thick at 500 mm/min speed. To cut a thicker material you need just to decrease the speed.

But the key advantage of the laser is its high accuracy. No artist can draw an image on a leather surface so perfectly as a laser beam. Any soft copy pattern can be engraved on leather micro-accurately. A 10W DPSS is able to engrave a readable inscription of 5 letters, 1.5 mm by 4 mm in size.

What is the best leather for laser engraving?

Smooth leather is rightfully considered the most popular type of natural material, it is made from the highest quality raw materials, from the surface of which wool is removed.

Here are some types of leather:

1. Smooth leather

Smooth leather is rightfully considered the most popular type of natural material, made from the highest quality raw materials, from the surface of which wool is removed. This type of leather has pores, due to which it is able to “breathe” and has a long service life. Products made of smooth leather are distinguished by increased wear resistance; the most expensive and luxurious models of shoes, outerwear, and furniture are made from it.

2. Nubuck

Nubuck is a beautiful, but rather delicate material that is made from the leather of pigs or cattle by chrome tanning. The velvety effect is achieved by sanding with fine-grained materials. Nubuck is used for the production of leather goods, upper part of shoes, as well as for upholstering furniture.

The material is less protected from moisture and dirt, and is more prone to salting than suede. Nubuck requires special care, especially during the first months after purchase. It is noteworthy that dark nubuck clothes brighten over time, and light ones darken.

3. Velor

Velor is similar in structure to nubuck, only in the first case the leather is sanded from the inside, and in the second – from the outside. Depending on the processing technology, velor can be both soft and thin, or hard and thick. It is made from chrome tanned pork or sheep leather. The material is used for the manufacture of clothing, upper part of shoes, as well as leather goods.

4. Suede

Suede is considered one of the most popular types of genuine leather. It is made from the leather of goats, pigs, sheep, deer, elk. By its nature, it is a soft, porous and highly durable material with a fleecy surface, the appearance of which is to the taste of many. Suede is comfortable to use, has the ability to “breathe”, and is also able to maintain its softness even after cleaning in soapy water.

This type of natural leather is obtained by the fat-tanning method. The suede is velvety thanks to subsequent sanding. Exclusive models of outerwear, bags, shoes and accessories are made from suede.

5. Aniline leather

Experts consider aniline leather to be of the highest quality. It is colored with organic dyes and processed to a minimum. Natural marks can be found on aniline leather, including scratches or scars. Aniline leather is quite sensitive to influences, and in the process of use it can acquire an antique look.

6. Nappa

Despite the fact that the name may not be familiar to you, this type of natural leather is actively used to create accessories and other products. Nappa is made from the leather of young and adult animals, and thanks to the double tanning, this material becomes incredibly soft. Depending on the finish, nappa can be matte or glossy, smooth or perforated.

The main advantages of the nappa:

- excellent appearance;

- softness and smoothness;

- durability;

- high quality;

- resistance to dirt and moisture;

- ease of care and cleaning.

7. Patent leather

Patent leather is obtained by dyeing the hide and applying varnish at high temperatures. This material has an attractive appearance, but is less durable than genuine leather, and at temperatures below -10 and above +25 degrees Celsius it becomes cracked. High-quality patent leather withstands multiple bends, has a uniform color and, with proper care, lasts for more than one year.

8. Nappalan

Nappalan, also known as silka, is a type of suede that is treated with a solution with the addition of a rubber mass. Thanks to such a coating, nappalan is able to protect against rain and snow, but after a while it can begin to crack, and if you scratch such a product, you will not be able to restore it.

9. Laika

Laika is a soft and elastic natural leather, for the creation of which the leather of lambs and kids are used, processed with chrome-fat or chrome tanning. This material is almost always used to make gloves.

10. Brushed and embossed leather

Animal leather often have many natural defects: plant scratches, insect bites, and others. As a result, the hole formed does not heal, which significantly reduces the value of the material. Such defects during production are eliminated by grinding, and a coating is applied to make the surface of the product even. Such genuine leather must be dyed without fail.

If, after grinding, defects remain on the surface of the material, then embossing is applied. The leather is heated and then pressed using large plates.

Types of natural leather tanning:

Chrome. In this case, the leather is treated with basic chromium salts. This allows leather products to become soft, elastic and heat-resistant. Such products are resilient, get wet and quickly, and easily let water through.

Vegetable. Based on the use of tannins – special tanning agents contained in the bark and leaves of trees. The final product has great thickness, high density, water resistance, but low heat resistance. This method is used in combination with others.

Zirconic. A zirconium compound is used here. This method is designed to produce white leathers that are more resistant and durable, and are not afraid of exposure to water and sweat.

Synthetic. Syntans give natural leather elasticity and attractive appearance. This method is used in conjunction with others.

Fatty. This method of tanning natural leather is carried out using fish oil, as well as oil from marine animals.

Aluminum. Tanning is based on the action of aluminum salts. Using this method, a husky is obtained, which is soft and elastic, but is afraid of exposure to water.

You may engrave on any type of leather but you need to find out proper laser cutting/engraving parameters.

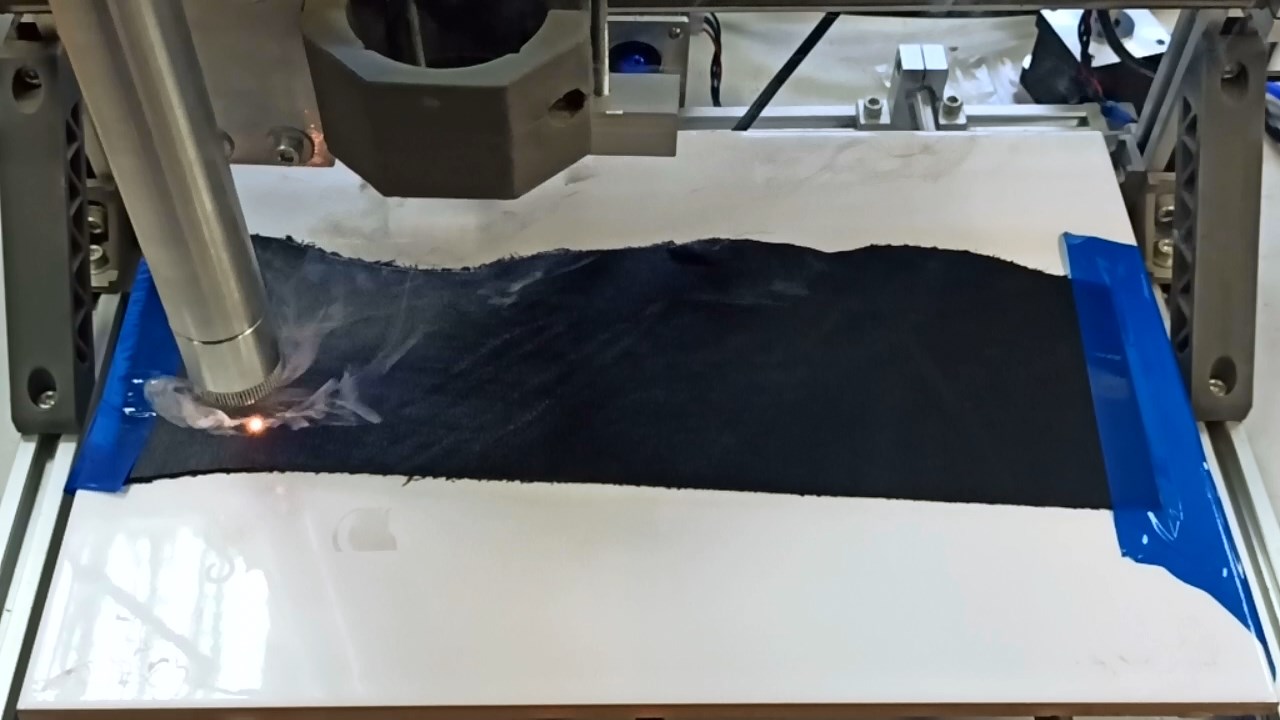

What happens with leather during lasing

Many people wonder how laser cutting/engraving goes and what happens with the processed material.

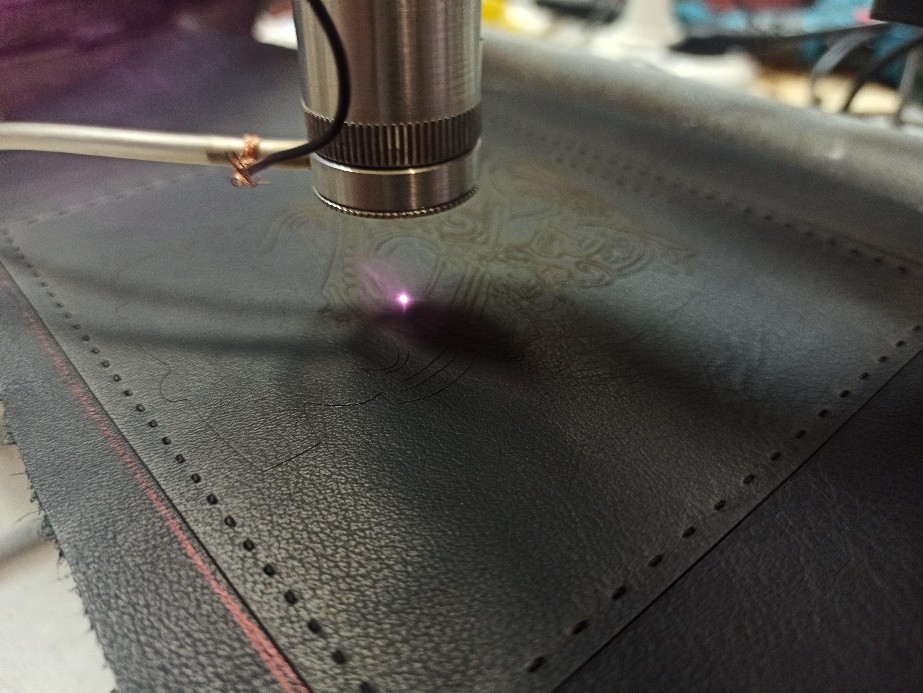

It’s all simple enough. The focused laser beam hitting the leather surface vaporizes its upper layer leaving a kind of micro crater (hole) at the place of the impact. As the laser beam moves on this crater is lengthening, turning into a line, the depth of which depends on the laser power (which consists of the pulse frequency) and speed (the slower is the speed the longer the laser processes a given area). Both parameters affect the engraving depth. Thus, for example, at 1000 mm/min and 5% power, a 10W DPSS singes the surface of black leather, changing its black color for gray. At 500 mm/min and 100% power it burns through butt leather 4 mm thick in three passes.

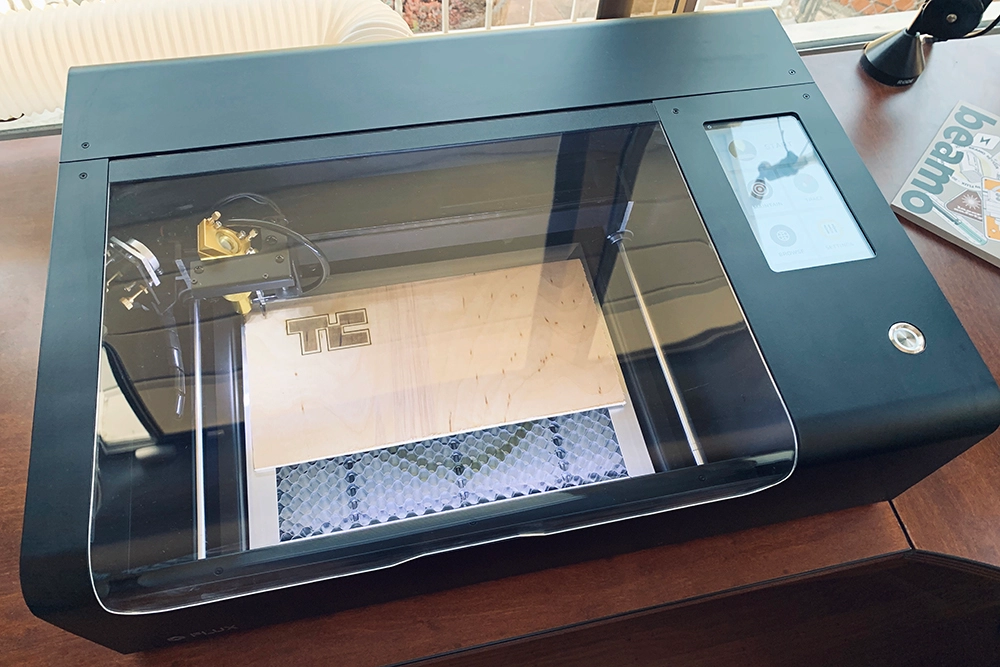

But it should be taken into account that cutting and engraving parameters of different lasers will vary. A 30 W CO2 like BEAMO FLUX laser cuts 3mm leather at 180 mm/min and 60% power and does a light engraving on its surface at 9000 mm/min and 30% power.

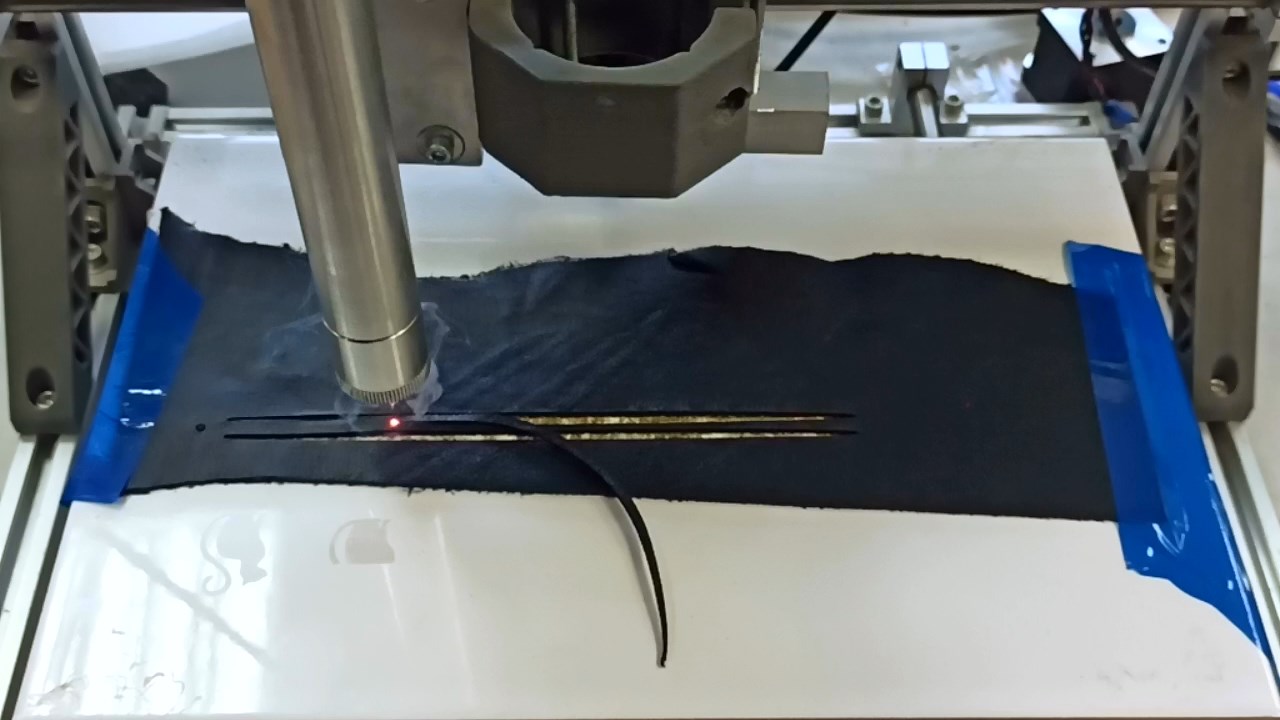

Laser cutting is actually deep engraving. The only difference is in the modes of processing.

Specific features of leather engraving

Any leather type independent of its thickness or currying fits for laser cutting and engraving. But it is important to know a number of ends and outs when leather lasing.

To start with, dark-colored leather is easier to cut and engrave than light-colored. This fact should be taken into account when choosing a processing mode. The engraving embossment will be deeper on a dark material than on a light one with the same parameters.

Secondly, during laser processing leather might shift and deform due to heating of the cutting edge at high laser power. To avoid this problem it is recommended to fix a leather workpiece, for example, with adhesive tape before processing. Additionally, it is good to moisturize the leather workpiece when needed.

Thirdly, under laser treatment leather might emit much smoke. To make the working conditions more comfortable it is necessary to use additional devices: a fan or compressor airflow (air assist), fume extractor, and exhaust system. When working with a DPSS Laser Nd:YAG an air assist is a must add as smoke might grime the focusing lens. In this case, you will have to clean it or substitute for another one.

Fourthly, it is preferable to use vector patterns and images as templates. It takes the laser much more time to process any material when raster images are used. If you have only raster images it is not a problem to convert them into vector files using free software for work with vector graphics.

Practical application of a laser engraver in leathercraft

What can you do out of leather using a laser? Almost anything.

Create a template of an image you need in any program for vector graphics work, then open it in a program for work with the laser (e.g., LightBurn). The laser will cut or engrave the parts of the item according to the template. When all the parts are cut out it remains only to join them together. Besides engraving, the laser engraver can do a great many of other operations such as: making perforation for stitching, holes for studs, snaps or eylets, sketching, line marking for applied ornaments, and much more. The laser capabilities are really invaluable.

Here are some examples of the items made with the help of the laser engraver.

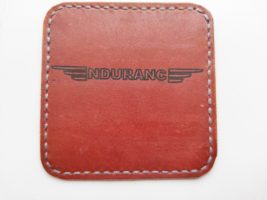

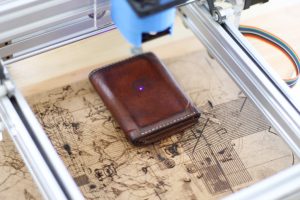

A wallet of combined leather with applied ornaments.

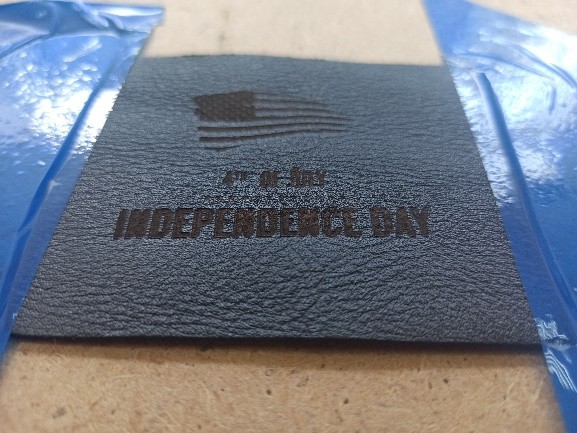

A sew-on patch devoted to Independence Day.

If you need a long leather string but don’t have a leather piece long enough, here is a solution:

The laser will cut it out spirally using a template. For a leather string 2 m long you will need a leather workpiece 11 by 11 cm.

What laser to choose to process leather?

Before buying a laser determine what tasks it will perform.

For smaller items, such as a wallet, watch strap, document organizer or phone case, a DPSS Laser Nd:YAG 10 W with a 20 by 30 cm working area will do. This laser is able to do both engraving and cutting at a rather high speed.

To engrave ready-made products a 3.5 watt (3500 mw) solid-state (diode) laser will be suitable. But for a good speed choose a double version of this model.

For bigger items, you need a laser with a big enough working area. To cut leather for clothing making you need a working area of, at least, 50 by 50 cm. A suitable solution, in this case, is a laser machine with a CO2 tube.

But take into account the fact that the engraving accuracy of this machine is worse than that of the DPSS laser Nd:YAG. For surgical precision, the DPSS laser is the best choice. To work with large items you will have to equip it with a big working table.

How to make a passport jacket with additional sections for documents

Creation of a pattern template in a graphic editor.

Creation of a template for engraving.

Opening of templates by turn in LightBurn and starting of the laser.

Joining of the elements together by stitching.

The result of the work.

We have good news for leathercrafters and dressers.

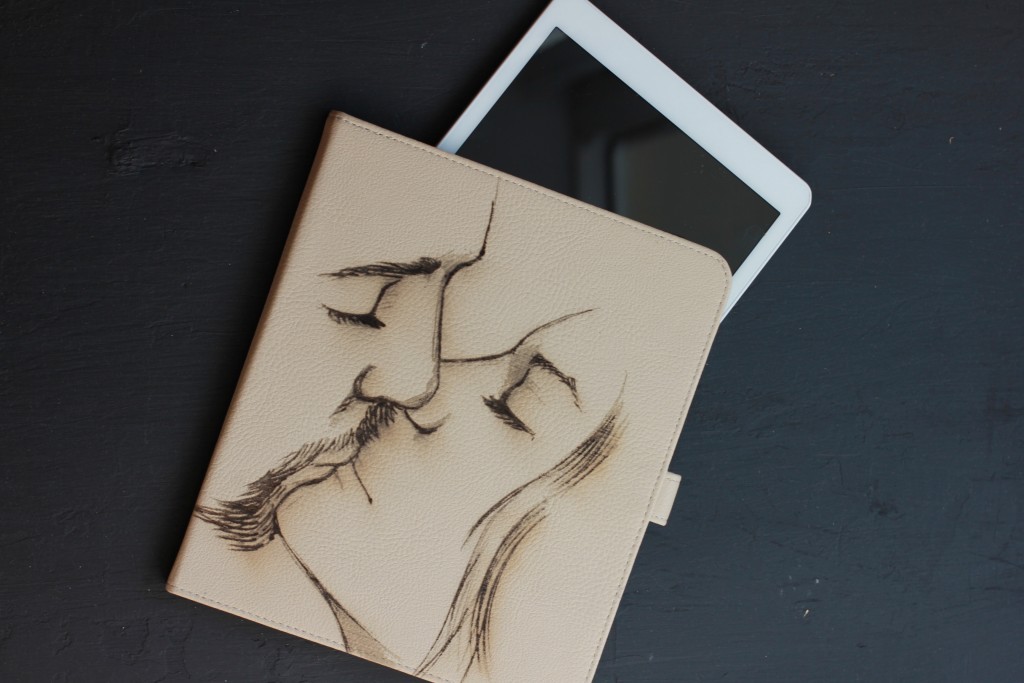

An impressive leather laser photoengraving.

An impressive laser photo engraving on leather.

Using Endurance semiconductor (diode) lasers, you can easily engrave or cut leather items.

No doubt, any crafter would like to make high-quality patterns for their products, easily cut out intricate patterns and small leather details without spoiling the material. Endurance semiconductor (diode) lasers will help you in your work.

For practical and high-quality leather cutting, Endurance recommends semiconductor (diode) lasers with an output power of 3.5 W and higher, something like 5-5.6 watt laser power output. The use of lasers with higher power will significantly reduce the time of cutting or engraving and will allow cutting thicker samples.

A laser cutter/engraver is easy and convenient to work with. Using a laser engraver you can engrave a finished product or a workpiece. To do this you do not need additional technical knowledge or special skills. All you need is to create a file with a template or a sketch in a graphics editor and load it into the working program of your laser engraver.

See a detailed video instruction on the preparatory work and the engraving process on our YouTube channel

TOP-5 items where you can add your name, brand, image or simply write something.

Subscribe on our Youtube channel and do not miss our news and guidance.

If you are not able to watch our video – let us know. All video are free for Endurance customers. We have more than 500 video guidance and tutorials.

You will remain satisfied with the accuracy of laser cutting. The accuracy of the laser beam focusing is 0.1 mm, which allows you to cut out or engrave patterns of almost any complexity.

We would like to remind you that a direct or reflected laser beam can damage your vision. We strongly recommend the use of safety goggles with OD4+ / OD5.

Create and enjoy!

Leather laser cutting

Engraving on leather shoes

Leather and ceramics engraving

Tips for Laser Engraving on Leather

Laser engraving on leather is a great way to add a personal touch to your projects. Here are some tips to help you get the perfect laser engraved design on your leather:

- Pick the right laser for the job: If you’re working with thin leather, you’ll need a laser that can produce a very fine beam. For thicker leather, you’ll need a laser with more power.

- Use the right settings: The speed and power of your laser will have a big impact on how your design turns out. Experiment with different settings until you find what works best for your project.

- Be careful not to overdo it: It’s easy to accidentally burn through leather if you’re not careful. If you’re not sure, err on the side of caution and go slowly.

- Test on a scrap piece of leather first: Before you laser engrave your final project, it’s always a good idea to test out your design on a scrap piece of leather first. This will help you avoid any surprises later on.

- Keep your design simple: The more complex your design is, the more difficult it will be to laser engrave. If you’re just starting out, stick to simple shapes and lines.

- Use laser-friendly leather: Some types of leather are better suited for laser engraving than others. Do some research to find a leather that will work well with your laser.

- Prepare your leather properly: Before you start laser engraving, it’s important to clean and prep your leather. This will help ensure that your design turns out to look its best.

- Mark your lines clearly: Make sure that your lines are marked clearly on the leather. This will help you stay on track.

Having looked at the tips for laser engraving on leather, let’s now have a look at the best laser cutting and engraving machines.

There are many different types of laser cutters and engravers available on the market, so it’s important to choose one that’s right for your needs.

10 Best Laser Cutting and Engraving Machines

Endurance Lasers

Endurance Lasers is a company that has been involved in the laser industry for years. They specialize in the manufacturing of endurance lasers, which are designed to be used on a wider range of applications. The laser cutters can be used on different types and thicknesses of materials.

Endurance lasers are very efficient and durable, making them perfect for use in many different types of businesses. One can be able to make cuts in various materials faster and more easily than ever before.

The lasers comes in varieties. They are available in both CO2 and fiber optic versions. Each type has its own advantages and disadvantages, so it is important to choose the right one for your specific needs.

CO2 lasers are more powerful than their fiber optic counterparts, making them ideal for cutting through thicker materials. They are also more expensive to purchase and operate.

Fiber optic lasers are less powerful than CO2 lasers, but they are much cheaper to buy and operate. They are also better suited for engraving tasks because they do not produce as much heat.

Whether you need one for your workshop or you want to add one to your business’s arsenal, they can help you find the perfect machine.

- Type of Laser: CO2 and Fiber Optic

- Power: There are varieties ranging from 4, 5.6, 10, 15, and even 40 Watts

- Working area: 300 * 210 * 45mm

1.Flux Beamo

Flux Beamo Laser Cutter. Image source:Techcrunch

Flux Beamo is a next-generation laser cutter that offers the power and precision needed to tackle a wide range of projects. With its powerful 40-watt laser, the Flux Beamo can cut through thick materials like wood and acrylic with ease. It also features an intuitive touchscreen interface that makes it easy to select the perfect settings for your project. And because it’s compact and portable, the Flux Beamo is perfect for taking to your local maker space or workshop. Whether you’re a seasoned maker or just getting started, the Flux Beamo is the perfect tool for your next project.

- Type of Laser: CO2

- Power: 40 Watts

- Working area: 300 * 210 * 45mm

2.Universal Laser Systems X60

For businesses that need a powerful laser cutter and engraver but also require advanced automation features, the Universal Laser Systems X60 is an excellent option.

Universal Laser Systems X60 is an advanced laser engraving system designed for a wide range of applications. Whether you need to engrave text on metal, leather, or wood, etch intricate designs into glass, or mark industrial parts and components, this system can get the job done. Its high-power CO2 laser allows it to cut through a variety of materials with ease, while its precise focusing and marking capabilities make it ideal for detailed work. And thanks to its advanced software capabilities, it can be easily customized to suit your individual needs and preferences. Whether you’re an artist looking to engrave original designs onto leather or a manufacturer in need of marking tools, this advanced laser engraving system is sure to meet all of your requirements.

- Type of Laser: CO2

- Power: 10-150 Watts

- Working area: 480 x 240 x 120 mm

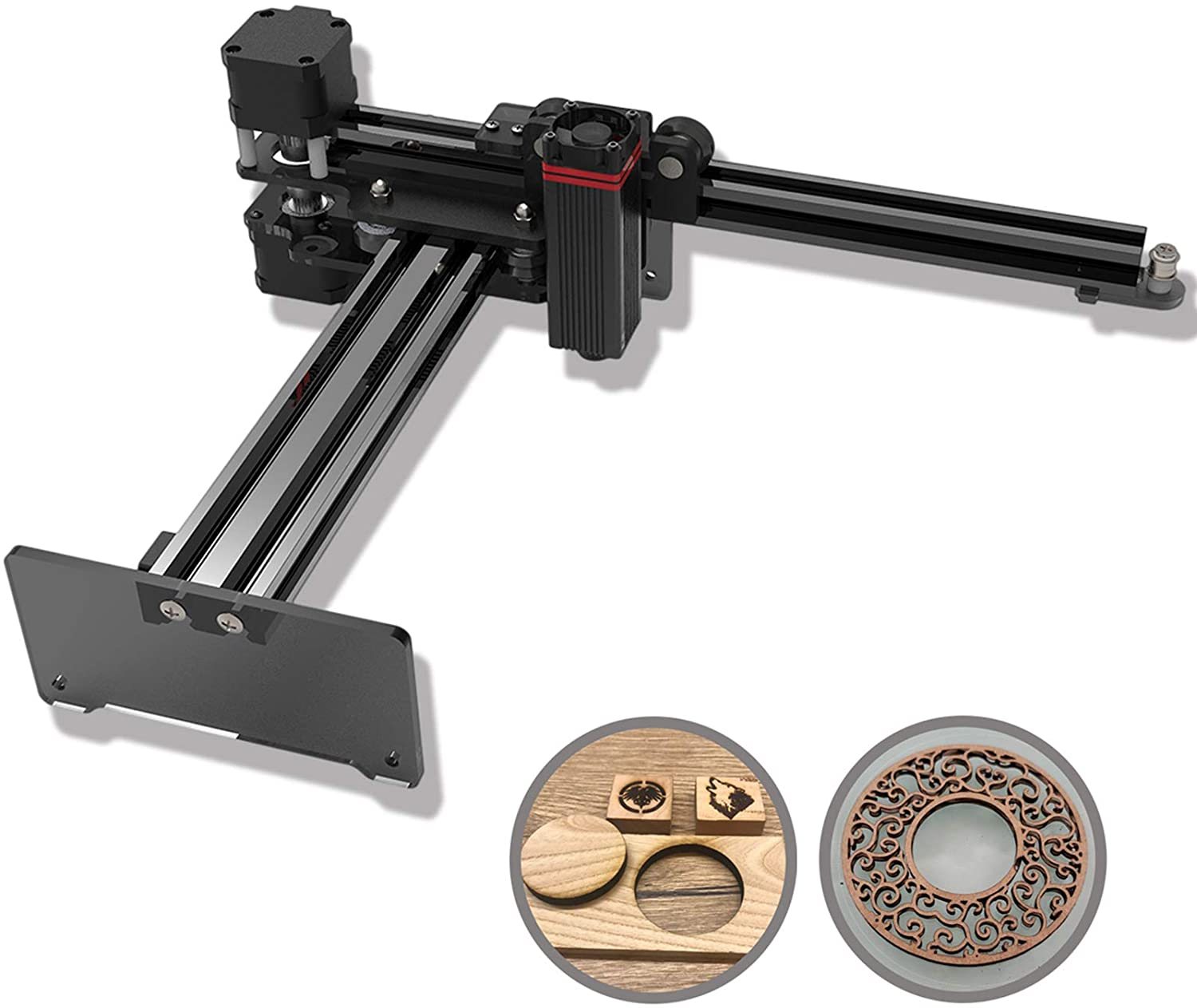

3.NEJE Master 20W

NEJE Master 20W laser machine. Image source:https://ubuy.ke/

The NEJE Master 20W is one of the most powerful laser cutters and engravers on the market. With a sturdy build and high precision capabilities, this machine is perfect for businesses or professionals who need a durable laser machine.

The NEJE Master 20W is a powerful engraving machine that is perfect for both beginners and experienced users. With a user-friendly interface and a variety of features, it it easy to create beautiful engravings. The machine comes with two different laser heads, allowing you to switch between engraving and cutting mode. In addition, it comes with a built-in fume extractor, making it safe to use in any environment. With its high power and versatility, the NEJE Master 20W is the perfect choice for anyone looking for a top-quality engraving machine.

- Type of Laser: CO2

- Power: 20 Watts

- Working area: 170 x 170 x 170 mm

4.Epilog Laser

Epilog laser machine. Image source:epiloglaser.com

The Epilog Laser is a popular choice for both laser cutting and engraving, thanks to its high-quality construction and versatility.

Epilog’s laser machines are designed for precision and detail, making them perfect for intricate projects. The company offers a wide range of models to choose from, so you can find the perfect machine for your needs.

This laser is also known for its durability, which means you can rely on your machine for years to come. If you’re looking for a top-quality laser cutter or engraver, the Epilog Laser is a great choice.

- Type of Laser: CO2, Fiber & Dual-Source

- Power: 60-80 Watts

- Working area: 610 x 610 x 228 mm

5.Trotec Lasers

Trotec lasers are known for their reliability and precision. They feature advanced software that makes it easy to create detailed designs and patterns. The company also offers a wide range of models to choose from, so you can easily find the right machine for your needs. And with its high-quality construction and durable components, a Trotec laser cutter or engraver can be a valuable investment for your business or professional work. So if you’re looking for a reliable and flexible laser machine, the Trotec line is definitely worth considering.

- Type of Laser: CO2, Fiber & Dual-Source

- Power: 60-80 Watts

- Working area: 610 x 610 x 228 mm

6.The K40 Whisperer

The K40 Whisperer DIY Laser. Image source: Hackster.io

This is a great choice for hobbyists or DIY enthusiasts who are looking for an affordable laser cutter or engraver.

The K40 Whisperer offers a wide range of features and customization options, making it easy to create detailed designs and patterns. With its intuitive software and user-friendly interface, it is perfect for beginners or anyone who wants a versatile laser cutter without investing too much money. And with its compact size and portable design, this machine is also ideal for those who need a laser cutter that can easily be moved from one workspace to another.

So if you’re looking for an affordable yet high-quality laser machine, the K40 Whisperer is definitely worth considering.

- Type of Laser: CO2

- Power: 40 Watts

- Working area: 300 x 200 mm

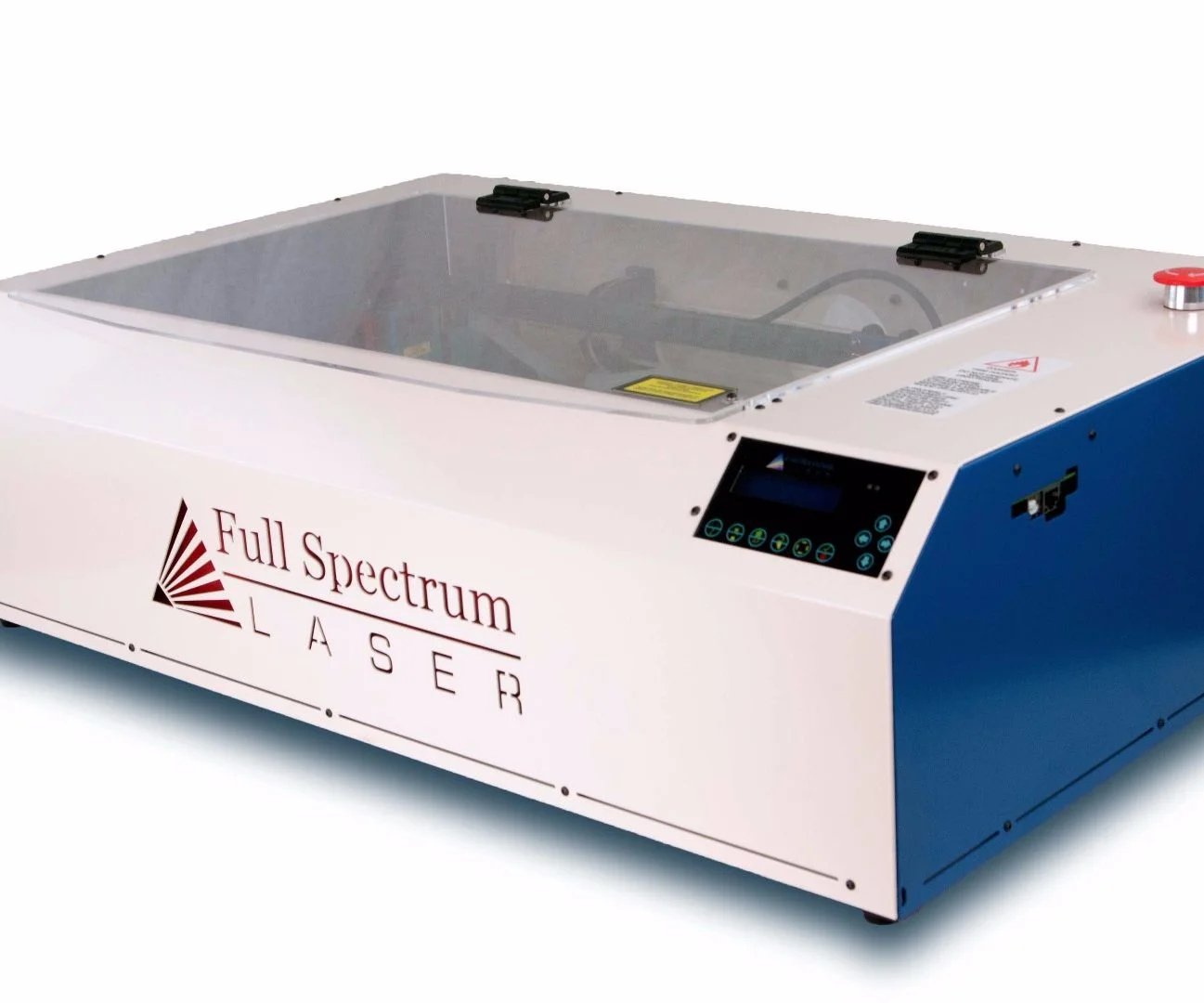

7.The Full Spectrum

The full spectrum laser. Image source:Instructables.com

The Full Spectrum Laser is another great choice for those who need a versatile and powerful laser cutter or engraver.

It offers high-quality construction and advanced features, making it perfect for businesses or professionals who need a reliable machine. With its wide range of models to choose from, you can easily find the perfect machine for your needs. And with its high precision and durable components, the laser is a great choice for those who need a top-quality machine that can handle even the most intricate projects.

- Type of Laser: Sealed CO2 Laser Tube

- Power: 45 Watts

- Working area: 939.8 x 698 x 898.525mm

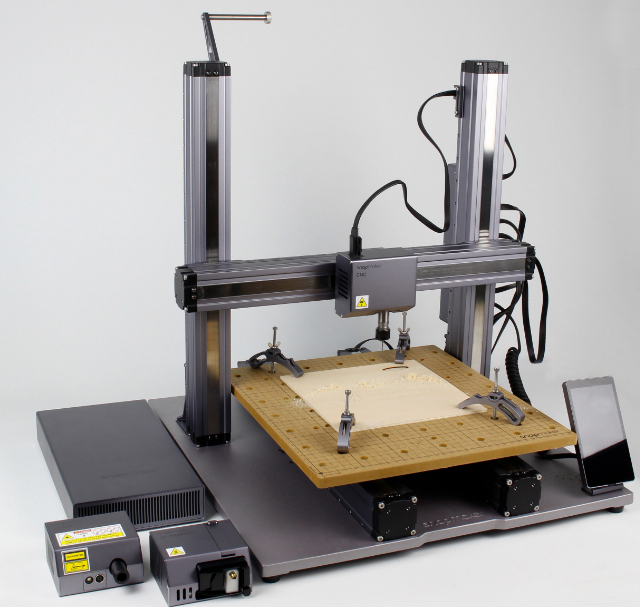

8.Snapmaker 2.0

Snapmaker 2.0 laser machine. Image source:makezine.com

If you’re looking for a laser cutter or engraver that is both affordable and easy to use, the Snapmaker 2.0 is a great choice. It offers a wide range of features and customization options, making it perfect for beginners or anyone who wants an easy-to-use machine.

With its compact size and portable design, the Snapmaker 2.0 is also ideal for those who need a laser cutter that can easily be moved from one workspace to another. So if you’re looking for an affordable and user-friendly laser machine, the Snapmaker 2.0 is definitely worth considering.

- Type of Laser: CO2

- Power: 10 Watts

- Working area: 160 x 160 x 145 mm

10. The Epilog Laser

The Epilog Laser is one of the most popular choices for those who need a reliable and precise laser cutter or engraver.

The Epilog Laser offers high-quality construction and advanced features, making it perfect for businesses or professionals who need a top-quality machine. With its wide range of models to choose from, you can easily find the perfect machine for your needs. And with its high precision and durable components, the Epilog Laser is a great choice for those who need a reliable and precise laser cutter or engraver. So if you’re looking for a top-quality laser machine, the Epilog Laser is definitely worth considering.