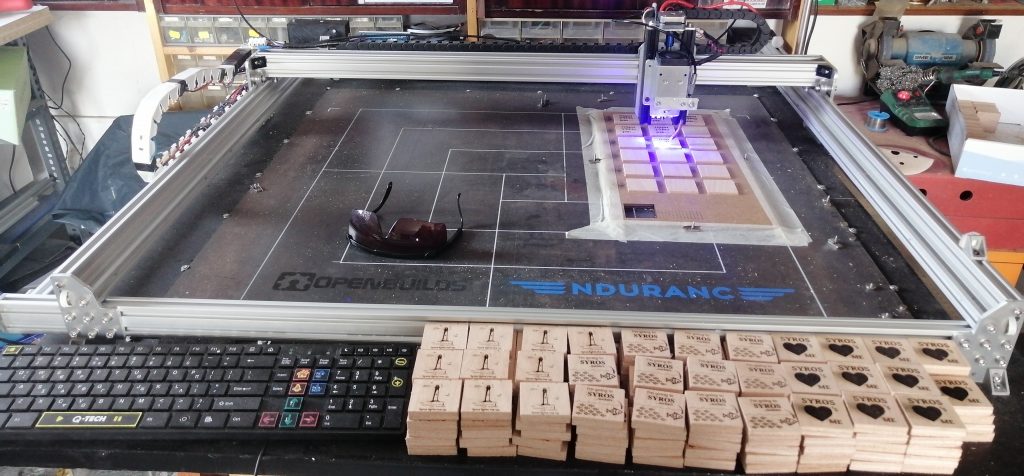

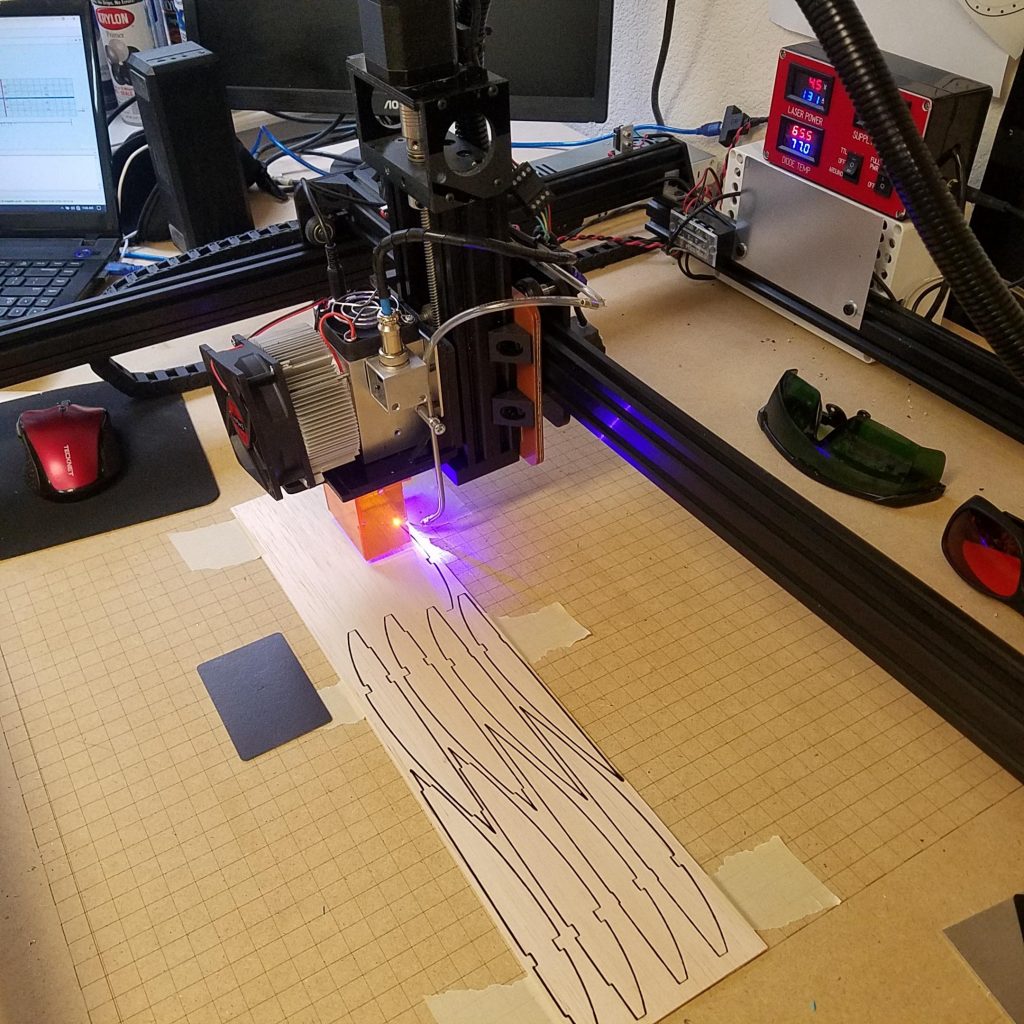

Our customer is very happy with an Endurance laser

“Hi George,

I thought you would like to see this video I made of my endurance laser in action.

I am very satisfied with the laser’s performance! It totally works as advertised!

Have a happy new year,

Carman Lynner”

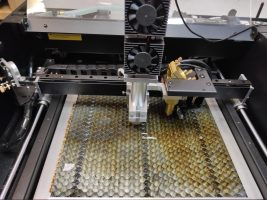

This video is created with Lightburn and run on a CNC router frame with Mach 3/ smoothstepper card using PWM M11/M10 commands.

(0)

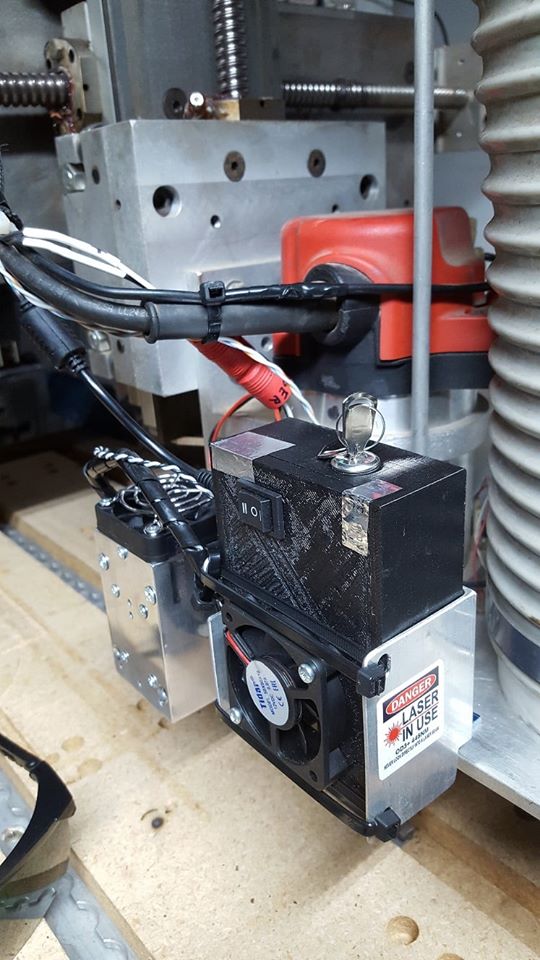

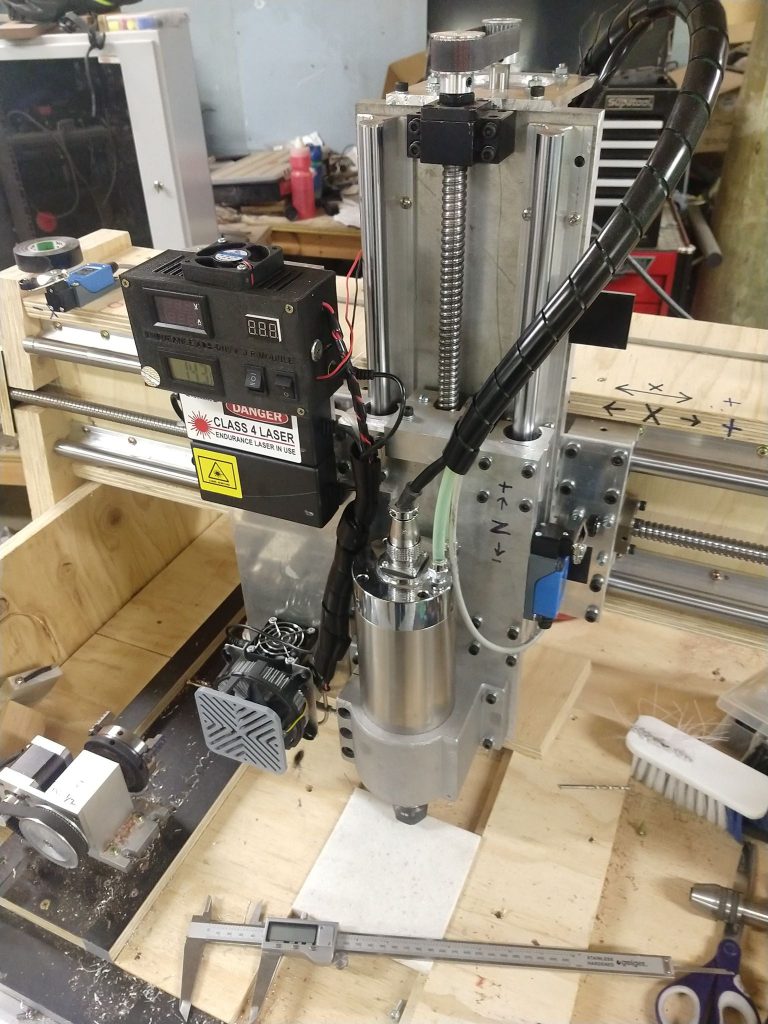

A real customer 10 watt PLUS laser review

Installing 10 watt Delux laser (made by Ed Macri)

Endurance lasers are fully compatible with all CNC frames:

- WorkBee V2.2 Complete Kit

- Openbuilds | OpenBuilds ACRO Systems

- Workbee from Ooznest

- Shapeoko 3

- Eleksmaker A3 / A5

- Shark HD4/ HD5 (only with PRO lasers)

- Stepcraft

- CNC 3018 / 3040

- CNC Beaver

- X-Carve

- Blue Elephant

- Avid CNC

- MPCNC

- MillRight CNC Carve King | Mega V Router Bundle

Installing Endurance lasers on a different CNC machine

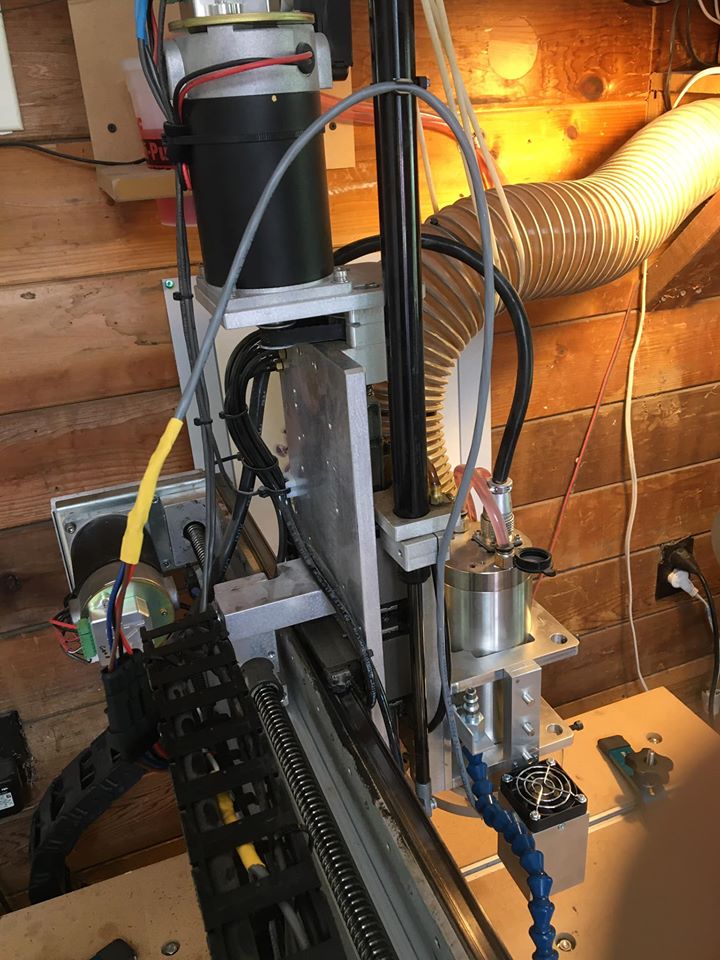

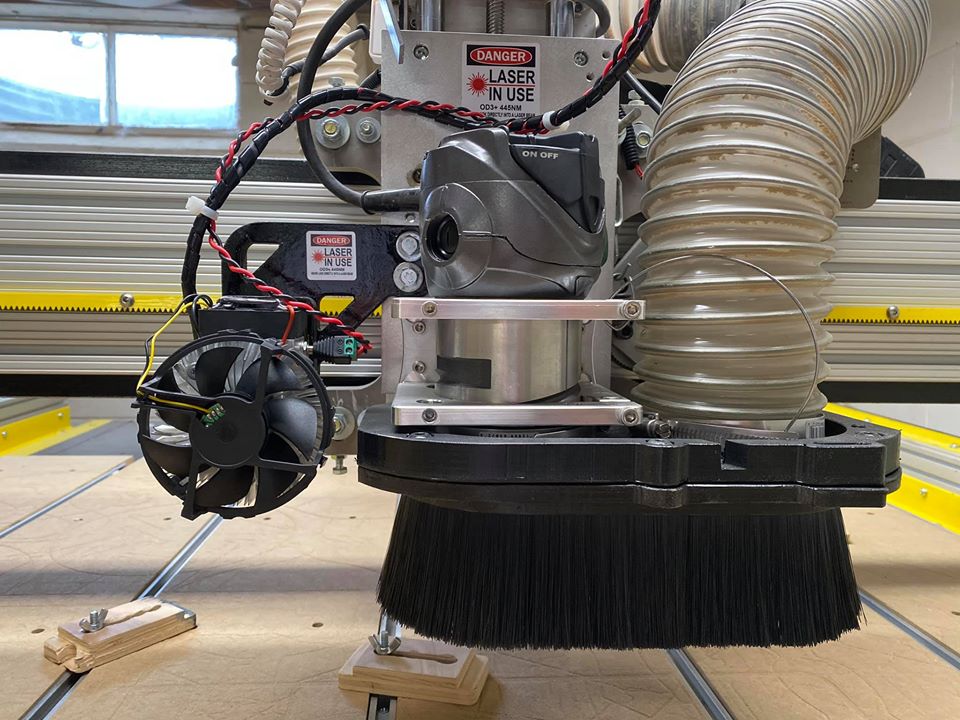

Installing a 15 watt “DUOS” ver 1.1 on a Shark CNC frame (NextWave Automation)

Use dynamic PWM for better control.

Next Wave – SHARK HD520 CNC Machine Features:

- Linear Guides and bearings on the gantry

- Anti-backlash, wear-compensated leadscrews on all axis

- Interlocking rigid aluminum table with virtually unlimited clamp positioning

- Aluminum gantry backplate for heavy machining capabilities

- Aluminum router mounting clamp

- Steel encased gantry legs for increased rigidity

- Automatic router on and off control

- USB Interface

- X and Y homing capability

Next Wave – SHARK HD520 CNC Machine Specifications:

- Table dimensions: 28″ x 63″

- XYZ travel: 25″ x 50″ x 7″

- Overall Dimensions: 36-1/4″W x 63″L x 24-1/2″ H

- 110 /115 V

- Lifetime Technical Support

- Made in the USA

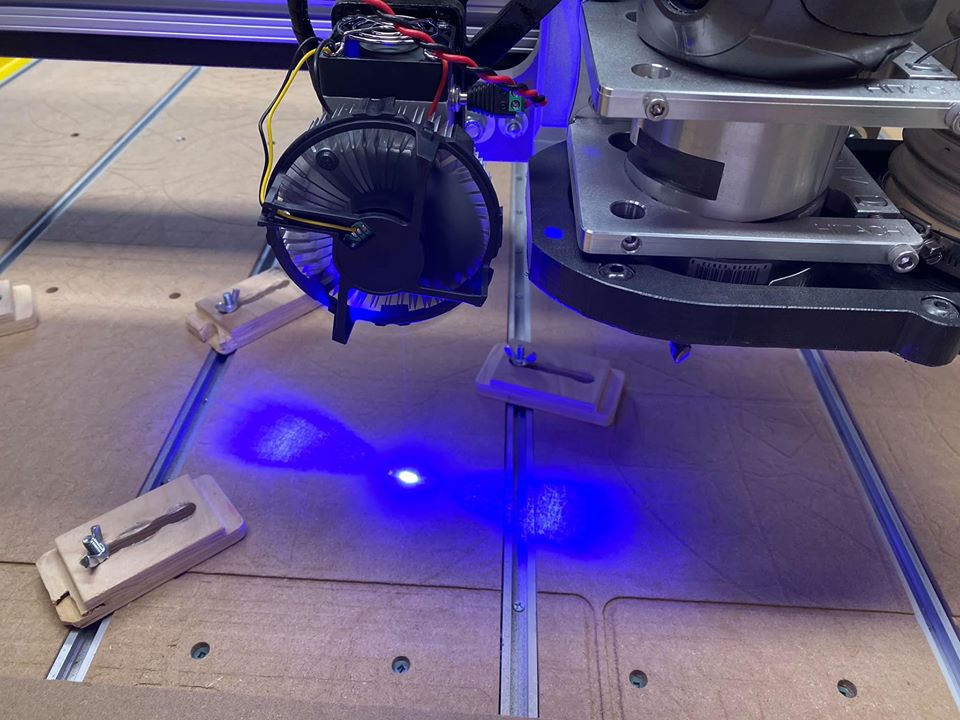

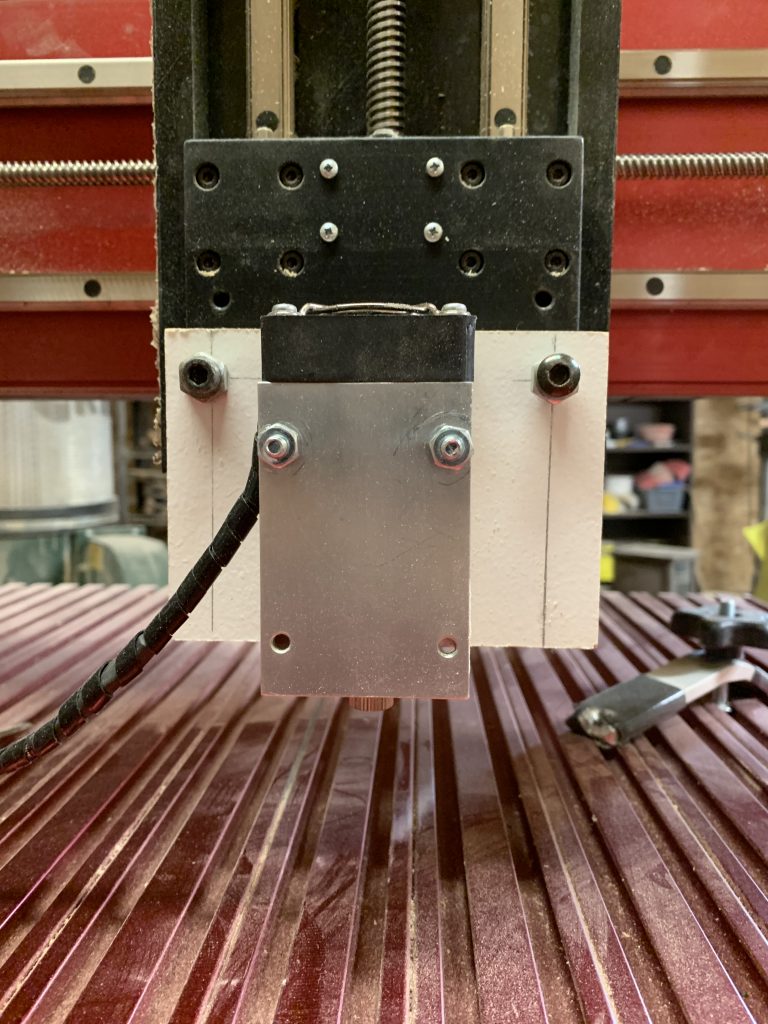

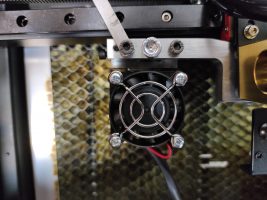

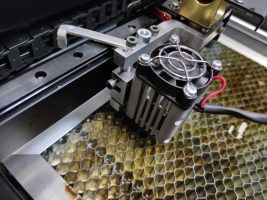

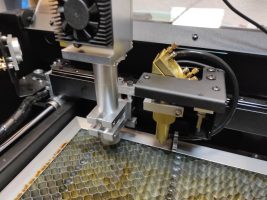

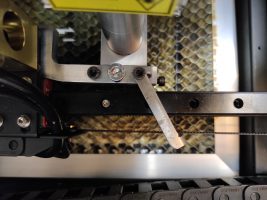

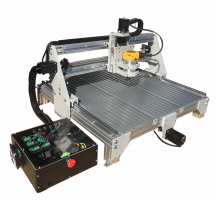

(1)

Building Your Own Laser Engraving Machine with Arduino >>>

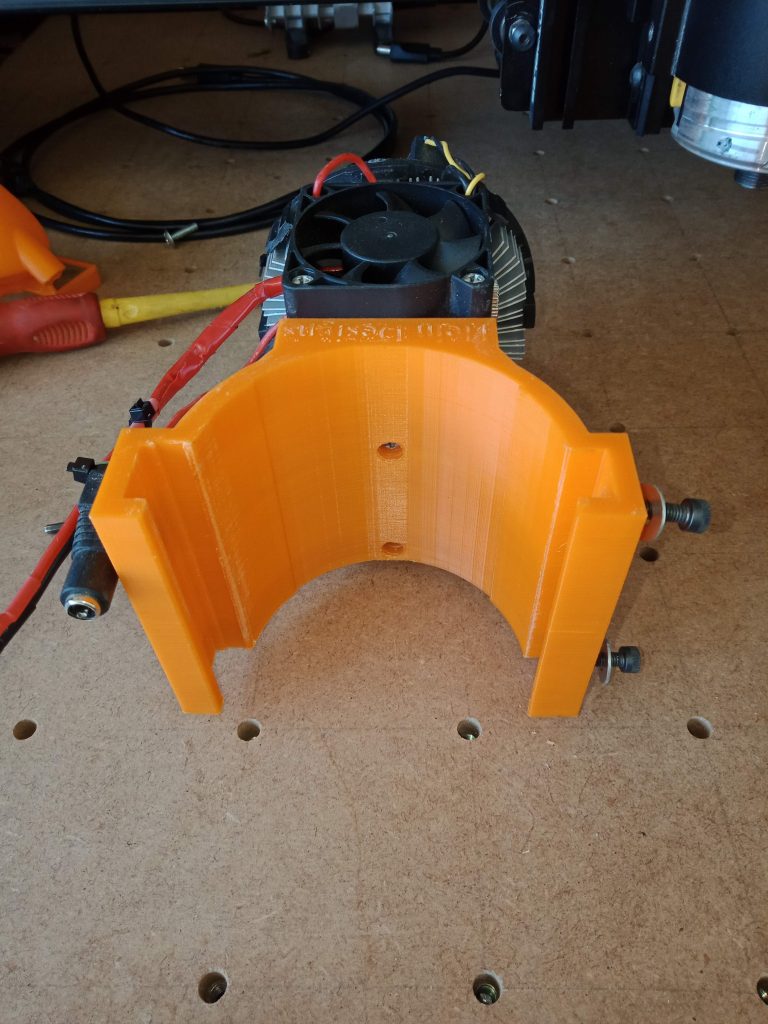

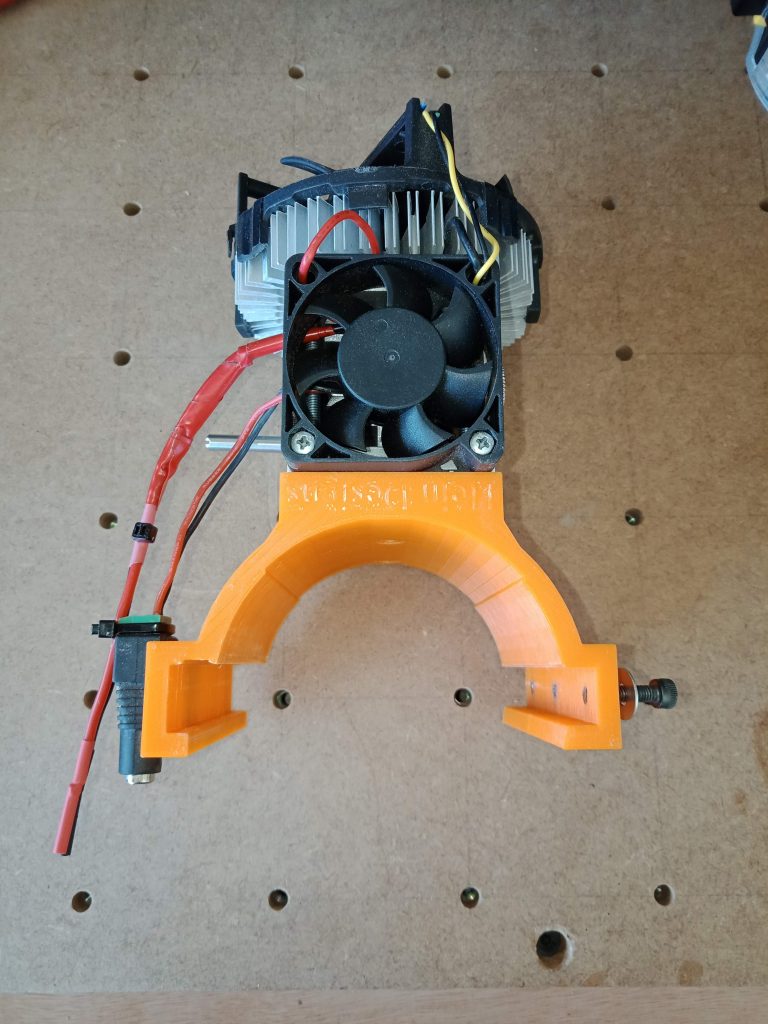

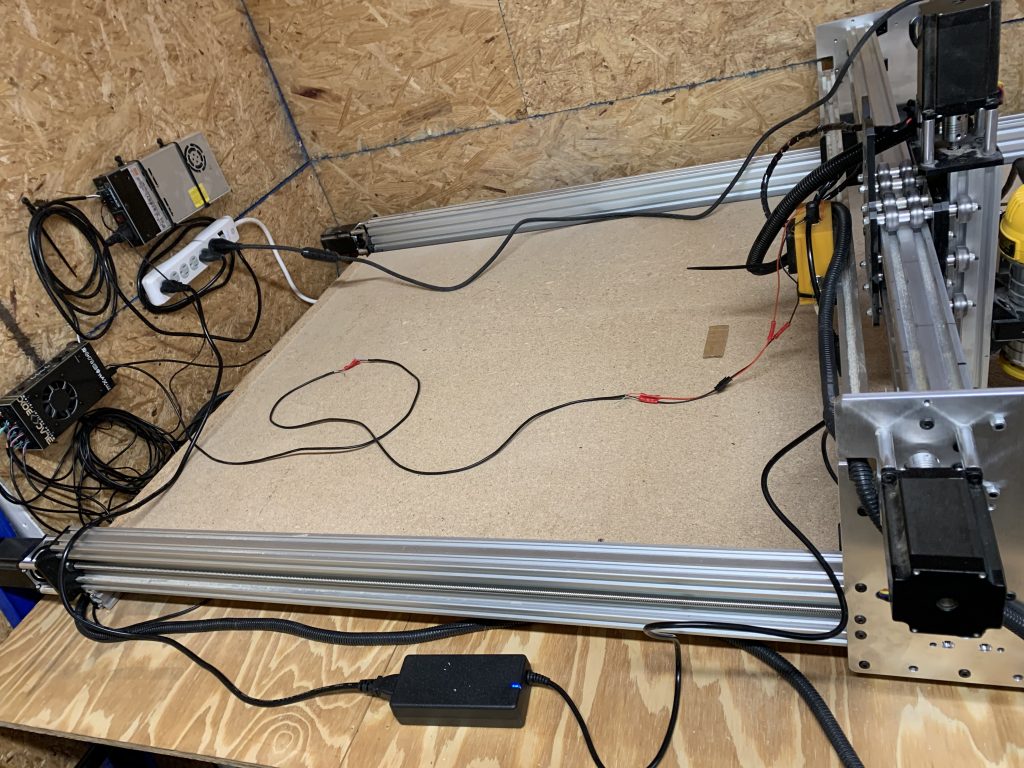

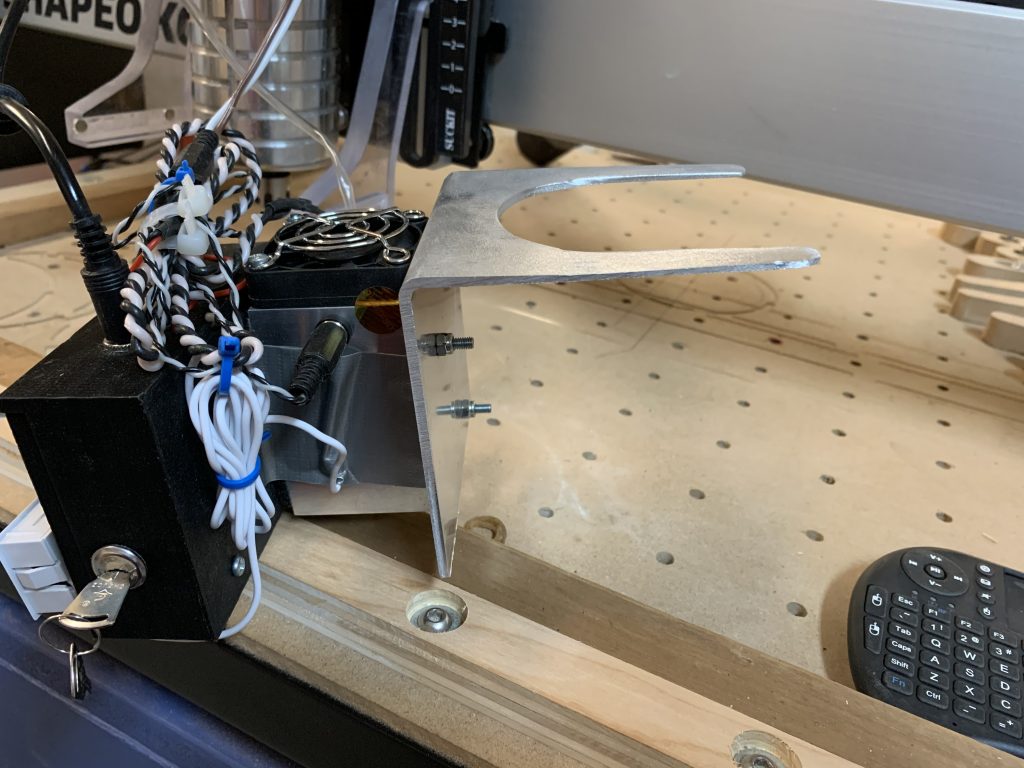

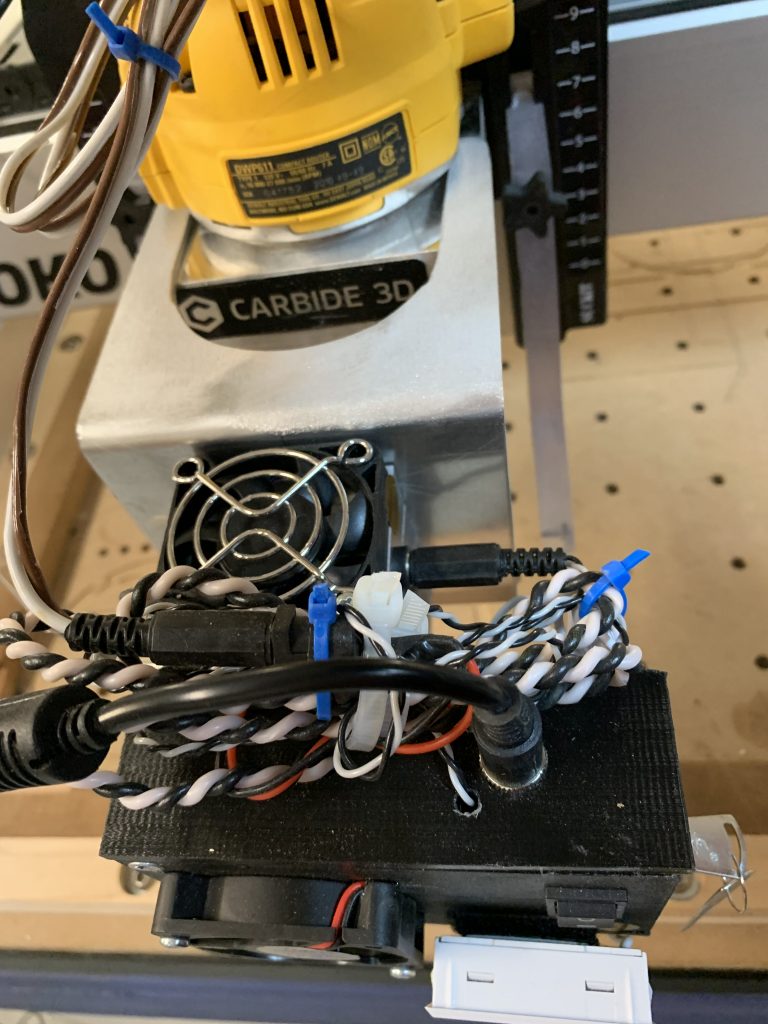

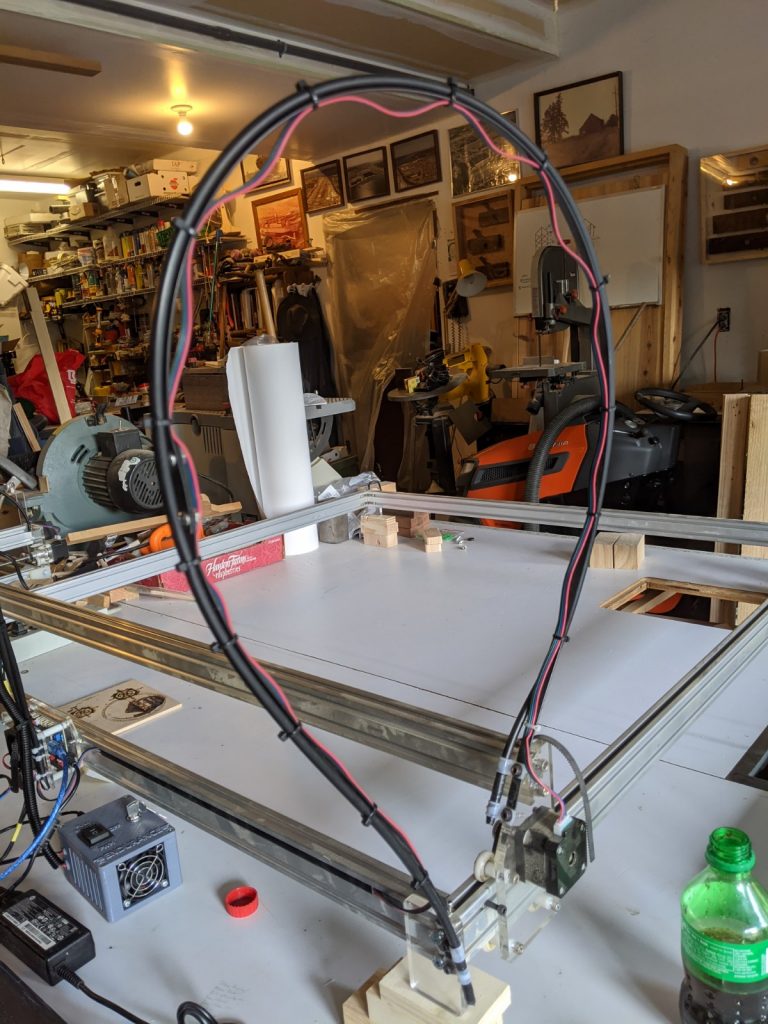

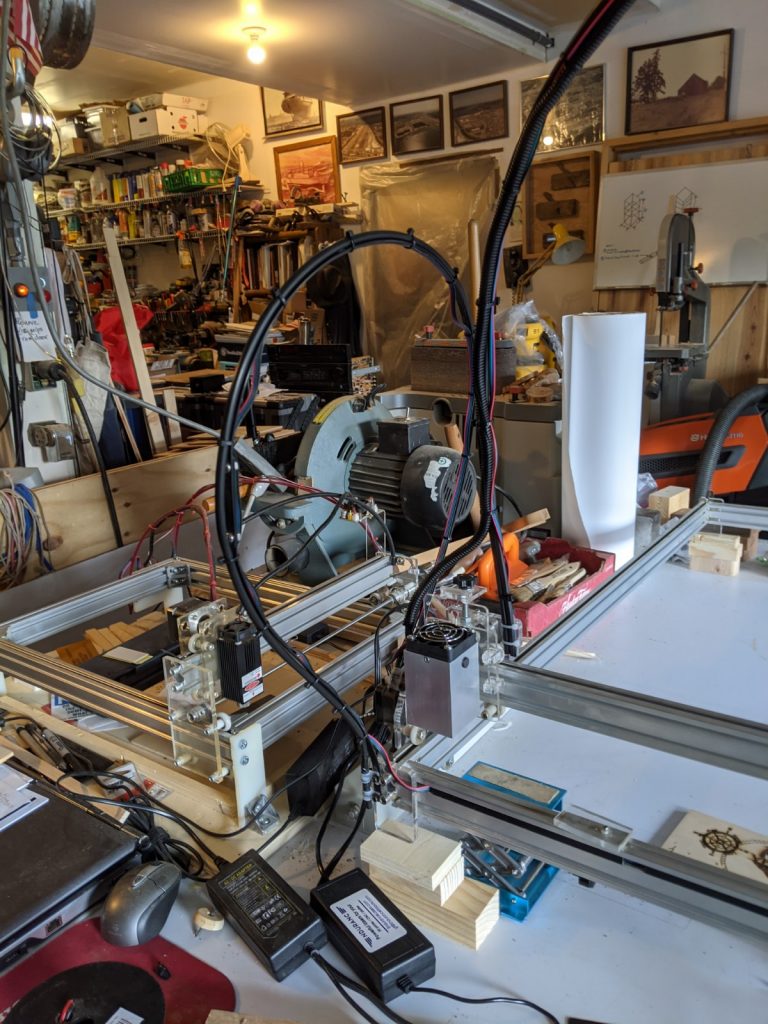

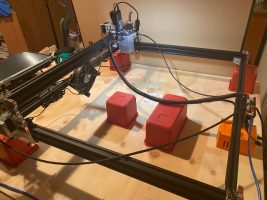

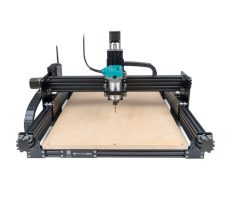

(2) X-carve

by Sam Gironda

X-carve data specs:

- Cutting area: 300 x 300 x 65mm (500), 500 x 500 x 65mm (750), 750 x 750 x 65mm (1,000)

- Machine footprint: 750mm x 500mm (500), 1010 x 750mm (750), 1250 x 1000mm (1,000)

- Weight: –

- Firmware: GRBL

- OS: Browser

- Features: Hackable/expandable, open-source, free design software, enclosed/protected electronics, single sheet wasteboard

Learn more about X-carve CNC on All3DP>>>

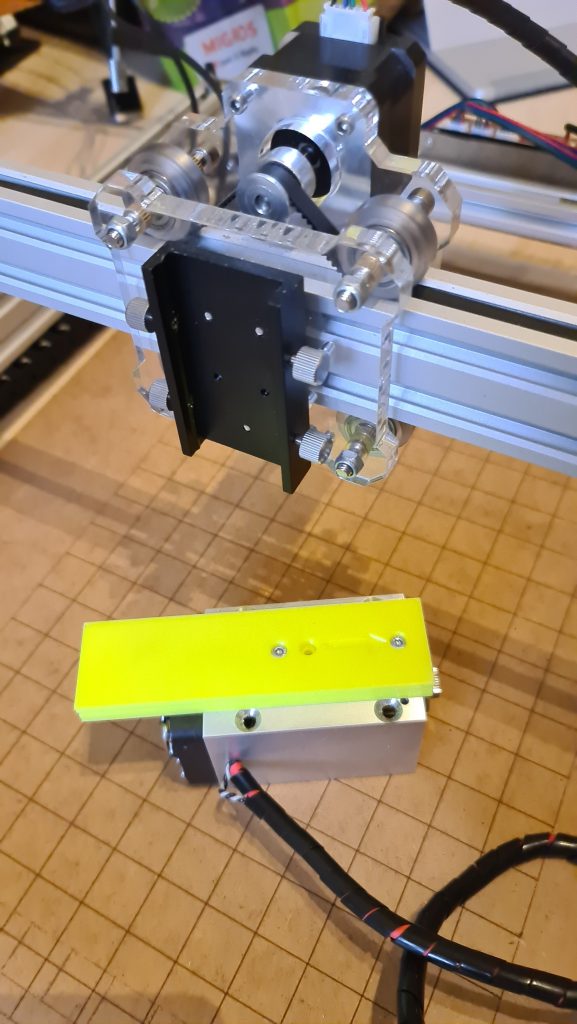

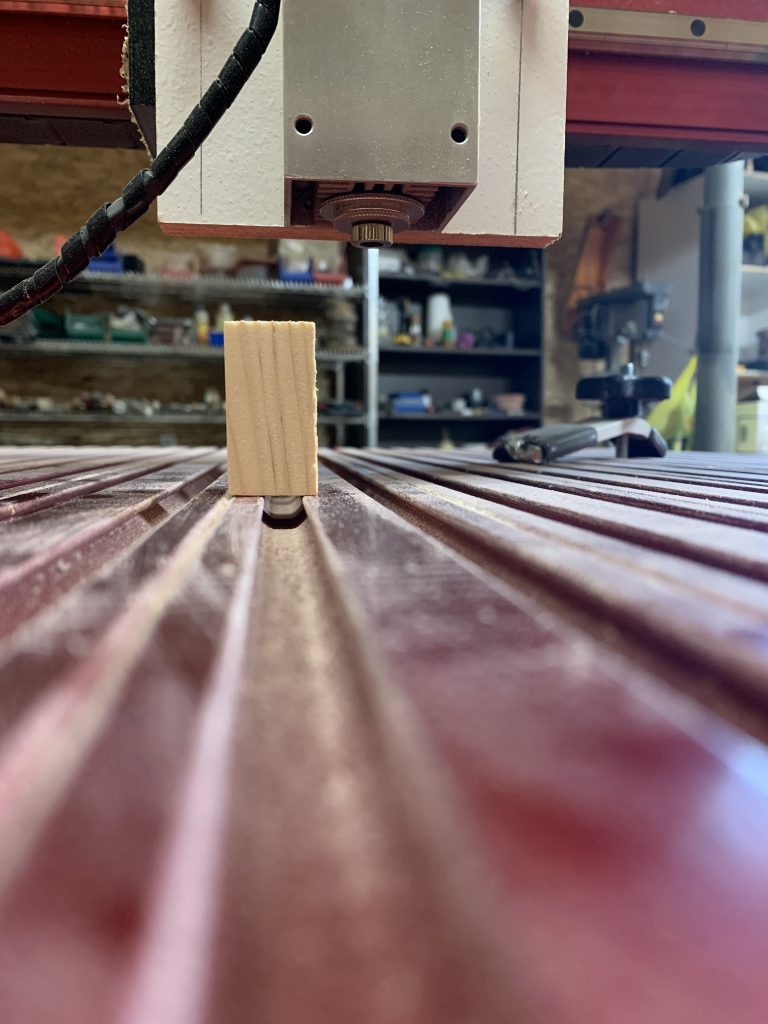

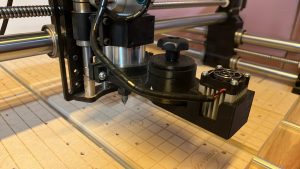

(3) a DIY plywood CNC router

(4)

(5)

(6)

(7)

(8)

(9)

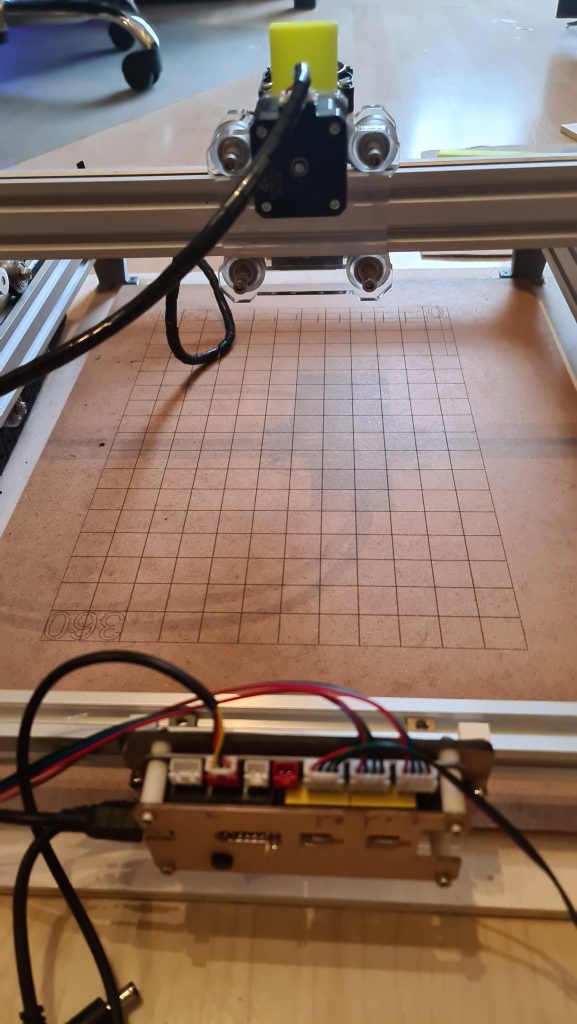

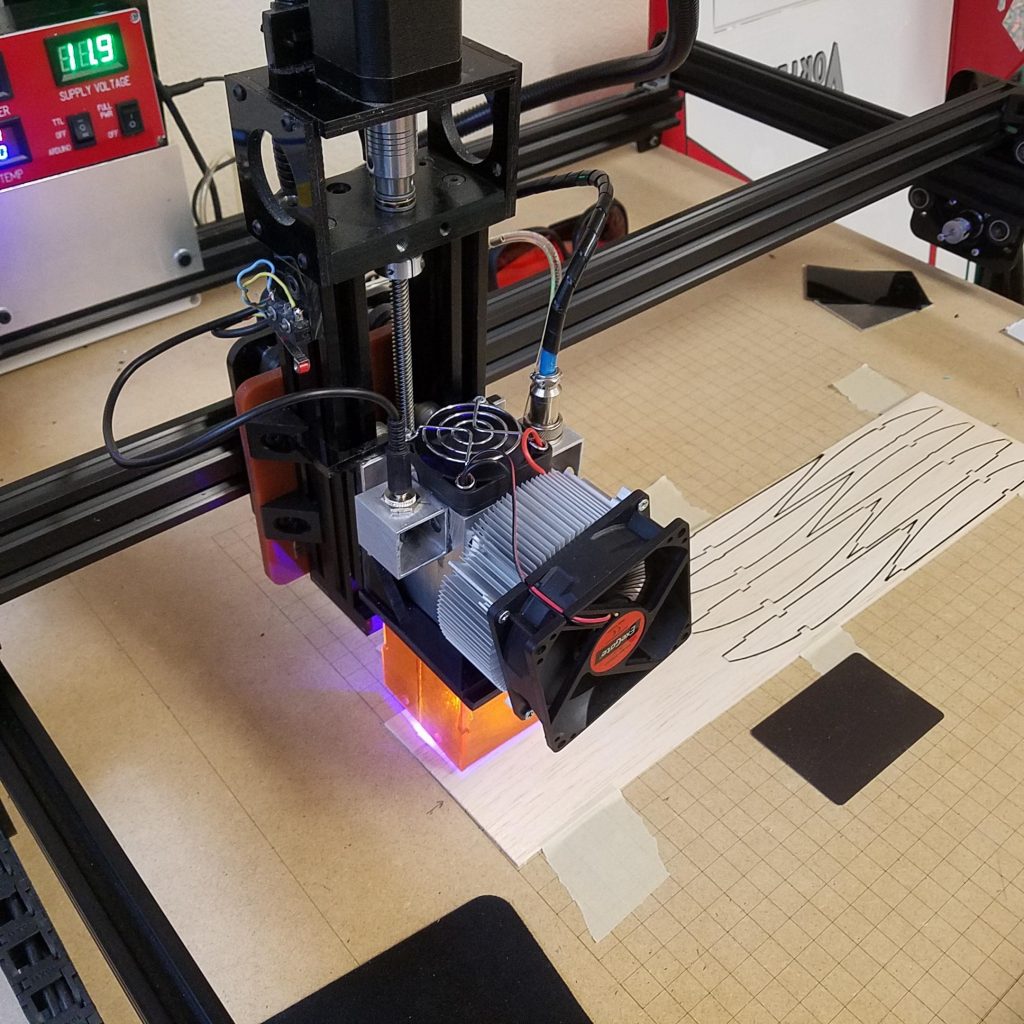

By Alexander_Scheiflinger

My machine is number 9, it’s a 3040 CNC. It operates with LaserGRBL firmware on an Arduino board, controlled by Lighburn.

CNC 3040 technical specifications

MECHANICAL SPECIFICATIONS

- Motor: 500 W motor, 8,000 RPM

- Upgradeable: Yes (laser module or custom spindle)

- Machine dimensions: 610 x 450 x 390 mm (24.0″ x 17.7″ x 15.4″)

- Frame: Extruded aluminum

- Worktable: Extruded aluminum

- Linear system: Extruded aluminum linear rails with three chrome plate hard shafts

- Motion: Two-phase stepper motors

- Z probe: Yes

- Limit switches: Yes

SOFTWARE

- Programs: GRBL v1.1 / GRBLControl (Candle)

- Interface compatibility: Windows and MacOS (Linux with use of a proxy)

OTHER

- Manufacturer: Vevor

- Connectivity: USB

- Onboard controls: Yes

- Emergency shut off: Yes

Learn more about CNC 3040 CNC router on All3DP | CNC 3040 pdf guide

(10)

(11)

(12)

(13)

(14) Stepcraft – 420 CNC router

Starcraft 420 data sheet

Features

- Quickly turn your ideas into finished products in no time

- Stable, compact, accurate, and fast

- Strong, rigid construction

- Highly accurate, thanks to high-quality, precision components that are matched and test fit at the factory.

- Many accessories and add-on tools are available

- Works with a large variety of materials, including woods, plastics and non-ferrous metals (aluminum, brass, copper)

- The system comes completely ready-to-run

- Easy USB connection to PC

- STEPCRAFT designed and manufactured the custom aluminum extrusions that provide superior torsional rigidity and functionality – No off-the-shelf or Chinese manufactured frame parts

- Connecting elements made of stainless steel and aluminum

- 8-point ball bearing carriage on all axles/linear profiles

- High-precision lead screws from Switzerland

- Play-free movement of the carriages (continuous adjustability, freely accessible externally without disassembly)

- The maximum working speed of 3000 mm/min (50mm/sec)

- Inspection covers on the Y-axis for easy maintenance and care

- Silicone seals used to protect the mechanism from dirt on the Y-axis

- Worktop made of wear-resistant HPL (similar to Formica- countertop material), optional aluminum T-slot table

- A Quick-change system allows you to switch from one application to the next in seconds

- Integrated workpiece clamping system for plate materials with a thickness of up to 15mm

- Flexible tool holder through Ø 43 mm clamping collar, optional adapters available for Dremel, Proxxon, Dewalt DW611, and Bosch Colt

- Integrated control electronics in the machine housing. Only requires a power supply cable and USB cable to the computer – no wiring clutter.

- 4th-axis unit optional for rotary machining

- Compact size on many models – perfect for the desktop or workbench

- Our control software has been specifically designed to be easy for the novice, but to have all the functionality for the professional user

- Engineered and Manufactured in Germany with Support, Parts, Service, and Assembly in Connecticut, USA.

(15)

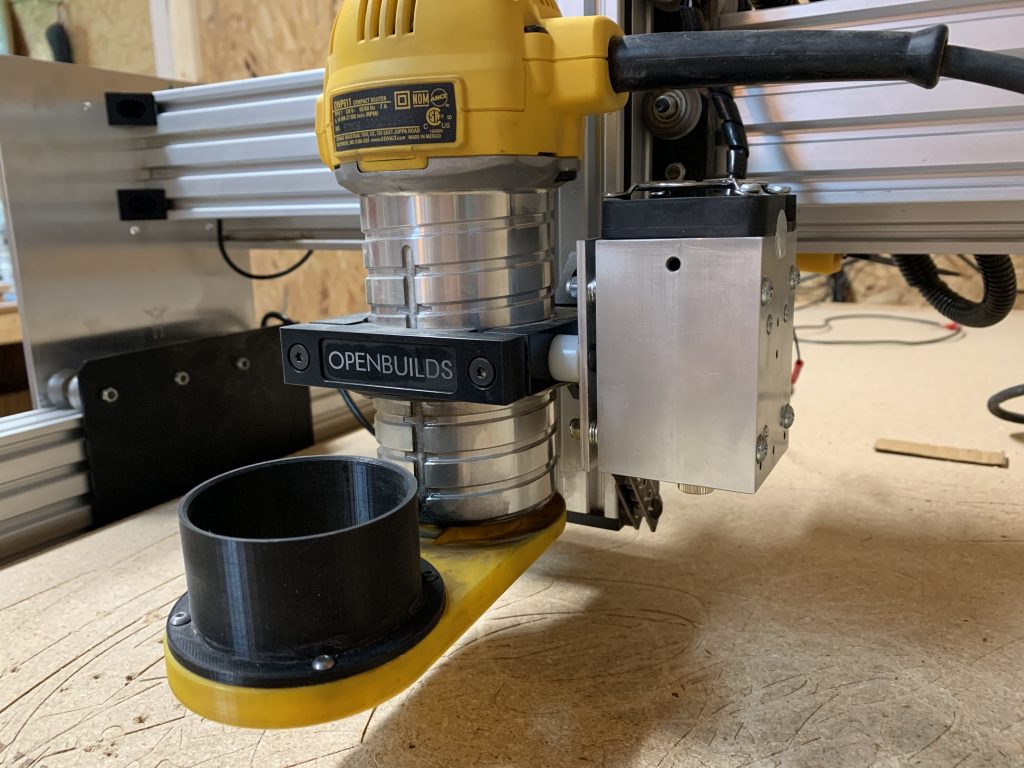

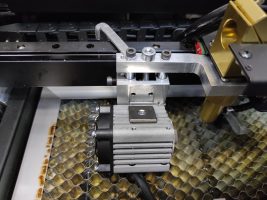

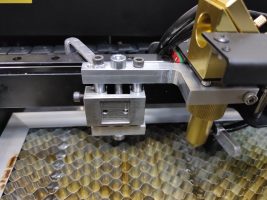

(16) Beaver CNC

By Michel Helvensteijn

I have a Beaver CNC, running on a xpro4 CNC board with lightburn software, installation is easy for the board, the software is great, and the Endurace laser does where i bought it for,

George from endurace is 100% behind his product and the community on facebook are ready for each other if there are any questions

(17)

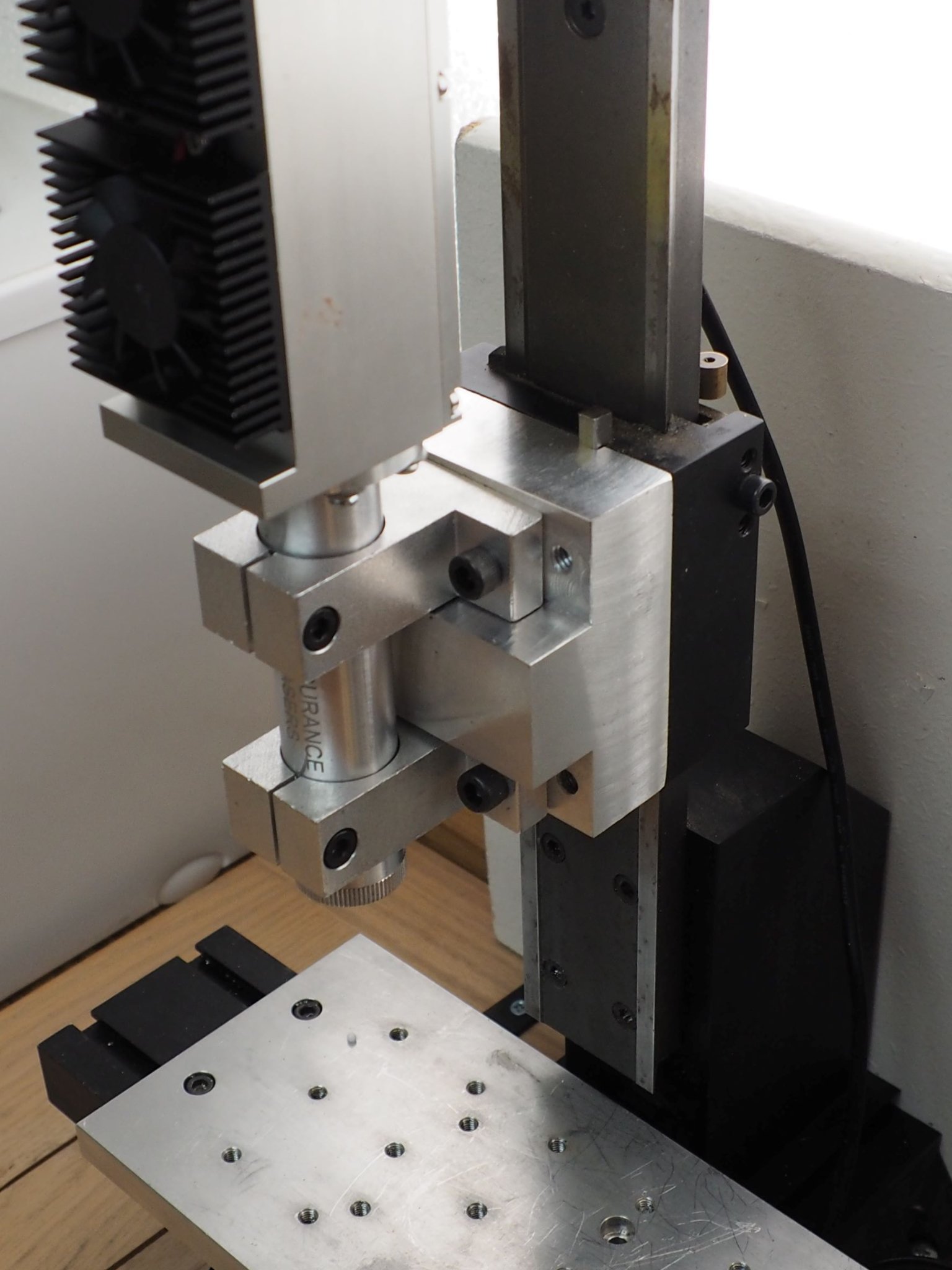

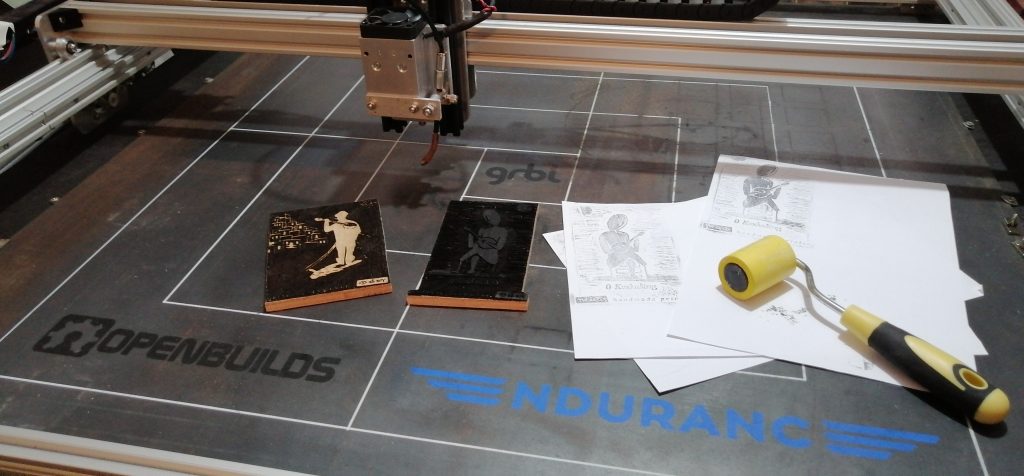

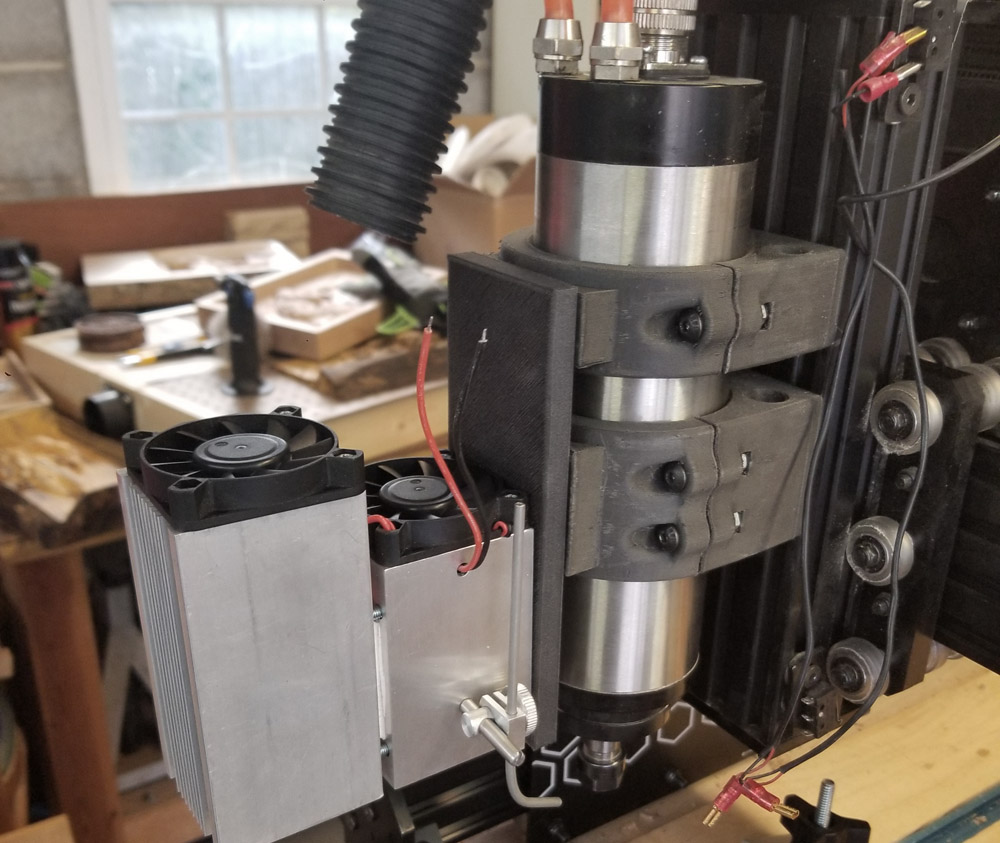

(18) Openbuilds C-Beam / DIY / CNC 3018

Openbuilds C-Beam Machine Specs:

- X Axis Travel 350mm – (13.5″)

- Y Axis Travel 280mm – (11″)

- Z Axis Travel 160mm – (6″) Actual working depth is 1.250″

- Available in Natural or Black versions

- Machine Accuracy – 0.05mm~0.10mm

Bundle Includes:

- Mechanical Parts

Electronics Needed (Sold Separately):

- Driver Board – We recommend the Blackbox

- Power Supply – 12V or 24V Depending on your set up

- Makita Router Spindle

(19)

(20)

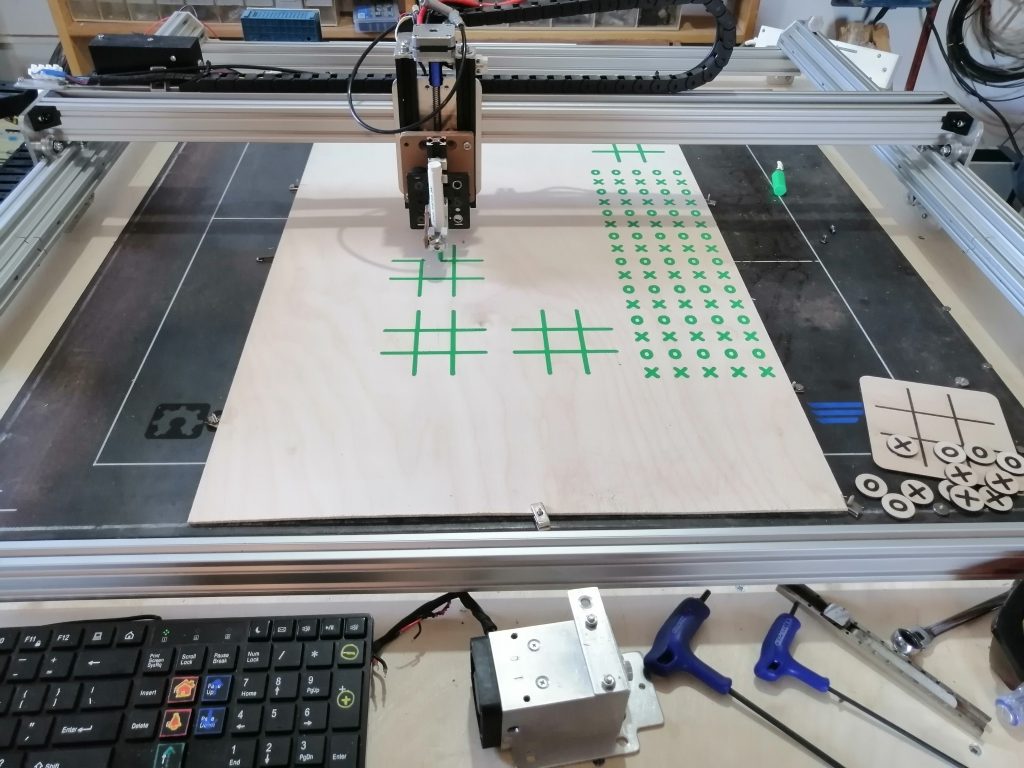

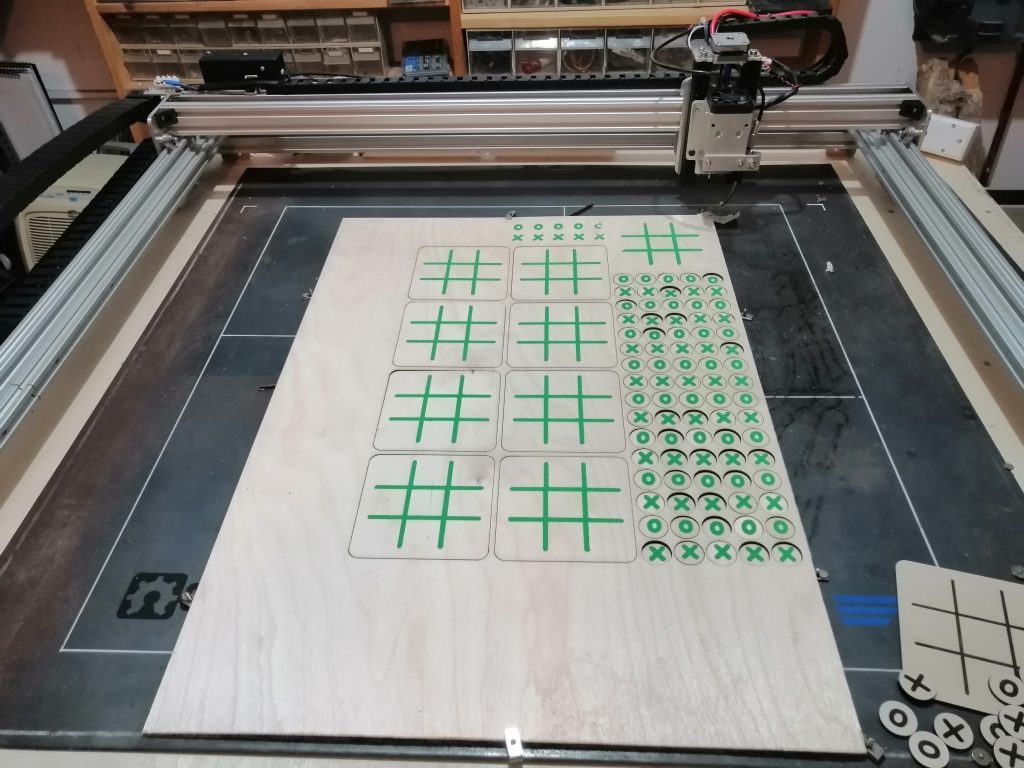

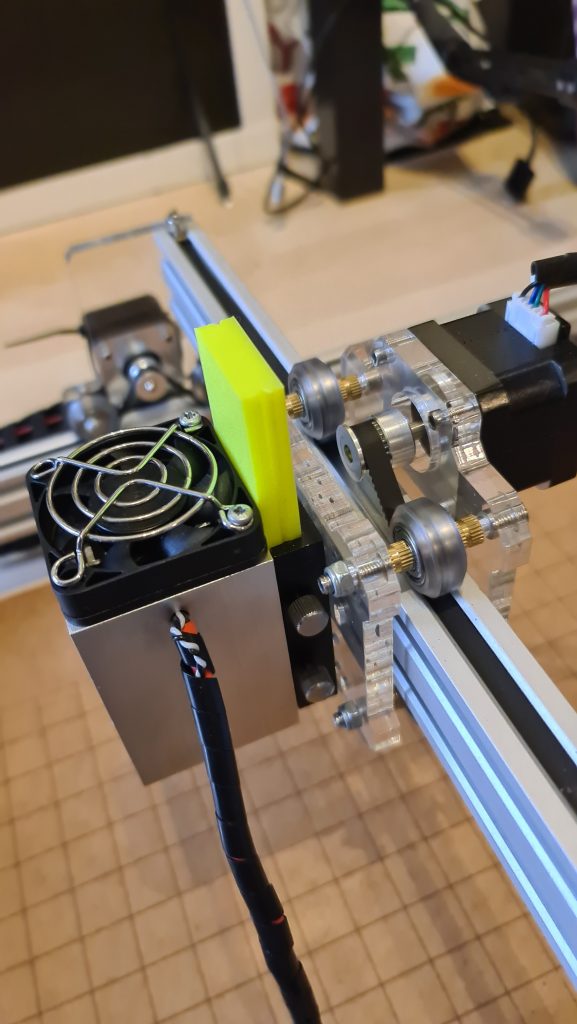

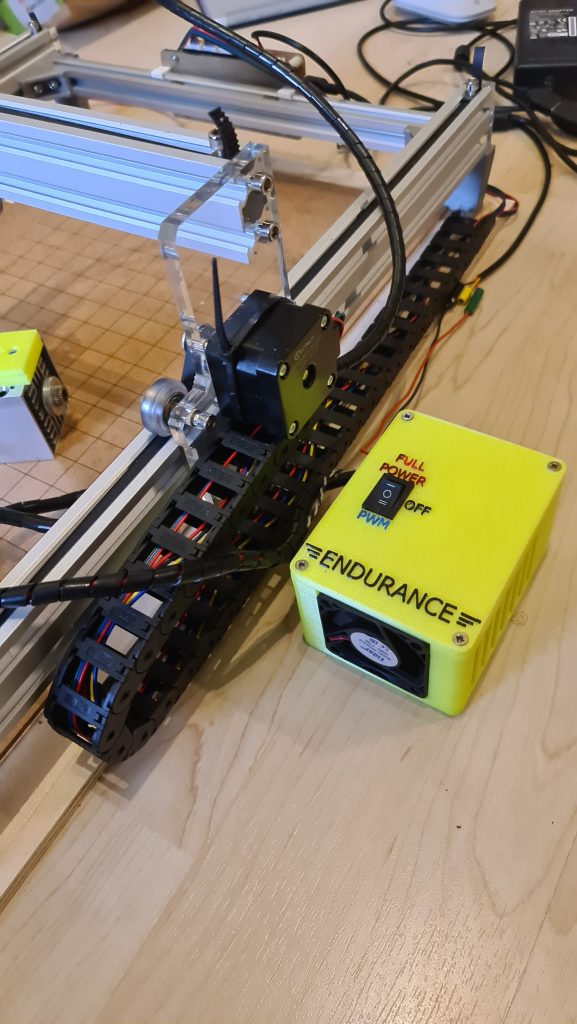

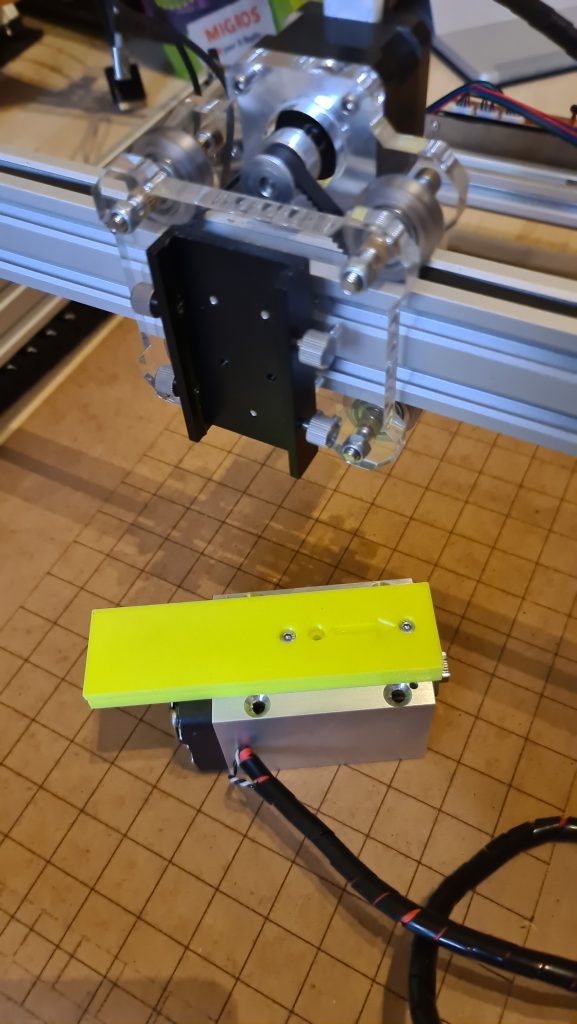

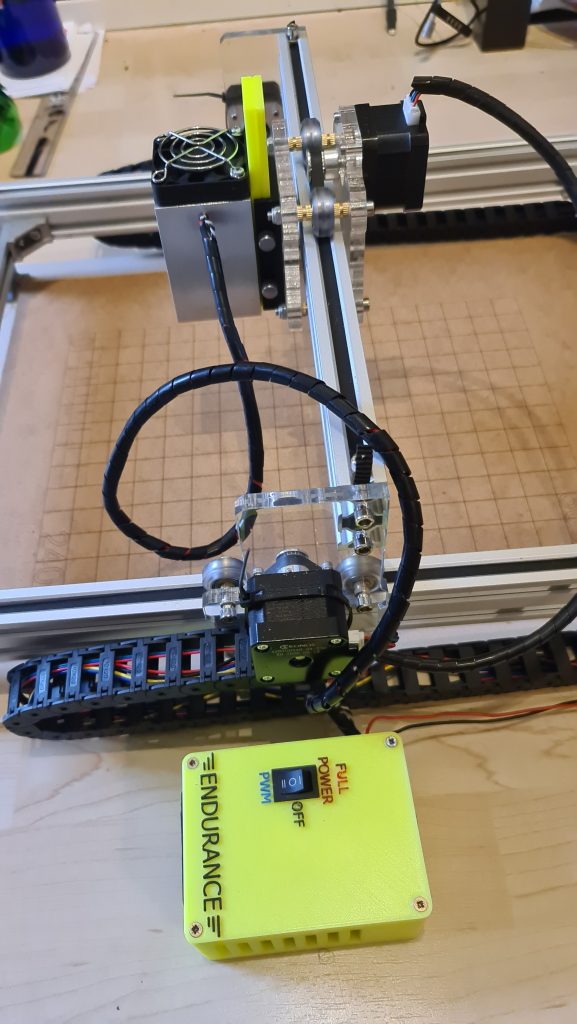

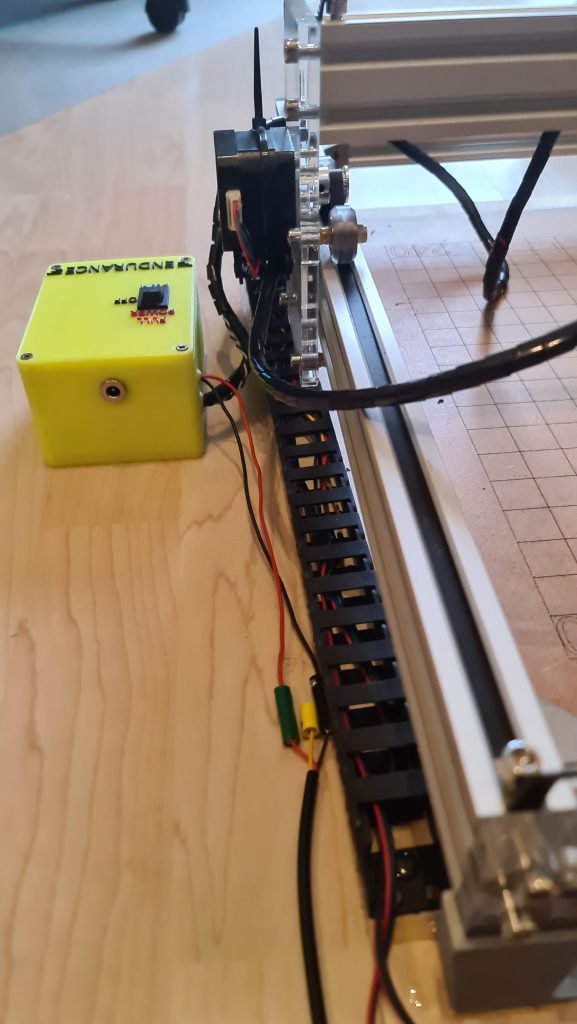

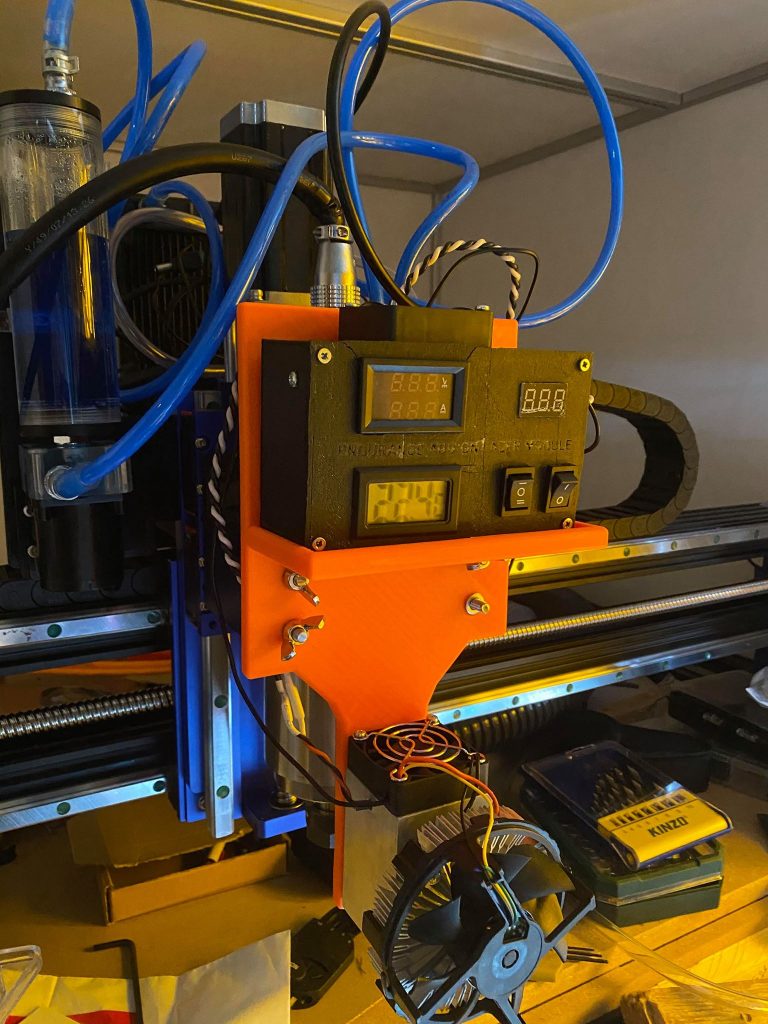

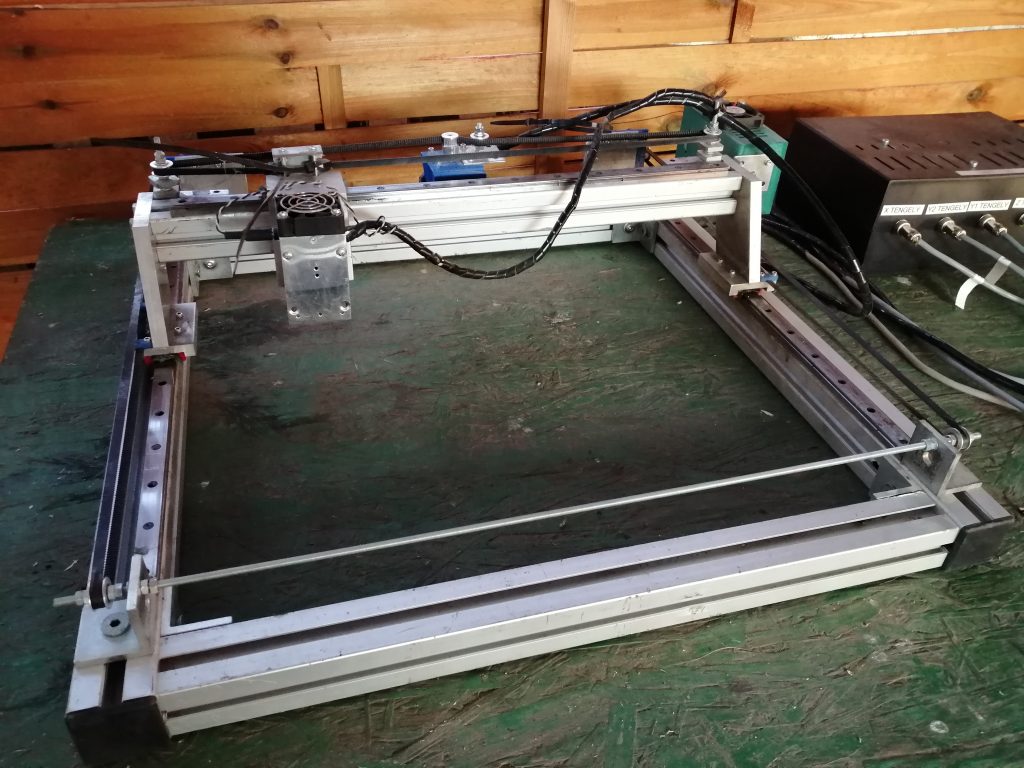

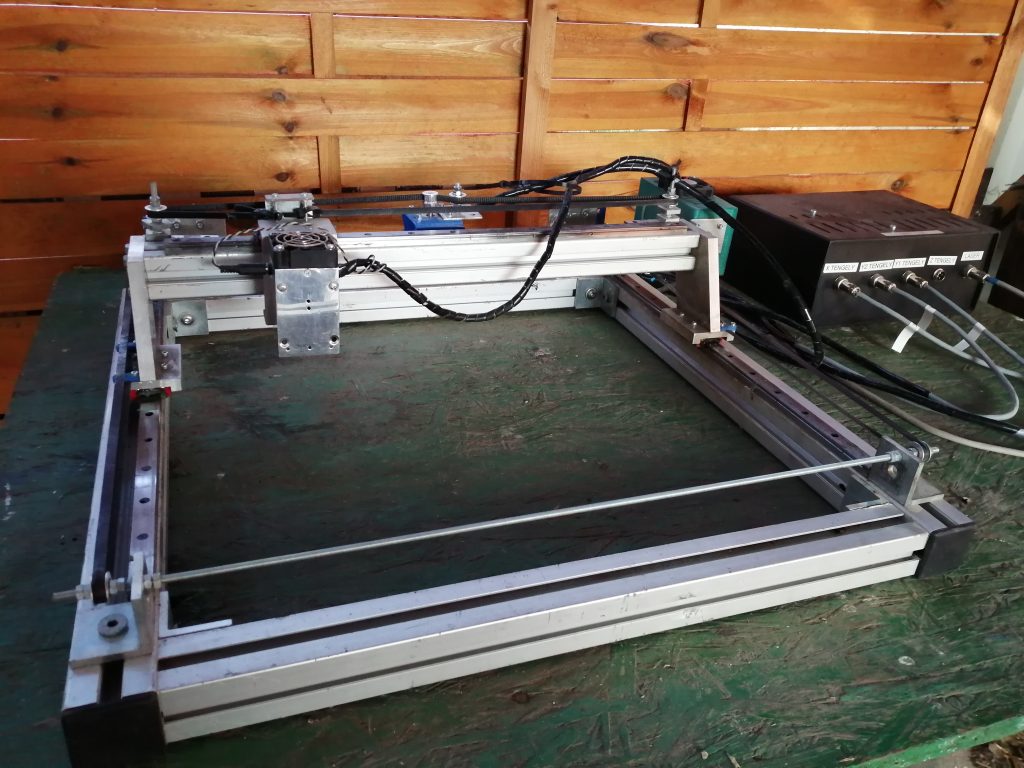

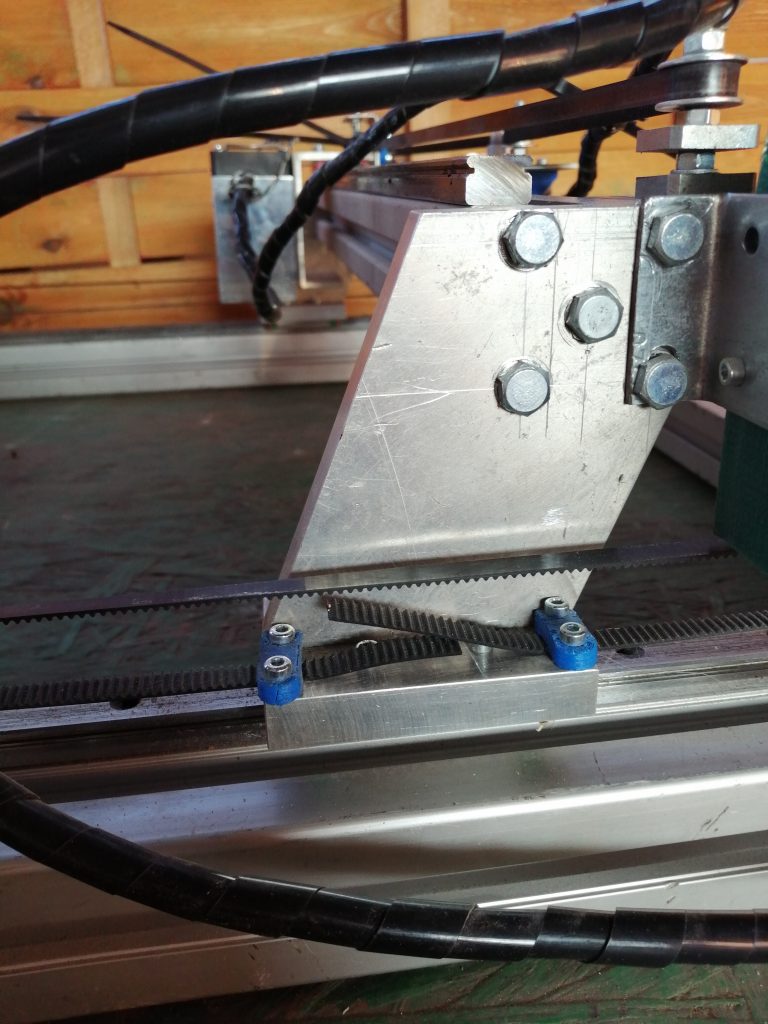

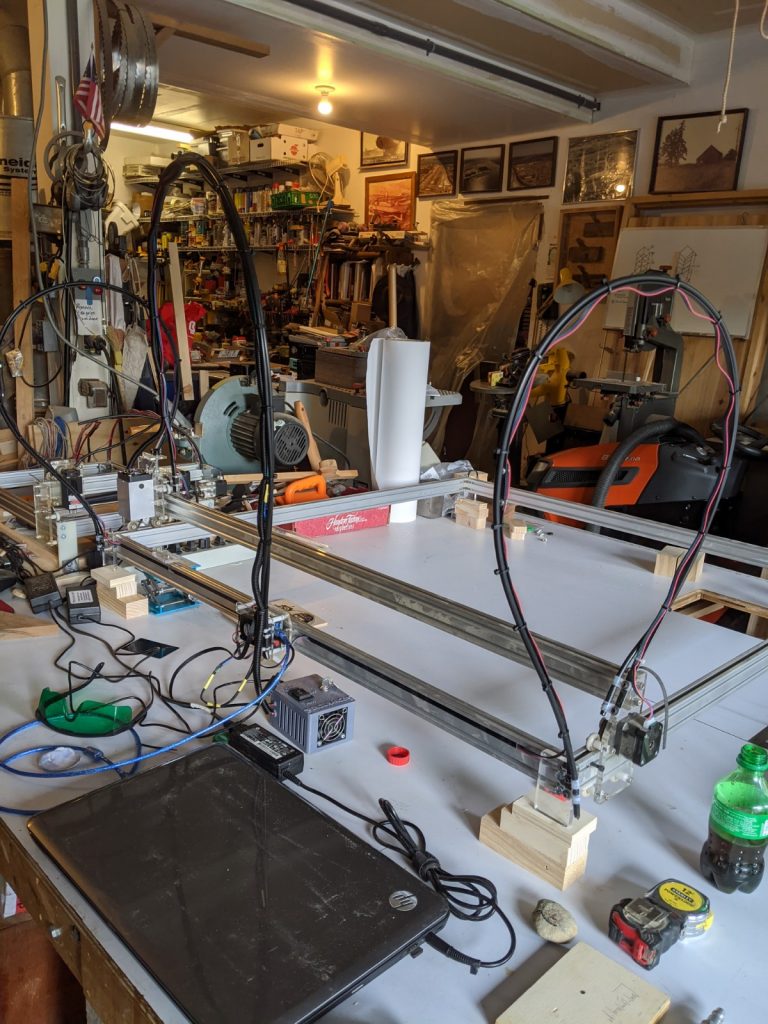

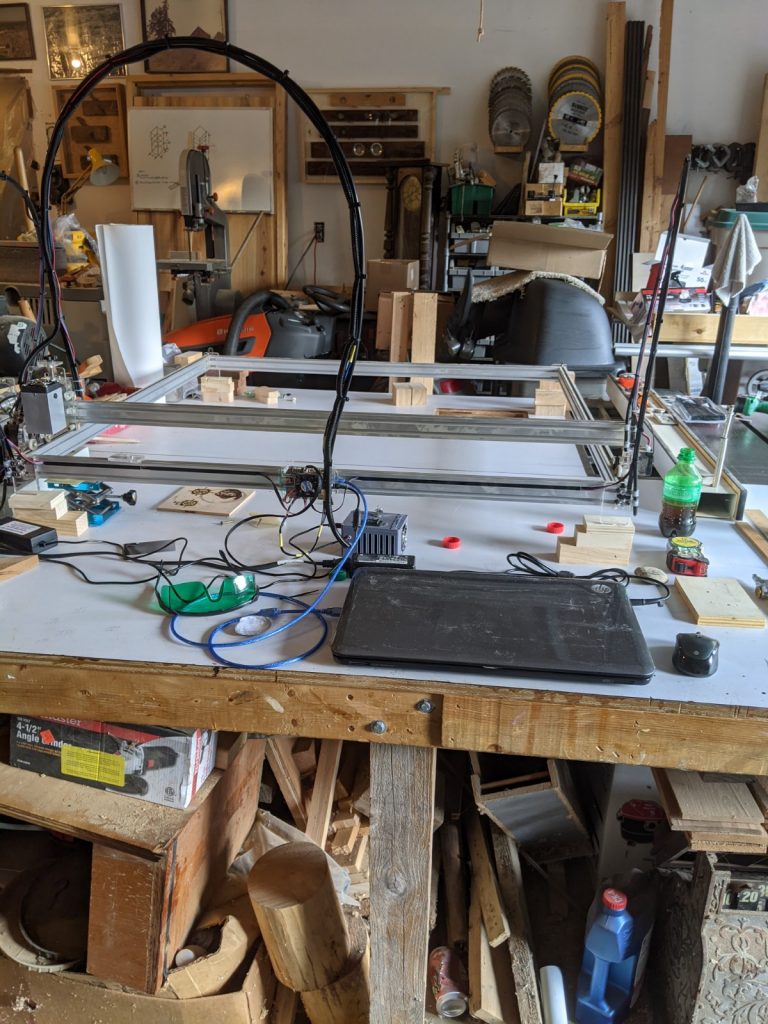

by Balog Ferenc

Machine: BFGlaser 🙂

Firmware: GRBL 1.1hControl software: LaserGRBL

Draw and NC code generator: LightBurn

(21)

(22)

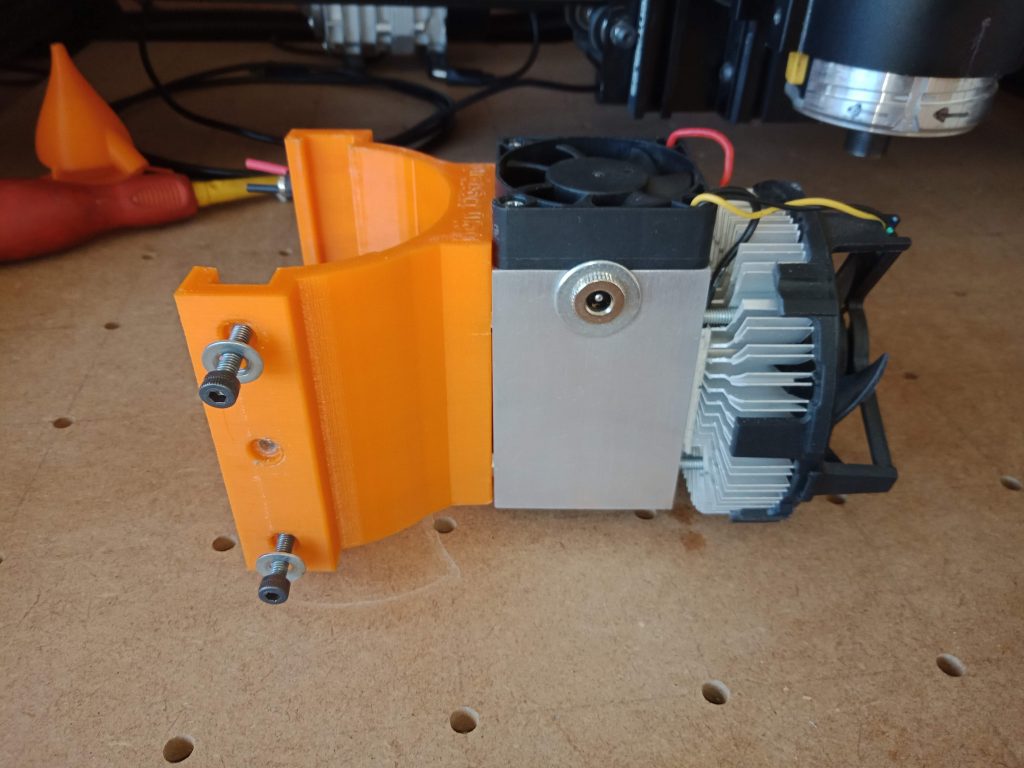

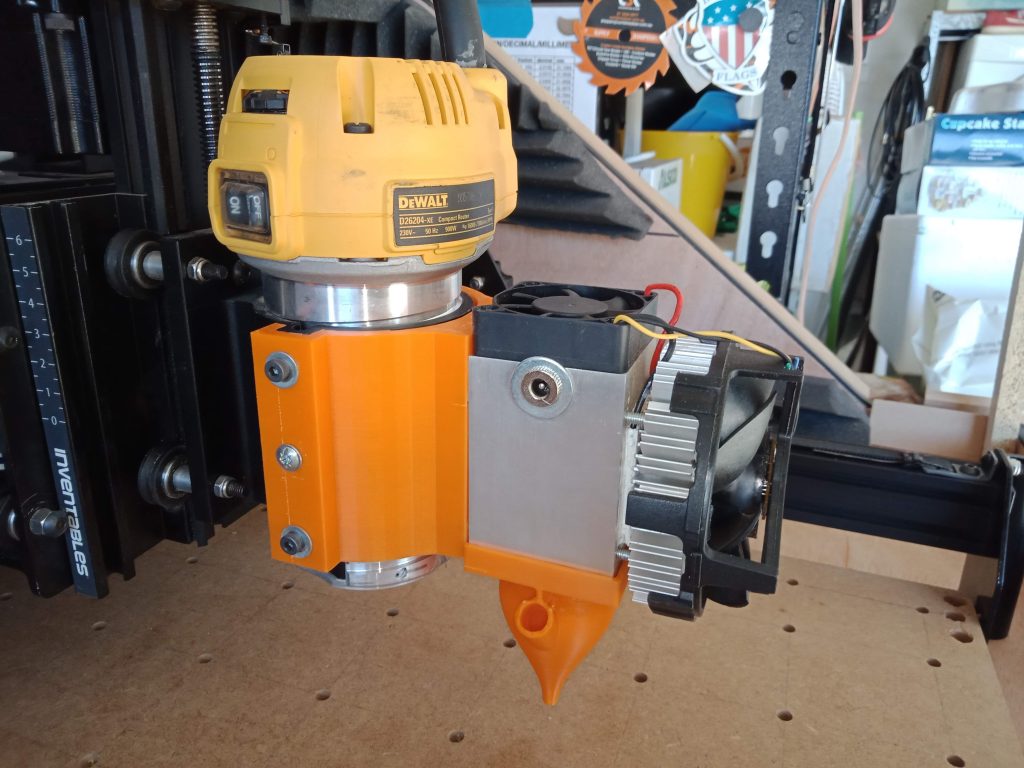

By Josh Finsel

Upgraded X-Carve running an Endurance 10 Watt deluxe with Lightburn.

(23)

(24)

(25)

Our customers use our 10 watt laser for foam cutting!

(26)

(27)

by Maxi Maz (works with MACH3)

(28)

(29)

By David Strong

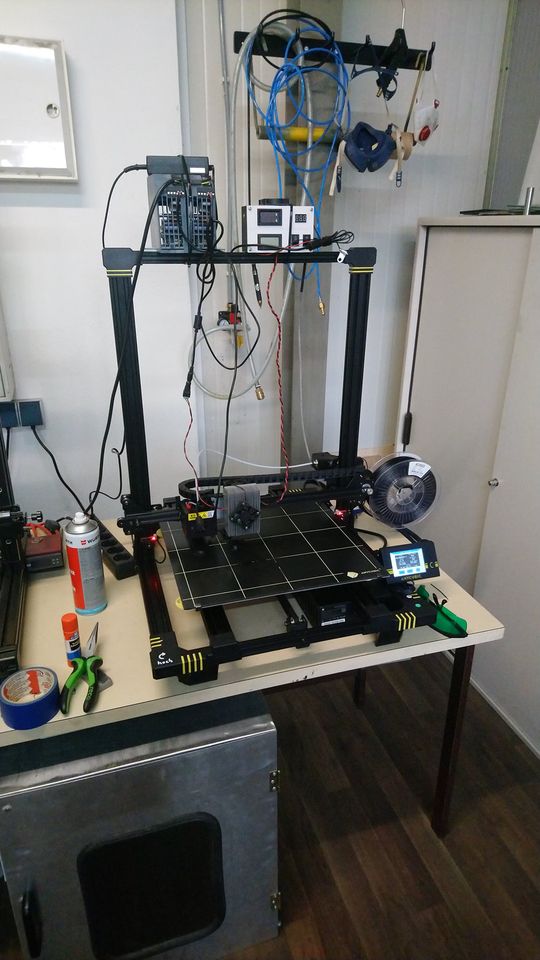

(30) 10 watt PLUS on an Anycubic Chiron

Added an Anycubic Chiron at work – mounting the Endurance laser was very easy and the printer can work with the laser still mounted…very nice ![]()

Markus Geßner Автор Laser is perfect since 2 years now 🙂 ….and he has worked somewhere around 500h/year.

Автор Laser is perfect since 2 years now 🙂 ….and he has worked somewhere around 500h/year.

by Markus Gessner

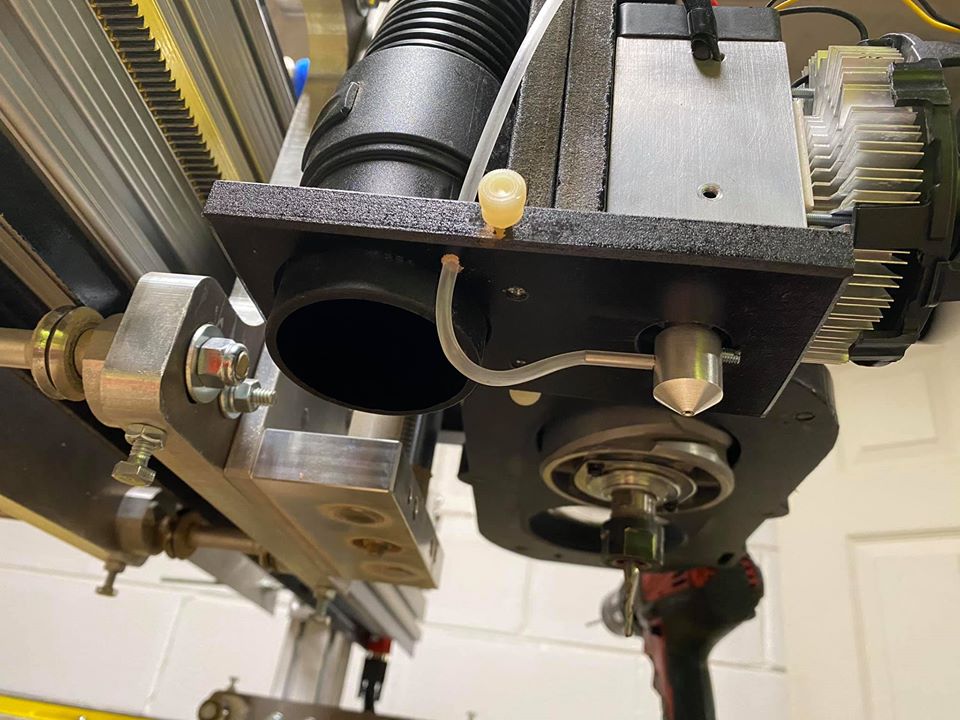

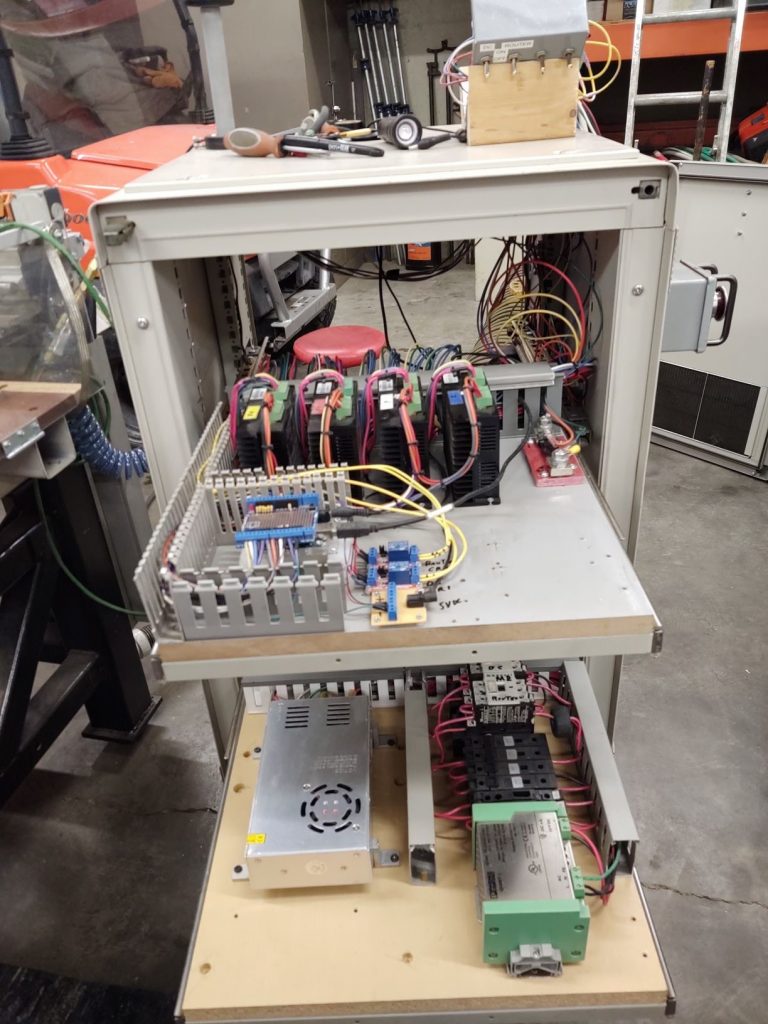

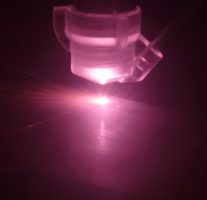

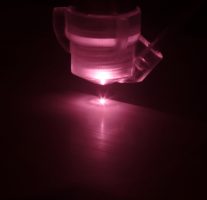

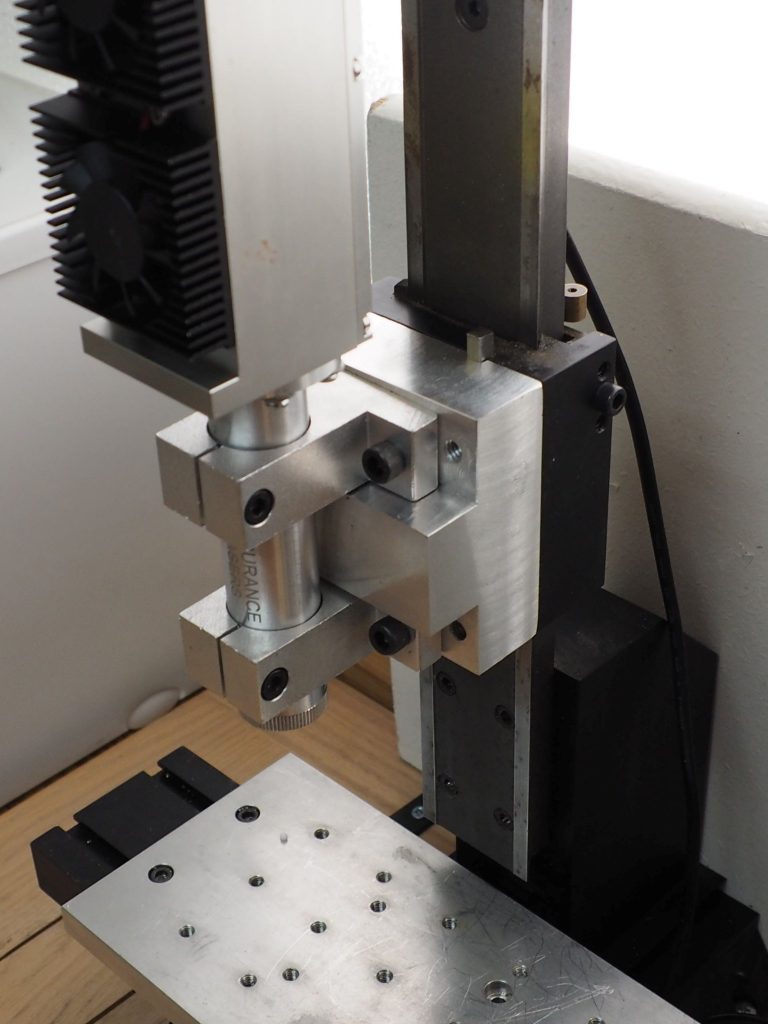

(31) 10 watt infrared DPSS (Nd:YAG) on a CNC

by Alain Roy

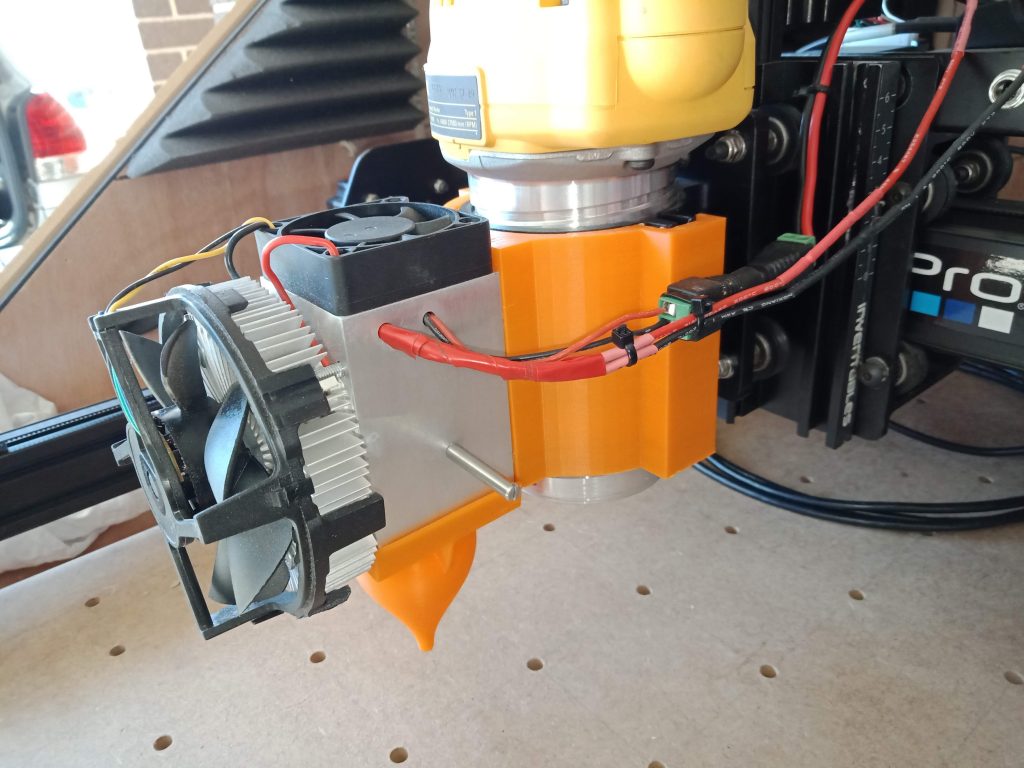

(32) 10 watt “Invincible” set up on the x-carve

by Chip Estrada

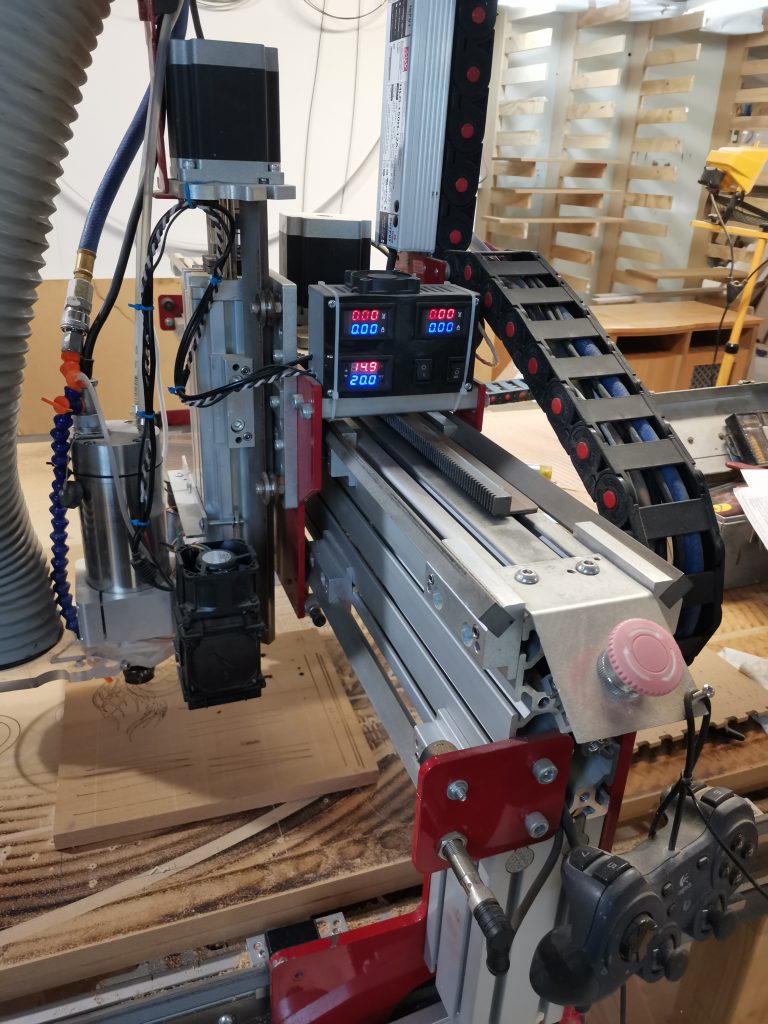

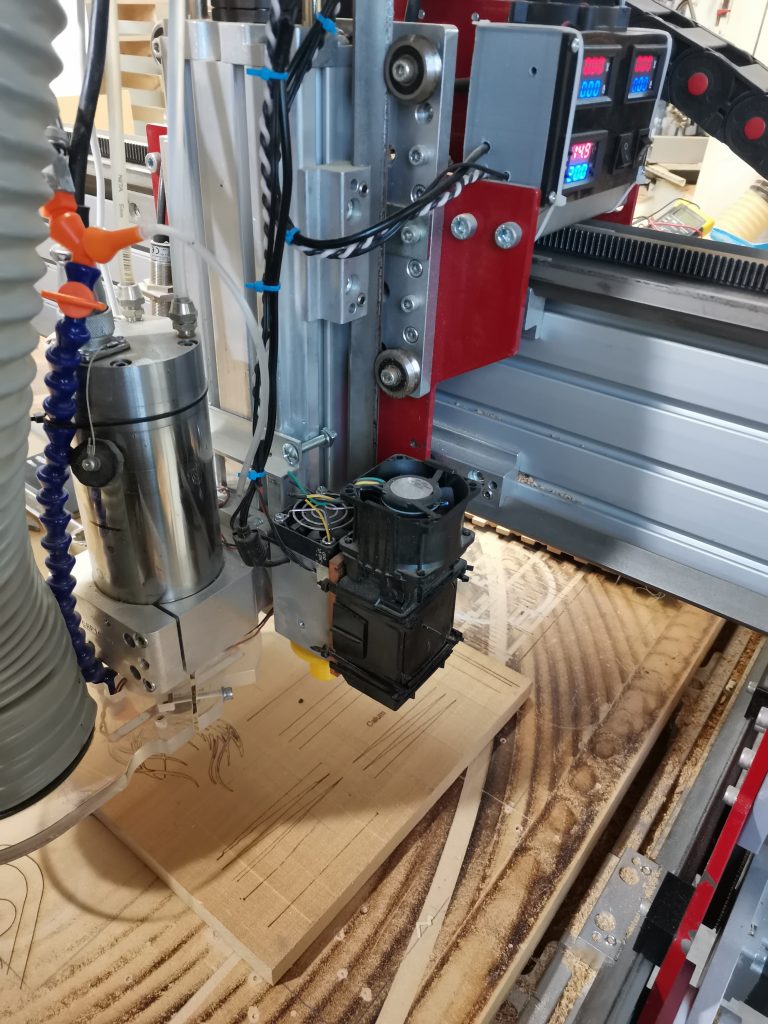

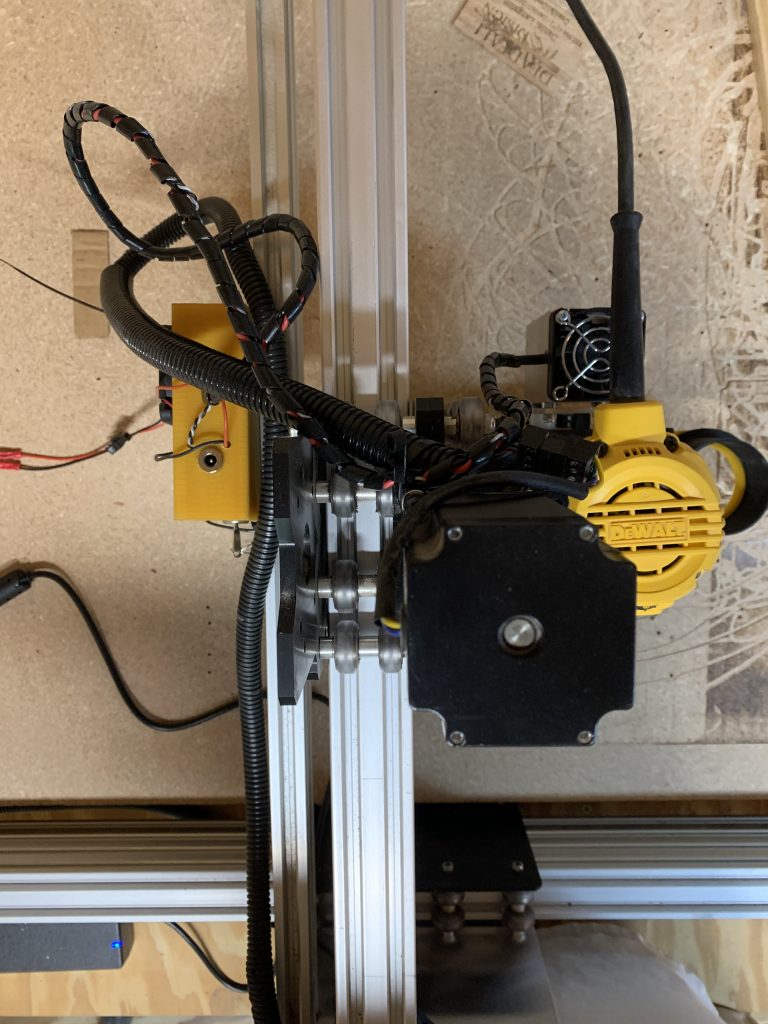

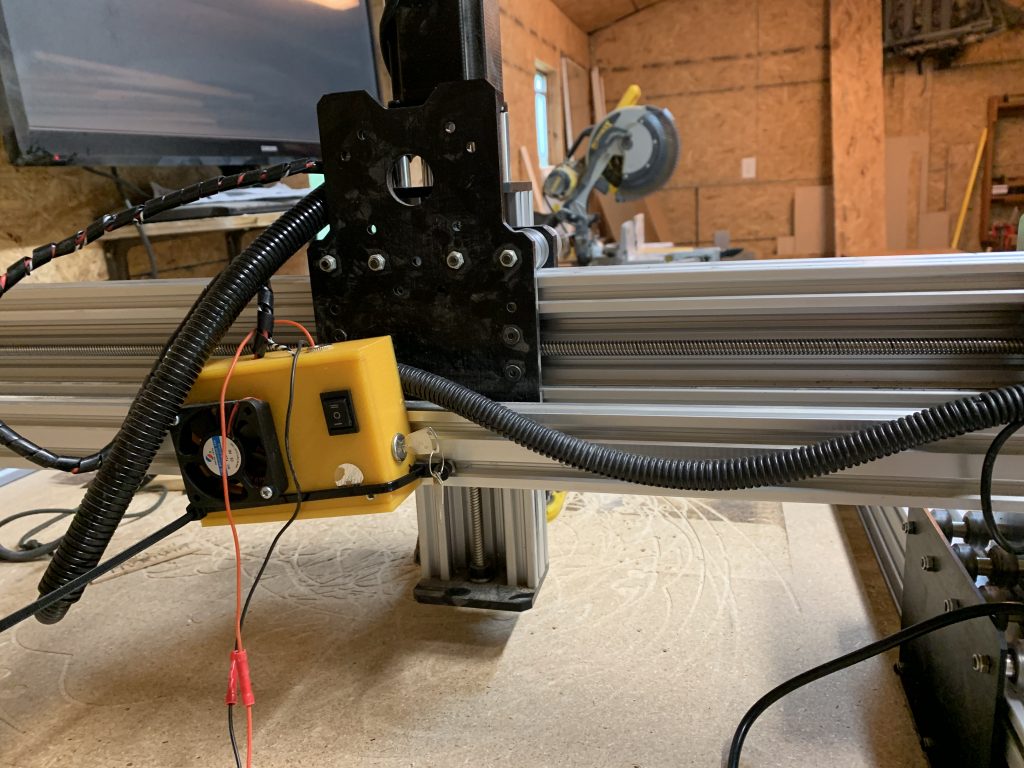

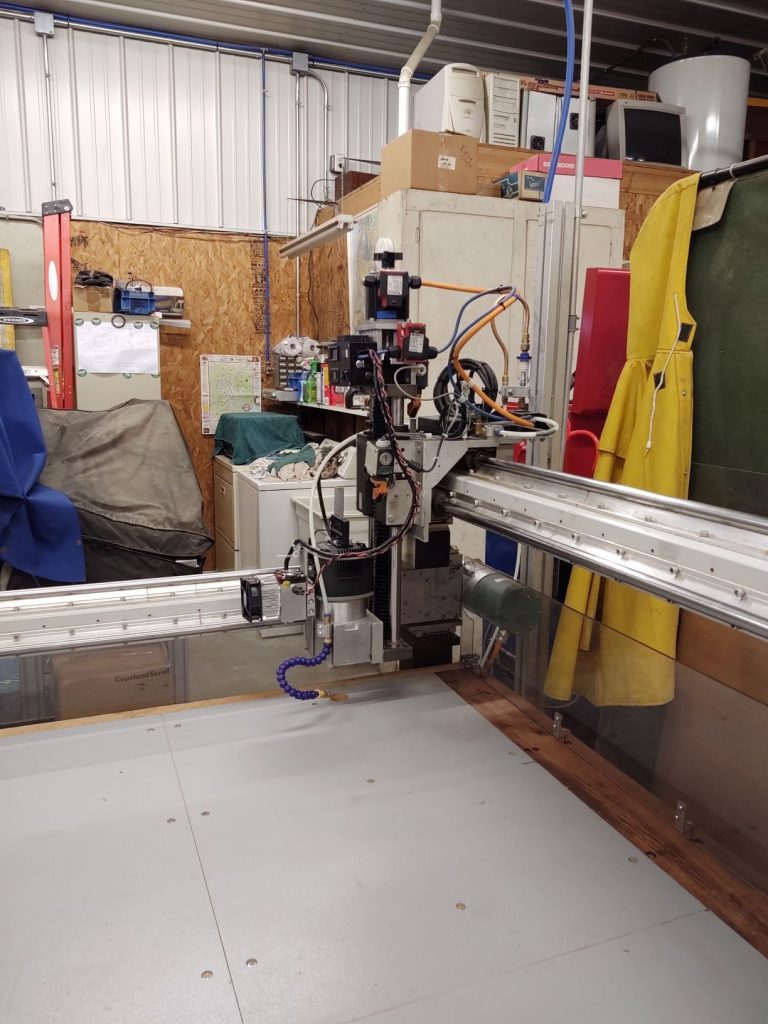

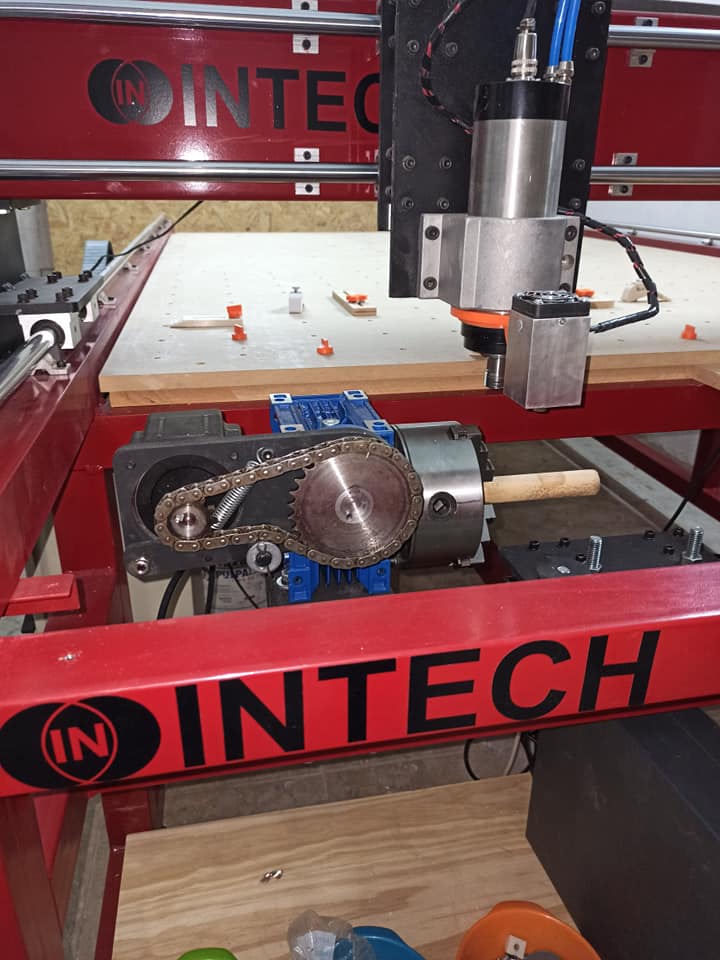

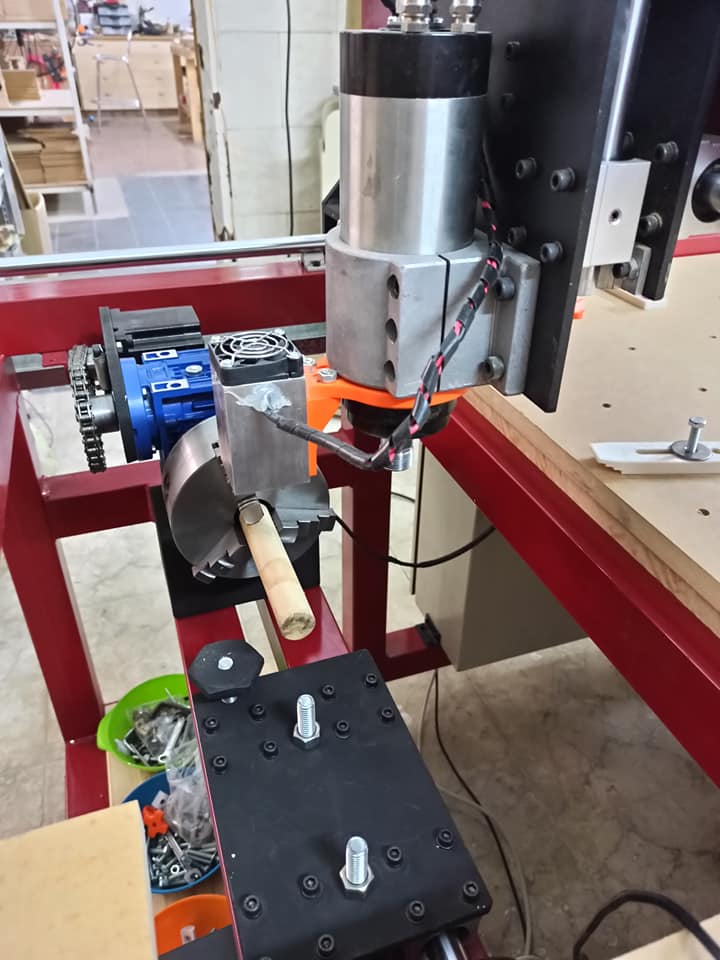

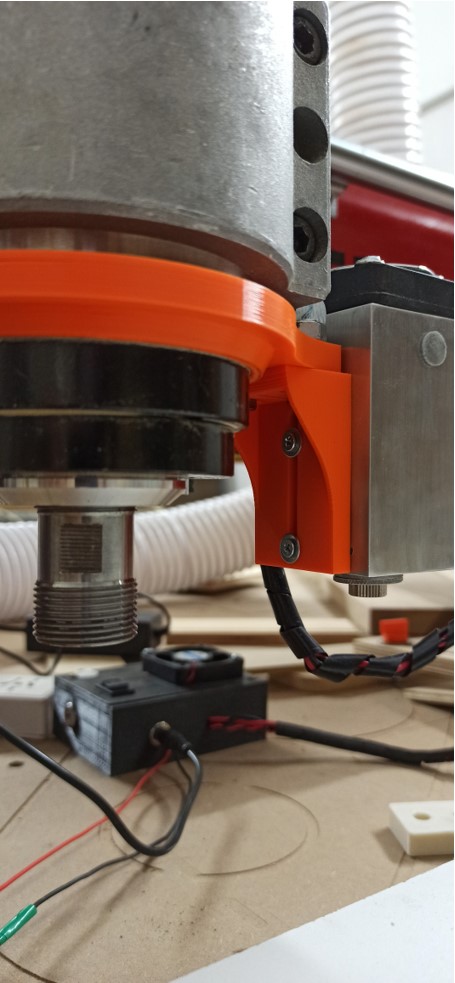

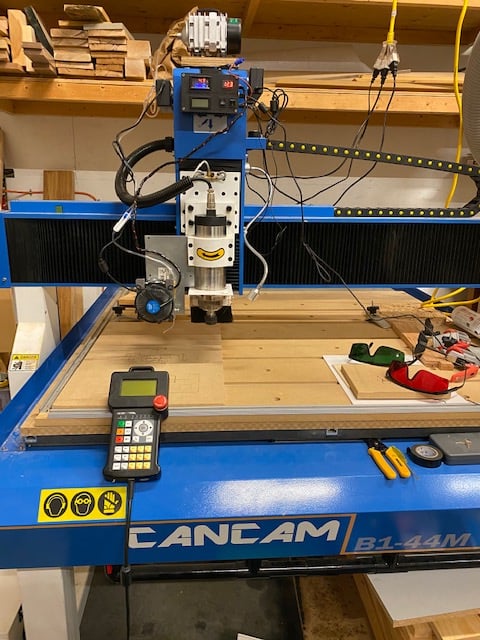

(33) A big CNC frame

My setup: custom-made CNC router with 3hp spindle, 2250x1480mm working area, front 4th axis, 10W endurance laser head. Just want to add an ESS board so I can use Lightburn (actually running Mach3)

Maxi Mazur

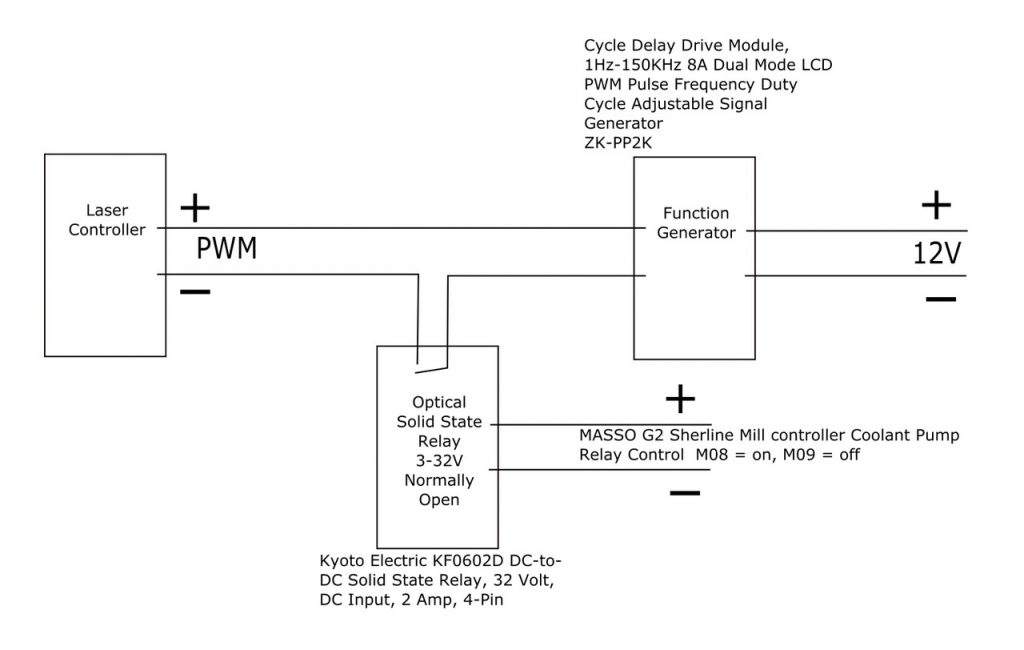

(34) The laser at work is a Full Spectrum Laser 24×36”. The mill is a Sherline 5800.

This allows me to toggle the laser on/off with the mill’s manual “coolant” controls to get the power preset on the function generator, then use M08 and M09 to cycle it on and off within the G-Code.

How to connect the laser to Acorn controller (sherline 8760 driver box)

Wheeler North

Product Highlights Sherline 5800

- Sherline 5800 Series NexGen vertical milling machine

- Includes many accessories in Package A

- Metric EU version (needs assembly)

- Features 18-inch extended mill table and 3 “T” Slots

- Comes with a powerful 90V DC motor with an electronic speed controller

Specifications (Sherline 5800)

- Max clearance(table to spindle): 14″ (356 mm)

- Throat(no spacer): Adjustable

- Throat (w/ headstock spacer): Adjustable

- Travel, “X” Axis: 13.65″ (347 mm)

- Travel, “Y” Axis: 11″ (279 mm)

- Travel, “Z” Axis: 9.38″ (238 mm)

- Hole through spindle: 0.405″ (10 mm)

- Spindle nose thread: 3/4″-16 T.P.I.

- Spindle nose taper: #1 Morse

- Spindle runout of Morse taper: 0.0005″ or less

- Handwheel graduations: 0.001″ (0.01 mm)

- Electronically controlled spindle speed range: 70 to 2800 RPM

- Width Overall*: 20 (508 mm)

- Depth Overall*: Base footprint: 20.625″ (524 mm); With fully extended brass leadscrew cover: 27.875″ (708 mm)

- Height Overall (Max.)*: 24.50″ (622 mm)

- Hold-down provision: 3 T-Slots

- Shipping Weight: 50 lb. (22.7 kg)

- Movements in addition to X-, Y- and Z-axes: Headstock rotation (90° left/right)

- Column pivot: (90° forward/back)

- Column swing: (90° left/right)

- Column travel: (in/out) 5.5″ (140 mm)

- Motor: 90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

- Spindle Speed Range: 70-2800 RPM continuously variable by an electronic speed control

(35.1) 10 watt DPSSL installed on Sherline

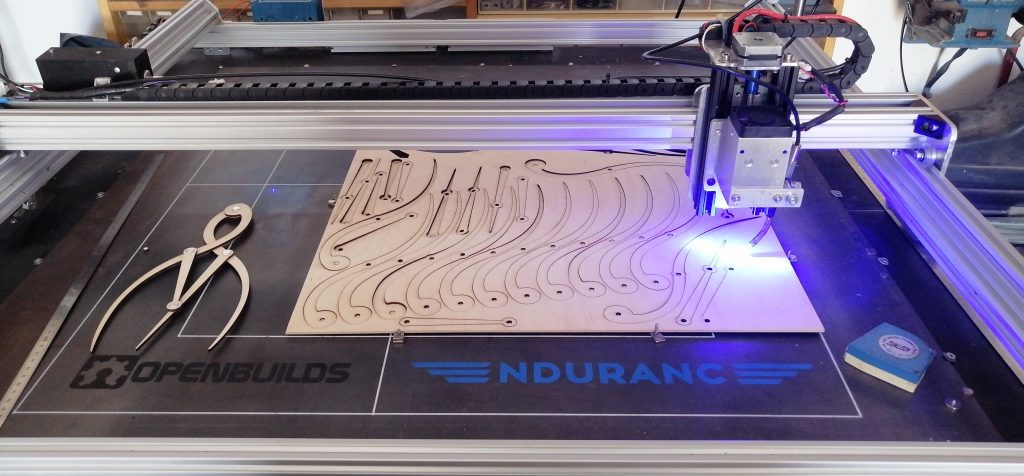

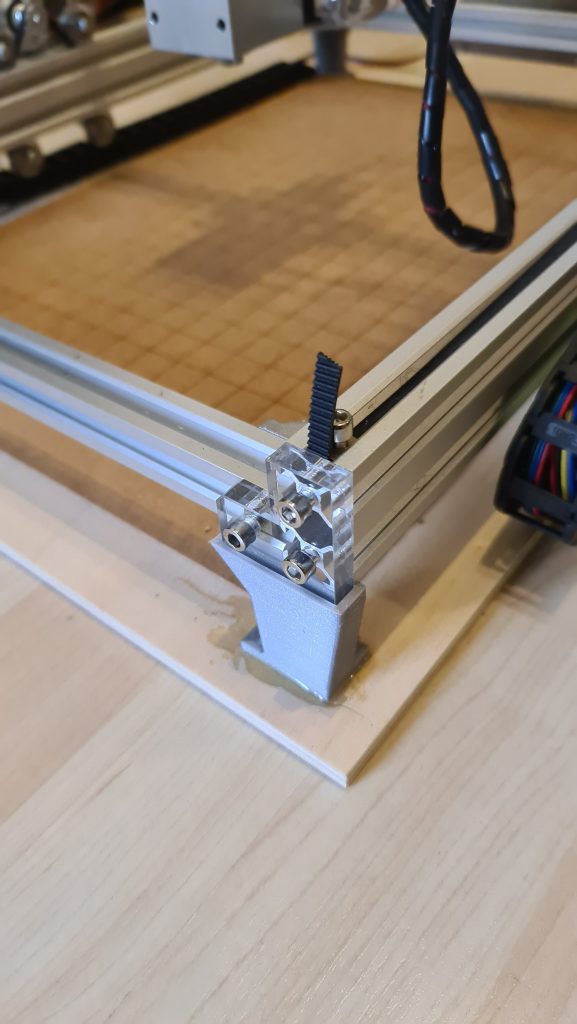

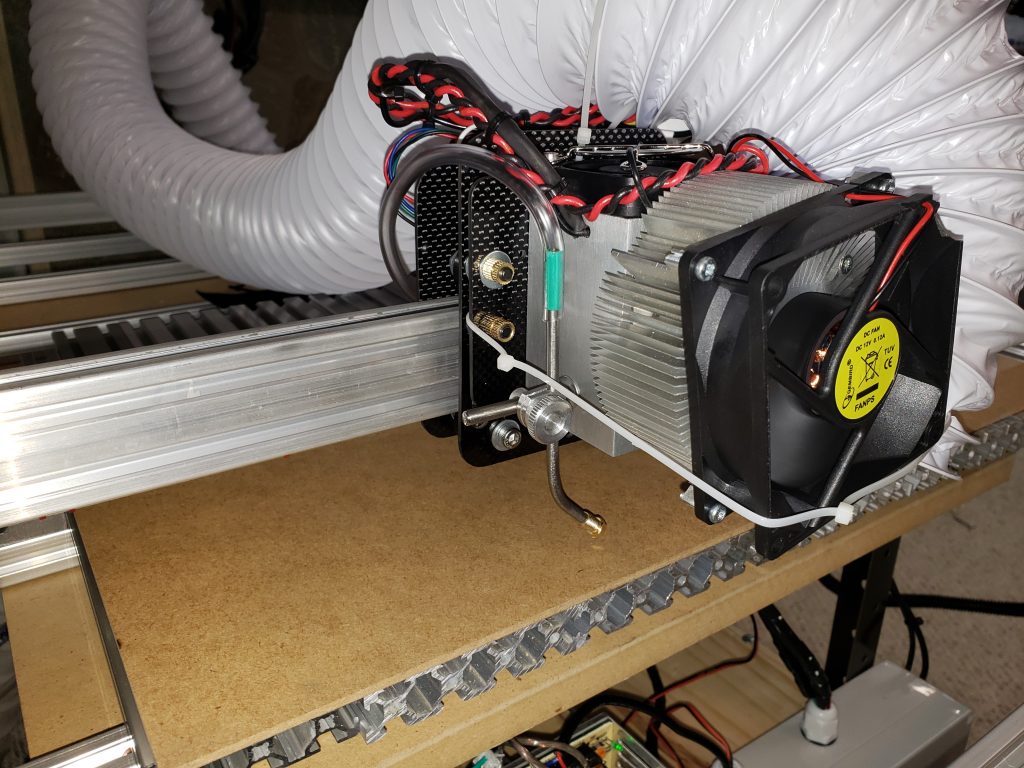

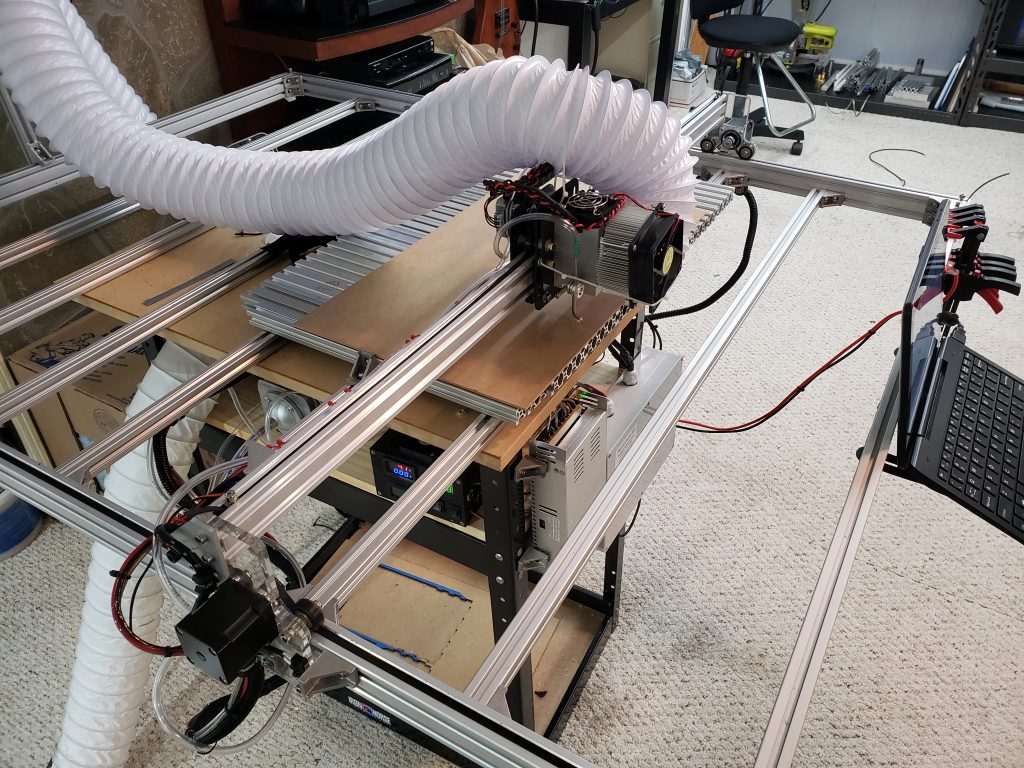

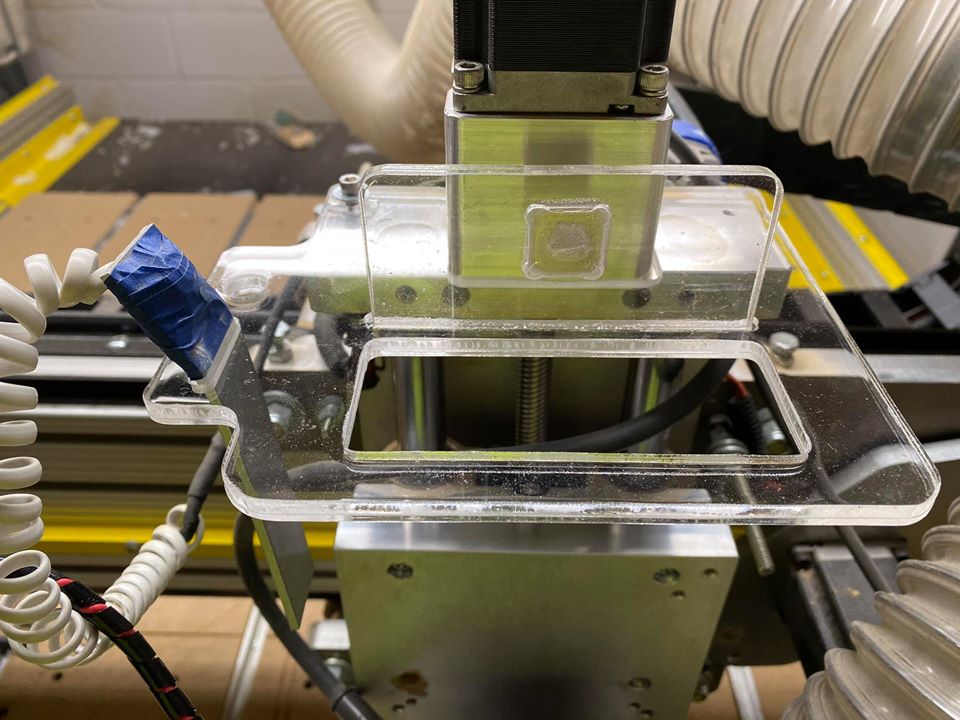

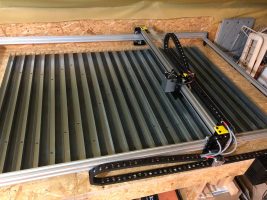

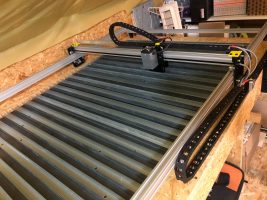

(35) 10W in tunned Acro System from Openbuilds

by Paweł Kohls

Acro Systems Openbuilds data specs

Specifications of the OpenBuilds ACRO system:

- 4.5 micron resolution: 30% more resolution than systems in its class

- Z Axis Travel 70mm – (2-3 / 4 “) manually adjustable Z-axis length

- Available in industrial black or elegant silver

- The fixing plate includes mounting holes for multiple accessories and tools

AFFORDABLE – OpenBuilds budget-friendly parts allow Builders the opportunity to freely create.

EASY TO BUILD – With the V-Slot Modular Framing System and OpenBuilds Build-Along Videos, assembly is quick and easy.

OPEN SOURCE – The Builder community is encouraged to modify and build on this design. We are excited to see what you attach to your ACRO System and the things that you make!

CUSTOMIZATION – Take it to the next level and make it your own! Share your builds with the Open Source Builders community OpenBuilds.com.

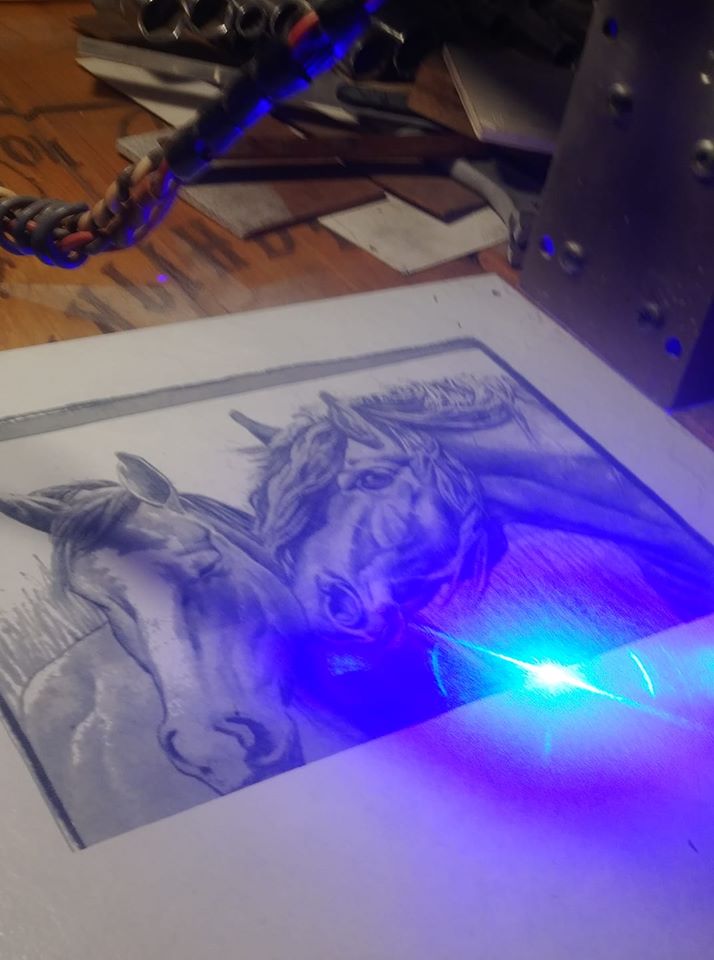

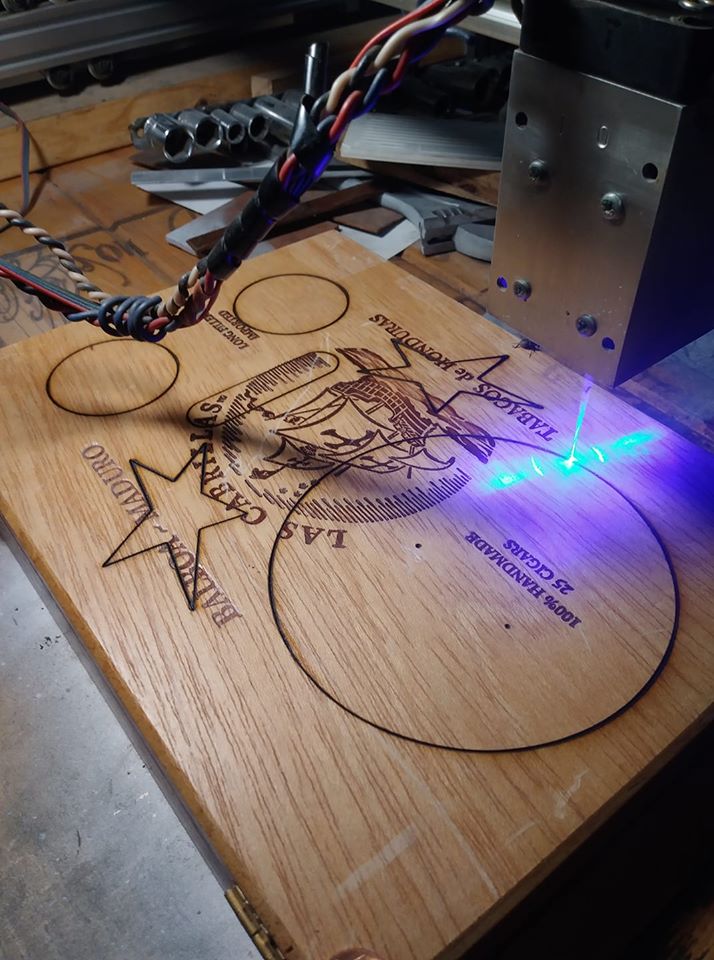

(36) 10 watt laser in action

by Chris Croft

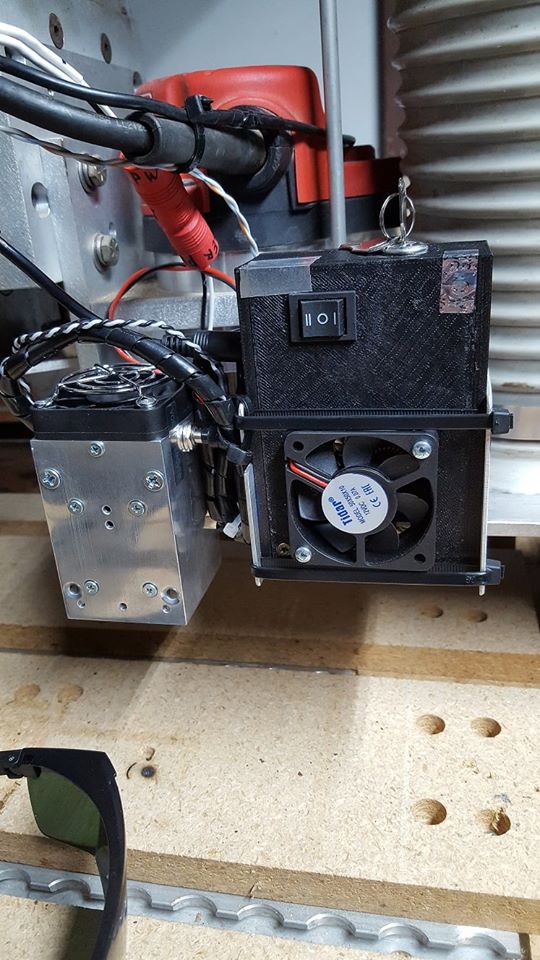

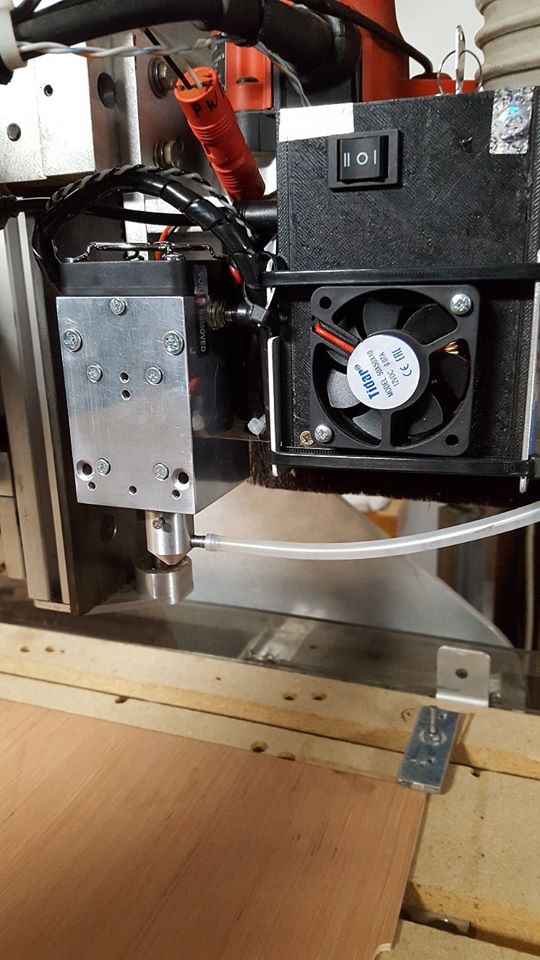

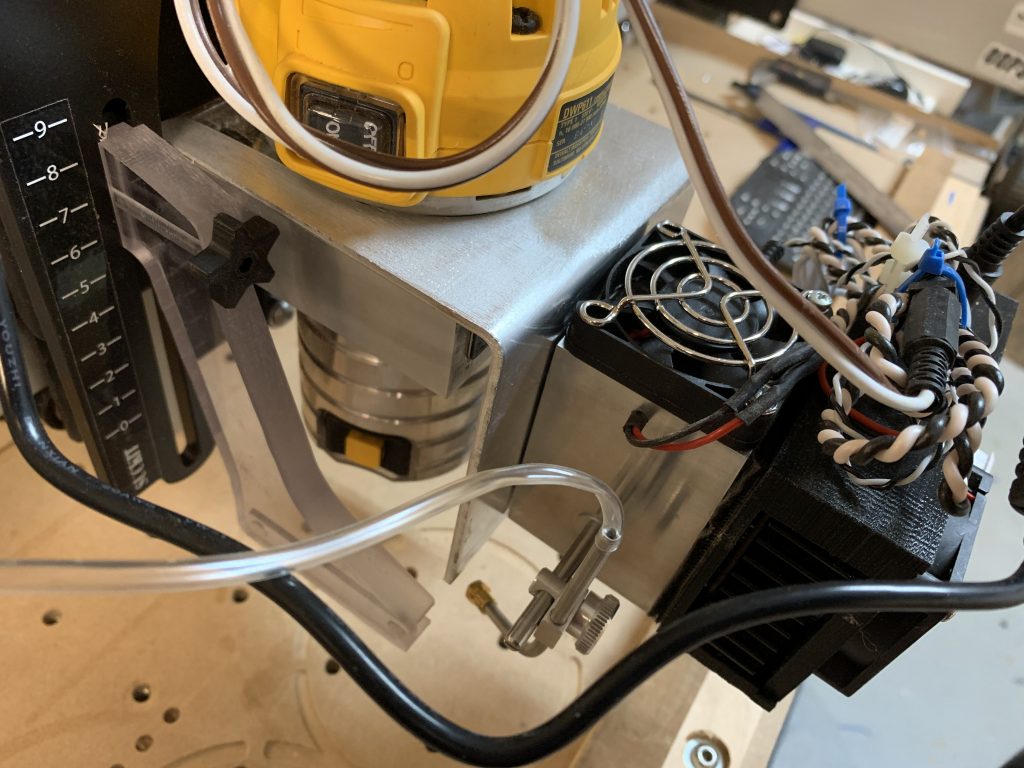

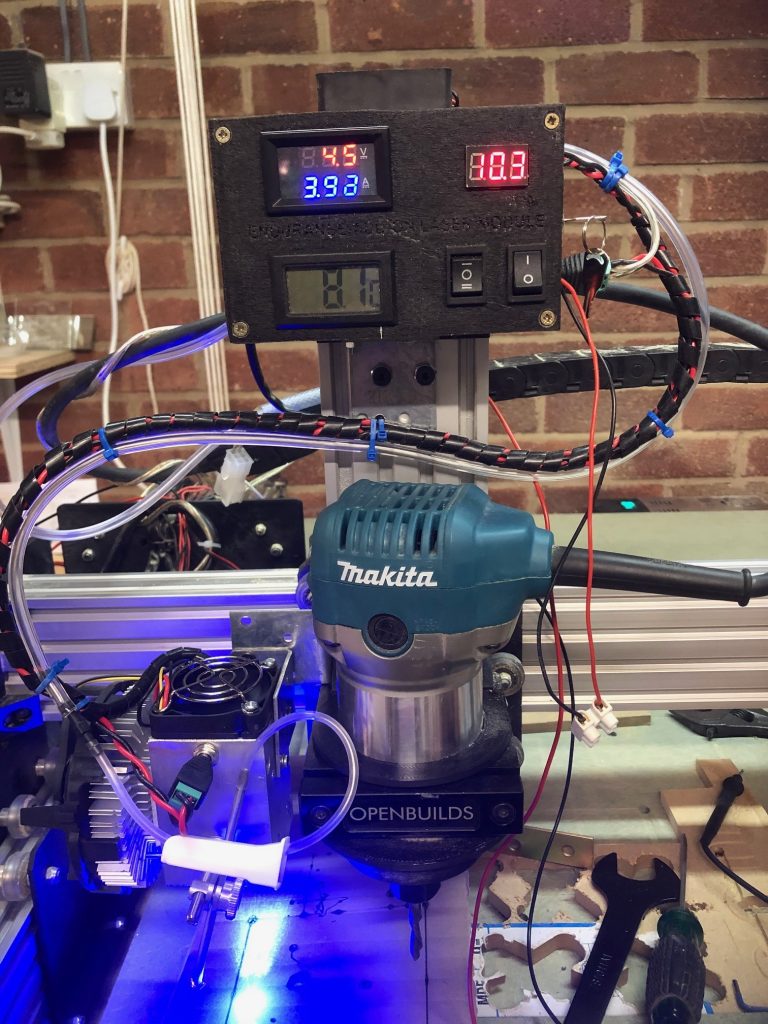

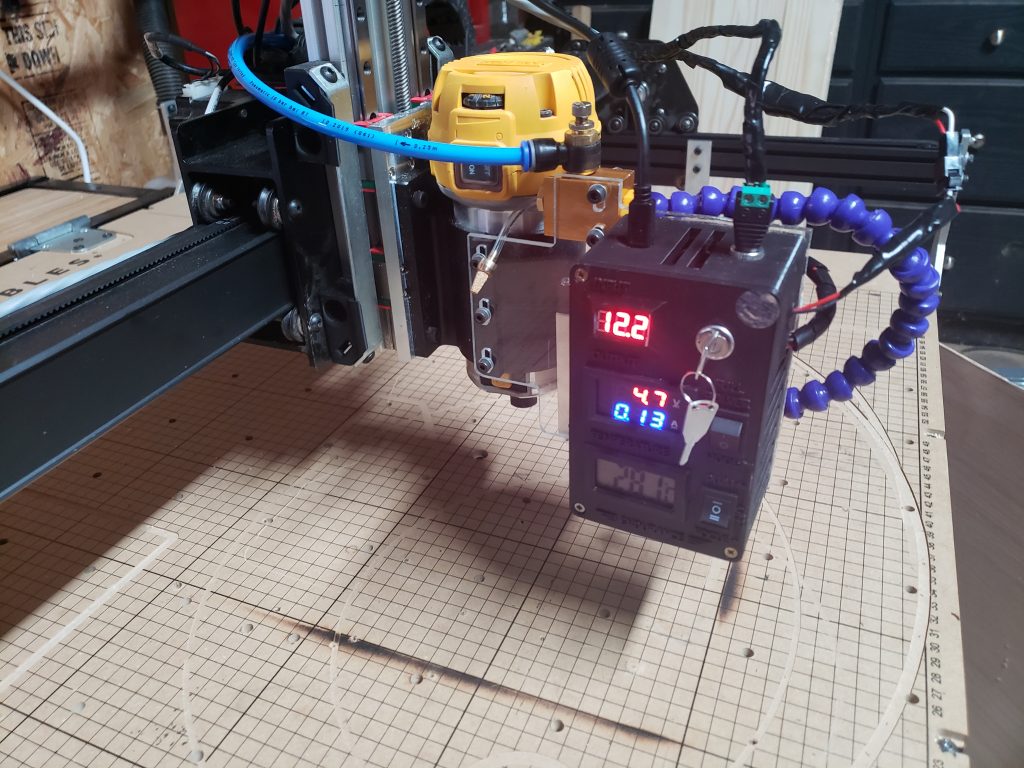

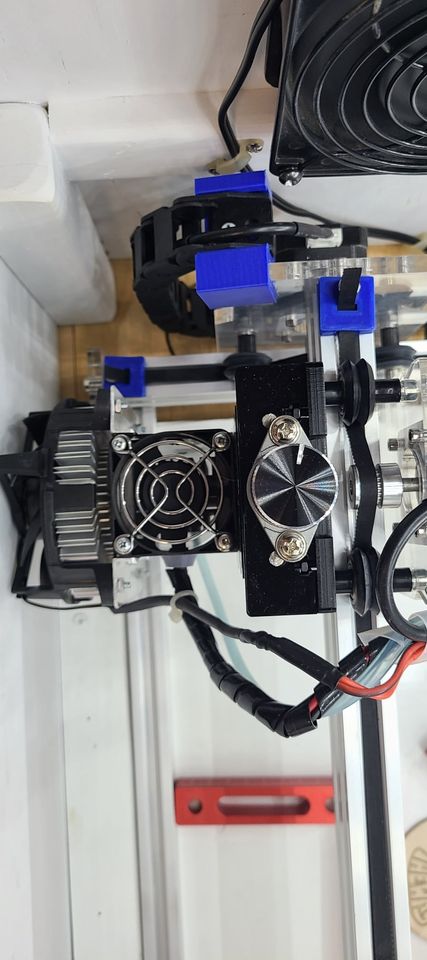

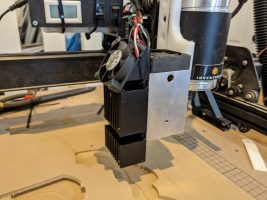

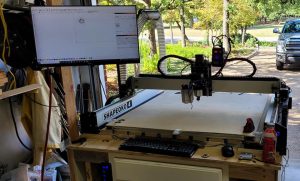

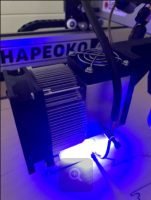

(37) 10 watt PRO laser in installed on Shapeoko

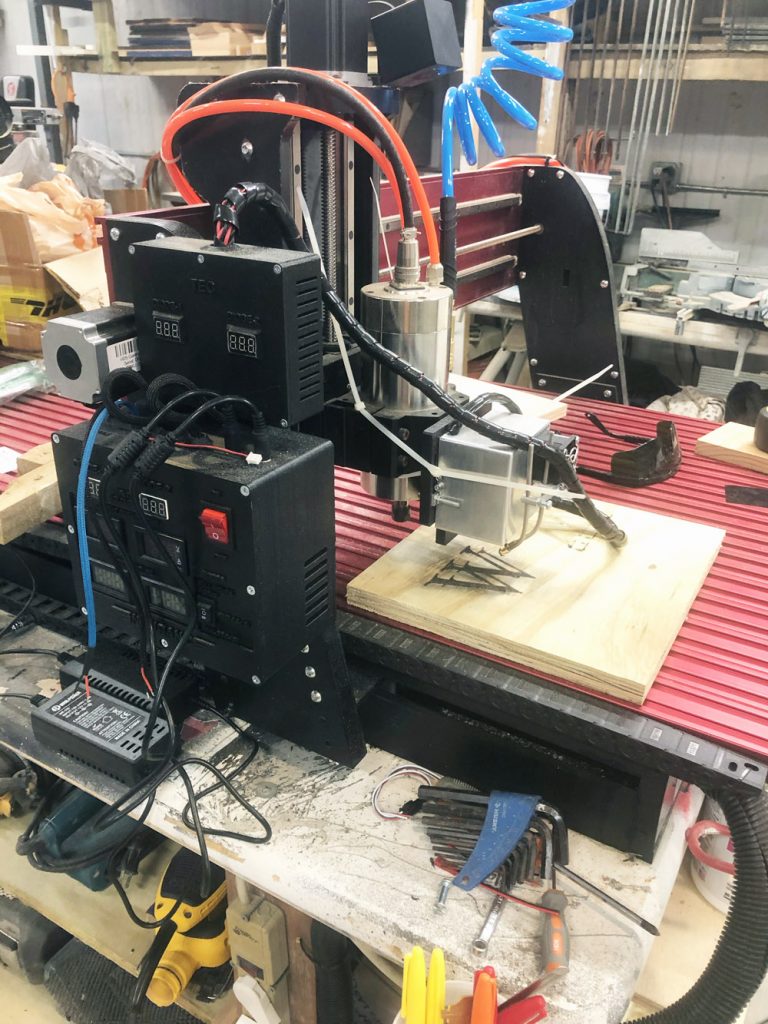

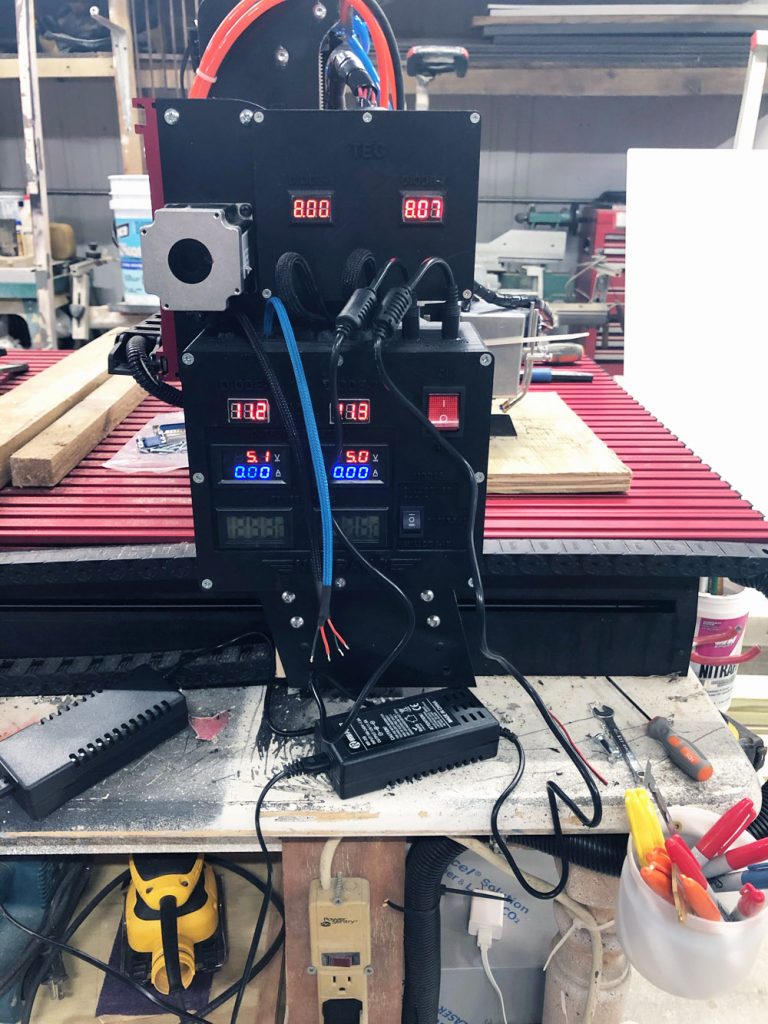

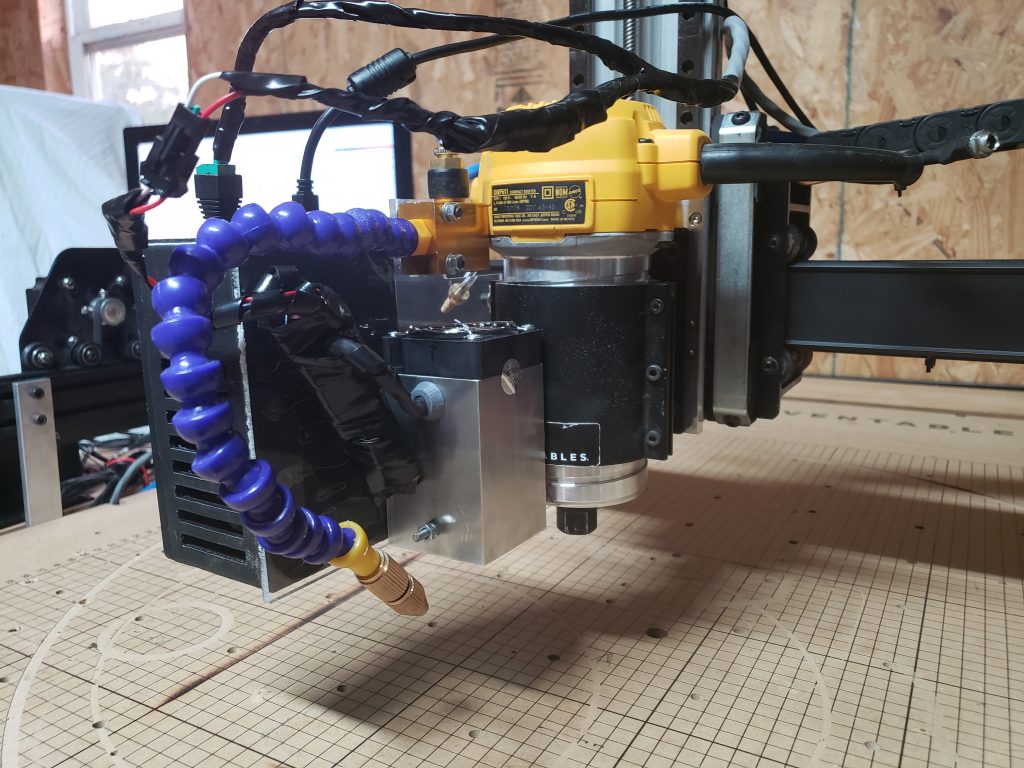

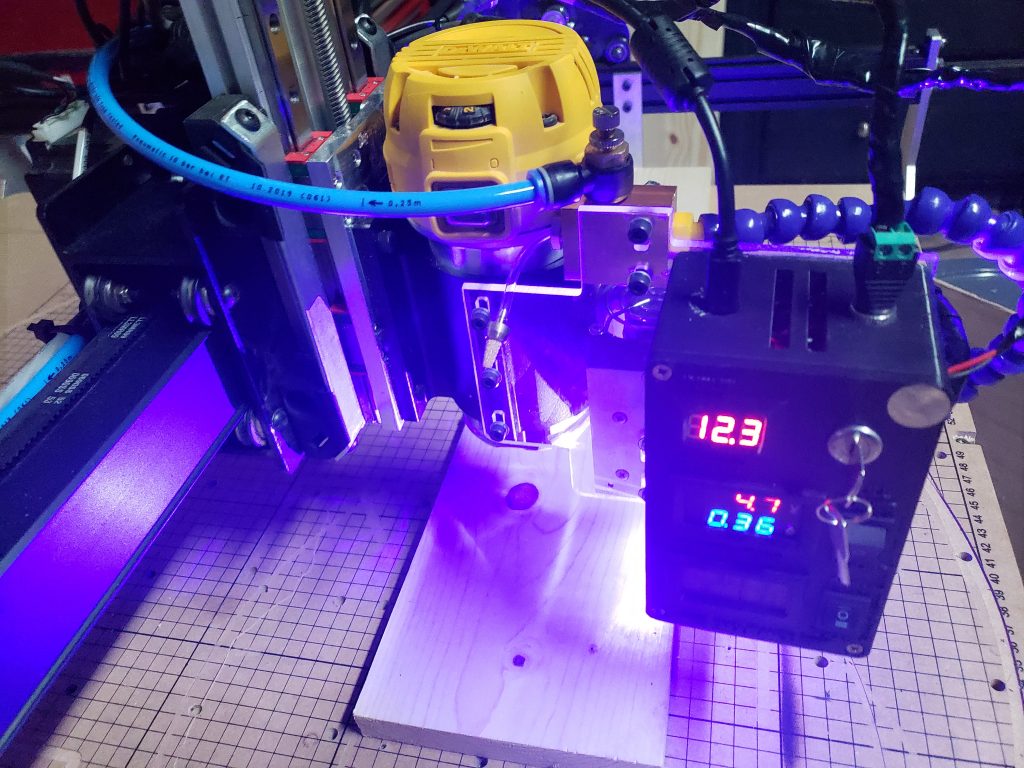

Never finished fine tuning and tweaking setups, but this is my current setup on a shapeoko4 xxl. It’s all running off a 600watt 12v power supply wired to auto/marine switches. Air assist hooked up to compressor and turned on via the switches as well the tec cooling. 4 bolts and unhook wires above laser power unit to remove and go back to cnc router. Laser mount is 1/4″ aluminum welded at a 135deg angle.

by Bruce Keliikoa

(38) 10 watt PLUS laser in installed on Shapeoko

by Jeff Boykin

(39) 10 watt DPSS laser on a CNC machine

CNC is a significantly modified old PCNC1100 Tormach Mill

by Tim Sos

(40) 10 watt diode lasers on a DIY gantry

by Alex

(41) 5.6 watt diode laser (PRO) installed Onefinity CNC Woodworker.

by Mike Hobizal

8.5 watt diode 445 nm laser / 10 watt DPSSL on Beamo FLUX

Endurance lasers work with all types of CNC machines:

- JFT 3040 3-Axis CNC Router,

- MillRight CNC Power Router,

- BobsCNC E3 CNC Router Engraver Kit,

- Genmitsu CNC 3018-Pro Router Kit,

- MY SWEETY 1610 CNC Machine,

- Carbide 3D Shapeoko 4,

- Ooznest Workbee,

- Onefinity Woodworker,

- Inventables X-Carve,

- The MPCNC – V1,

- Shark (NextWave),

- Stepcraft 420 – 840