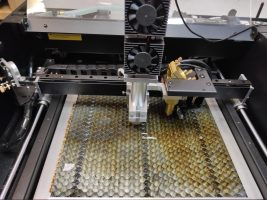

All types of laser engraving with Endurance 8.5 watt diode (445 nm) & 4 watt DPSSL (1064 nm) lasers.

General tech features of a Beamo Flux laser mach

ine

Dimensions: 615 x 445 x 177 mm

Weight: 22 kg

Work Area: 300 x 210 mm

Work Area Depth: 45 mm

Camera Preview Area: 300 x 195 mm

Power: AC 110V/220V

Speed: 0 – 300mm/s

Touch Panel: 1024 x 600 LCD

Camera: HD CMOS

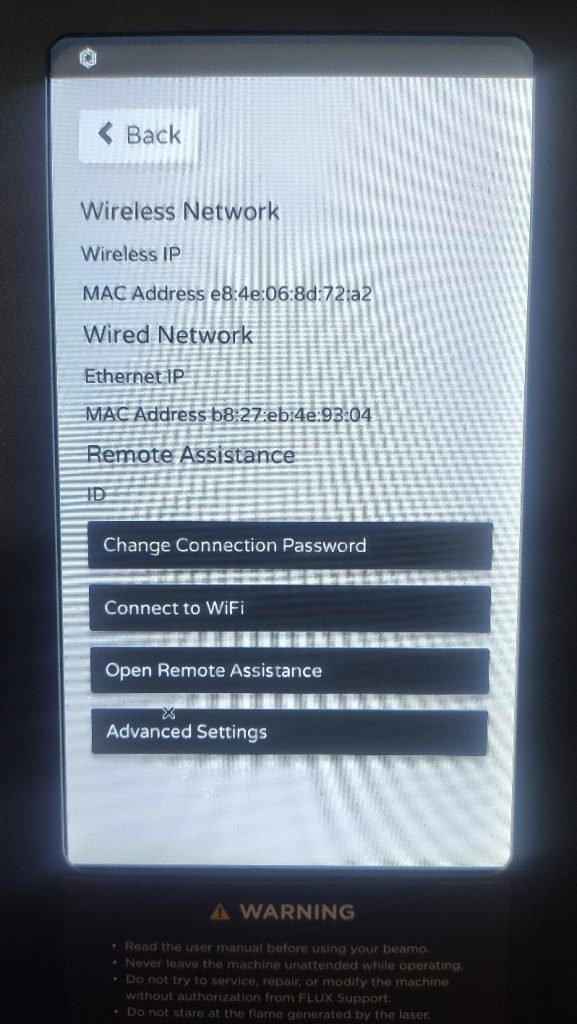

I/O: Wi-Fi / Ethernet / Direct Network Cable

Laser Spec: 30 Watt CO2 Laser

Wavelength: 10640 nm (10.6 um)

Cutting Thickness: 0 – 5 mm (varies by material)

Software – BEAM Studio

Mode: Vector / Graphic (monochrome, gray scale)

Operating System: Windows / macOS / Linux

File Type: JPG / PNG / SVG / DXF / AI / PDF

Beamo Flux overview

This is a compact-size machine for laser cutting/engraving. It is suitable for processing such materials as:

– plywood, up to 5 mm thick

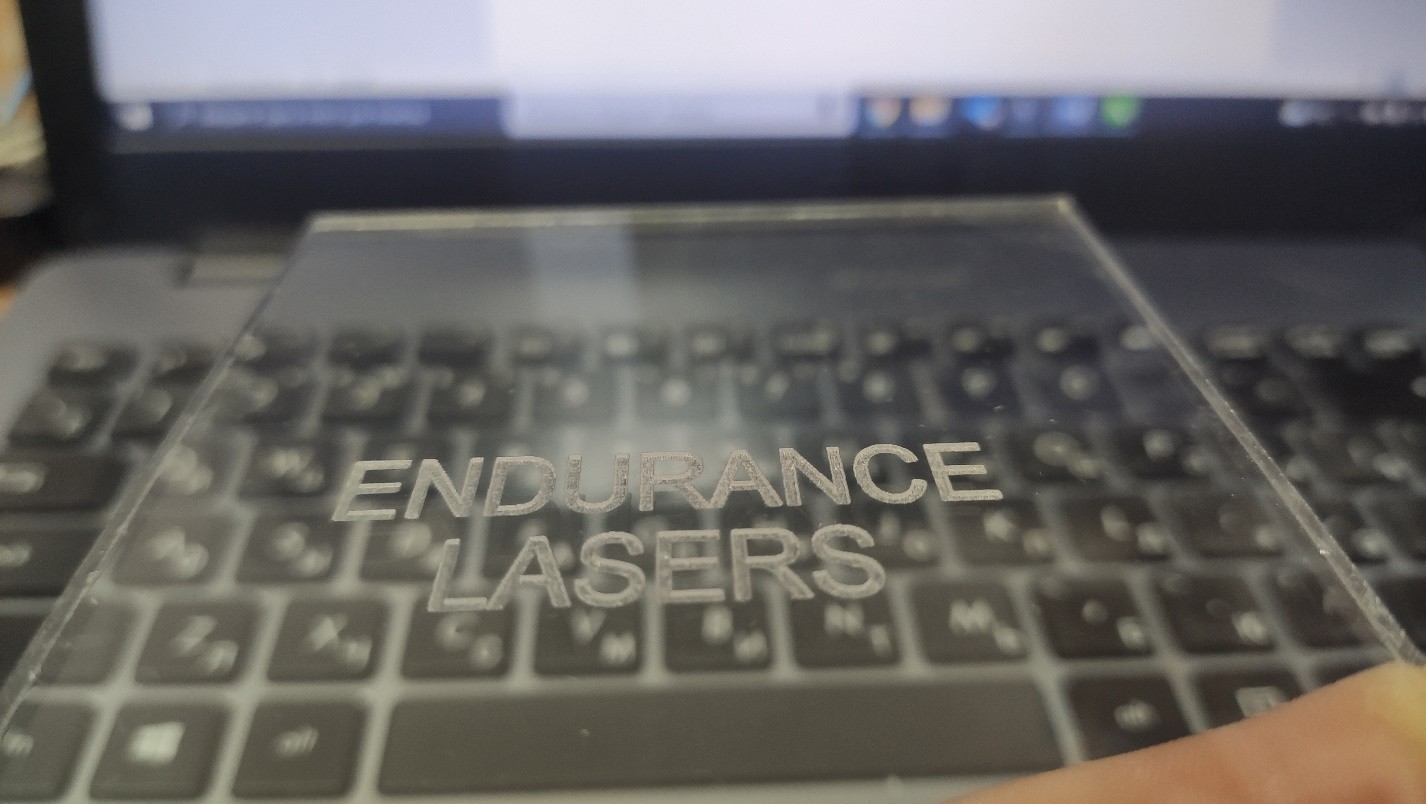

– acrylic, up to 5 mm (including transparent acrylic, plexiglass and polycarbonate)

– leather, up to 5 mm

– rubber

– glass

– metal

– paper/cardboard

The machine cuts well and engraves perfectly.

Though small in size, the machine easily processes most of the materials producing high-quality laser cutting or engraving.

Useful features of the Beamo Flux machine

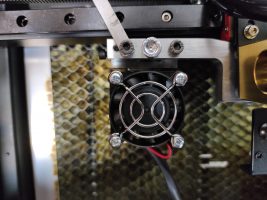

Air extraction system. Beamo has an exhaust fan with a power of 5,6 m3/min to remove air and smoke during an operation process. As it is known, a laser beam is a controlled flow of fire, which burns a material when processing it. Burning produces smoke. Depending on the material, this smoke might be very toxic. Besides, if you don’t remove the smoke, it will lodge on the mirrors and other parts of the optical system. The Beamo exhaust fan removes smoky air via a 4-inch exhaust hose, the end of which you need to put out the window. When installing the machine, don’t forget to leave an 8-inch room behind the back of the machine for the curve of the exhaust hose.

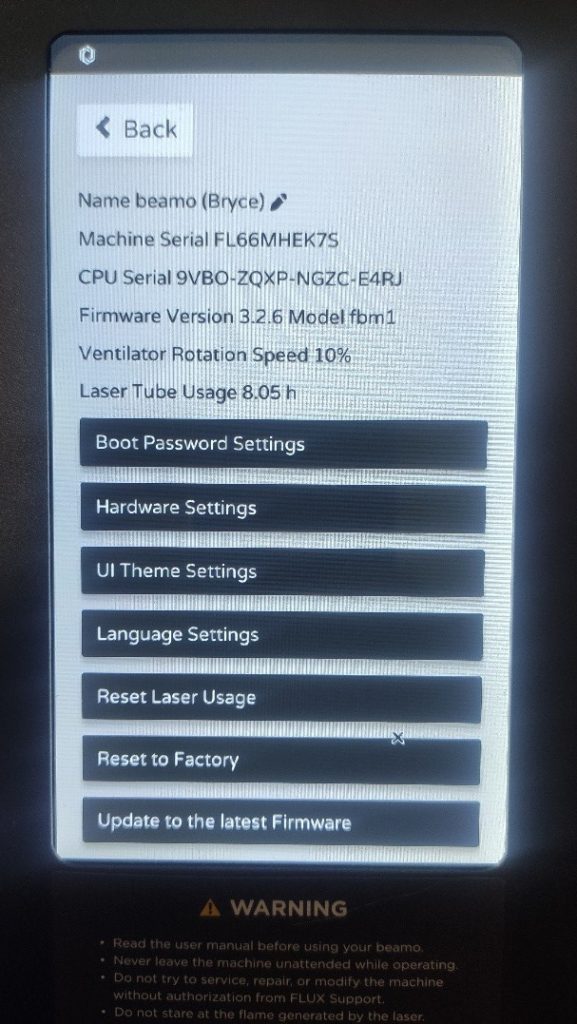

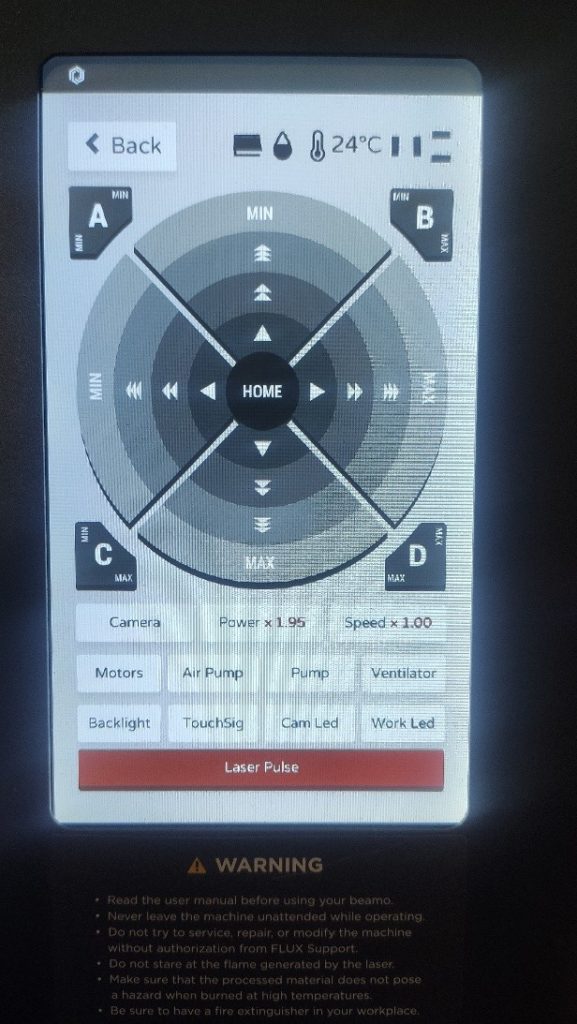

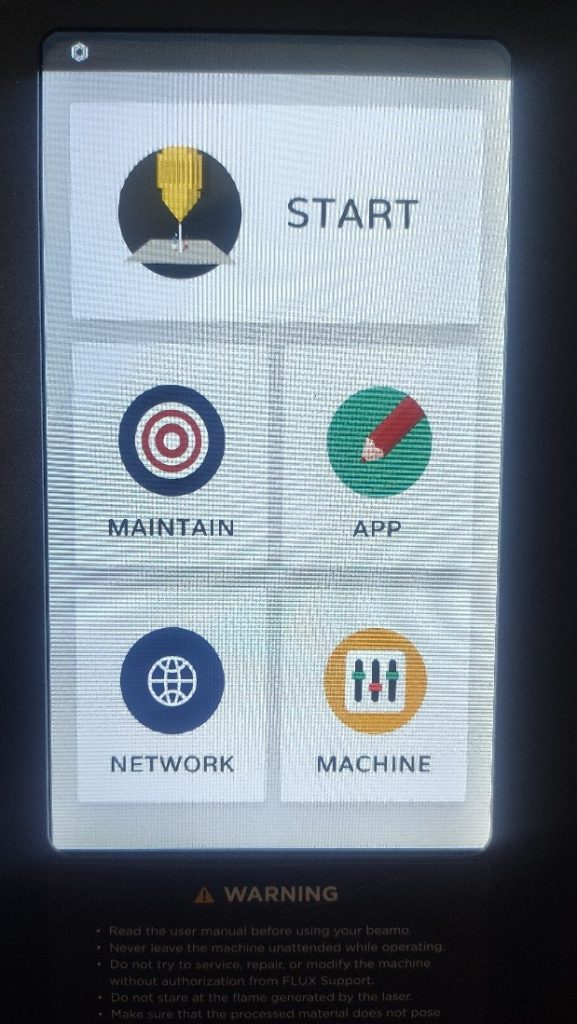

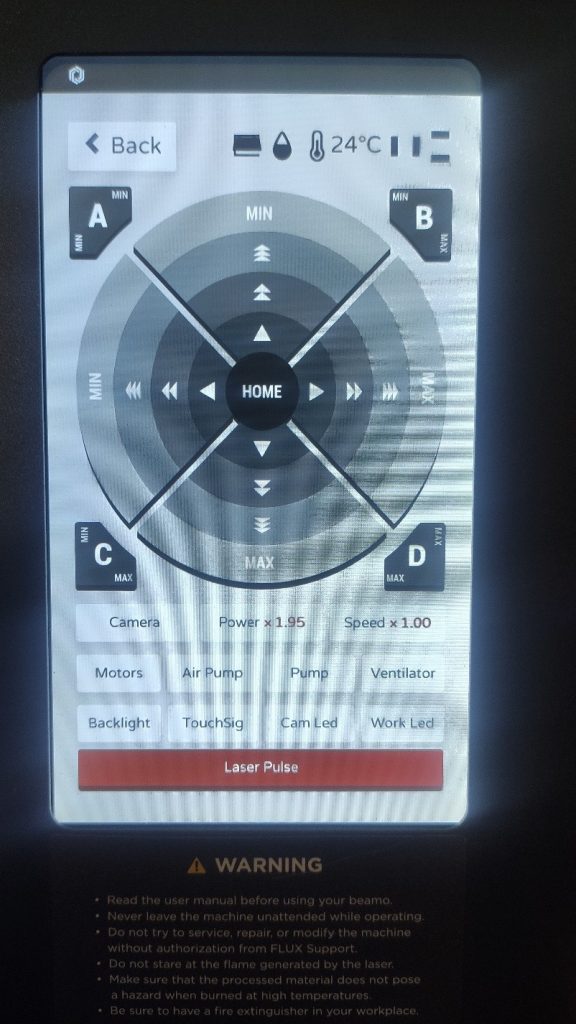

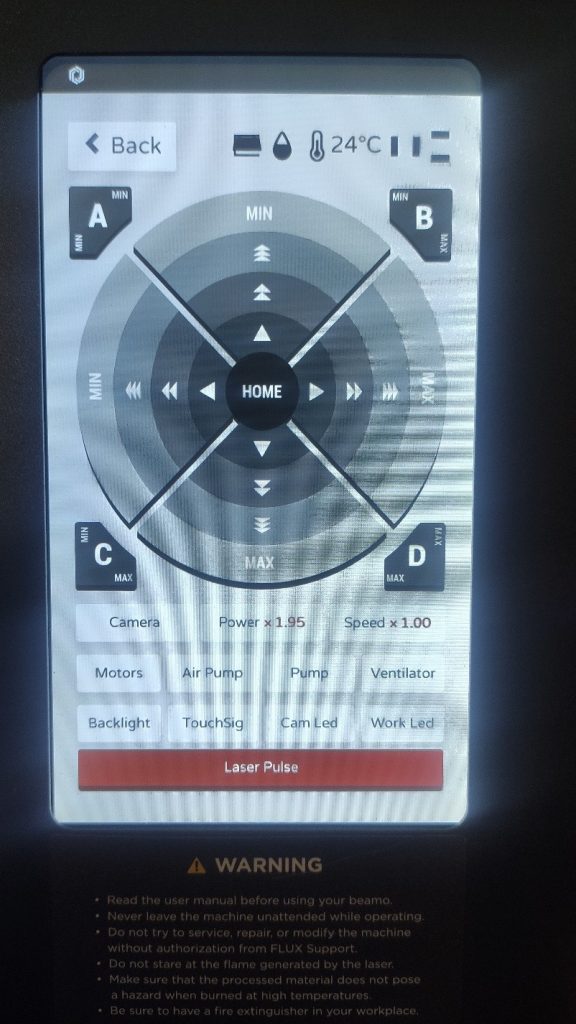

Built-in touch display. See the machine IP on the display when you turn on the machine for the first time.

The display is a very helpful tool. By using it it is possible to set up the machine parameters and put into operation the models uploaded into the storage.

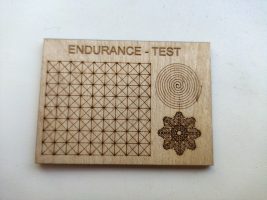

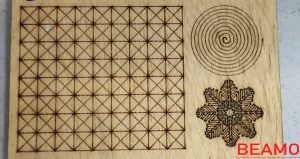

The machine is controlled via Beam Studio, a free software provided by Flux for Windows, macOS and Ubuntu. This program is very simple and user-friendly. It has a set of basic functions to operate the machine and a set of programs to cut and engrave different materials. They are perfectly good for most cases. Besides, a user can change any parameter or add a new one. Adjustment is also very easy. The program has special test tables. Running them on test workpieces you will easily see, which parameters fit better.

Beamo has a built-in camera to scan the working area before dragging the model (layout) to wherever you need. When first connected to Beamo you will be offered to calibrate the camera. That task is easy enough. The built-in camera helps position a model on the material. The camera is quick but not as quick as a lightning. Scanning of the entire working area takes 30 seconds. If you need to scan a part of the working area just drag the scan border frame to circumscribe the chosen area.

If you need to create some complicated model, which cannot be created in Beam Studio do it in any other program and then import it as a raster or vector file. This is very useful.

While working you can monitor the process of cutting or engraving on the machine display or on the computer in Beam Studio.

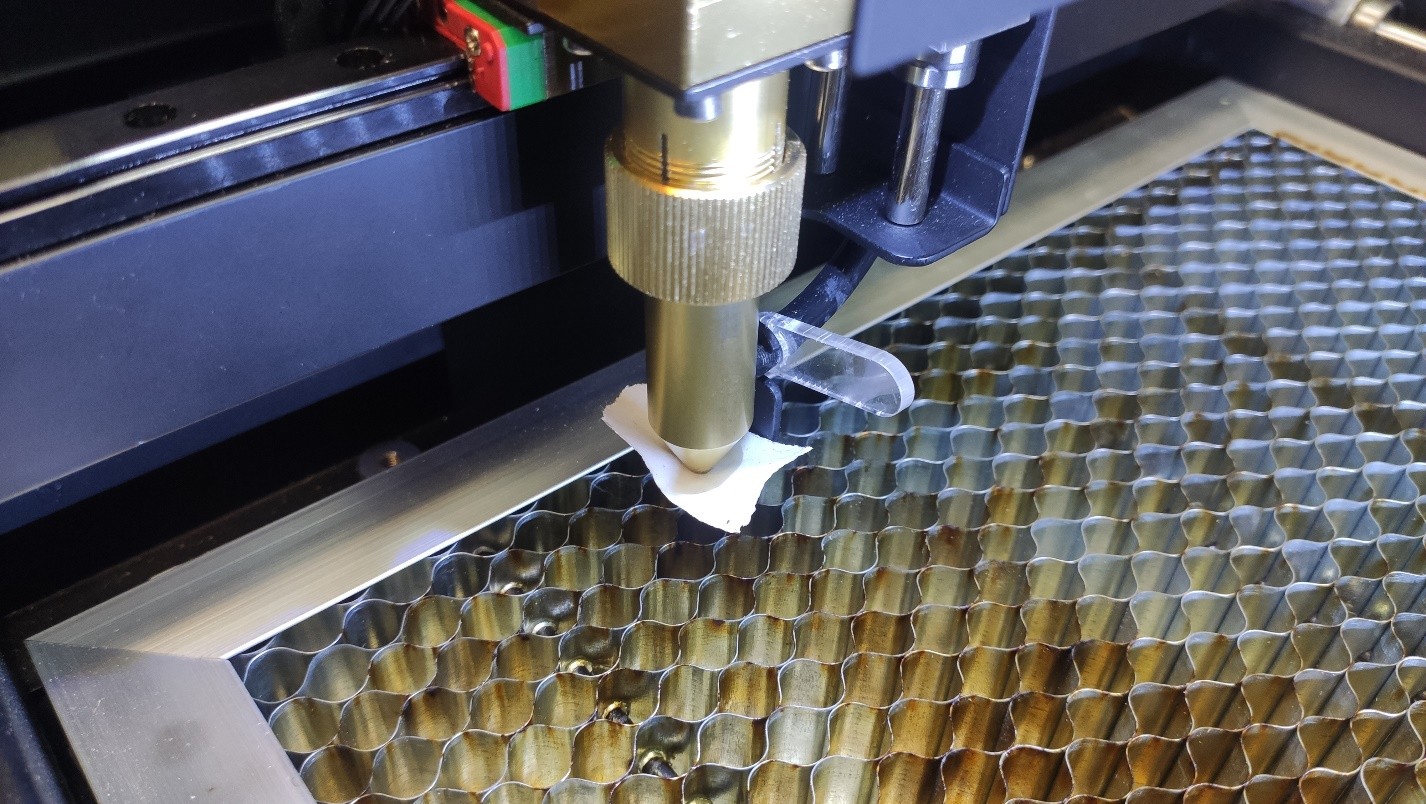

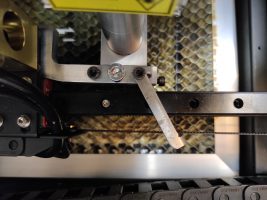

In the basic configuration, the Beamo laser focus is set manually. It means that you will have to focus the head on the material every time when you use new material. Happily, its focusing is very simple:

- place the material,

- rotate the acrylic piece fixed to the laser head,

- put down the laser head so that the acrylic hardly touches the material,

- fix the laser head there and raise the acrylic.

As for the noise: with the fans working at full blast it is a little noisy but not discomforting when you are around. According to the specification, the noise level is about 65 dB, which is higher than talking but less than the noise produced by a vacuum-cleaner.

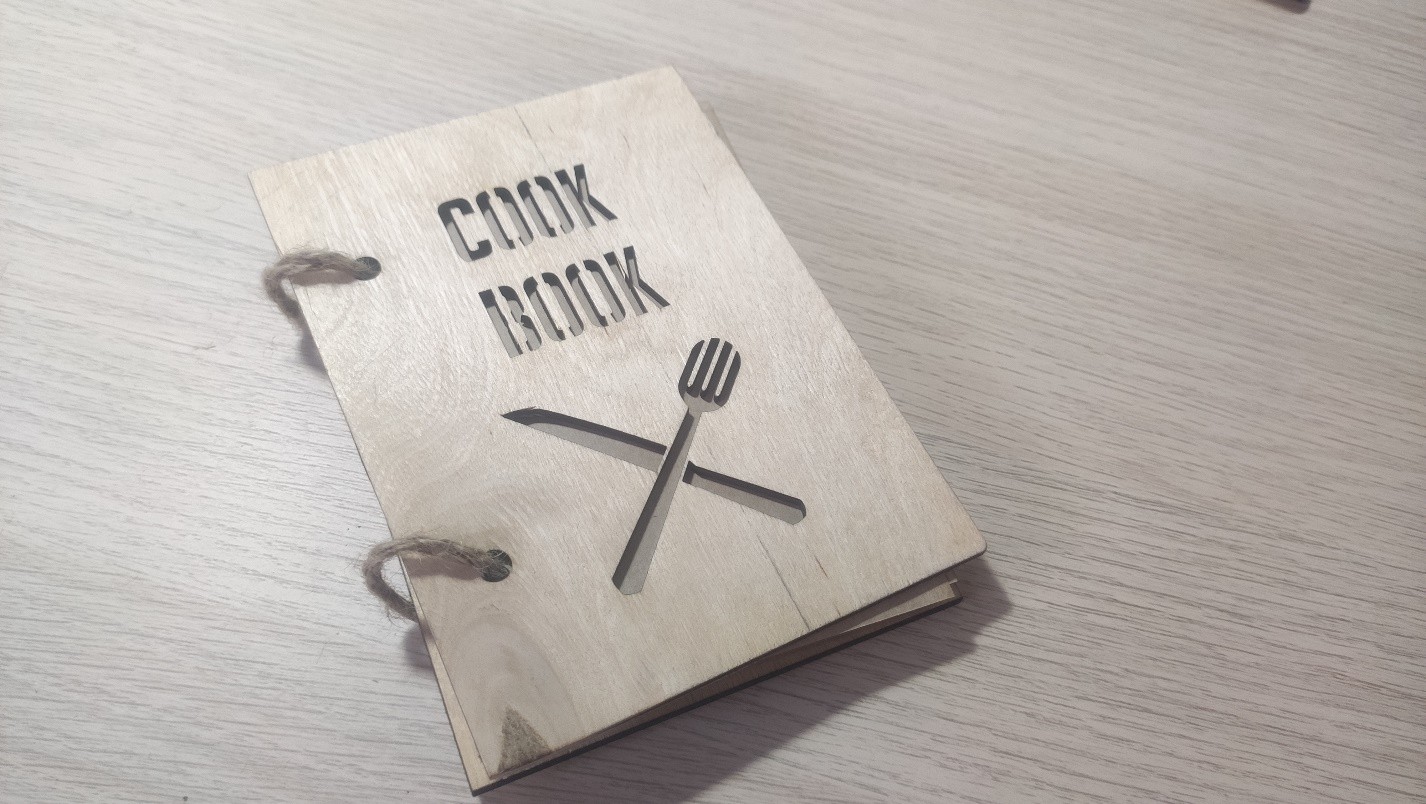

Laser-cut out and engraved items

After many tests, we realized that the operation modes offered by the manufacturer are rather well-chosen but sometimes some slight adjustment is needed.

Plywood, 3 mm thick, 0,7 g/cm^3 densitig

Cutting and engraving go smoothly. The cut edges are perfect and clean.

Acrylic 4 mm

Glass (BK7)

Leather, 1 mm thickness

3.2 (3/16″) mm white acrylic

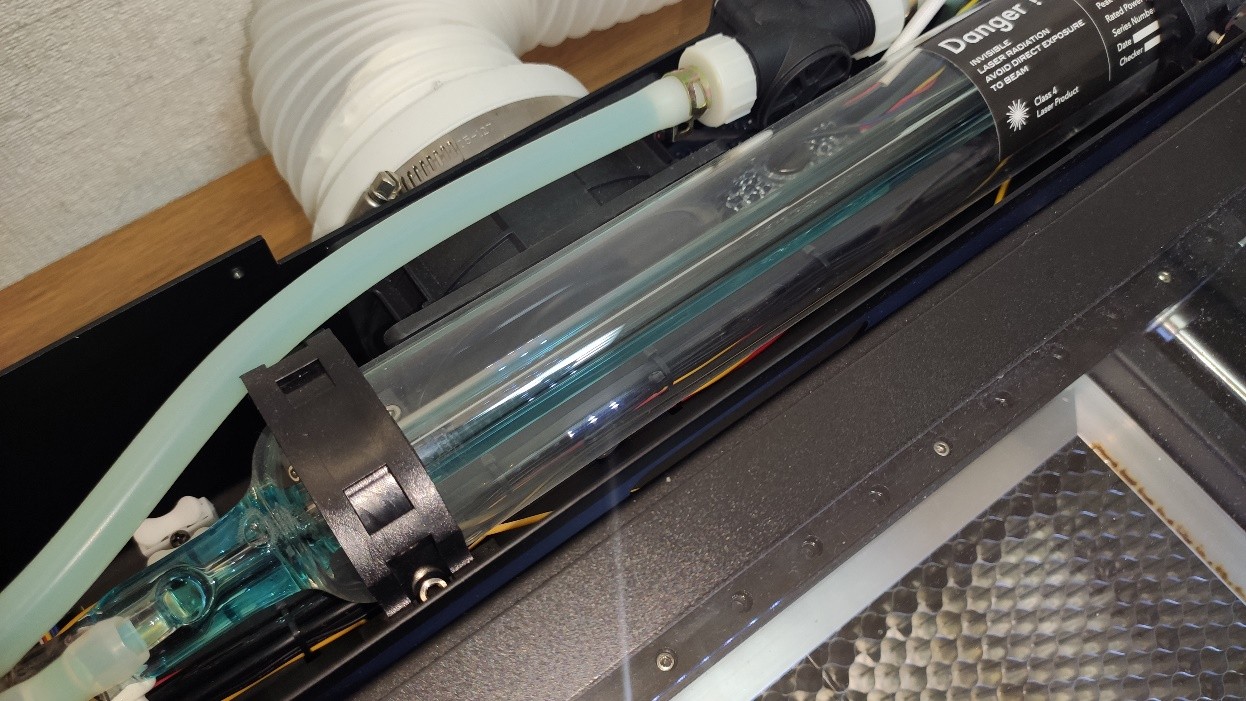

When you run the machine for the first time check:

The water level in the cooling system. Using the display, go to MAINTAIN in the MENU. Then turn on the pump by clicking “Pump”.

5 minutes later the pipe must be free from froth or air.

If air or froth is still present in the pipe add some more distilled water to the tank.

Temperature stability.

To operate the laser you must keep the water temperature between 25-35C. 35C is a critical temperature and may cause damage of your Co2 tube.

For example, if your room temperature is about 30C then the water temperature in your Co2 tube will reach critical 35C in about 4-5 minutes if you run the machine full power.

For an effective operation of your BEAMO FLUX laser, we recommend using a special water chiller by Endurance Lasers

An Endurance water cooling system (water + TEC Peltier chiller) – a chiller for your laser

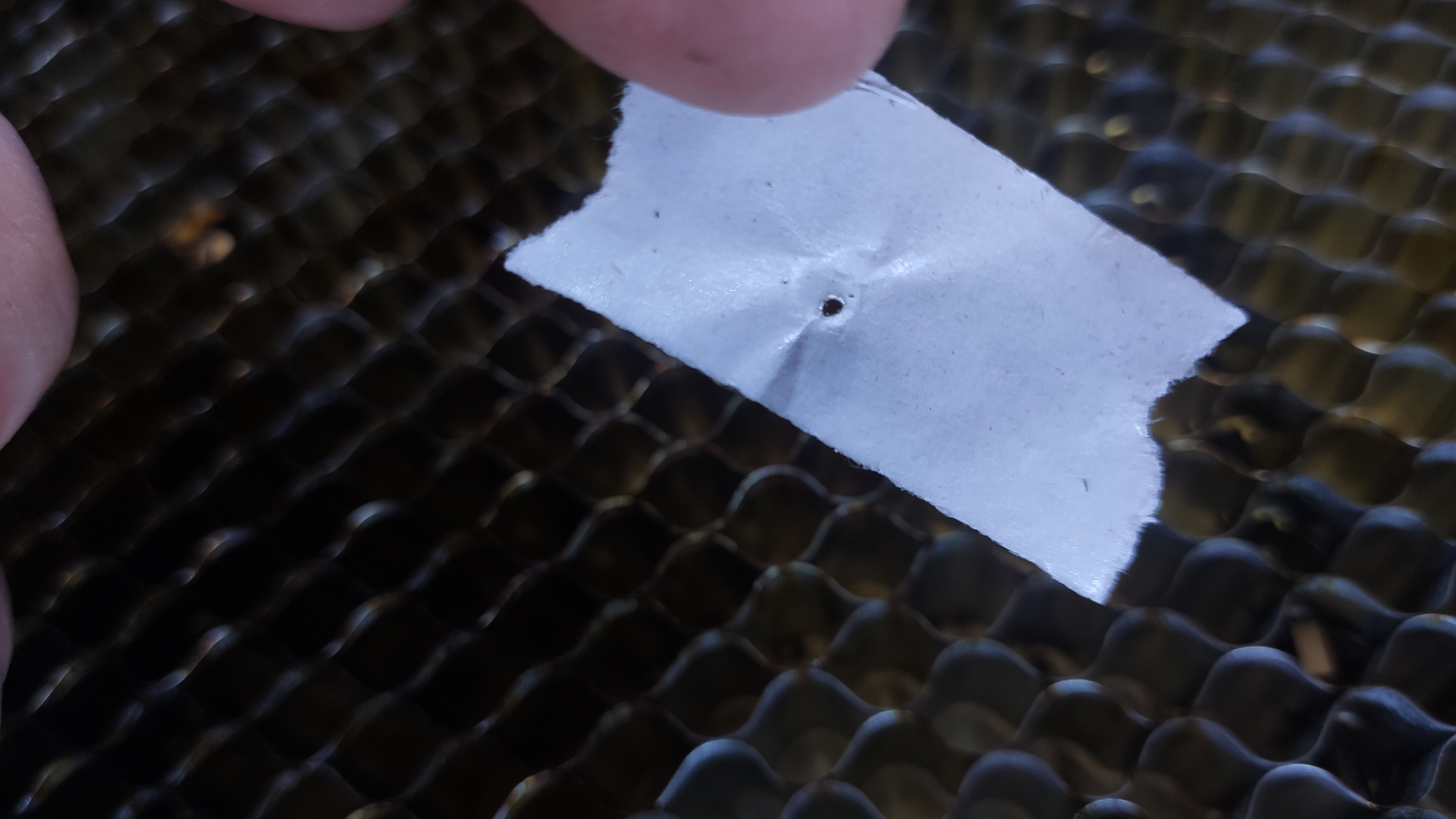

Mirrors adjustment. There’s special scotch tape provided to adjust the mirrors. There’s a detailed instruction in the manual concerning the mirrors adjustment. After the adjustment, it is important to check if the entire optical system is clean. To clean it you can use a cotton swab and distilled water. NO EXCESSIVE FORCE!

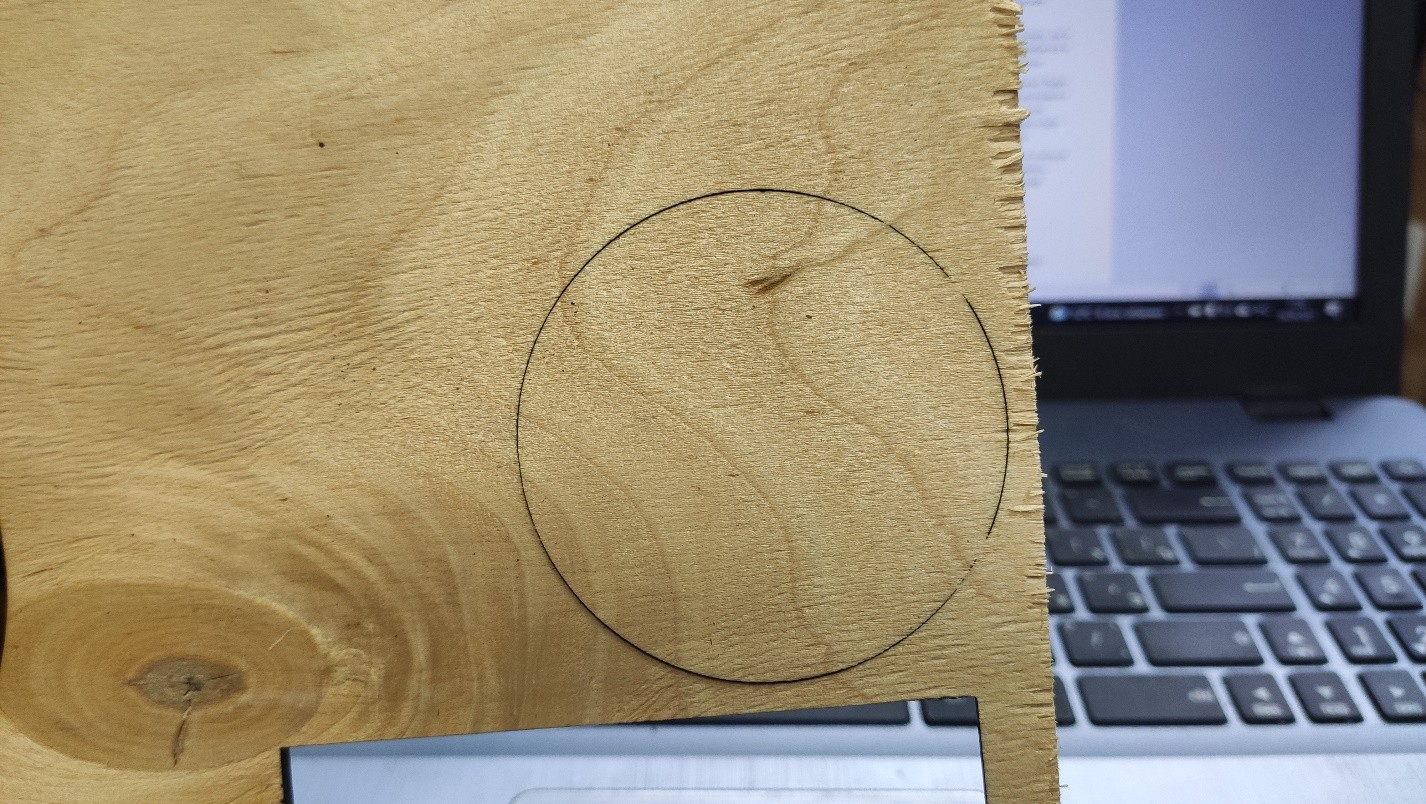

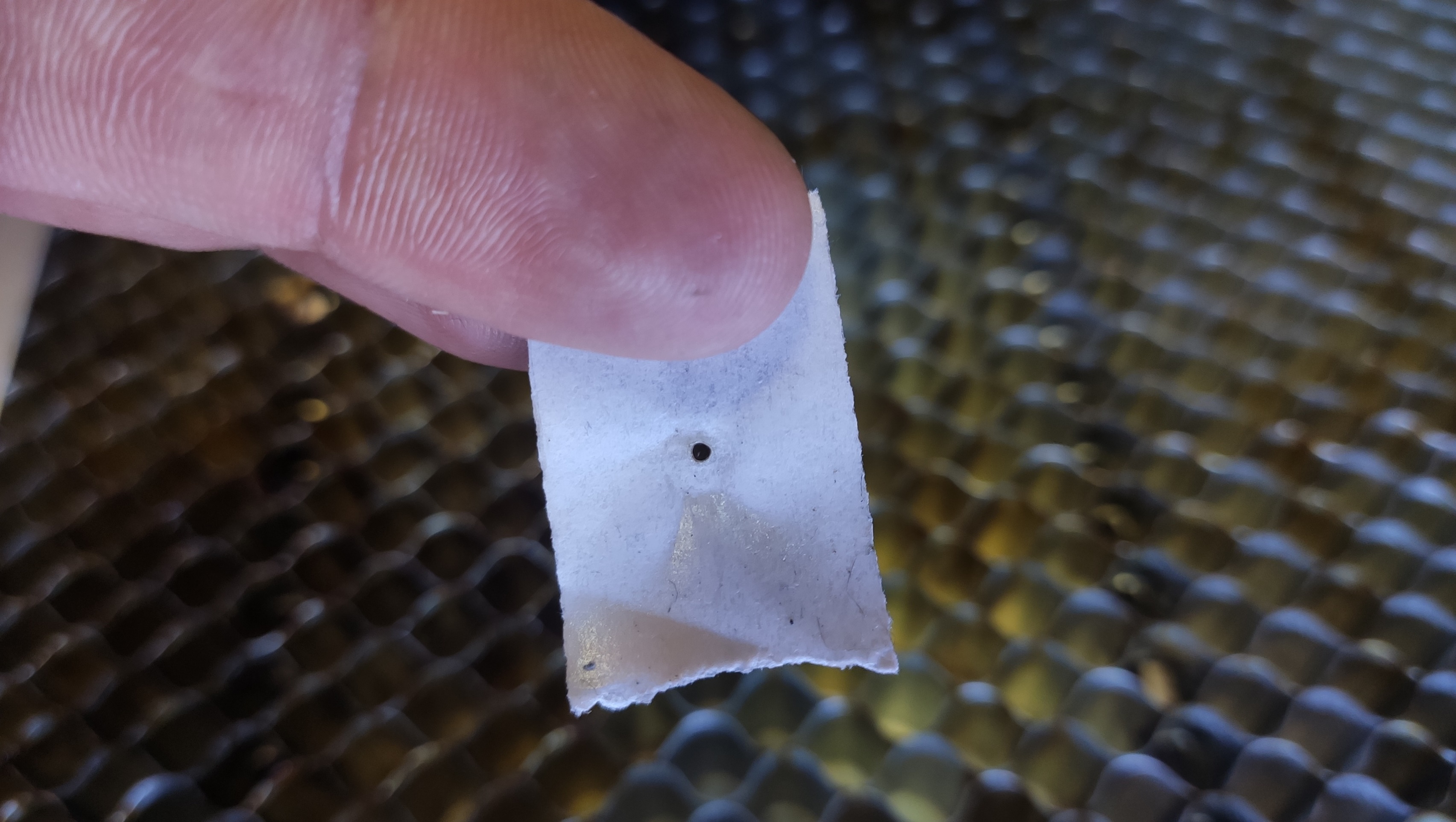

Spot form. After refocusing the beam on a material with a different thickness, check the spot form, because the jet has a short journey. To do this paste the jet with a piece of the provided scotch and click the red button Laser Pulse in the menu MAINTAIN. The top cover should be shut.

Then check the mark left by the laser shot on the tape. It should be perfectly round.

Bad:

: Good:

“Waves” while laser engraving – troubleshooting

While Co2 laser engraving, you may face not accurate laser engraving because of too high-speed. We suggest reducing laser engraving or cutting speed to reduce such artifacts.

Also please check mechanics and tension of drive belts.

Cutting 2 mm soft plywood for a stencil

Restoration the paint of car foot carpets – all you need to know

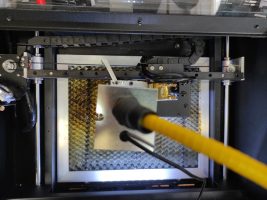

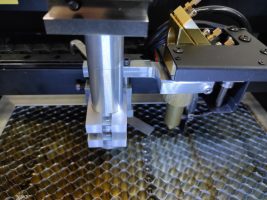

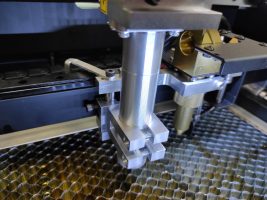

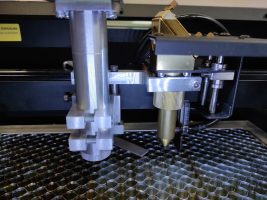

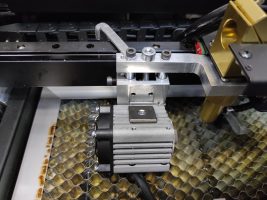

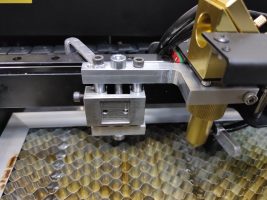

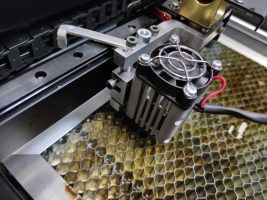

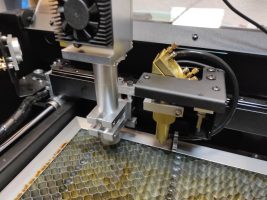

Diode laser installation on Beamo Flux

After purchasing the equipment it is necessary to:

- connect the laser wires to the Beamo machine board;

- install your diode laser on the optical system of the machine;

- do focusing.

- Pre-focusing is done by rotating the lens.

- For more precise focusing use an upper (focusing) screw.

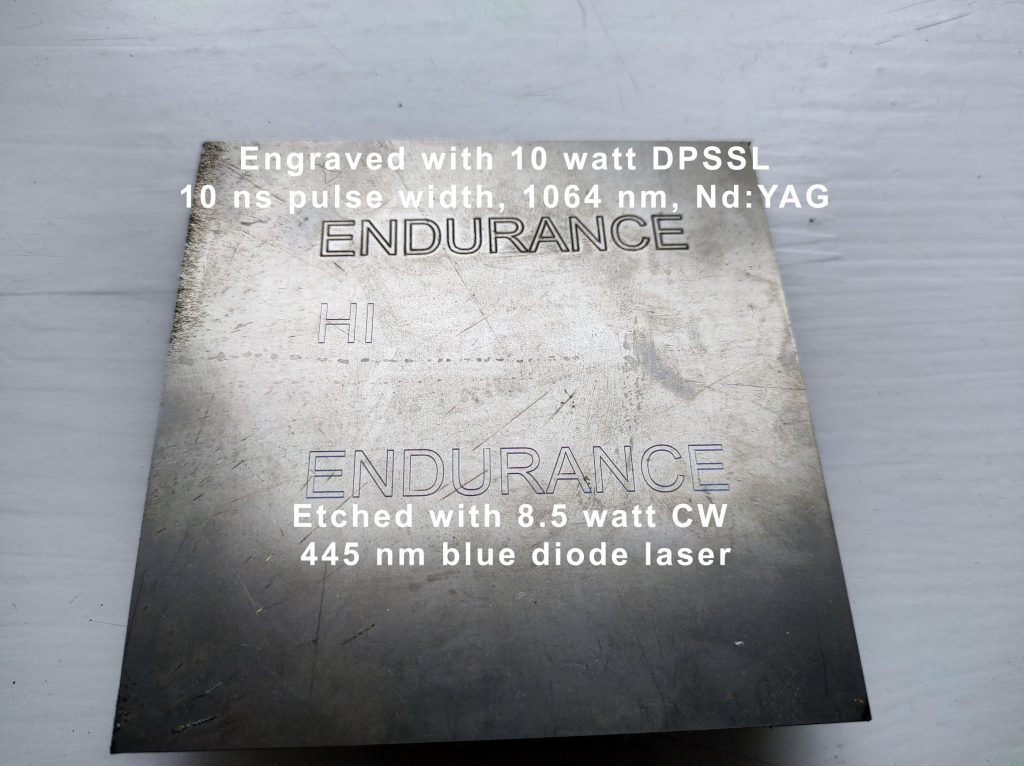

Adding Endurance 5 watt diode / 8.5 watt 445 nm blue PRO laser / 4 (10) watt DPSS laser on BEAMO FLUX

In general, the machine is a very effective tool for laser cutting/engraving.

Adding 4 watt / 10 watt DPSS laser on BEAMO FLUX

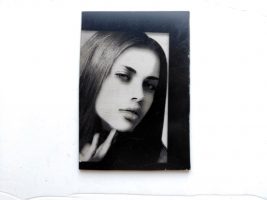

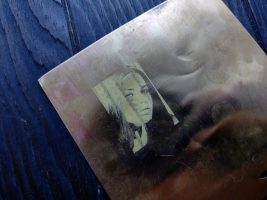

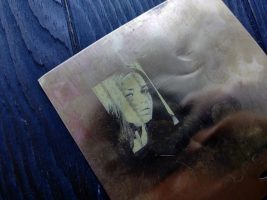

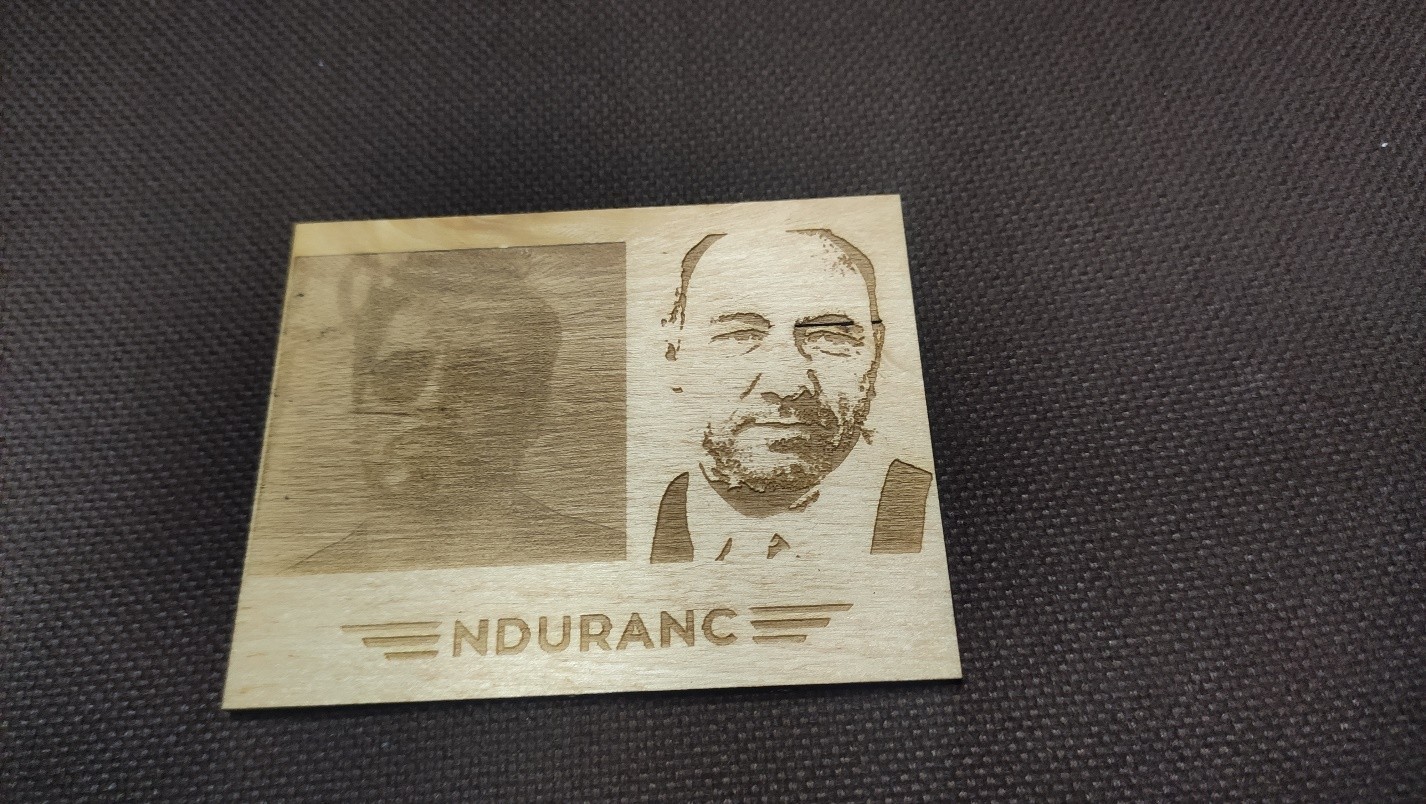

A photoengraving on stainless steel, galvanized steel, copper, brass, aluminum

Adding an 8.5 watt diode 445 nm laser / 10 watt DPSSL on Beamo FLUX

A laser photo engraving on plywood

Learn more about Beamo flux on their official web site >>>