A detailed guide on how to make an original badge from transparent acrylic using a 10 DPSS laser and a 40 watt Co2 laser?

Our installation:

– 10 watt DPSS laser

– a DIY galvo system

– acrylic (plexiglass) 4 – 5 mm or thicker

– CoralDraw software

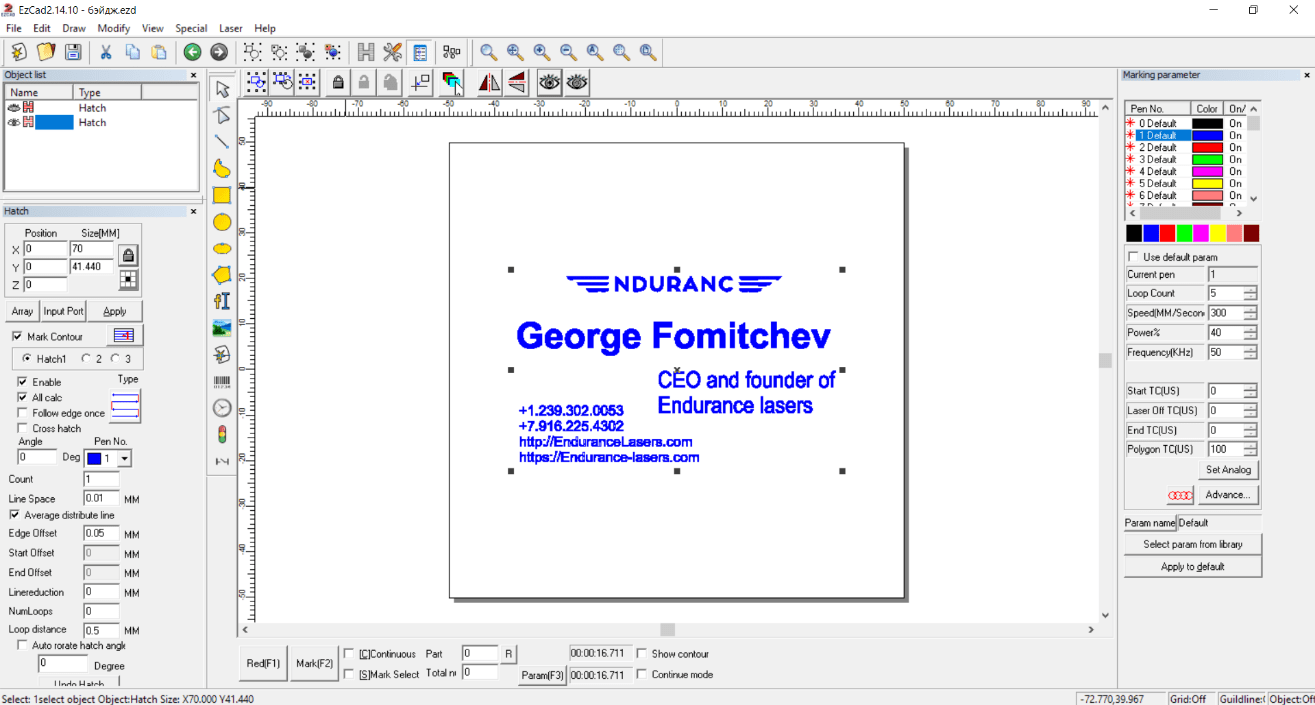

– EzCad laser software

I have a lot of experiments with acrylic. My idea was to make a 3D image inside it. My conclusion:

- An inscription in acrylic is more preferable as its quality is higher than that of any image.

- Vector files are better to work with. Raster images are prone to change.

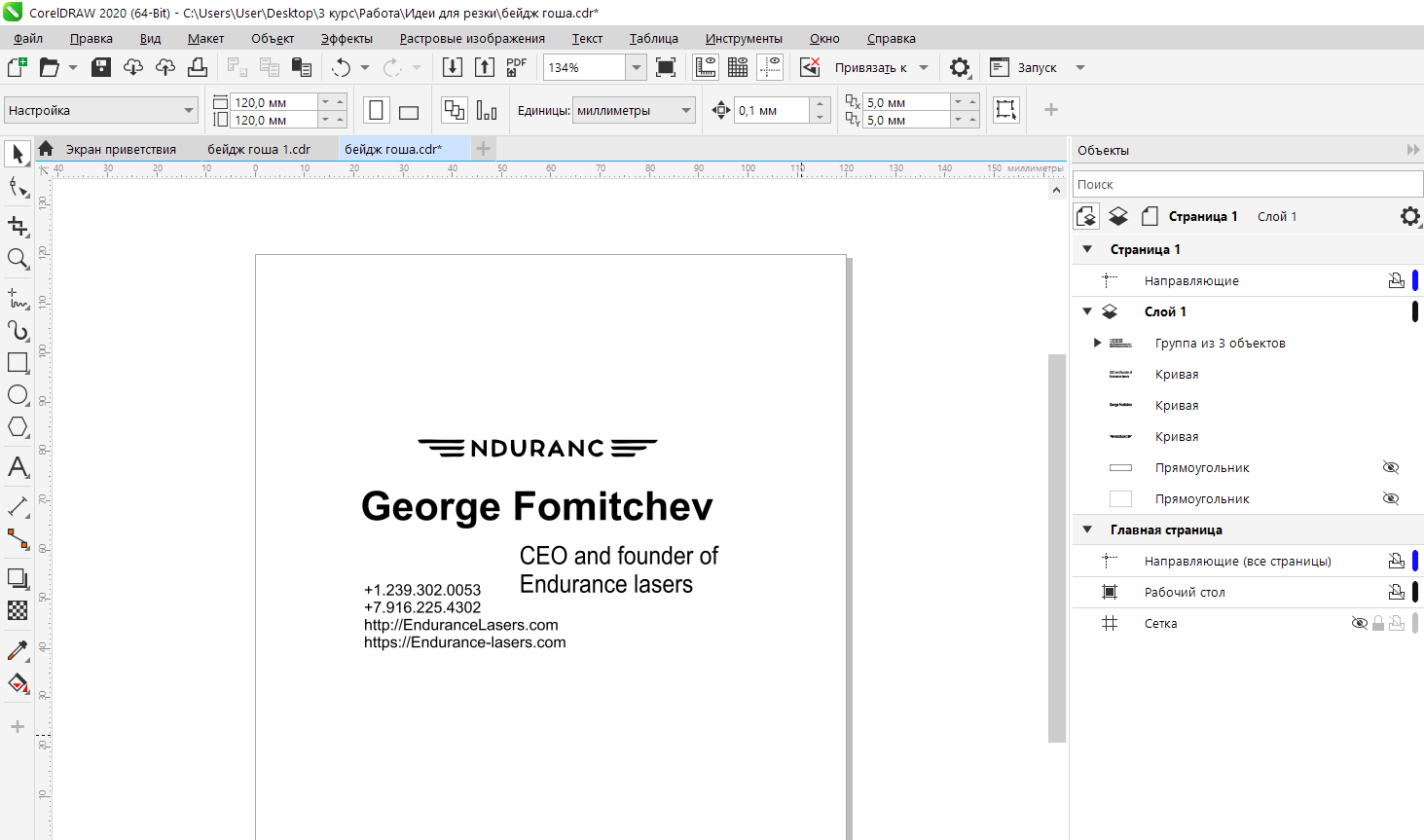

First of all we need to choose the size of the intended name tag.

Mine is 90 x 55 mm.

With these sizes in mind I created a name tag in CorelDraw with the name of the company, my name and contacts. I also tried to add a QR code (with all the necessary info) but failed to make it sharp enough for the cell phone to read it.

But that’s enough, I believe.

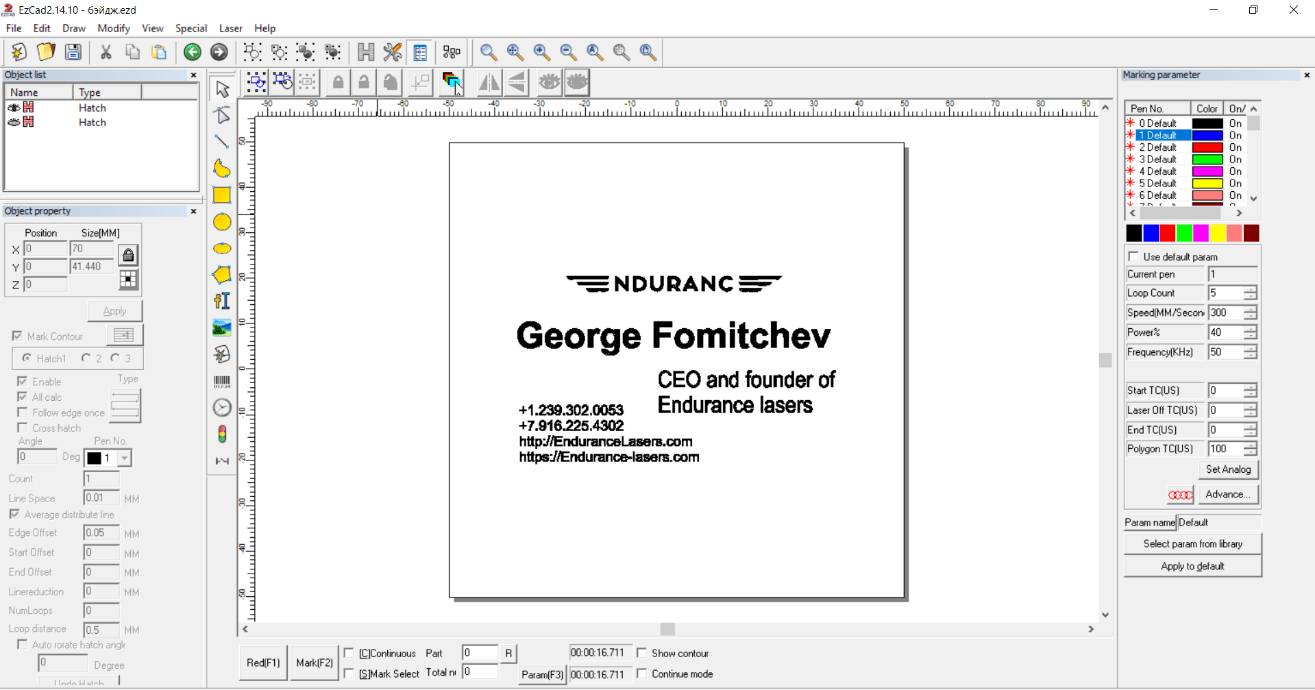

Then I saved it as a .dxf file to go on working in EzCad.

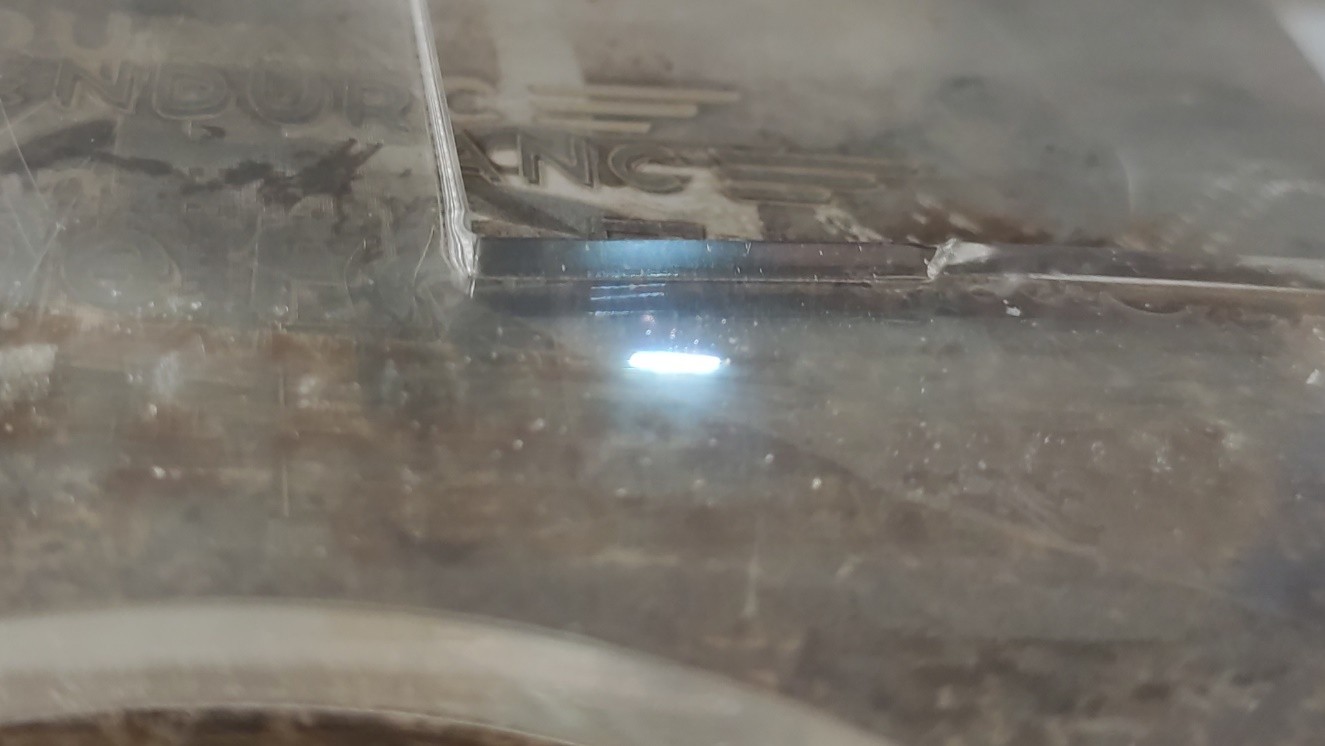

So I place a piece of acrylic on the working table and by way of the trial set an optimal focus centrally inside the acrylic workpiece.

When the focus is set, we put a new acrylic on which we will determine the parameters for work. I recommend doing it exactly on the model that we will engrave. Centering. Dxf file into EzCad. Then I fill it in the same way.

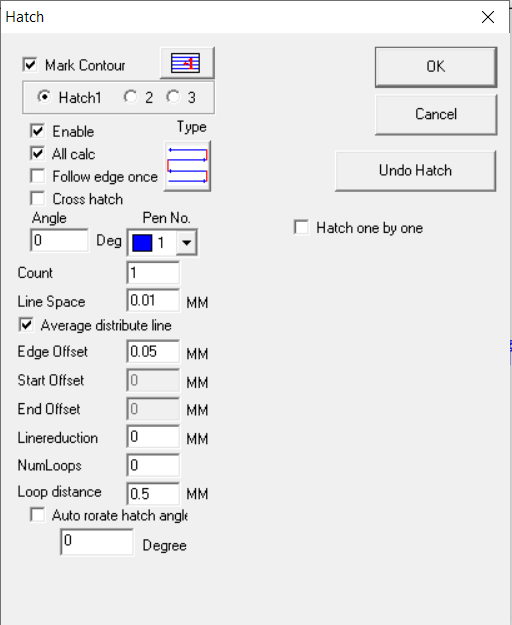

Now it is also necessary to determine the parameters empirically. All engraving consists of two parts. First, prepare the acrylic at a slower speed. Then we apply the required text at a higher speed.

I got the best result with:

– power 50%; speed 500 mm / s; repeats 5

– power 50%; speed 800 mm / s; repeats 4

Now we run the same file with known parameters on pure acrylic. Here is the result. Then, for more accuracy, I cut it out with a CO2 laser and attached a strap.

Another example – engraving inside the transparent acrylic!

Hope that you like that. If you have any more questions – let us know via Livechat.

How to make a beautiful laser engraving on acrylic and glass