Today I’d like to make a seal using a CO2 Endurance laser. According to the Internet info, CO2 lasers are the best choice for this task. I have:

A piece of special red rubber for stamps

An Endurance engraving machine (LE 5040 SainSmart Frame)

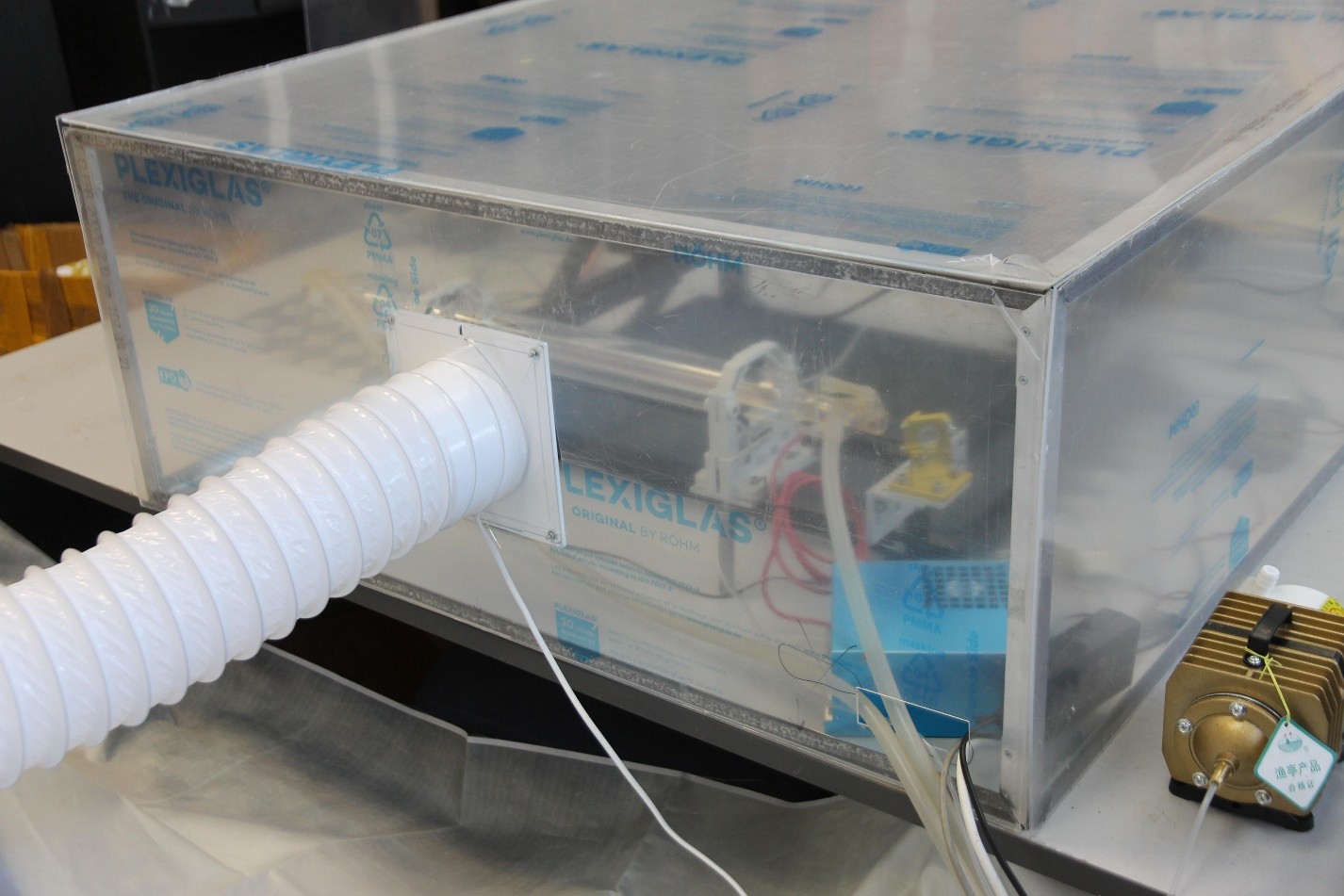

A box with an exhaust ventilation

To do rubber engraving is better with forced-air cooling. That is why the laser nozzle is supplied with air cooling to carry rubber fumes and smoke from the lens and to blow off the outburnt rubber.

Rubber when burning emits much smoke. For this reason, I engrave it in a box with exhaust ventilation.

In this picture, you can see a box with ventilation, a CO2 tube and an air compressor for blowing.

For the beginning, I had to define the speed and power parameters for engraving.

After at least 20 trials I found an optimal mode. The best result was obtained with 0.04 mm line frequency and 60% power.

The best parameters and settings

0.04mm pouring frequency,

power 60%

speed 1700 mm / min.

Now it’s time to upload the print file to Light Burn. Since I saved it in Corel as an .ai file, I can set parameters for each element separately. For the main print part, I choose “Filling” and for a wavy line I need to decrease the speed, so I set the “Line” mode.

Getting started

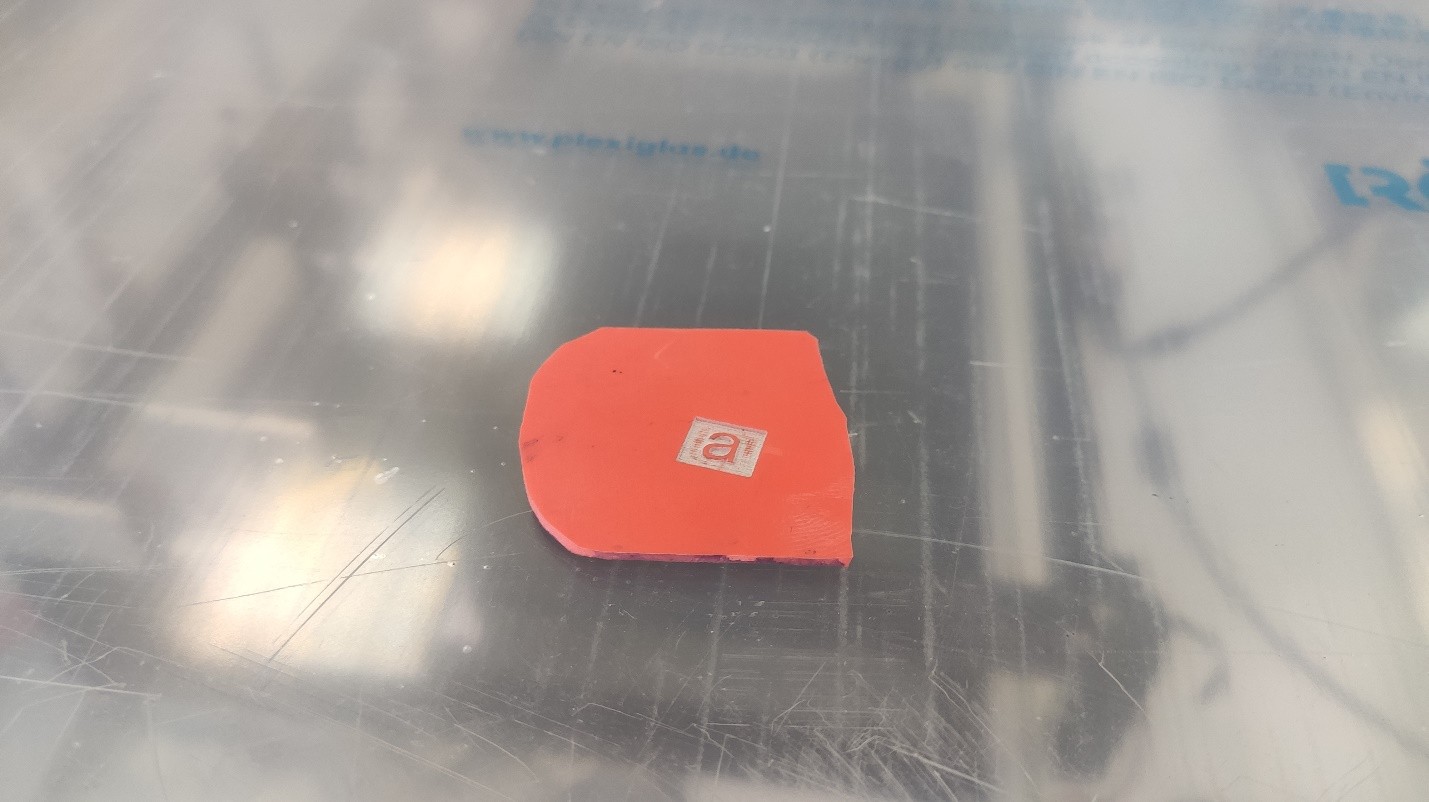

During the engraving process, I notice that I have forgotten to mirror copy the seal image. This is what I have. So a seal imprint on paper will look inversed.

In addition, I forgot to make a special layer for cutting, that is why I had to use scissors and the final result didn’t look perfect. I tried to process the item again in the cutting mode but failed to get even edges. So I had to start from the very beginning.

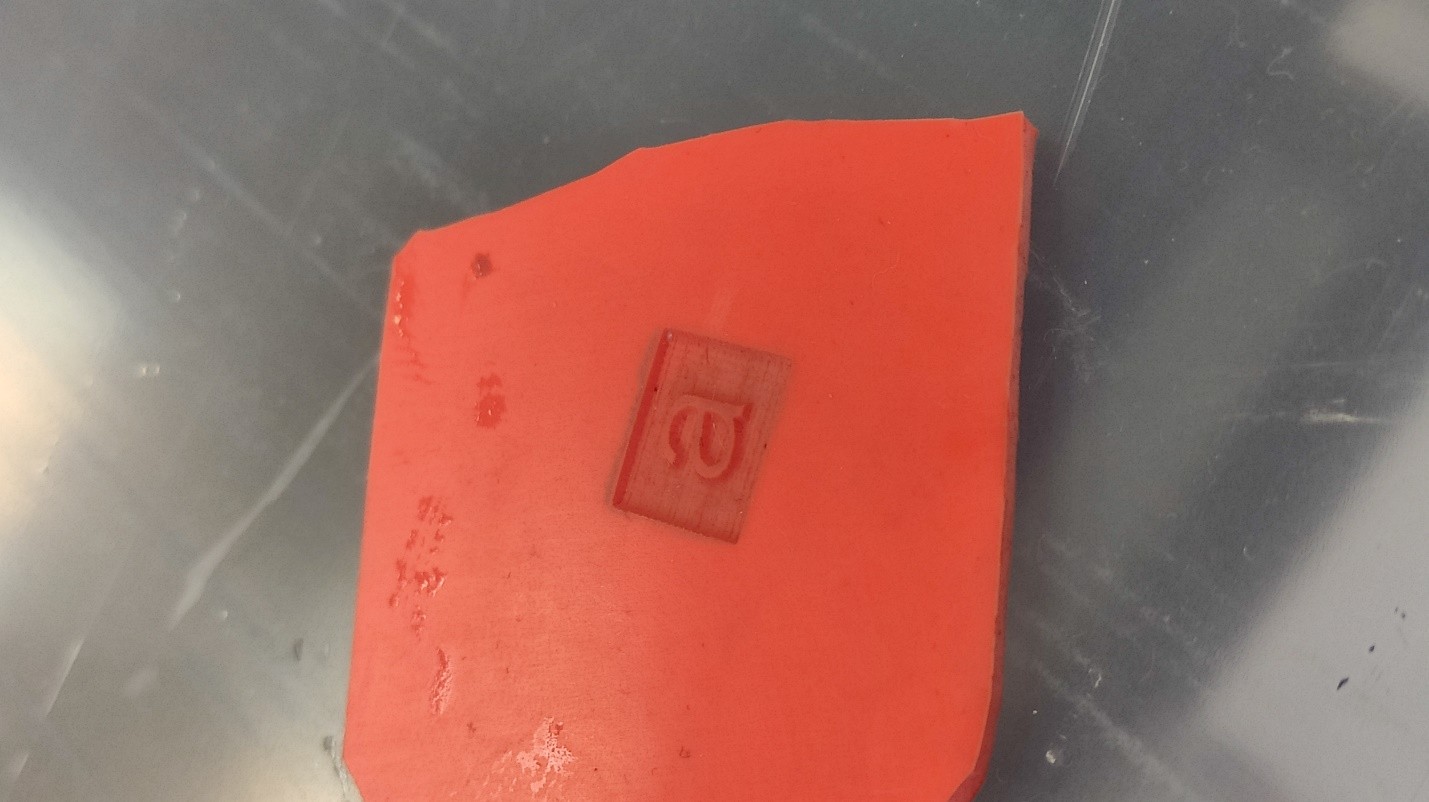

This time I did everything in the right way. Here is my final result.

The fittings for the stamp are 3D-printed. The stamp diameter is 38 mm. The rubber stamp is attached to the fittings with a double-sided tape. This is a ready stamp.

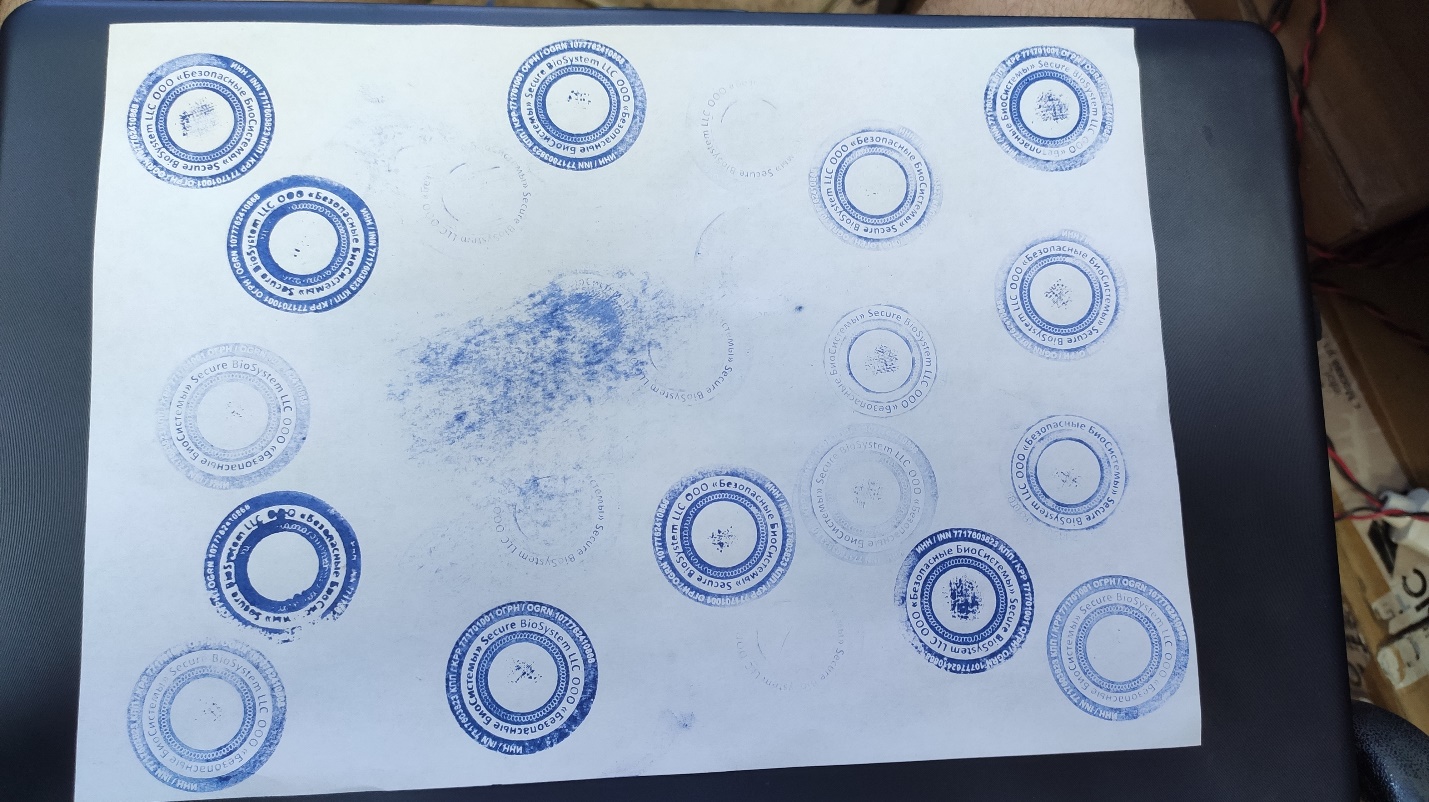

Here are seal imprints on paper.

A CO2 tube perfectly fits for making seals and stamps. The CO2 tube, the box and engraving machine I used are made by Endurance Lasers.