Wood/plywood density. Why it is important?!

There are a few parameters that matter when you do a laser cutting of wood/plywood: thickness, type of material and density.

There is a big demand for cutting wood and plywood on the market.

You may use a Co2 laser, CNC mill or a diode laser for that.

The main question is to understand what type of wood or plywood can be easily cut with the laser and what laser cutting parameters should be used for it.

In the post, we will highlight the density of different wood and plywood types.

The density of wood and wood-based materials

To measure the weight of constructions the wood density should be taken according to the following table:

| Types of wood | Density (Kg / M^3) | |

| Softwood: | Average to cut | |

| larch | 650 | |

| pine, fir-tree, cedar, silver-fir | 500 | |

| Hardwood: | Hard to cut | |

| oak, birch, beech, ash, maple, horn-beech, acacia, elm | 700 | |

| Softwood: | Very easy to cut | |

| aspen, poplar, alder, linden | 500 | |

Images of wood and plywood types

All these types of wood and plywood will be differently cut because they have different structures and a different densities.

- The density of freshly cut coniferous and soft hardwood should be 850 kg/m³, hardwood – 1000 kg/m³.

- The density of glued wood should be taken as non-glued.

- The density of ordinary plywood should be equal to that of veneer wood, and Bakelized plywood should have a density of 1000 kg/m³.

- The density of homodromous veneer wood is 500-600 kg/m³ (0.5-0.6 g / cm^3 and depends on the veneer wood.

Keep in mind that MDF is something different!

Medium-density fibreboard (MDF) is a wood product made by breaking down hardwood or softwood residuals into wood fibers, often in a defibrillator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally denser (something like 0.8-0.85 g/ cm^3 than plywood that makes it very hard to cut even with Co2 lasers. It is made up of separated fibers. It is stronger and denser than particleboard.

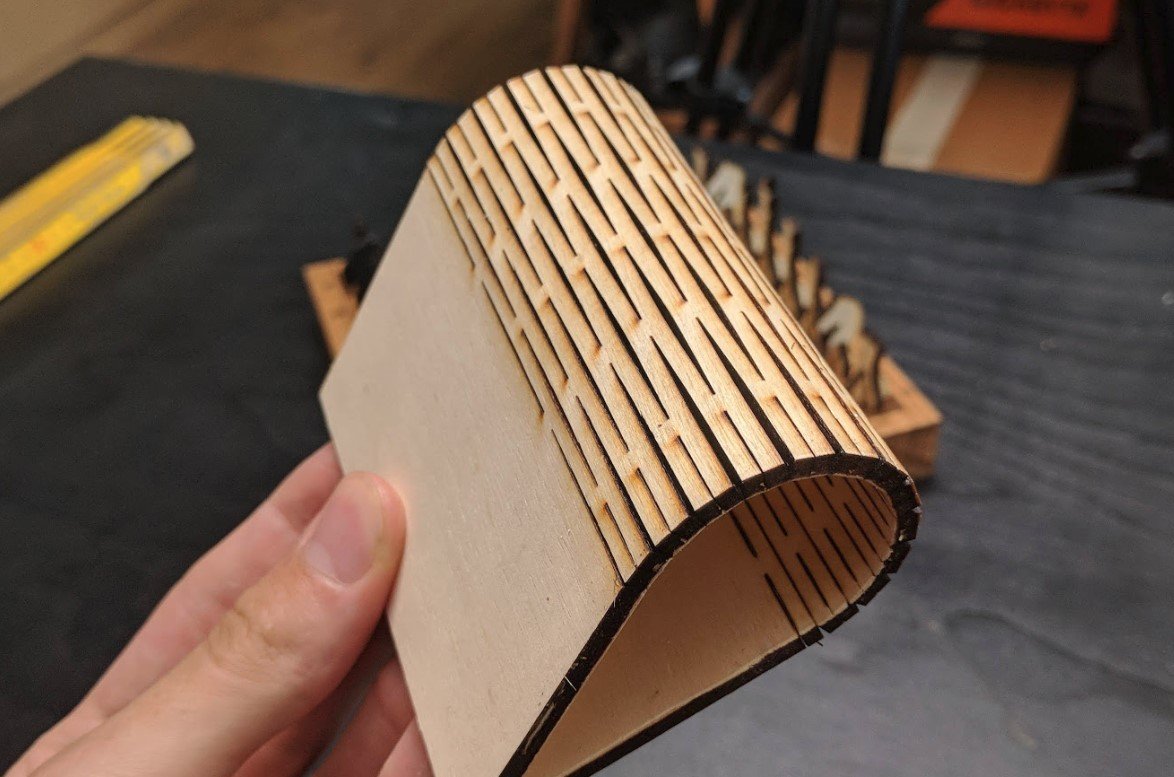

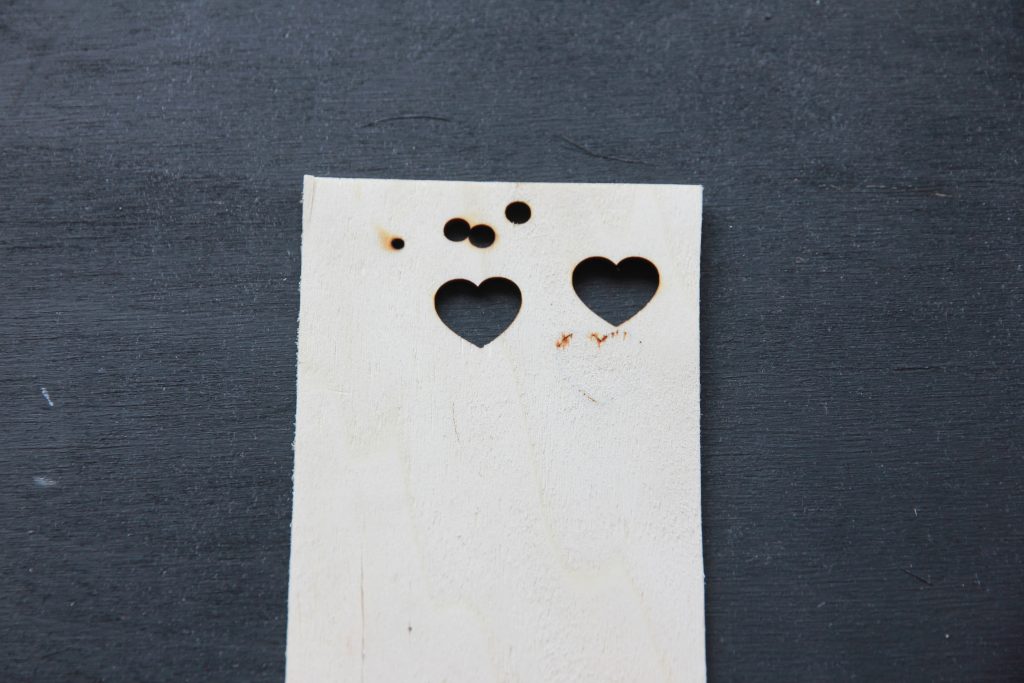

Examples of soft plywood (laser ply)

Those types of plywood usually have a density 0.3-0.5 g / cm^3 which is light enough.

Live test of a 10 watt ENDURANCE PLUS PRO cutting abilities

Cutting different types of plywood (different thickness and different density)

Laser cutting with Endurance 15 watt DUOS laser

A reference table of the density of various wood species

| Wood density of more common species of wood | ||

| Species of wood | Wood density kg / m³ | Easiness to cut |

| Balsa | 120-160 | Very easy |

| Siberian fir | 390-430 | Easy |

| Spruce | 400-450 | Easy |

| Sequoia | 410 | Easy |

| Poplar | 400-500 | Easy |

| Willow | 460 | Easy |

| Pine | 450-500 | Easy |

| Alser | 490 | Easy |

| Aspen | 510 | Medium |

| Linden | 530 | Medium |

| Mahogany | 540 | Medium |

| Horse chestnut | 560 | Medium |

| European chestnut | 590 | Medium |

| Cypress | 600 | Above medium |

| Bird cherry tree | 610 | Above medium |

| Sapelly | 620 | Above medium |

| Hazel | 630 | Above medium |

| Walnut | 640 | Above medium |

| Birch | 650 | Hard |

| Cherry tree | 660 | Hard |

| European white elm | 660 | Hard |

| Larch | 660 | Hard |

| English field maple | 670 | Hard |

| African oak | 670 | Hard |

| Common pear | 690 | Hard |

| Oak | 690 | Hard |

| Afromosia | 700 | Very hard |

| West Indies mahogany | 700 | Very hard |

| Sycamore | 700 | Very hard |

| Buckthorn | 710 | Very hard |

| Beech | 720 | Very hard |

| Horn-beech | 750 | Very hard |

| Padouk | 750 | Very hard |

| Yew | 750 | Very hard |

| Ash | 750 | Very hard |

| Doussia | 800 | Very hard |

| Kempas | 800 | Very hard |

| Plumtree | 800 | Very hard |

| Lilacs | 800 | Very hard |

| Thorn | 800 | Very hard |

| Palisander | 800 – 1000 | Extremely hard |

| Pecan tree | 830 | Extremely hard |

| Jarra | 830 | Extremely hard |

| Merbau | 840 | Extremely hard |

| Courbaril | 840 | Extremely hard |

| Dipteracarpus Alatus | 850 | Extremely hard |

| Coula nut | 850 | Extremely hard |

| Muntenia | 850 | Extremely hard |

| Wenge | 900 | Extremely hard |

| Lapacho | 900 | Extremely hard |

| Olive tree | 900 | Extremely hard |

| Sandal | 900 | Extremely hard |

| Panga-panga | 950 | Extremely hard |

| Boxwood | 960 | Extremely hard |

| Sieva bean | 970 | Extremely hard |

| Sukupira | 1 000 | Extremely hard |

| Cumaru | 1 100 | Extremely hard |

| True ebony | 1 080 | Extremely hard |

| Black tree | 1 160 | Extremely hard |

| Quebracho | 1 210 | Extremely hard |

| Guaiacum or bakaut | 1 280 | Extremely hard |

Reference: https://krovli.club/strojmaterialy/plotnost-drevesiny

| Main kinds of plywood | (thickness and density) | ||

| Type | h (mm) | p (kg/m3) | |

| Standard | from 3 (mm) to 30 (mm) | 650 (kg/m3) | |

| Birch | from 1 (mm) to 12 (mm) | 650 (kg/m3) | |

| Bakelite | from 5 (mm) to 40 (mm) | 1200 (kg/m3) | |

| Decorative | from 3 (mm) to 12 (mm) | 650 (kg/m3) | |

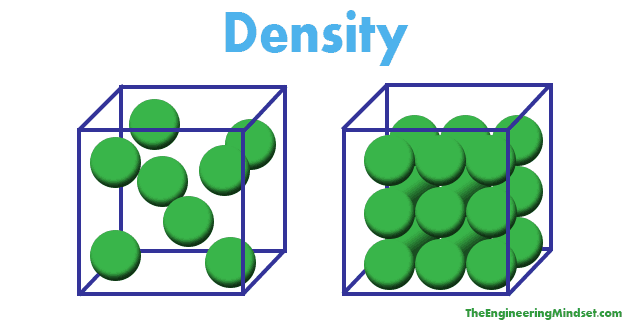

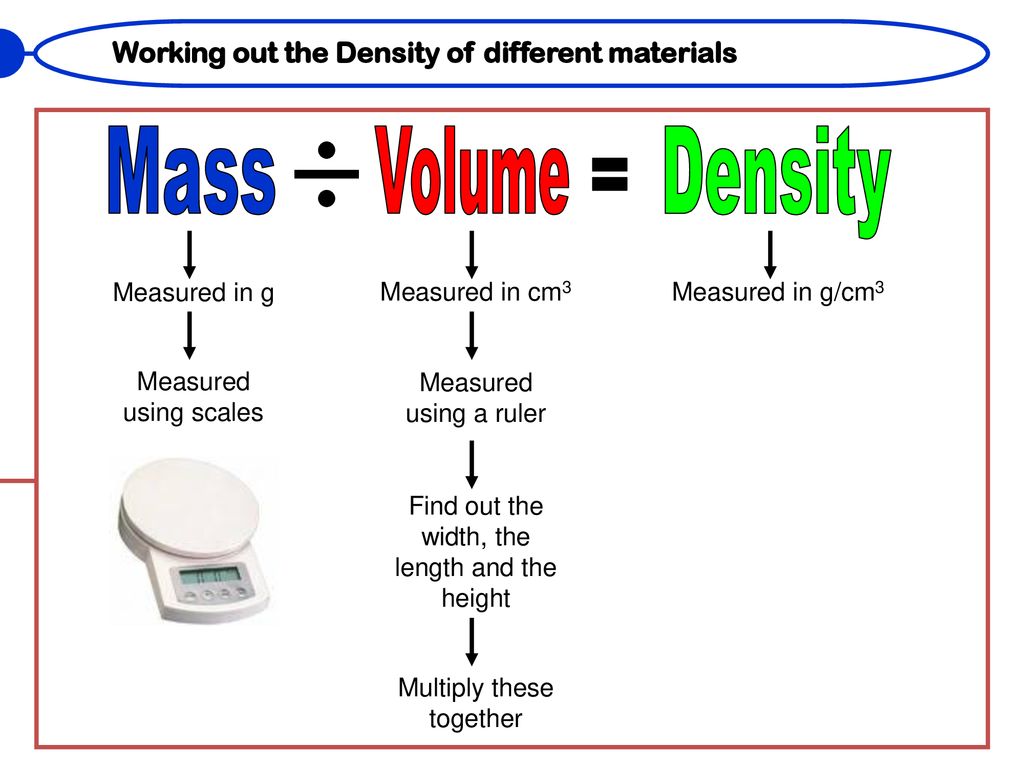

Wood density is the ratio of the wood mass to its volume. It is measured in kg/m3 . The wood density depends on its moisture content. All physical and mechanical properties of wood are determined at a moisture content of 12%. There’s a close relationship between mechanical strength and density. Heavier wood is more durable as a rule. Density is determined by the mass of a wood substance per unit volume. At a moisture content of 12% wood, depending on its density, can be divided into three groups:

| Wood species | Density, g/cm3 | Density, kg/m3 |

| Light | ||

| Balsa | 0.15 | 150 |

| Siberian fir | 0.39 | 390 |

| Fir tree | 0.45 | 450 |

| Willow | 0.46 | 460 |

| Alder | 0.46-0.64 | 460-640 |

| Aspen | 0.51 | 510 |

| Pine | 0.52 | 520 |

| Linden | 0.53 | 530 |

| Bloomy poplar | 0.55 | 550 |

| Medium-density | ||

| Horse chestnut | 0.56 | 560 |

| Cherry tree | 0.58 | 580 |

| Yew | 0.6 | 600 |

| Teak | 0.62-0.75 | 620-750 |

| Walnut | 0.64 | 640 |

| Sycamore maple | 0.65 | 650 |

| Maple | 0.65 | 650 |

| Birch | 0.65 | 650 |

| Beech | 0.65 | 650 |

| Cherry tree | 0.66 | 660 |

| Siberian fir tree | 0.66 | 660 |

| African oak | 0.67 | 670 |

| Beech | 0.68 | 680 |

| Oak | 0.69 | 690 |

| Mahogany | 0.70 | 700 |

| Sycamore | 0.70 | 700 |

| Hardwood | ||

| Ash | 0.75 | 750 |

| Plumtree | 0.80 | 800 |

| Horn tree | 0.80 | 800 |

| Pecan tree | 0.83 | 830 |

| Olive tree | 0.85-0.95 | 850-950 |

| Appletree | 0.9 | 900 |

| Boxwood | 0.96 | 960 |

| Black sapote | 1.08 | 1080 |

In an absolutely dry condition, the density is by 20-40% less than the one indicated in the table.

The wood density has a great practical meaning. The denser wood is heavier and harder and is more durable and harder to process. The denser wood is hard to be treated with wood preservatives, but it is more durable and wear-resistant when used for floors, stairs, railings.

If you substitute one wood species for another one the volume (and, accordingly, mass) of the adhesive in one cubic meter will change very little.

You can find out the general adhesive mass in a cubic meter by subtracting, for example, the specific weight of dry pine (500 kg/m3) from the specific weight of pine plywood.

To find out the mass of a cube of material from the veneer of larch, poplar, or linden it is just necessary to add 50 kg to the weight of dry wood of the corresponding species.

Our customer made and share

Laser cutting of a thick type of plywood

“Holy Guacamole10 watt Endurance laserI didn’t have any 3mm ply wood around. But i did have 5mm plywood and 9mm plywood.So I thought, lets put it through the test. 9mm took about 20 passes and had to lower Z axis 5mm for last 10 passes. The 5mm did a clean cut no change to Z in <8 passes.Videos to follow in post.”by Frank Estrada

Watch video footage

Conclusion

Use low-density plywood and wood for quick, efficient, and accurate laser cutting.

If wood or plywood has a density less than 500 Kg/m^3 (0.5 g / Cm^3) then it can be quite easily cut with diode, Co2 and CNC mill

Wood and plywood with a medium-density like 500-700 Kg/m^3 (0.5-0.7 g / Cm^3) would require air assist, very good focusing and a laser-cut speed would be lower and amounts of repeats will be higher.

Wood and plywood with a high density like 700-1000 Kg/m^3 or 0.7-1 g / Cm^3 would be very hard to cut and probably will require a professional powerful milling system or Co2 laser power more than 100 watt for clean edges. Diode lasers might only cut very thin pieces like 1-2mm (1/10”)

Laser-cut gallery using different types of plywood

Endurance lasers are very universal and can do very accurate laser cutting.