For more than 5 years Endurance lasers have been making and delivering high-quality powerful laser attachments for makers’ community. Our key goal is to help makers expand the abilities of CNC machines and 3D printers by adding powerful and reliable laser heads to their machines.

During this period we have made and delivered more than 3500 units. Our Facebook community now counts more than 2150 members.

https://www.facebook.com/groups/endurancelasers/

I would say that it is one of the most supportive and friendly communities in the diode laser industry. Our members are always supportive and eager to help and share their experiences. It is important to note that we always listen to our community and try to work at improvements.

Last news and updates

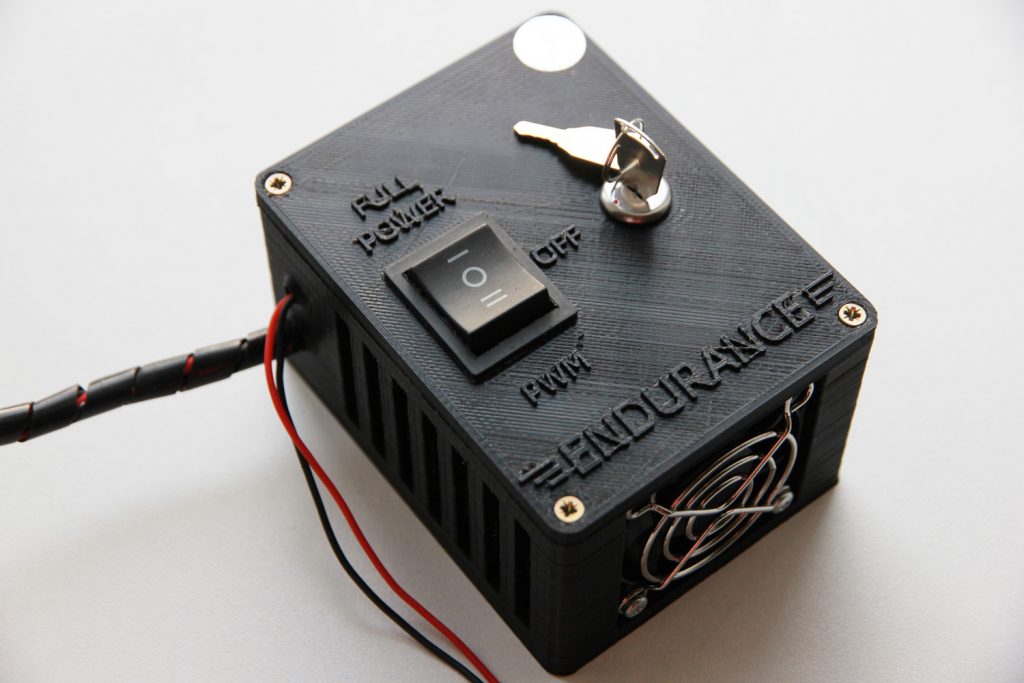

Laser box

So, let’s talk about some Endurance updates.

First of all we would like to mention that we have changed the design of our laser boxes a bit. Now they look better.

The key functionality of the laser box remains the same. It is designed to keep a laser driver and control board (PWM).

A bigger laser box additionally comprises indicators displaying the incoming voltage and voltage/current on the laser diode. It’s very convenient to see your laser diode power consumption in real time.

Besides, all lasers are equipped with a thermometer to monitor the laser temperature.

Be aware that our PLUS version is also equipped with a TEC cooling enabling to operate the laser even when the outside temperature is between 90-100F (35+ C).

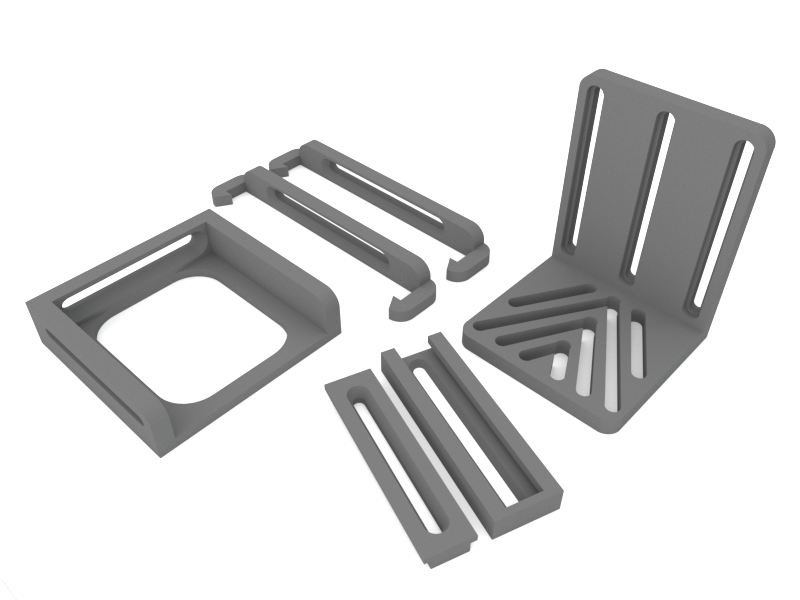

Mounts and brackets

Last week we finished the development of free 3D mounting brackets. We know that is it always a trick for newbies to hook up the laser to a 3D printer or a CNC router. After testing a dozen of 3D printers we came up with a number of new 3D printed mounting brackets.

Free 3D models of mounting brackets are available on our site https://endurancelasers.com/additional-laser-mounts-stls-3d-models-images/

Air nozzle

All professional lasers are equipped with an air nozzle and an air compressor necessary to do laser cutting.

To get the best laser-cut edges in wood and plywood you need to use an air assist with an air nozzle with your laser.

Here is a video showing laser cutting with a laser-equipped with an air nozzle and without it.

About a year ago “Datulab” (David) made his own version of a free 3D printed air nozzle:

We decided to improve it and offer a free air nozzle for all laser makers.

You can make it yourself out of metal or just print it out on your 3D printer.

https://endurancelasers.com/how-to-make-your-own-air-nozzle-for-the-laser-cutter-full-video-guide/

The good thing that this air nozzle can be used with any diode laser and at the end you can get a very clean and accurate laser cutting

https://endurancelasers.com/all-you-need-to-know-about-wood-and-plywood-laser-cutting/

Some people might think that diode lasers are not good enough for wood and plywood cutting. So, here is what…????

If you need to cut thick materials with close texture then diode lasers are not the best choice. Use preferably CNC mills or Co2 lasers. On the other hand, a diode laser is a great attachment for any 3D printer or a CNC router to cut softer wood and plywood with a density less than 0.5g / Cm^3.

Here is a post about Co2 lasers vs diode lasers:

https://endurancelasers.com/diode-lasers-vs-co2-laser-tubes/

Anyway, to cut through materials with close texture (that is more than 0.6-0.7 grams / 1 Cm^3) diode lasers might need many passes. That is why we’d recommend using softer special laser ply such as cedar, Moroccan plywood or balsa. The diode laser can quite easily cut through these materials up to 4-5 mm thick with 1-2 passes.

So keep that in mind when you work with wood or plywood.

Current R&D

15 watt

One of our most recent perspective development is to make a single beam laser with 14-15 watt power output. Here we will use a special polarizing prism or plate.

The key advantage of this solution will be a single beam multimode laser that will be capable to cut thicker materials.

Right now, we have completed a few tests and we see that it is working.

We are building an industrial prototype at the moment and as soon as it is ready we will offer our customers a special upgrade package.

75 watt DPSS

We get a lot of requests from makers and companies all over the world for lasers with an industrial speed to do fast metal engraving and thick metal cutting (up to 1-3 mm) including such materials as stainless steel, aluminum, brass and copper.

That gave us a nudge to build a powerful DPSS laser module.

We decided against fiber and went with crystal rods instead. We believe that an average power of 75 watt will be enough to cut rather thick metals.

Learn more about it https://endurancelasers.com/endurance-lasers-start-to-make-a-new-diode-pumped-yag-industrial-lasers-with-output-power-75w-200w-cw/

Conclusion

We are still fighting COVID-19 and that is why Endurance Lasers LLC (Fort Myers, Fl, USA) help doctors with free protective face shields.

We think it is important when the maker community stay together in such tough times.

And a cherry on top!

We offer a special FREE DHL shipment and an Extra 50$ off to ALL OUR readers and followers who will visit our online store.

Explore our models https://www.endurance-lasers.com/discount/Cyber-Monday-Special