Before you begin, safety precautions are paramount.

- You should not engrave mirror side up with a diode laser. The lens can be damaged.

- You should always wear goggles every time you operate your laser.

- Toxic fumes are released from certain chemicals on materials and proper ventilation is essential when working with your diode.

- Due to the amount of possible smoke buildup and possible material build-up, you should check and clean your lense after each engraving.

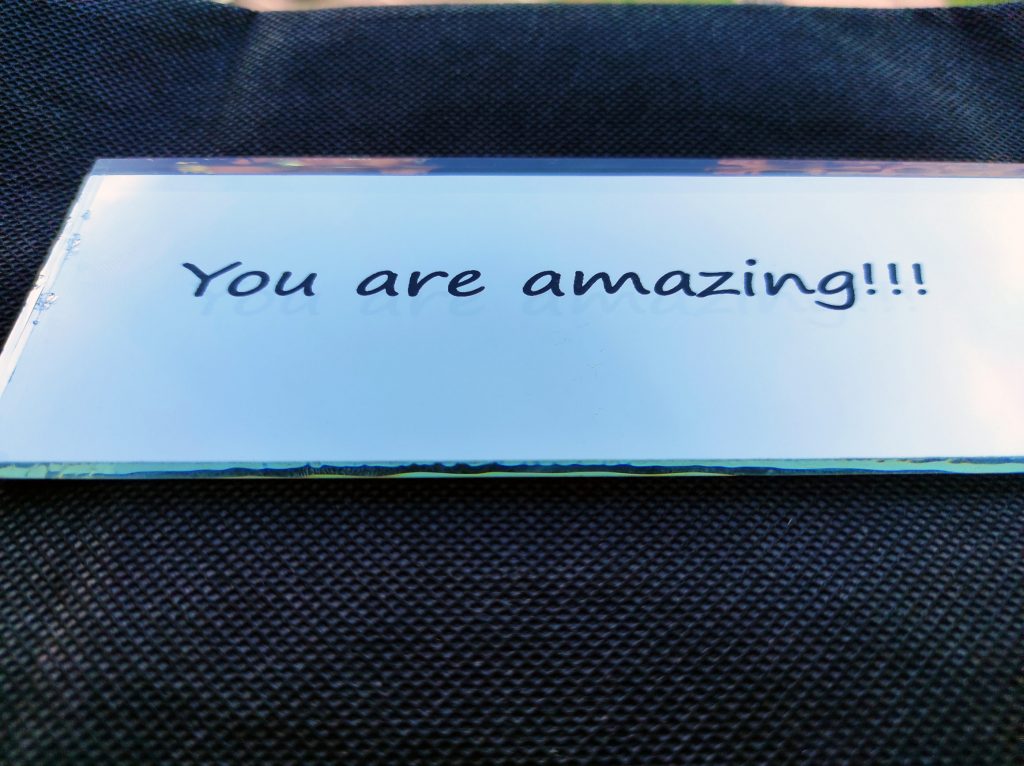

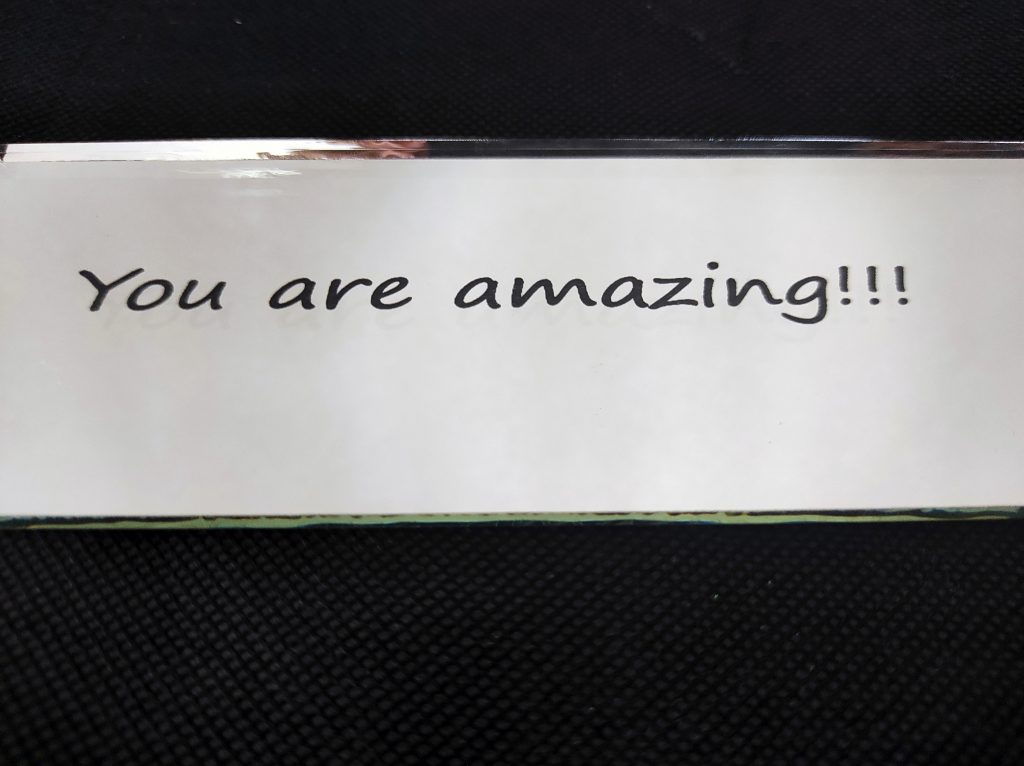

Laser engraving on mirrors is a great way to use your laser and make unique and decorative pieces. The laser works by vaporizing the material off the back of the mirror. The reflective coating is thin, and the laser will remove some of that coating leaving a visible etch in the mirror.

You can engrave names, quotes, patterns, images, and much more customized designs on the mirror with your laser. If you want to personalize your mirror, you can do that quite easily by using your Endurance laser.

You can customize your mirror using your laser to engrave or even cut, a design of your choice. The effect of a laser used in creating these types of designs makes them perfect for displays because it produces very smooth and beautiful designs.

The mirror itself is essential to know what type you are working with to get the best results.

There are also different types of mirrors available with various thinness and thickness and you will have to engrave through the material before getting to the actual mirror. You can find a variety of different material types on the back of mirrors. They can be painted, they can be made up of plastic, or even have a special coating. This will affect your Engraving

To begin, you should load the material with the back of the mirror facing upward. The front of the mirror should be down.

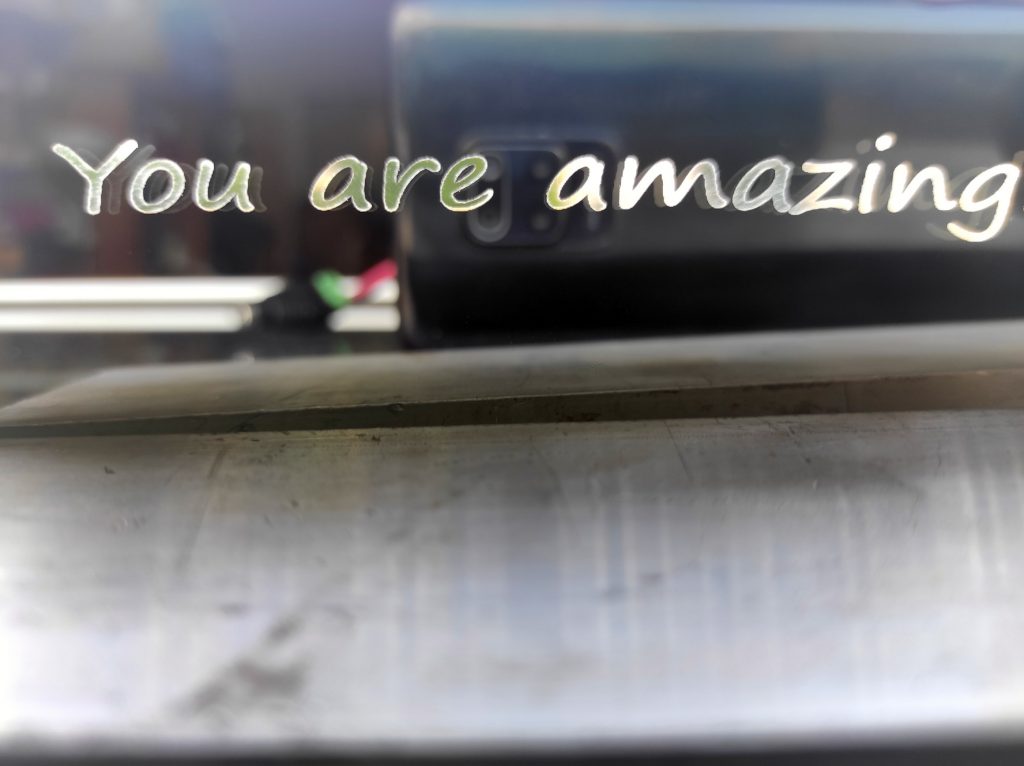

The main difference in mirror engraving compared to others is that mirrors will make a reversed engraving. You will need to flip the image on your designer software.

The speed, power, and lines per inch will all affect the quality of your mirror engraving. The more the DPI the more solid your engraving will appear on the final result.

Any stickers will also affect the engraving. The sticker glue should be properly cleaned off. This is because the sticker glue will also be engraved and leave an inconsistent shade on the final piece.

Once your engraving is finished, you may notice some sediments remaining, you can simply use a brush a clean it off.

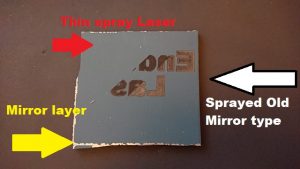

1. Old mirrors

This is an old mirror type. This is the easy sort of mirror to laser as the coating which is in RED is only a thin cheap cover over. YELLOW is the mirror layer. Sometimes old mirrors are mercury before 1840s after it goes to silver nitrate for cheap old mirrors.

These things are TOXIC SO DO NOT BREATHE IN.

This does not stop you from engraving them you just need to be aware of the facts. It is best to use as much ventilation as you can set up for this sort of mirror is best.

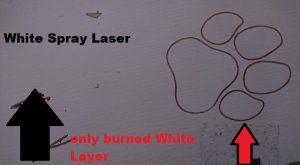

2. Cheap mirrors

This sort of mirror is found all over the world and a lot of the time it is thin glass.

Aluminum layered mirror with white paint sprayed on after. This sort of mirror

can be lasered easily when you have set proper power settings to burn the white paint off then into the aluminum layer. Still keep vented when doing this sort of mirror.

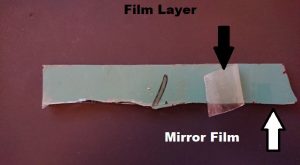

3. High-end Mirrors

This is a high-end sort of mirror with the mirror layer being a film mirror and a protective film over the back. Film mirror is the most high-end sort of mirror. It is the clearest mirror and also the hardest mirror to engrave on. You can remove the first film layer but this may remove the mirror film layer as well.

You can layer on to both but it is a lot harder to laser and will be burning polypropylene. When doing mirror with this you will need to be well vented as well. Test engrave first as this may take more than one pass.

4. Make your own mirror

This is a high-end sort of mirror with the mirror layer being a film mirror and a protective film over the back. Film mirror is the most high-end sort of mirror. It is the clearest mirror and also the hardest mirror to engrave on. You can remove the first film layer but this may remove the mirror film layer as well.

You can layer on to both but it is a lot harder to laser and will be burning polypropylene. When doing mirror with this you will need to be well vented as well. Test engrave first as this may take more than one pass.

Mirror engraving using 30 watt Raycus fiber laser emitter installed on a DIY Endurance galvo machine.

CONCLUSION

Rethink how mirrors are put around your living space. Some great designs can be made. The mirrors can add a nice touch to the traditional mirror and will look great when put on a wall. They will be able to hold memorable words, neat designs, or images that can appear anywhere within the mirror. A laser engraved mirror can be made to your taste and be decorative for businesses like offices, restaurants and diners, lounges, and make great gifts.