Laser cutters are universal tools to cut various materials. There are different types of lasers to do the task, but not all of them are powerful enough to work with metal.

In this article, we’ll deal with CO2 and fiber laser cutters. These two types of laser cutters require special attention to be used properly.

To cut metal, you will need, at least, a 150 W machine with oxygen assist. It is also important to keep in mind that most CO2 lasers, can’t handle the laser being reflected back into the laser emitter. That’s why CO2 lasers in the 150-300 W range are good to work on steels that aren’t too reflective.

Warning:

Observe proper safety measures when working with lasers and any flammable gas. Don’t forget to use and store oxygen safely.

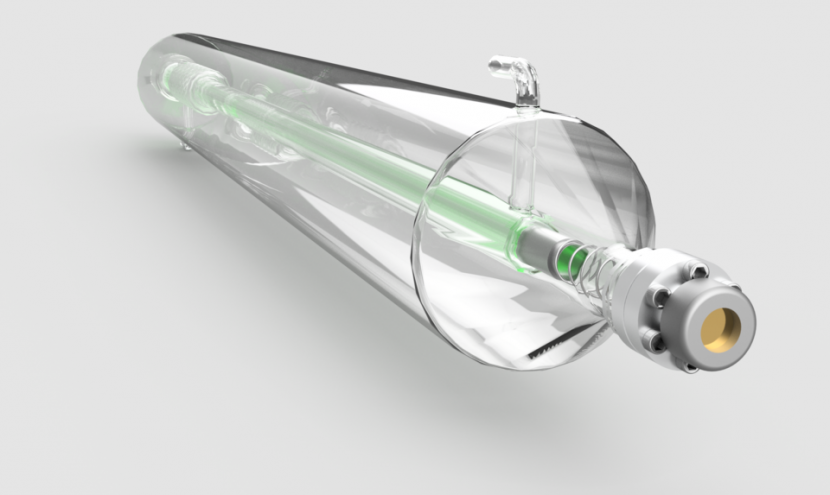

Diode lasers vs. Co2 laser tubes. Advantages and disadvantages

FIBER LASERS

Fiber lasers work on a different principle and are several times more powerful than CO2 lasers, with nearly none of the drawbacks. Exposure to the laser beam, even indirect, can cause great harm such as burns and blindness. Wear the proper safety glasses for the laser’s frequency and use the appropriate laser enclosures and a well-ventilated area. To avoid leaving oils or other residues we recommend wearing gloves when adjusting components in the device.

Always be sure to have an ABC-rated fire extinguisher at hand to handle any extreme situation.

LASER CUTTING METAL

Fiber lasers are very powerful but more expensive. They can cut without a support gas and require less maintenance.

CO2 lasers are generally cheaper, but they need oxygen as gas assist and cut only less-reflective metals.

Because of the high prices (over $10,000), these machines are limited to professional and industrial use.

One of the options for makers and hobbyists is building a laser cutter of one’s own.

Properties of Metal

Before you start cutting metal you need to know important metal properties.

Metal unlike wood, acrylic, or cardboard, is reflective and heat conductive. So more intensive light is needed to cut through it.

Different metals have different properties, depending on which you need to choose the right laser cutter.

Here is a list of various metals that can be cut with lasers.

- Steel: Low reflective rating, easily cut with fiber lasers and high-powered CO2 lasers.

- Stainless steel: High reflective rating, easily cut with support gas.

- Aluminum: Medium–high reflective rating, can be cut with fiber lasers, more resistant to CO2 lasers.

- Copper: Medium–high reflective rating, highly conductive, easily cut with fiber lasers if under 0.5 mm thick (anything higher requires multiple passes; using oxygen as a cutting gas).

- Brass: Medium–high reflective rating, harder than copper, ideal for nitrogen.

Gas assist (nitrogen or oxygen) makes the cutting process easier by clearing out debris or heating up the cutting area.

An Endurance Brand New DPSS Laser Module For Metal Marking & Metal Cutting!

Preparations

To get the best possible results, you need to choose the proper laser cutter for the material you are going to work with and to follow some simple tips.

- Conduct tests.a) Do a test run with your software without the laser running to expose any possible mistakes that may occur and to secure oneself against time and material loss. b) Do a test run on scrap material with the laser running to focus the beam and set the power and speed parameters. c) Cut test templates every time when you experiment with new materials

- Elevate the material. Use an elevated platform (on spikes or a honeycombed work surface) to save heat from dissipating and the machine from molten material.

- Make good cuts. When cutting, make sure that all the parts are completely cut out from the stock material to make post-processing easier and the final result better.

- Separate gas from the laser. When using oxygen gas-assist with CO2 lasers or oxygen or nitrogen with fiber lasers, keep the gas tank in a separate, flame-proof container as far from the machine as possible for safety.

Cutting

Cutting metal doesn’t really differ from cutting wood or acrylic. The laser cutter emits a beam that melts or vaporizes the material, using a gas-assist that either helps heat the material and blow away debris or just expels debris.

Finding the correct focus point, power, and speed, the correct pulse, and amount of power to use for different materials through testing is the path to get successful results in metal laser cutting. It is also important to bear in mind to use a CO2 laser for cutting only low-reflective metals such as steel. While fiber lasers are good for cutting through most metals.

Once you have the proper machine and parameters and take the necessary precautions, the process will go smoothly.

Post-Processing

When the work is done, always check through your machine to make sure that all the components are clean and in good working order. Maintaining a well-tuned machine is the key to your successful work.

Cut out metal pieces may need a cleaner finish. To improve the cut sharp edges it is helpful to use a deburring tool or sanding down. There are also other means of finishing the ready product and adding some extra character to it such as painting, polishing, acid etching, hydro dipping, and more.

Learn more about different laser wavelength >>>

Comparison of a different types of lasers and different wavelength

Absorption wavelength spectrum for different materials: glass, metal and others.