The key idea of this post is to give a quick overview of different Co2 tubes.

Many people think that Co2 lasers are the best for laser cutting and laser engraving and have no problems. In fact, there are some issues that you need to pay attention to.

Co2 Laser Tubes Lifetime

The laser tube is one of the main units of any Со2 laser machine. The radiance wavelength of a Со2 tube is 10600 nm (10.6 μm). Laser generation, which makes it possible to cut or engrave the material you choose, takes place inside the laser tube. Usually, tubes have the life-time declared by their manufacturers. It’s something around 1 000 – 10 000 hours. It is less than a diode or a solid-state laser.

The main problem lies in the fact that in many cases the declared lifetime is much less in reality, or the power drops critically after the machine has been in use during 50-70% of the declared lifetime period.

It is important to bear in mind that the durability of the laser tube depends on its correct operation.

The operation temperature (18-22ºC) is of paramount importance. At 30ºC or higher, the tube durability decreases by 40-50%. At 40ºC the tube might go wrong quickly enough. That is why it is advisable to use a freon chiller with forced cooling. The price for this type of chiller is, approximately, $500-1000.

While working with the machine

it is important to keep the lens clean at the exit of the laser beam from the tube. There should be no dust or soot. Don’t operate the laser tube at its maximum power for a prolonged period of time because it decreases its lifetime. If you need 100W use a 150W tube. If you need 60W use a 80W tube.

An Endurance 80 watt Custom Co2 Laser Machine with 6×5′ (2×1.7 m) working size area

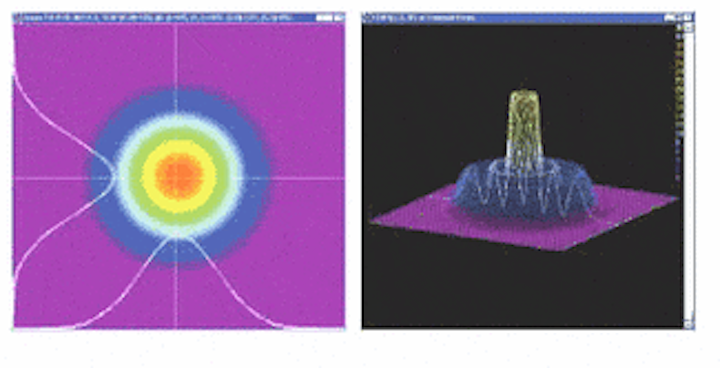

Radiation (laser beam) quality

The laser resonator mode is a standing electromagnetic wave. The resonator is the laser basis. Its size depends on the radiation wavelength. Particularly, the resonator length should be divisible by ½ of the wavelength.

Radiation of the main mode is a process when a beam before going out of the resonator and becoming output radiation, runs exactly along the resonator axis (or parallel to it) and when reflected from a transparent and semitransparent mirrors gains power (amplifies) to pass a semitransparent mirror and exit the tube.

All glass CO2 laser tubes are multi-mode. The quality of the laser beam depends on the internal setting of the tube optical tract, made at a manufacturing facility. The best result of the declared setting is the spot of a ТЕМ00 form. But it’s a rare occasion for cheap tubes. At the same time, this form of the beam enables to generate a well-focused laser beam with a declared power and density, and small sizes of the spot, which will ensure high-quality cutting and engraving of materials.

Laser tubes produced by SPT have a power below 80W and their lifetime is no more than 3000 hours (that is not a lot at all).

Peculiarities of metal tubes

Their main drawback is their high price. At the same time lasers with RF-tubes are considered to be everlasting. They serve 4-5 times as long as dc lasers. Their durability justifies the high price of the RF laser. They are air-cooled. That is there is no need to change the water in the cooling system. It means that machines with metal tubes practically have no need in service.

AC-pumped RF- metal laser tubes generate faster laser pulses resulting in a higher-speed operation. But these tubes are not very common.

Let’s go back to the types of laser tubes.

Below you will find a list of laser tube types with an active gas medium produced by various manufacturers in ascending order of their price and quality.

- Chinese «non-branded» glass laser tubes of a very low quality. Their lifetime is 1000-1500 hours (just a few weeks).

- Chinese glass tubes made by «Chengdu» differ from the previous ones in the better fixing of lenses and stability of work. They have a brass cooling jacket (providing a better heat dissipation) and a life-time of 1500-3000 hours.

- Chinese RECI tubes have no cooling of the optics. Their housing is shorter but has a bigger diameter (keep in mind its size when installing in a certain machine). They are very sensitive to the temperature of the coolant (in the cooling system of a laser machine it is recommended to use a freon chiller). High-voltage contacts of the RECI tubes are attached to special terminals (and not soldered as in tubes by other manufacturers) and have reliable insulation, which makes the installation much easier.

As the rated operational power for RECI tubes, an average stable maximum is stated, not the peak value. Thus, in comparison with its analogs, RECI tubes turn out to be a little more powerful. Their life-time is up to 10 000 hours (if meeting the requirements of operation conditions recommended by the manufacturer). The average life-time, as a rule, does not exceed 5000-7000 hours.

- A number of Chinese manufacturers make tubes similar to RECI but with greater power (due to the multi-circle gas discharge channel).

- Chinese «RF-tubes» are similar to those made by «SYNRAD» but are cheaper. They are comparable in quality, but their lifetime is second to the analogs of «SYNRAD».

- All Chinese laser tubes but the last one are intended to work with their high-voltage power supply.

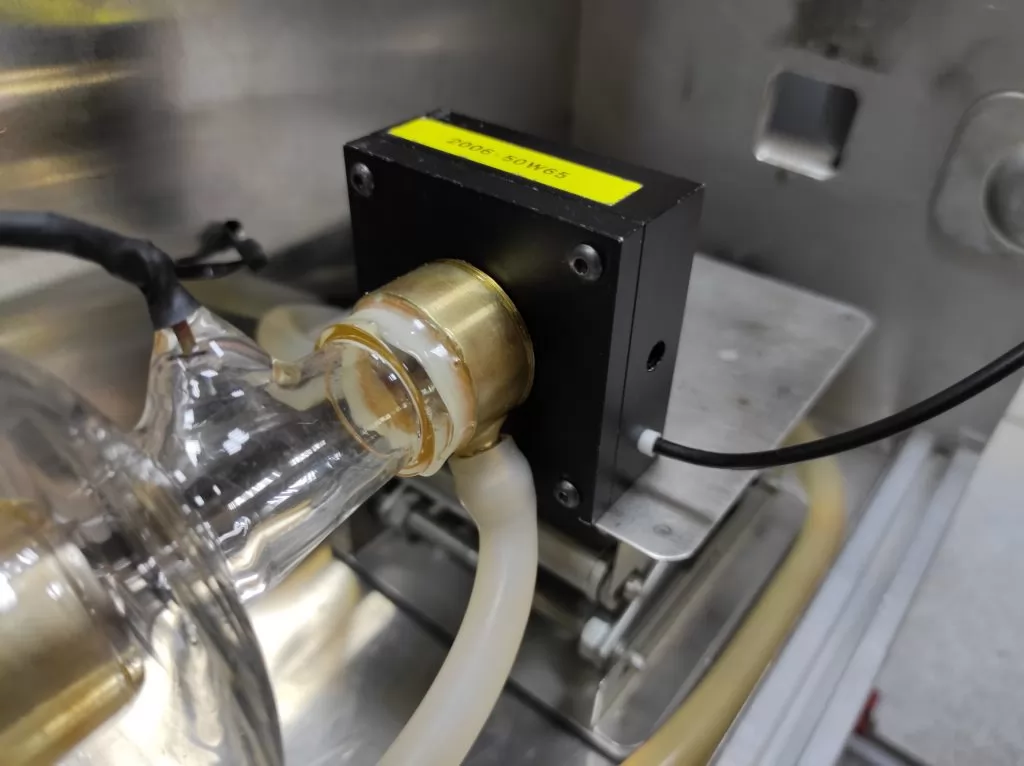

Cooling of Со2 laser tubes

Why cool a laser machine?

Popular laser machines use rather expensive laser tubes, the life-time of which it is important to extend as much as possible. As in any source of energy the efficiency of a laser tube cannot be 100%, because part of its energy transforms into heat in the gas chamber itself and then is wasted in the pumping system and on the lens that is not absolutely transparent.

That is why the tube construction includes a must-have coolant supply, the role of which is to maintain an optimal temperature condition in the system. The outer flask or jacket has two branch pipes to connect hoses for water supply and disposal in the jacket. In this case, the laser tube operates in an optimal condition when its temperature is in the range of 10-25ºC.

25ºС is a permissible temperature, but with it the radiance power decreases, and the resource of this expensive component is spent much faster. That is why laser tubes in laser machines must be equipped with coolant systems.

The declared lifetime of laser tubes in laser engravers

- The life-time of laser tubes for laser engravers declared by manufacturers holds true for practically ideal conditions: the current under 25mA or no more than 40-50% from the maximum power, water cooling 10 l/min, water temperature 10°С.

- These conditions are suitable for engraving, that is why laser tubes in engravers serve for several years. But to do cutting many users raise the power up to 90-100% to increase the cutting speed and cut through the material with one pass. This dramatically shortens the life-time of a laser tube in a laser engraver.

It is vital to provide good cooling, suitable for the power of the laser tube for laser engravers. Freon chiller CW5200 is a good choice to stay independent of the environmental temperature and to control the machine temperature and the water flow.

The operating temperature of the chiller is set at 18° C. It should be understood that this temperature is measured inside the chiller water tank, and is valid in the case of a fully operational pump. If the pump fails, the chiller will beep to inform you to replace it. You must not use the tube if the chiller pump is defective.

But if you use a simple water pump instead of a chiller, and due to the wearing process it will not provide the declared capacity of liters per minute, of which you will not be able to know, the temperature in the laser tube will become much higher than the temperature in the water container. Running the machine in this condition will quickly destroy the tube.

Never fill in pure antifreeze or tosol cooling agent. These coolants have a higher viscosity than water. Because of it the pump will wear out quickly, and the water flow sensor will not work properly. In this case, the machine will start running even if the pump is out of order or the coolant does not circulate. This will destroy the tube at the very first step of the operation.

Secondly, tosol is an aggressive liquid that eventually corrodes even the partitions of the valve cover in a car. Thus, it will quickly disable the chiller. Pour only distilled water into the chiller. To keep the water from blooming it is possible to add red or green antifreeze 100-150 gr/10 liters of water.

A Co2 tube list with key parameters: power, size.

Laser tube PURI PRR-700, 40W

Power: 40W

Tube length: 700mm

Diameter: 50 ± 2mm

Laser tube LA SEA CL-1000, 50W

Power: 50W

Tube length: 1000 ± 2mm

Diameter: 50 ± 2mm

Laser tube PURI PRR-1000, 50W

Power: 50W

Tube length: 1000mm

Diameter: 50 ± 2mm

Laser tube LA SEA F0, 50W

Rated power: 50W

Maximum power: 60W

Tube length: 1000mm

Laser tube LA SEA CL-1200, 60W

Power: 60W

Tube length: 1200 ± 2mm

Diameter: 50 ± 2mm

Laser tube PURI PRR-1200, 60W

Power: 60W

Tube length: 1200mm

Diameter: 55 ± 2mm

Laser tube LA SEA CL-1600, 80W

Power: 80W

Tube length: 1600mm

Diameter: 60 ± 2mm

Laser tube LA SEA F2, 80W

Power: 80W

Tube length: 1200mm

Diameter: 80 ± 2mm

Laser tube PURI PRR-1200, 80W

Power: 80W

Tube length: 1200mm

Diameter: 80 ± 2mm

Laser tube LA SEA СО2 ZS-1250, 90W

Power: 90W

Tube length: 1250 mm

Diameter: 80mm

Laser tube LA SEA F4, 100W

Power: 100W

Tube length: 1400mm

Diameter: 88 ± 2mm

Laser tube PURI PRR-1400, 100W

Power: 100W

Tube length: 1400mm

Diameter: 80 ± 2mm

Laser tube LA SEA СО2 ZS-1450, 110W

Power: 110W

Tube length: 1450 mm

Diameter: 80mm

Laser tube PURI PRR-1600, 120W

Power: 120W

Tube length: 1600mm

Diameter: 80 ± 2mm

Laser tube LA SEA F6, 130W

Power: 130W

Tube length: 1600mm

Diameter: 80 ± 2mm

Laser tube LA SEA СО2 ZS-1650, 140W

Power: 140W

Tube length: 1650 mm

Diameter: 80mm

Laser tube LA SEA F8, 150W

Power: 150W

Tube length: 1800mm

Diameter: 80 ± 2mm

Laser tube PURI PRR-1800, 150W

Power: 150W

Tube length: 1800mm

Diameter: 80 ± 2mm

Laser tube LA SEA СО2 ZS-1850, 160W

Power: 160W

Tube length: 1850 mm

Diameter: 80mm

Laser tube LA SEA F10, 180W

Power: 180W

Tube length: 2000mm

Diameter: 80 ± 2mm

Laser tube PURI PRR-2000, 180W

Power: 180W

Tube length: 2000mm

Diameter: 80 ± 2mm

Laser tube / composite CO2 laser emitter / TS220 200W

Rated power: 220W

Emitter body dimensions: 1600 * 245 * 148 mm

Laser tube / composite CO2 laser emitter / TS300 300W

Rated power: 300W

Emitter body dimensions: 1810 * 245 * 148 mm

Laser tube / composite CO2 laser emitter / TS500 500W

Rated power: 500W

Emitter body dimensions: 1870 * 355 * 148 mm

Laser tube / composite CO2 laser emitter / TS620 620W

Rated power: 620W

Emitter body dimensions: 1870 * 400 * 215 mm

An Endurance water cooling system (water + TEC Peltier chiller) — a chiller for your laser

Heat generation for 80 watt Co2 tube (Endurance laser lab experiment)

Current conditions

Room temperature 30 degrees

Water temperature in the chiller was 19.5 degrees

Pump speed 2 liters per min

The volume of water in the tube itself is ~200 ml

Installed 3 tremor sensors before and after the tube

How to measure Co2 tube heat distribution. True Co2 laser tube efficacy.

Protocol results

| Time, min | The temperature before the Co2 tube | The temperature after the Co2 tube | Delta | ||||||

| T1 | T2 | T3 | average | T4 | T5 | T6 | average | ||

| 0 | 19,4 | 19,4 | 19,7 | 19,5 | 19,6 | 19,6 | 19,7 | 19,6 | 0,1 |

| 1 | 19,7 | 19,8 | 20,1 | 19,9 | 22,5 | 22,4 | 22,5 | 22,5 | 2,6 |

| 2 | 19,9 | 20 | 20,1 | 20,0 | 22,5 | 22,5 | 22,6 | 22,5 | 2,5 |

| 3 | 20,1 | 20 | 20,4 | 20,2 | 22,5 | 22,6 | 22,7 | 22,6 | 2,4 |

| 4 | 20,2 | 20,2 | 20,5 | 20,3 | 22,7 | 22,8 | 22,9 | 22,8 | 2,5 |

| 5 | 20,4 | 20,4 | 20,6 | 20,5 | 22,8 | 22,9 | 23 | 22,9 | 2,4 |

On average, it turns out that when the tube is operating at 100% power, the water in it heats up by 2.5 degrees

From these data, we can conclude that the heat dissipation in the tube is somewhere around 330-350 watts.

Co2 laser tube efficacy: 80 watt Co2 tube / 330-350 heat dissipation = ~20-23%