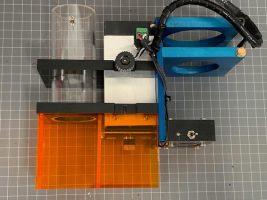

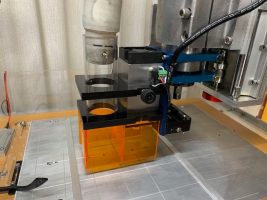

dimage by Sam Gironda

Endurance lasers work with all types of CNC machines: JFT 3040 3-Axis CNC Router, MillRight CNC Power Router, BobsCNC E3 CNC Router Engraver Kit, Genmitsu CNC 3018-Pro Router Kit, MY SWEETY 1610 CNC Machine, Carbide 3D Shapeoko 4, Ooznest Workbee, Onefinity Woodworker, Inventables X-Carve, The MPCNC – V1, Shark (NextWave), Stepcraft 420 – 840

All you need to know about hooking/wiring the laser head on your CNC machine!

Explore detailed wiring diagrams wiring to 3D printers and CNC routers:

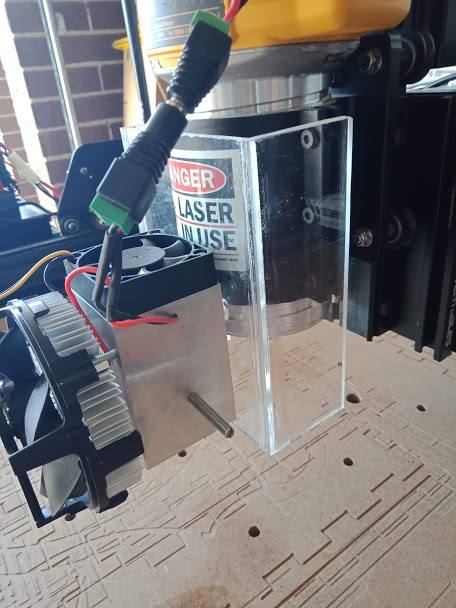

Our customers share an experience (by Graham Ham) – installing 8 watt diode laser on CNC

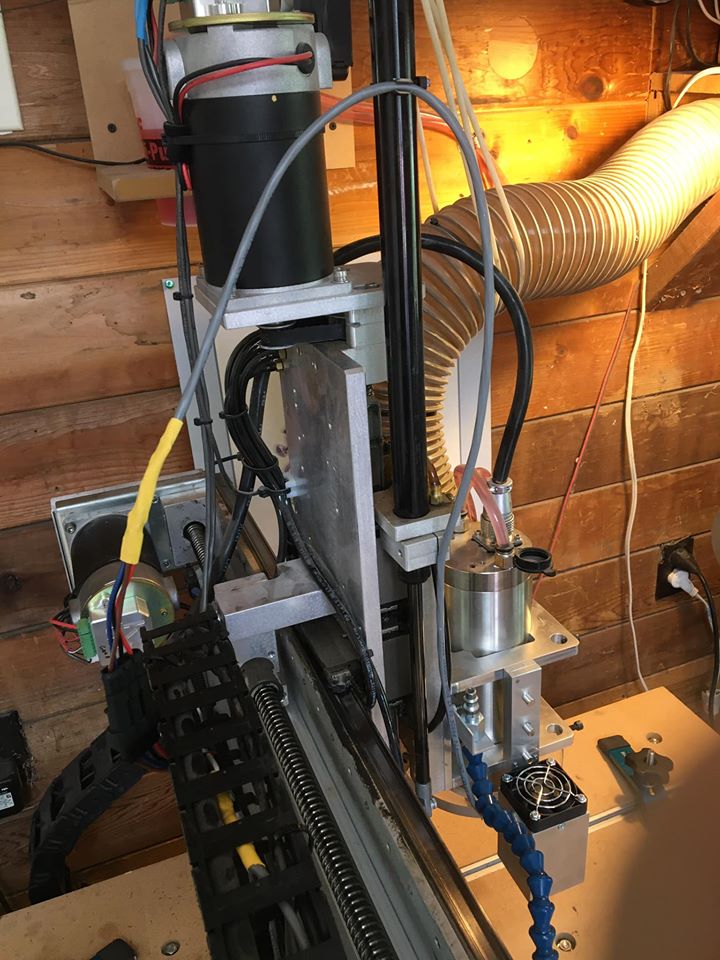

Fitting a Laser to my Home Built CNC Router (by Graham Ham)

Adapting Endurance LASER to MT CNC Router V2 (a story by Graham Ham)

Laser addition to CNC RouterParts 48”x96” – a detailed video

Endurance lasers hook up to MACH3

StepCraft Laser setup for Mach or UCCNC (PDF guide)

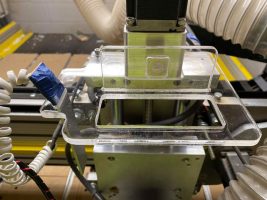

Tube 44.6mm OD x 38 ID. It is turned down to 43mm OD x 39 ID, (2mm wall thickness) and 25mm long.

Glued it to the laser body with PA10 primer.

PA10 is an etch primer paint made by International Paints. (This primer sticks very well to aluminum.)

WorkBee-Full-Kit-Assembly-Manual-xProV3.pdf

PROBOTIX setup: PBX-RF-Board-Pin-Outs-Jumpers

Smooth Stepper setup: use PWM pin for spindle SmoothStepperUserManualV1.0

PROBOTIX setup: PBX-RF-Board-Pin-Outs-Jumpers

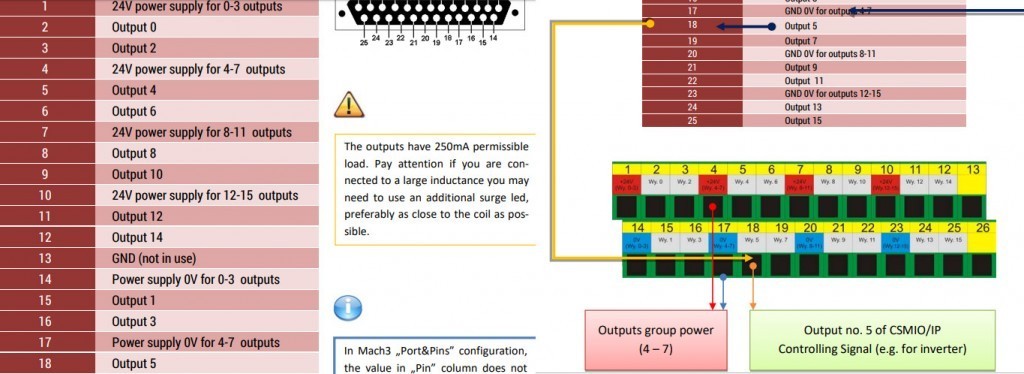

CSMIO/IP-S setup : manual_csmioip-s_en_v2

Connecting Endurance Laser to The Buildbotics CNC Controller

Endurance lasers with MillRight CNC machines

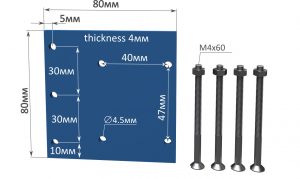

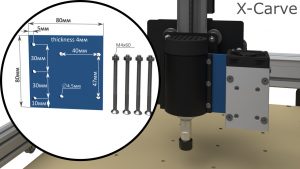

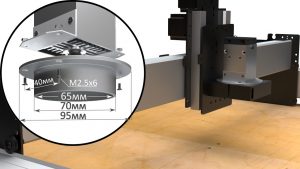

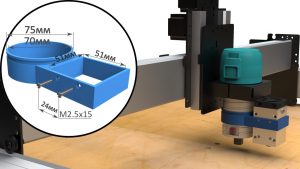

G-code for 3D printed mount

STL file for 3D printed mount

For more files, please visit our download center.

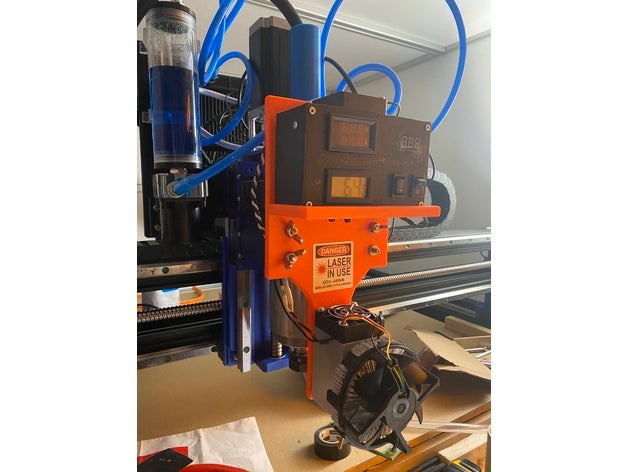

X-Carve CNC laser mount example

Explore X-Carve Facebook group >>>

Installing the Endurance laser head on X-carve

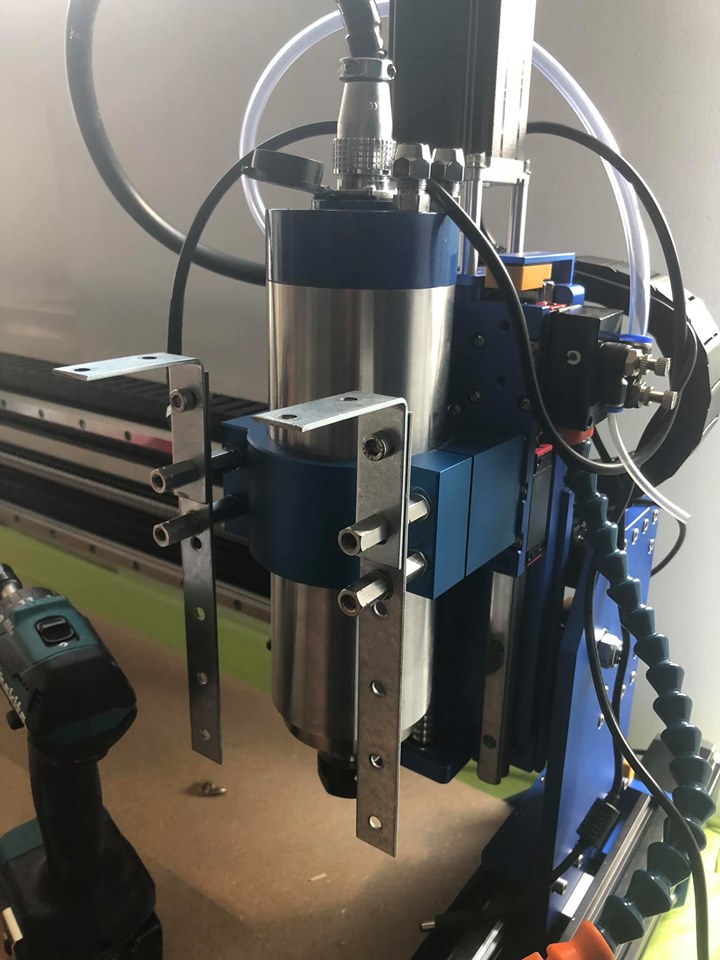

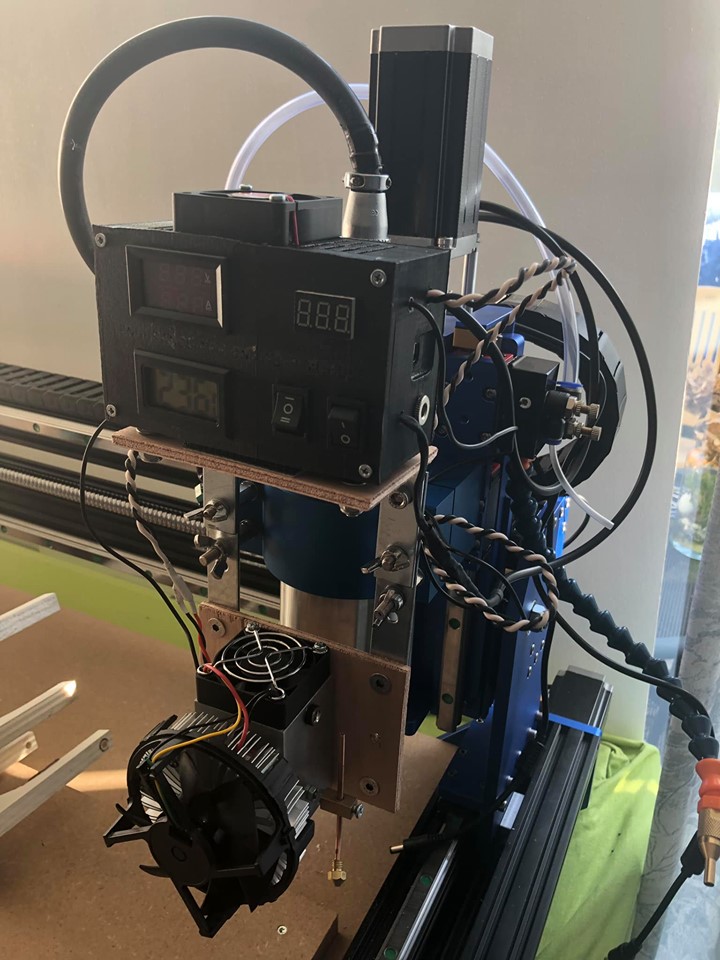

Endurance laser on a Bever HDZero CNC

Shapeoko CNC machine – Endurance laser mount example

Thank you, John Walker, for making this video!

Setting up an Endurance 10 watt laser on Shapeoko CNC

The best getting started video for Shapeoko XXL 3 CNC machine!

Endurance Laser Shapeoko Quick-Start Guide (FULL PDF GUIDE)

>

Shapeoko XXL 3 laser brackets (zip)

Download a sketch from Thingiverse (laser mount).

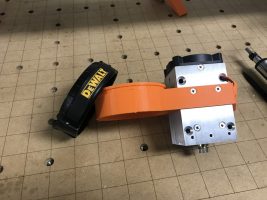

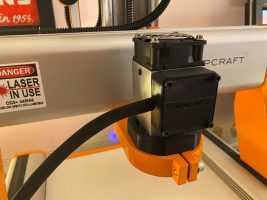

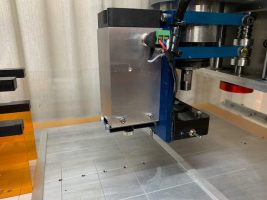

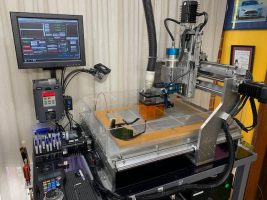

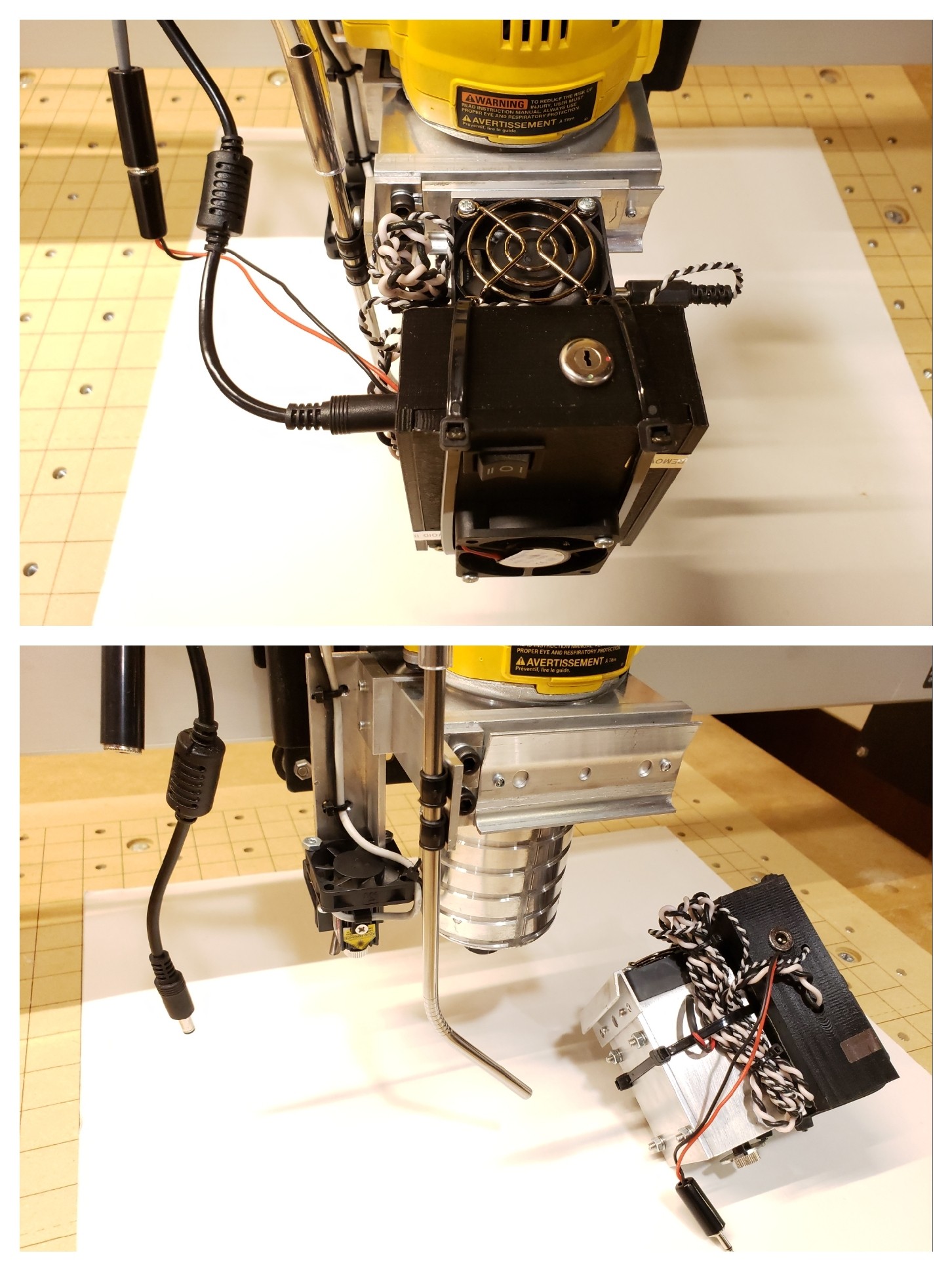

images were made by Sam Gironda

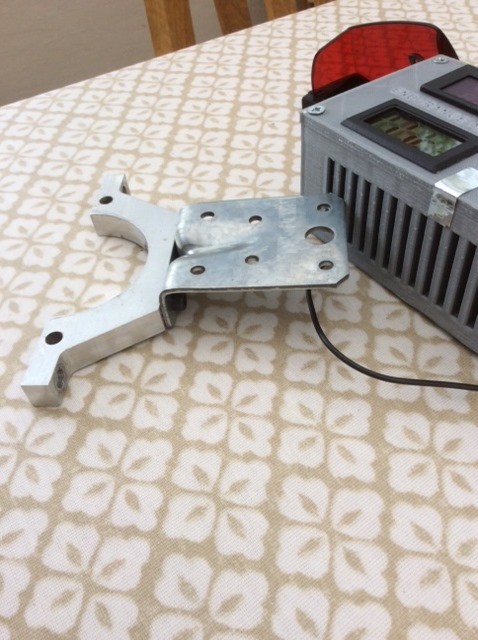

Stepcraft 420 mounts of an Endurance laser (our customer’s modification)

Stepcraft 420 installation files (STLs)

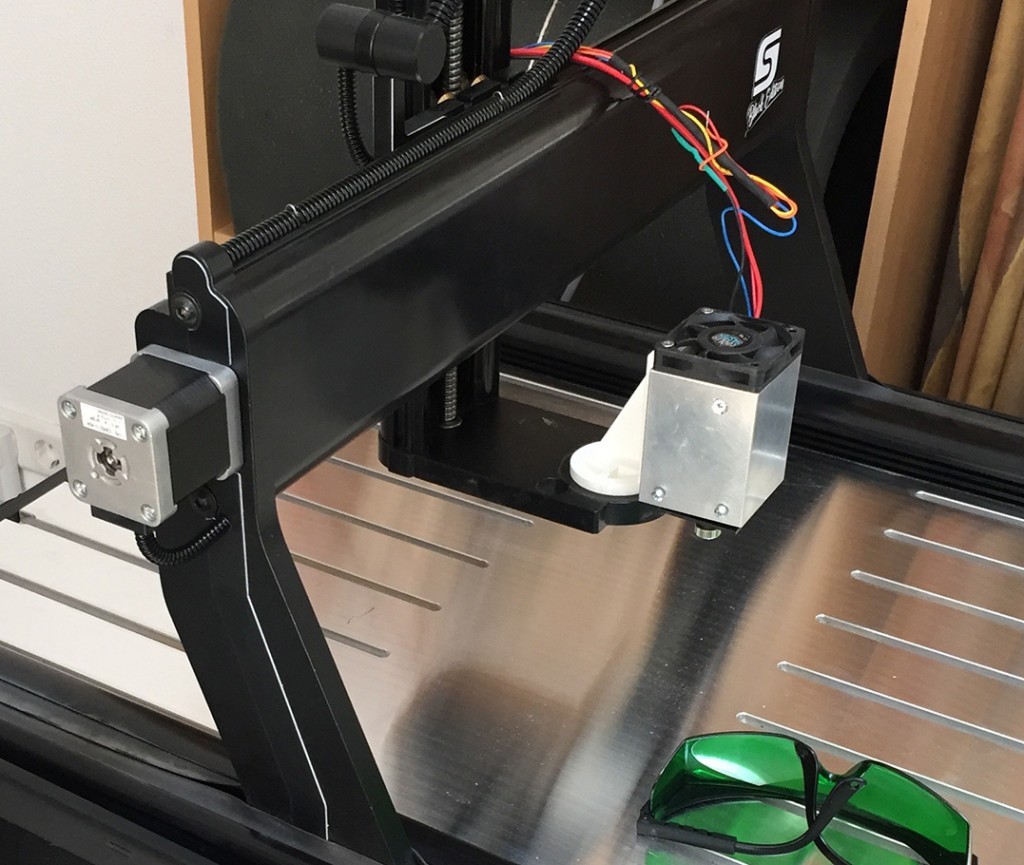

Laser mount on StepCraft 600 Black Edition

Laserhouder02_v10 |

Laserhouder02_v10 |  Alex CNC_50x76mmBase

Alex CNC_50x76mmBase

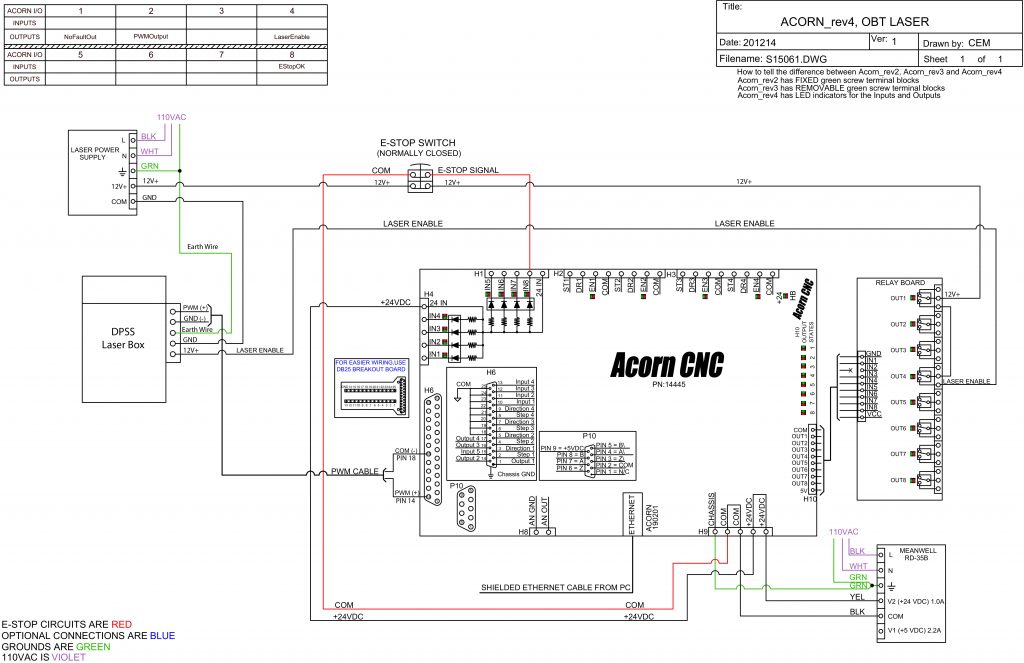

Endurance Laser Hookup and Configuration Buildbotics

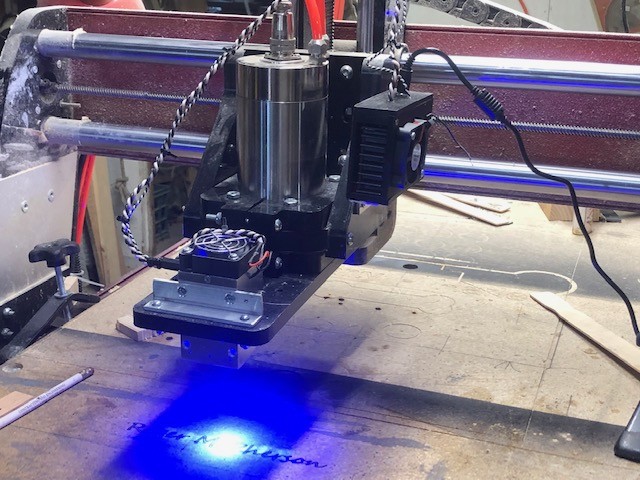

Running 10 watt PLUS laser on an ACRO (by Frank Kaylor)

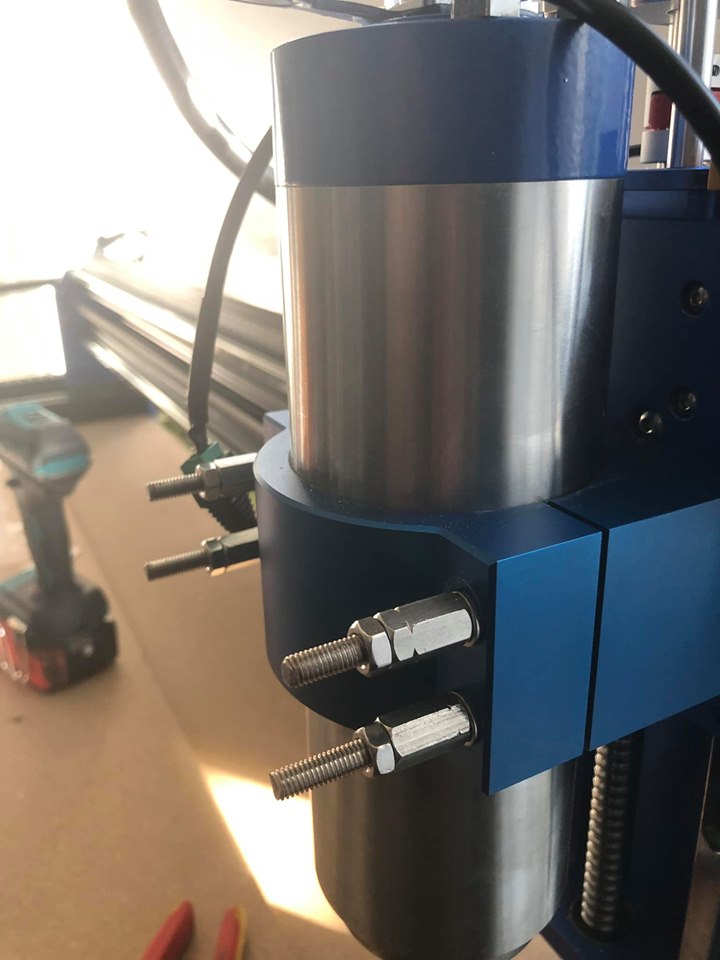

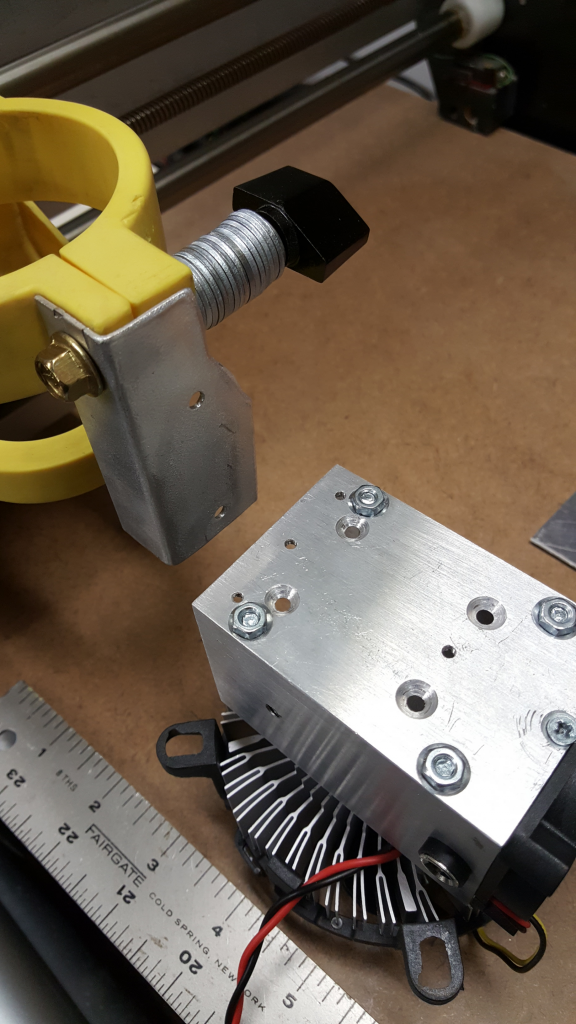

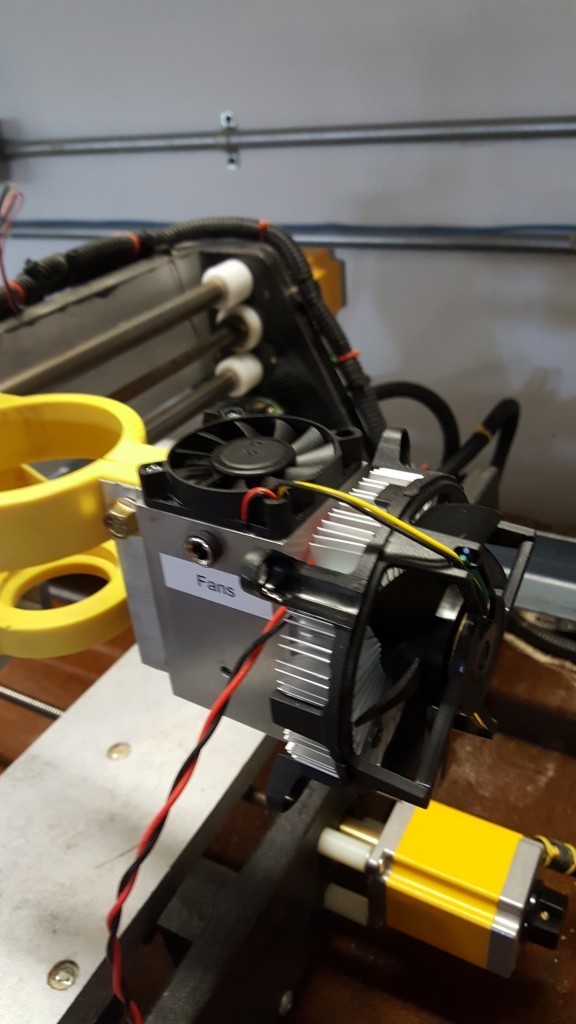

Bever DHZ Endurance laser holder for 80 mm spindle

How to hook an Endurance laser to CNC machine (3018 CNC)

K2CNC router installation

More mounts about laser mounts (free STLs)

All STLs in one place repository >>> https://www.thingiverse.com/endurance_lasers/designs

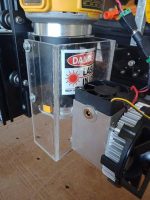

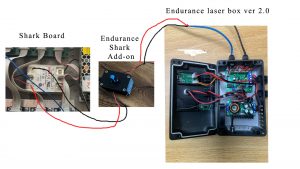

How to install the laser to the CNC Shark router

Wiring to CNC Shark by Next Wave Automation

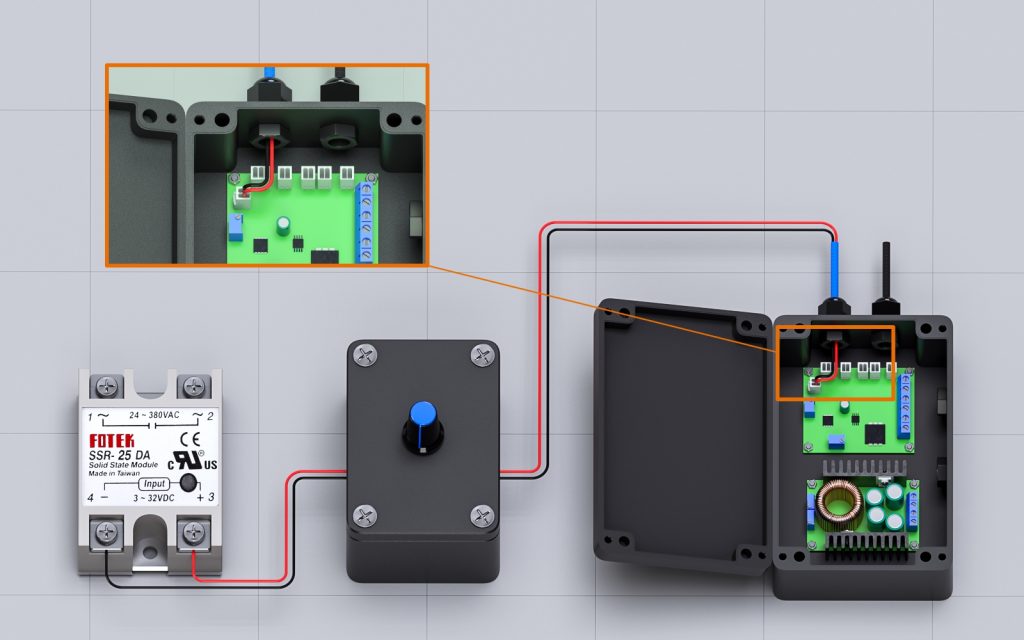

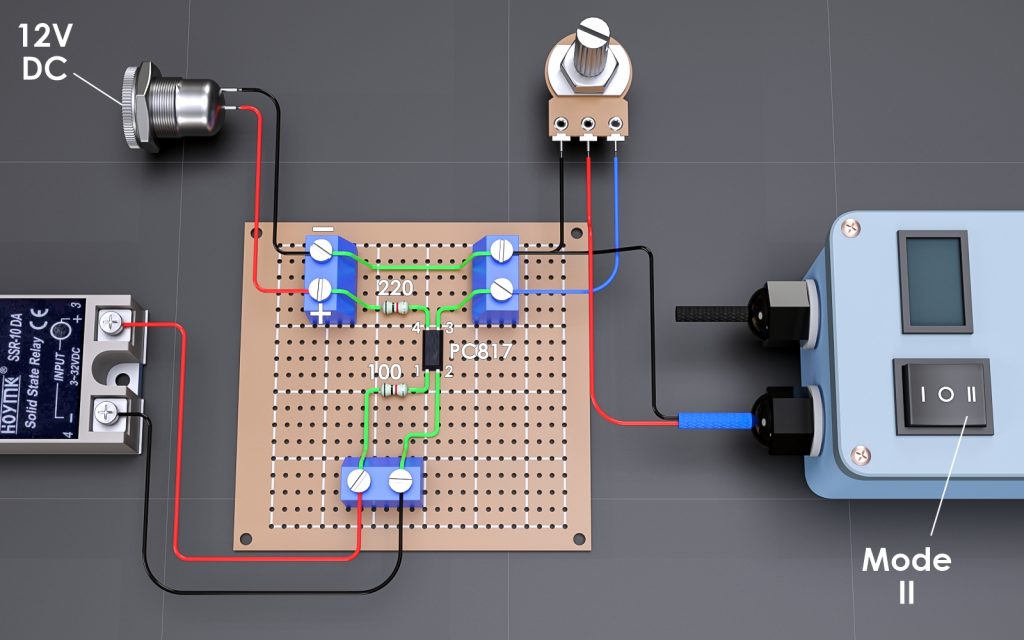

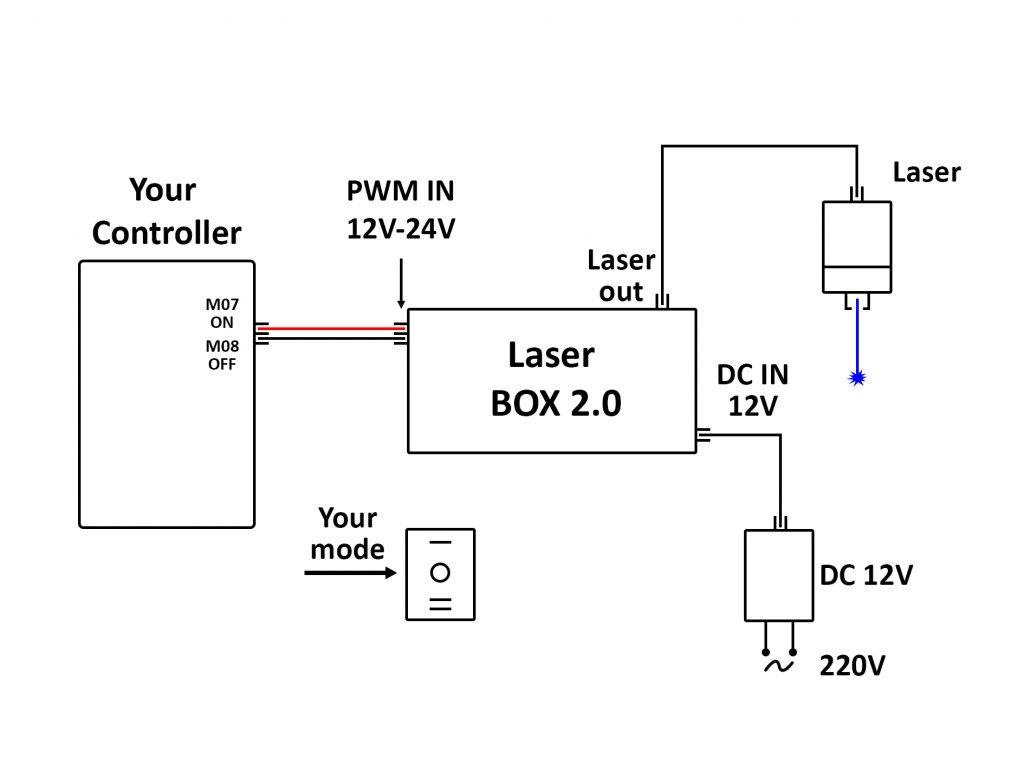

The laser is connected to CNC Shark via Dynamic Pwm Box. There is a spindle control connector on the control board, from which two wires go to the relay (circled on img1). Connect the Dynamic Pwm Box to these wires: red wire to the “in2+” terminal, black wire to the “in2-” terminal. The most convenient way to do this is to connect the wires coming from the Dynamic Pwm Box to the relay terminals to which the spindle control wires are connected. The laser is connected to the Dynamic Pwm Box to the “pwm” terminals via blue braided wires: the red wire is connected to “pwm+”, the black wire is connected to “pwm-“. As a result, you should get a connection diagram, as in img2.For laser operation, the three-position button on the LaserBox is set to “0”. On the Dynamic Pwm Box, the button is set to “II” mode. The laser is turned on and off by spindle on/off commands (M3/M5). The laser power is set by the handle on the Dynamic Pwm Box.

There are several versions of the CNC shark that have been developed over the years. You need to look at your controller and see if it has an output for the spindle to turn it on and off. Many of the newer models like the MAKO have this feature. If you do, then you are in luck! The spindle control uses a relay to switch the power on and off to the spindle. This relay is controlled by a DC voltage signal. This is the signal we need to turn on and off the laser.

Mount for bachinmaker d8-4050p engraver

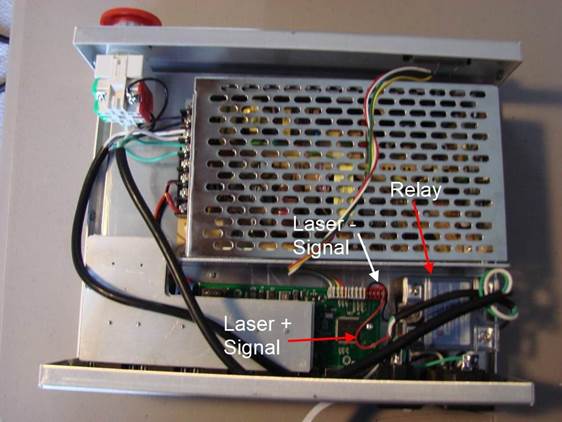

If you open up your controller box, it should look something like this:

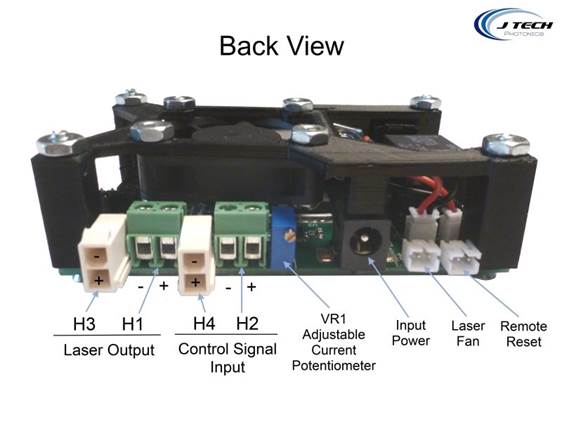

You are going to use the signal from the control board to the spindle relay and connect it over to the laser driver board input. Here is a more detailed picture:

Attach a wire from the relay “+” signal to the laser driver “+” terminal H2. Attach another wire on the relay “-” signal to the laser driver “-” terminal H2. Or, you can use the 3′ Molex Mini-fit cable and connect it into terminal H4 on the laser driver:

That is it, you are done!

Controlling the laser

You now can control your laser on and off using the same spindle commands of M3 to turn on the laser and M5 to turn it off.

Shark Laser wiring (alternative version)

Wiring to Sherline CNC machine (Endurance PRO laser)

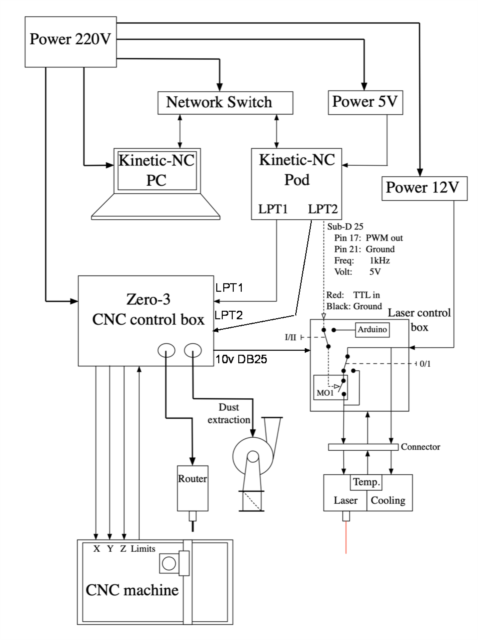

Wiring the laser to Kinetic-NC PWM

Big collection of CNC routers and installed Endurance lasers

Wiring to a Denford Maxirouter using analog output (ENdurance PRO laser model).

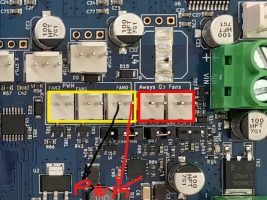

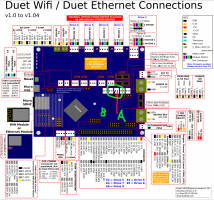

How to Connect the laser to Duet3D Wifi Board

The PWM input of the laser is connected to the Fan0 output of the Duet board.

Power control teams

M106 S127 – 50% power

M106 S255 – 100% power

M106 S0 – Laser Off

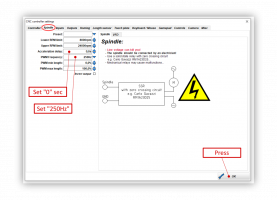

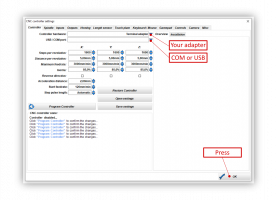

PWM setup MACH3 – all you need to know – CPO-10V CNC4You.co.uk

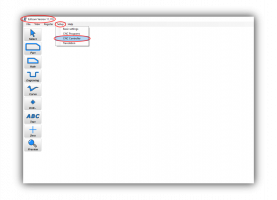

Estlcam laser wiring

Thanks to one of our experts: Michael Poling, M.Sc.(Kin), M.Sc.(PT), CAFCI, Cred. MDT

Owner/Physiotherapist, Fairway Physiotherapy

Asst. Professor, Northern Ontario School of Medicine

who made this wonderful video guidance!

Running your Endurance laser with Mach3 — wiring / pinouts / setup

TOP-41 CNC machines with installed lasers. Upgrade your CNC with a powerful and reliable laser head!

Hooking the laser to the MACH3 machine

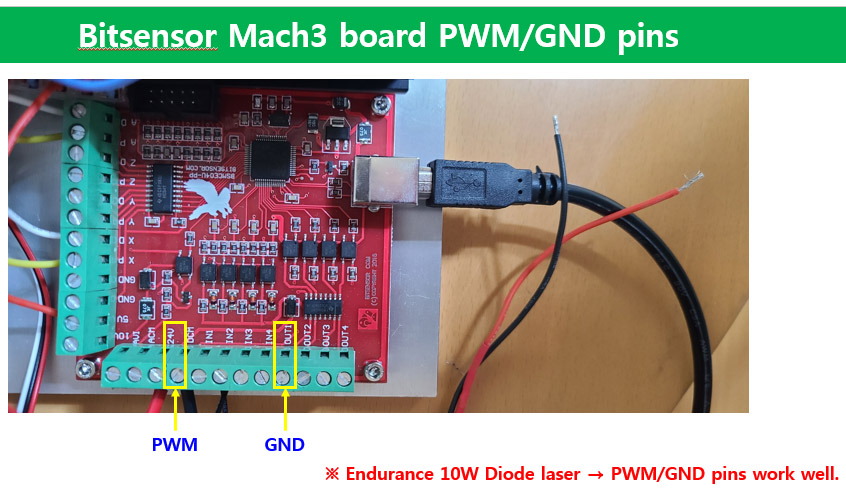

Bitsensor MACH3 board laser wiring

How to find a PWM pin on your CNC mainboard – all you need to know.

Read about an Endurance 10 Watt Invincible Plus Installed on a Bobs CNC E3 (PDF)

BladeRunner Ether-Cut CommandCNC for LINUX User Manual (PDF)

Personal experience of running 4×4 CNC router and 4 G201X Gecko controllers by Paul & Jaime Revel (Akari Studios)

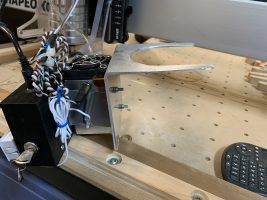

The hardware configuration we are currently running consists of a 4×4 CNC router and 4 G201X Gecko controllers with a C10 breakout board which is hooked to a UC300ETH-5LTP. Our software to control this mess is UCCNC. We are using Vetric Aspire as our design program. The laser we currently have is an Endurance 10W+ that comes with a laser control box which makes it super easy to get the laser going thanks to the PWM wires. We routered a custom mount from plywood that slips over the spindle that was large enough to accommodate the laser and the control box. The laser comes with two 12 volt power adapters. One for the laser and one for the control box. The cord length on these are short so in our case, we need a 120-volt plugin close to the spindle. We ran SO cable through our cable run and plugged it into a power strip inside the CNC control panel. On the other end, by the spindle, we installed a GFI outlet. Then, we plugged in our two wall transformers for the laser. We ran a two-conductor shielded cable from our CNC control panel and ran it out to the spindle. We crimped male and female terminals on the laser control box’s PWM wires and on the shielded cable. Now when we want to use our router, it’s very easy to unplug the laser control box and the laser to set aside while the router is cutting. To get the laser to fire with UCCNC is about as easy as it was to hook it up. All we had to do was hook up one wire to pin 16 and the other to ground on our breakout board. Then, go into UCCNC’s I/O configuration and select pin 16 on the laser pin. Now, poof! It is hooked up.

The g-code was a little bit trickier because, at the time of writing this, there were no specific post processors for UCCNC from Vectric. To solve this problem, we modified a post-processor for Stepcraft. To check to see if your laser is working properly and you have control (everybody likes control, right?) you would type this into your MIDI: M3M10Q50. This should turn your laser on to 50% depending on how you have things set up. The caveat to the Stepcraft post-processor is that it uses S commands for speed and we need Q so you have to modify the post-processor to accommodate this.

3 axis cnc router (1250x1250x120 cut area)

300×300 D-bot 3D printer

750mm X-Carve

a 5 axis cnc from 5axismaker (500x500x400)

A large CNC machine controlled using Mach3 and an Ethernet Smooth Stepper

Acro

ADIMLab

Alfawise U30 printer

Anet A8

Anycubic

Anycubic 4max

Anycubic i3 (Anycubic i3 Mega)

Anycubic Photon

Atom2 Gizmo 3D

axiom precision ar8 pro cnc router wiring

Azteeg X3 Pro

Big ox CNC

Craftbot+

Creality 10 S5

Creality CR-10

Creality CR-10S pro

CTC flashforge replica

Custom Delta 3D printer

Davinci 1.0a with repetier

DlyingBrad

Eleksmaker / Eleksmaker A3 Mana board

Creality Ender

Creality Ender 2

Creality Ender 3

Creality Ender 4

Felix

Flashfordge (Flashforge)

FlSun

Folgertech FT-5

FT-5

Gecko g540 controller (GeckoDrive 540)

Geeetech

Home built 3D printer / Home built CNC Router

Home made printers from 220×220 to 1080×600

Hyper Cube

JG Auroga

Kossel

Laseraxe 2.5w CNCC

Laser-Bot

Legio 3D

Lutzbot

MakerBot

Makerfarm

MakerGear M2 (MakerGeora M2)

MakiBox

MillCarve

Monoprice

Monoprice maker select v2

MPCNC

MPMS v2 L

OpenBuilds C-Beam

OpenBuilds MiniMill with Duet electronics

Openbuilds Ox (OpenBuilds OX CNC router)

OpenBuilds-C Beam

pmdx – 411 interface

PrintrBot

Prusa

Prusa i3

Prusa mk3 / Prusa mk3s

Raise3D

Raprap RAMPS 1.4

Replicator 2 / 2X

Reprap

ReXYZ S22.

Rigitbot

Robo 3D

Robo3DR1+

Rostock max v2

SeeMeCNC

Shapeoko 2 / 3 XXL

Shark (Shark 4HD / Shark XD4)

Shopbot

Snapmaker

Solidoodle 2

Stepcraft 420

Stepcraft CNC

Taig Mill

TAZ5

TAZ6

Tevo / Tevo Little Monster

TinyG

TRex 2

Tronxy

Tronxy x5s

Tronxy XY-2

Ultimaker 1 / 2

Ultimate

Velleman K8220

WanHao

Wanhao 4S

WanHao Duplicator i3

X-Carve / X-carve 1000×1000

XYZ / XYZ Davinci A1.0.

Zortrax

Eleksmaker Mana

RAMPS

Arduino Uno + CNCShield V3

SKR 1.3

Anet A8

Duet 3D wifi

mks 1.0

CNC xPro V4

xpro v3

Rambo 1.3

Ethernet Smootstepper

Smoothieboard

Lerdge S,X,K

mks dlc

SainSmart Genmitsu CNC 3018

Laseraxe 3 axis board

blackbox openbuilds

DDCSV offline controller

fystec f6

Sainsmart Genmitsu 3018 MX Toshiba MCB with Mach 3&4

Duet LAN