The general principle of the method

In the process of cutting of any material, a small part of it may remain molted on the base plate where the material is placed. When cutting wood you’ll have a small amount of resin from the wood piece on the base plate. Under the influence of the laser beam, the formed substance sticks to the base plate copying an outline of the cutting.

In this article, we are going to consider generally available materials using which it is possible to make an outline drawing on an aluminum surface.

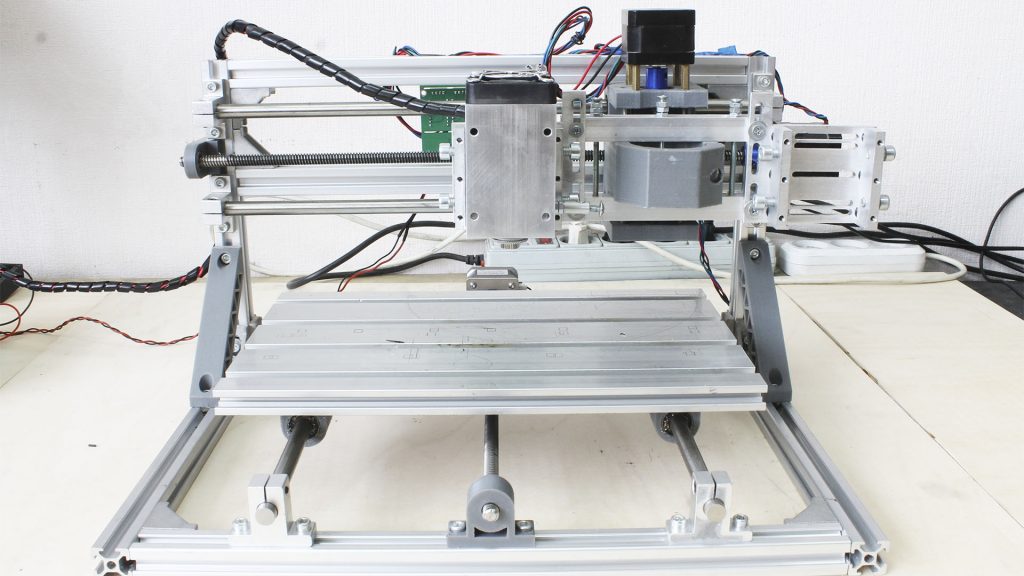

For cutting we’ll use a CNC machine (CNC3018) equipped with a 10 Watt laser.

To get an outline of better quality we’ll repeat cutting of the material. The more times we’ll repeat cutting the higher quality of the outline we’ll have. For better cutting of the material, we’ll need to increase the number of passes by 1-2. At the end for better adhesion of the substance to the aluminum sample without the material above, we’ll make four additional passes at 100mm/min.

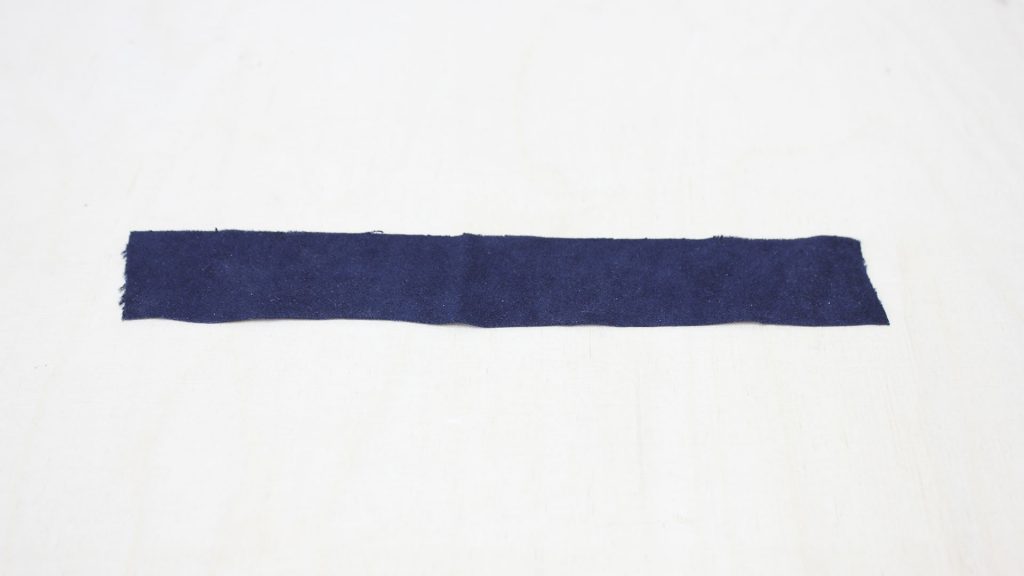

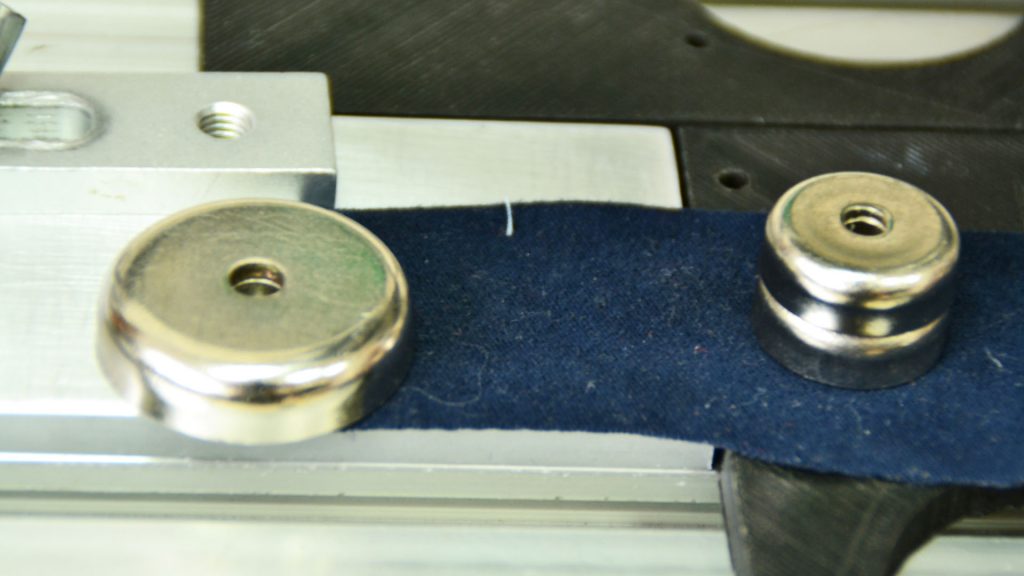

Velvet

Thickness: 0.4 mm

Cutting parameters:

Laser power: 100%

Speed: 400 mm/min

Number of passes: 2

Number of repeated cuttings: 7

|  |  |

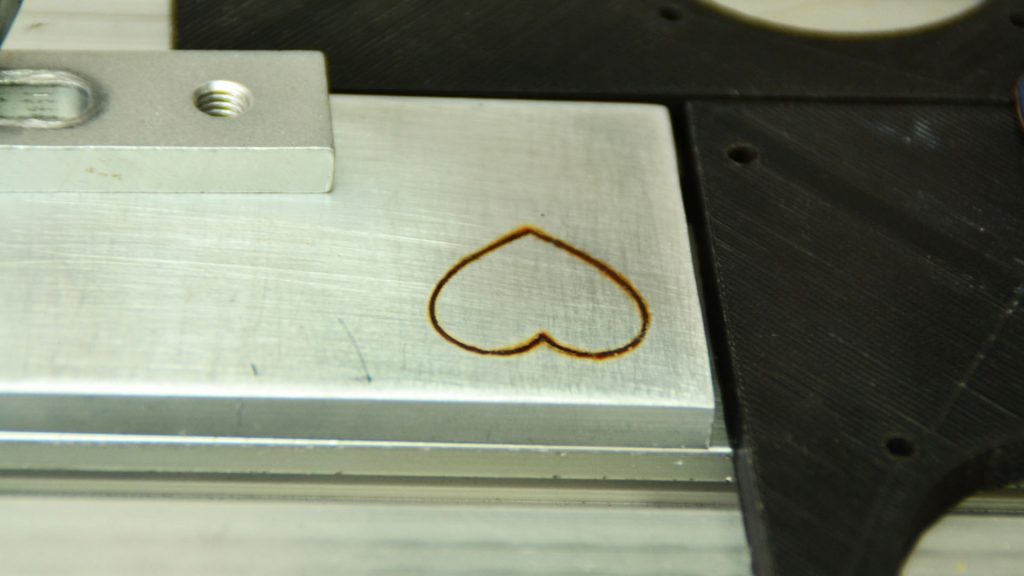

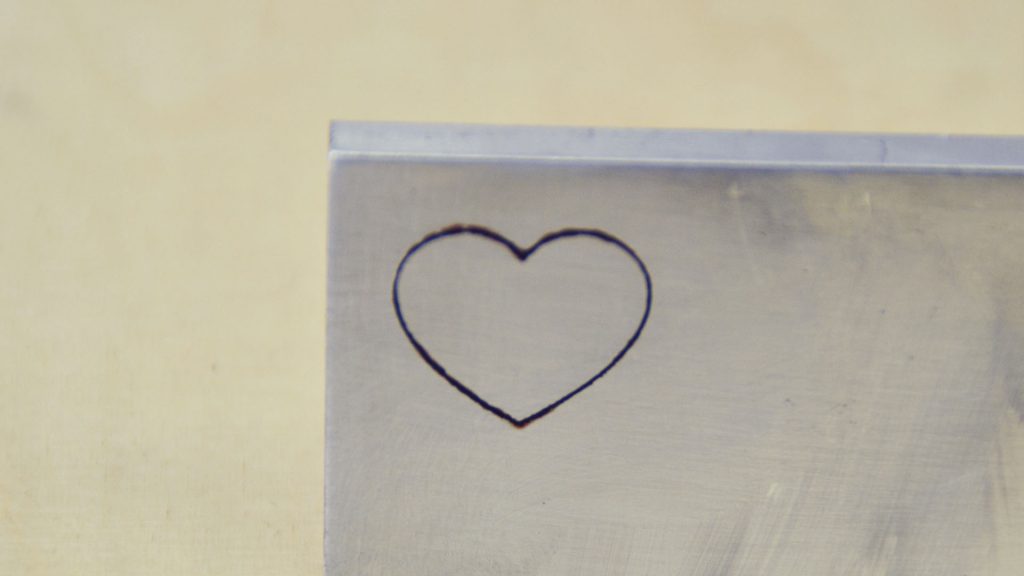

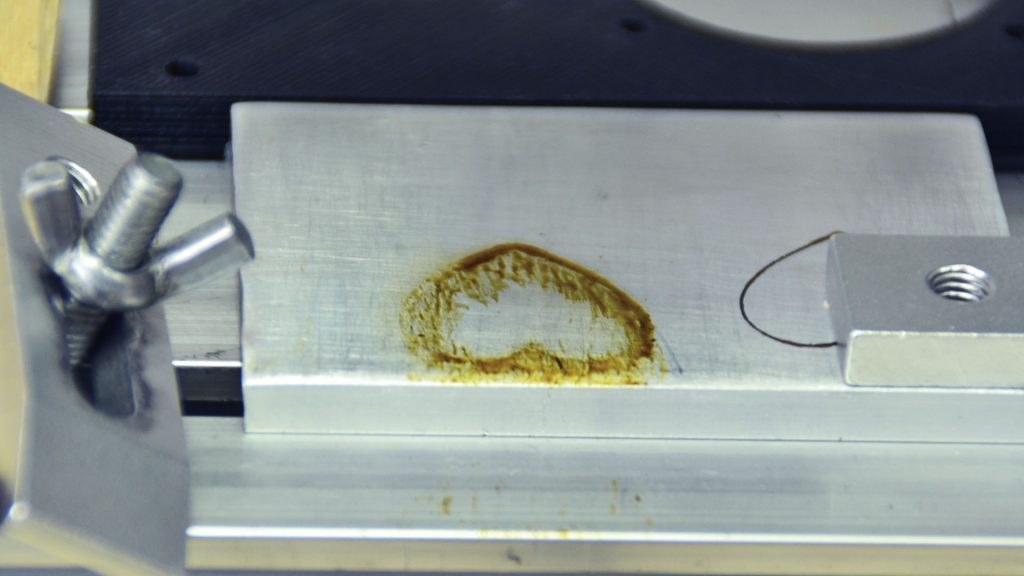

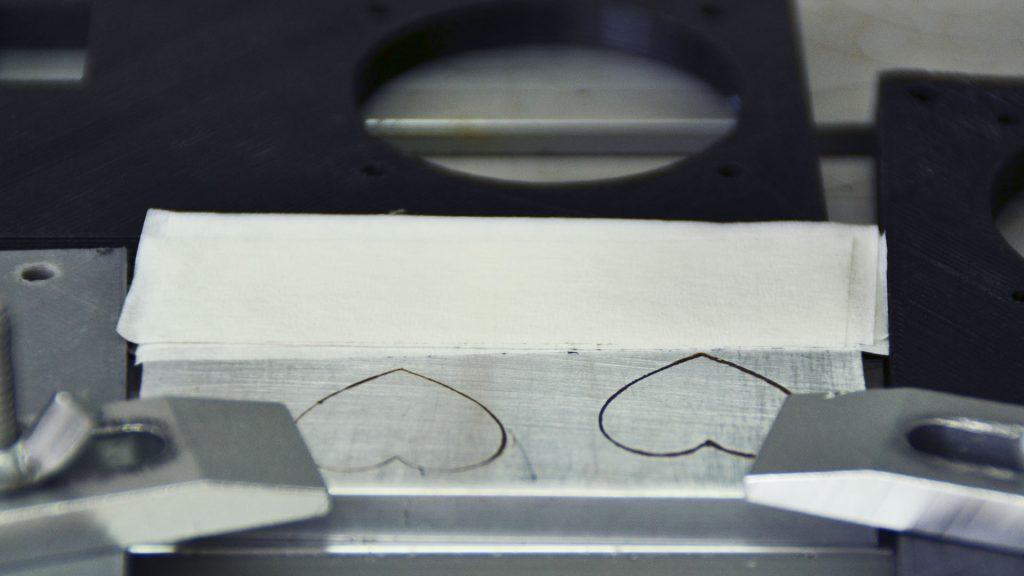

| Fixed at the work table | After 7 repetitions of cutting | After 4 passes at 100 mm/min |

References to g-codes: Heart_velvet (download)

The obtained outline at the end of the process needs 20 minutes to get dry. After that wipe the excess of the substance, formed during the process of the outline making, with a solvent-wet cloth. Do it carefully so that not to remove the outline itself.

|  |

Triply birch plywood

Thickness: 3 mm

Cutting parameters:

Laser power: 100%

Speed: 400 mm/min

Number of passes: 6

Number of repetitions of cutting: 5

|  |

| During the cutting process | After 5 repetitions of cutting |

|  |

| After 4 passes at 100 mm/min | After cleansing |

Reference to g-code: heart_speed400_pass6 (download)

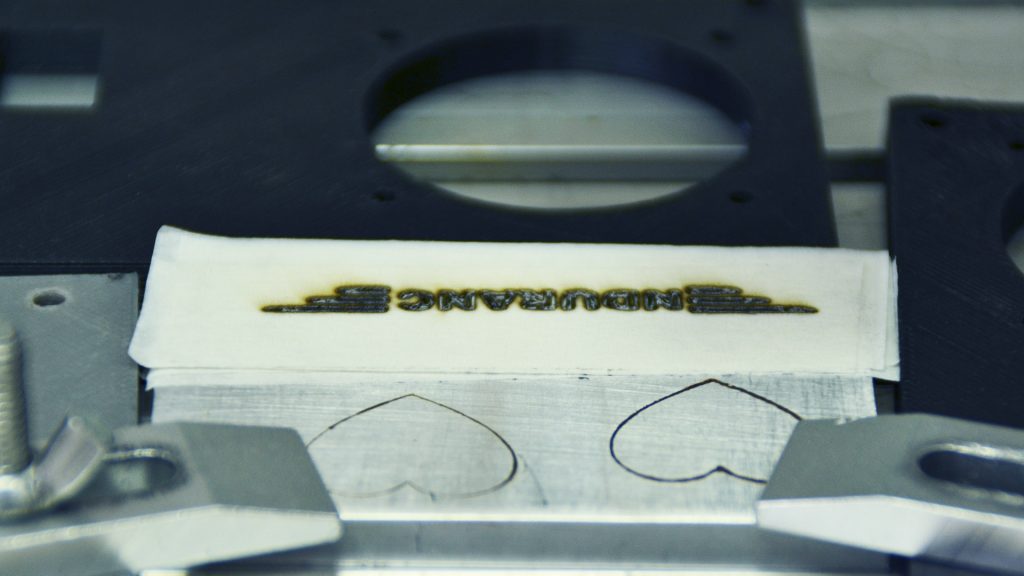

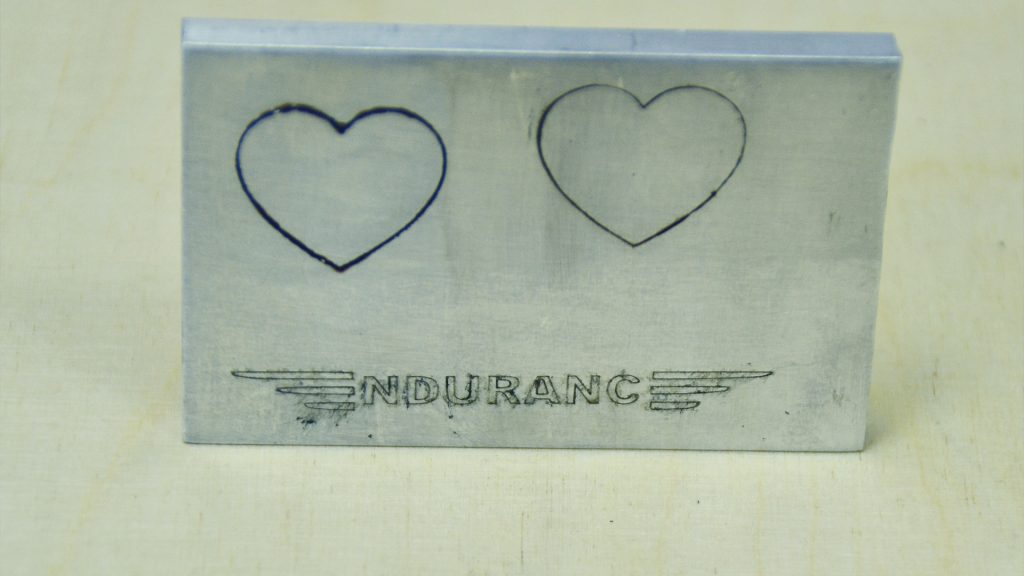

Painter’s tape (masking tape)

To get a better result we paste 5 layers of the tape to the aluminum base. The more layers the better result.

Cutting parameters:

Laser power: 100%

Speed: 400 mm/min

Number of passes: 4

Number of repetitions of cutting: 1

Unlike with other materials, we don’t remove the tape from the aluminum before cutting at 100 mm/min.

|  |

| Fixed to the work table | After all passes |

|  |

| After tape removal | After cleansing |

Reference to G-codes: logo_speed_masking_tape (download)

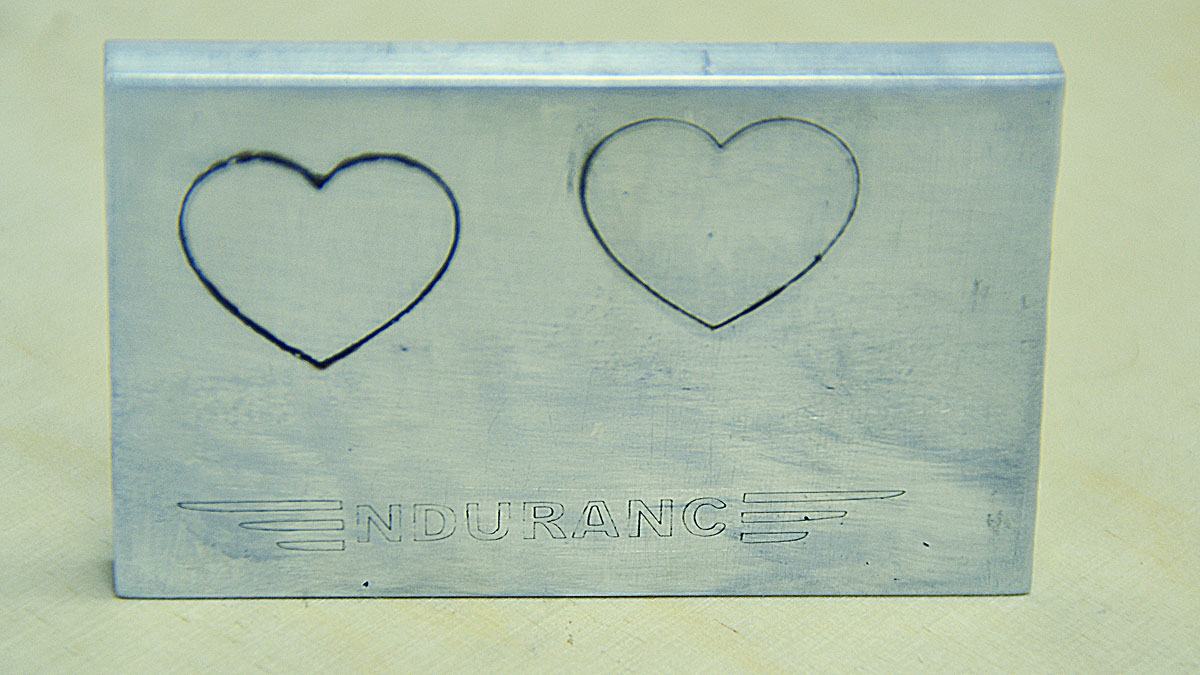

Metal engraving using a thermal grease / paste 15 watt (15000 mW) Endurance “Duos” laser