A story was written by an Endurance customer who bought an Endurance 10 watt Delux laser.

”

It took me about 2 years to learn how to design and build my own laser CNC. At the cost of about $600 CAD, along with multiple lasers excluding my newest favorite laser from ENDURANCE LASERS the 10w Deluxe.

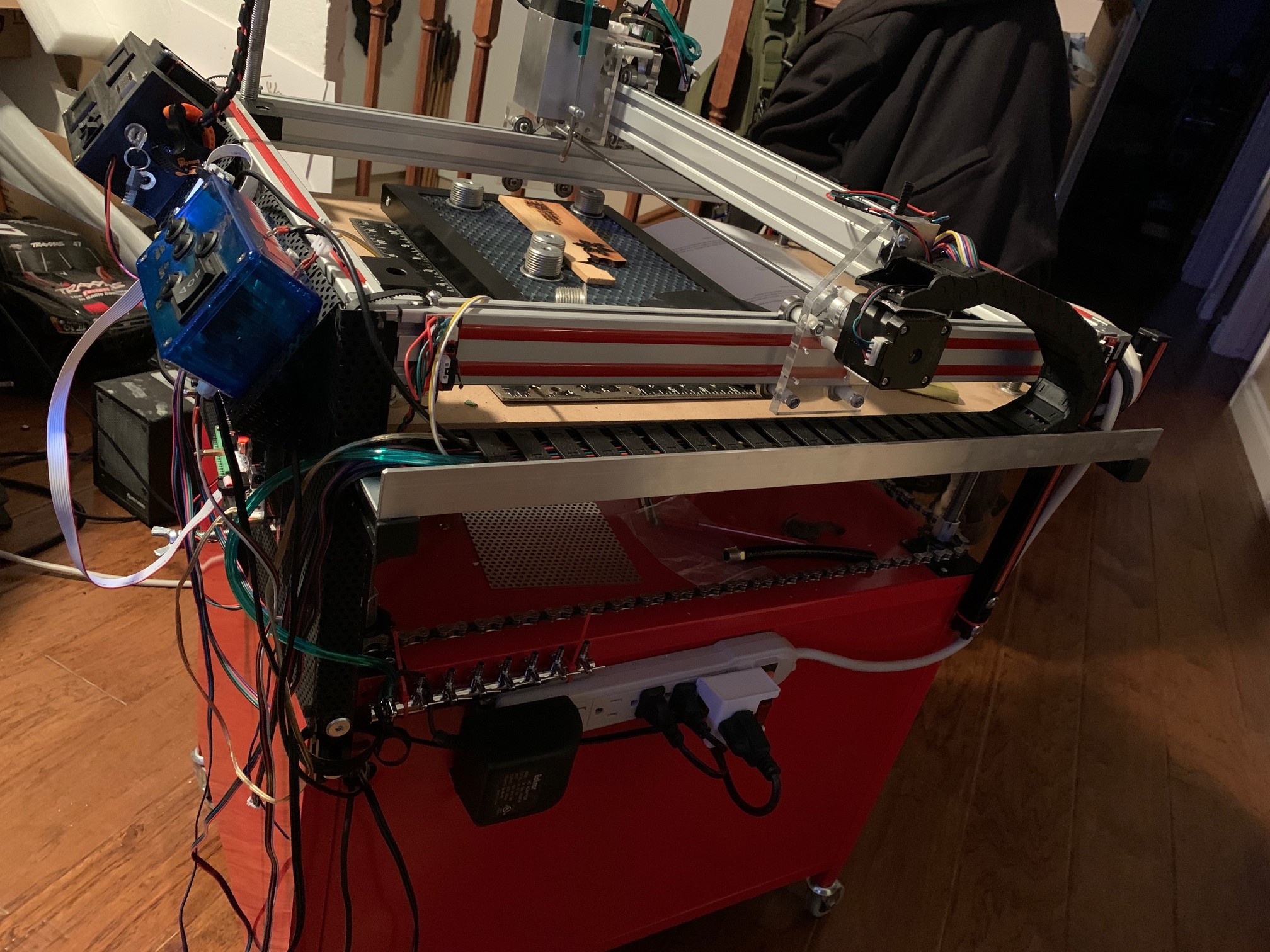

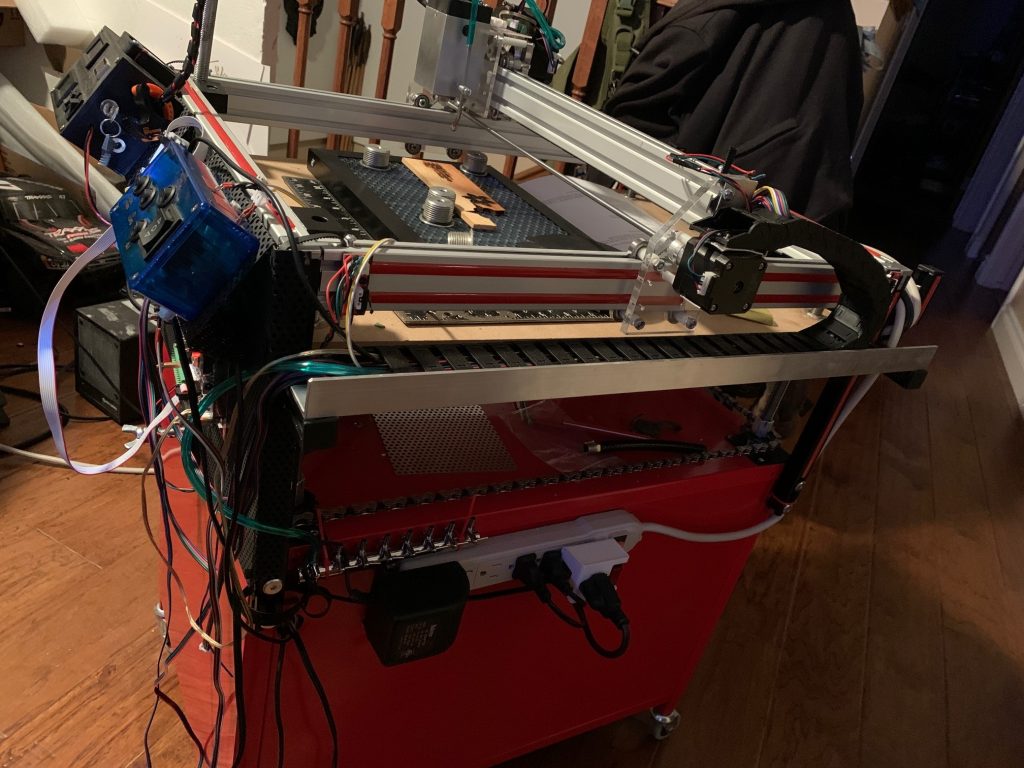

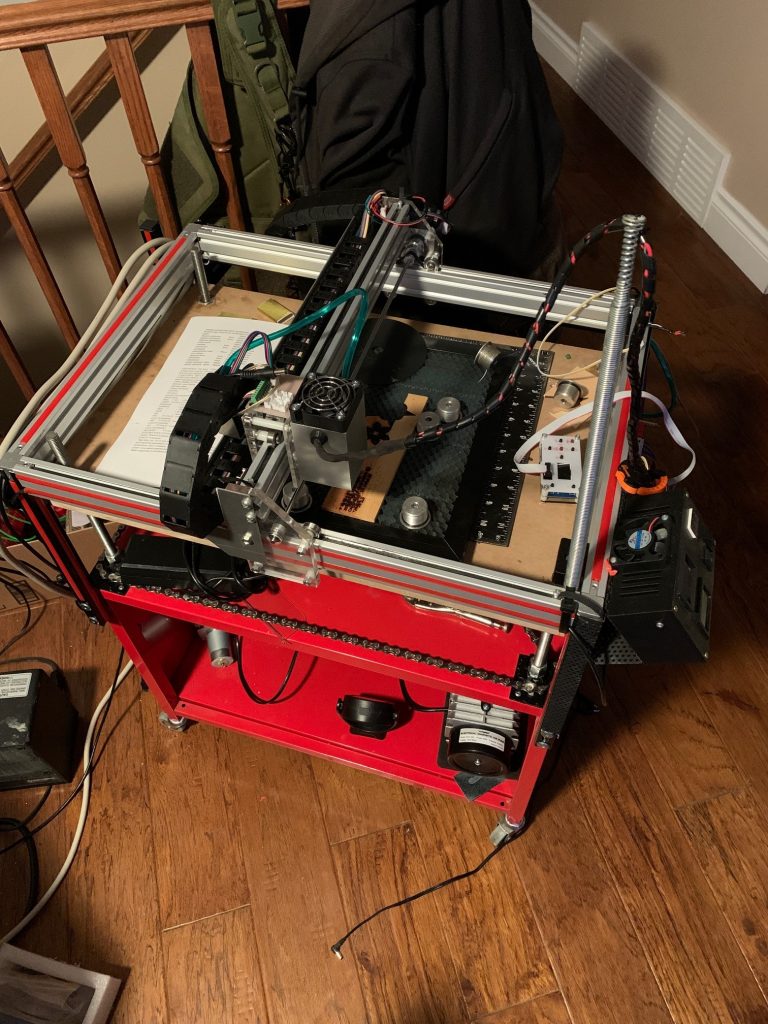

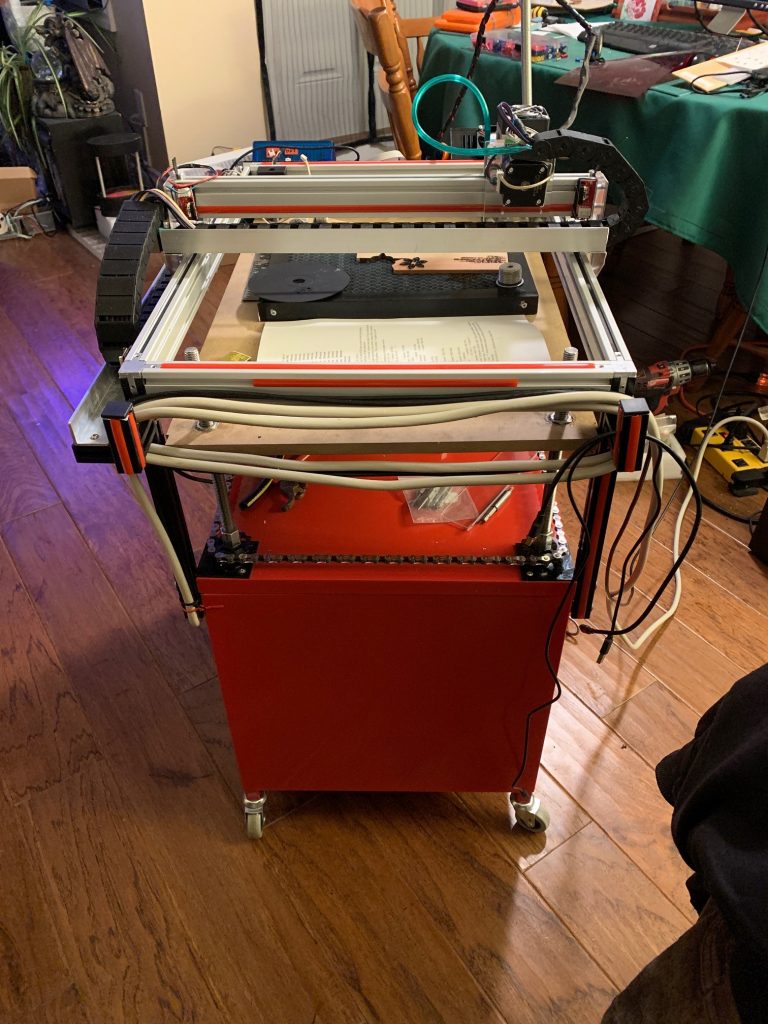

I built a height-adjustable table unit to raise and lower the platform. (so I can now get rid of the STACKS of CD cases). The full unit is 22’”w 30”L 35” h . The overall weight is 40 lb. so it easily transports from room to room or shows.

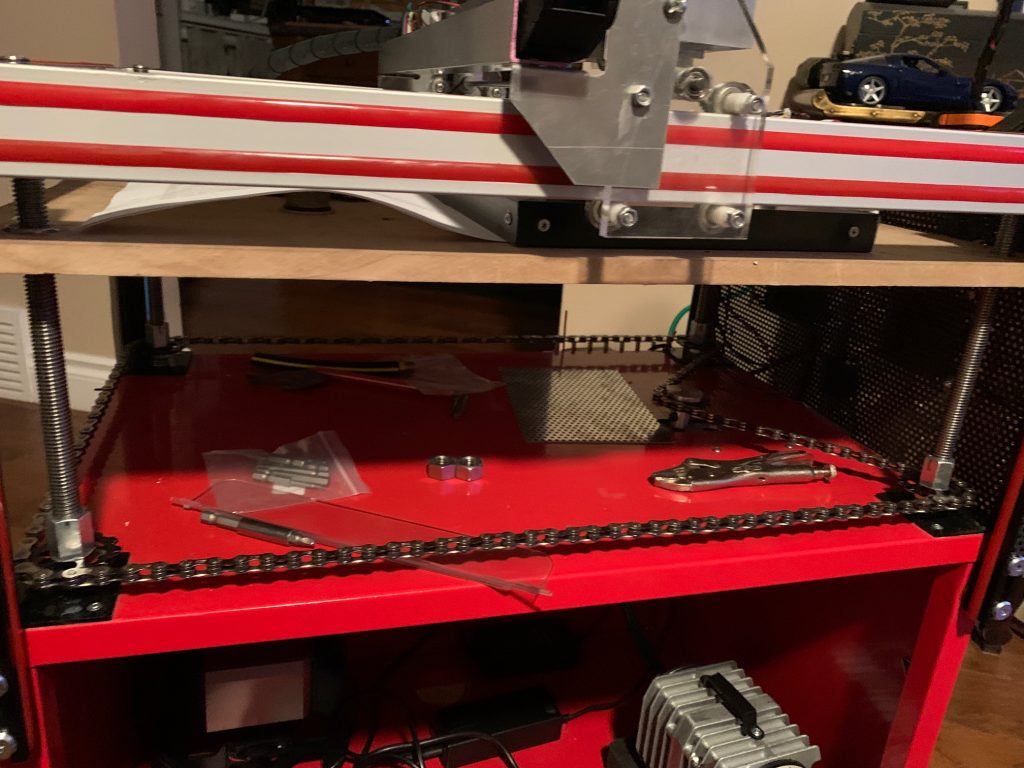

My laser travel is 18” x 15” with the capabilities of the table travel of 7” for bigger items (without the stacks of CDs). To make the table, I used four 1/2” threaded rods and an MDF sheet with embedded epoxy nuts. I fabricated bike gears to the threaded rod and linked the four rods with a bike chain, underneath a small angle 24v motor to run thread rods to adjust the table height.

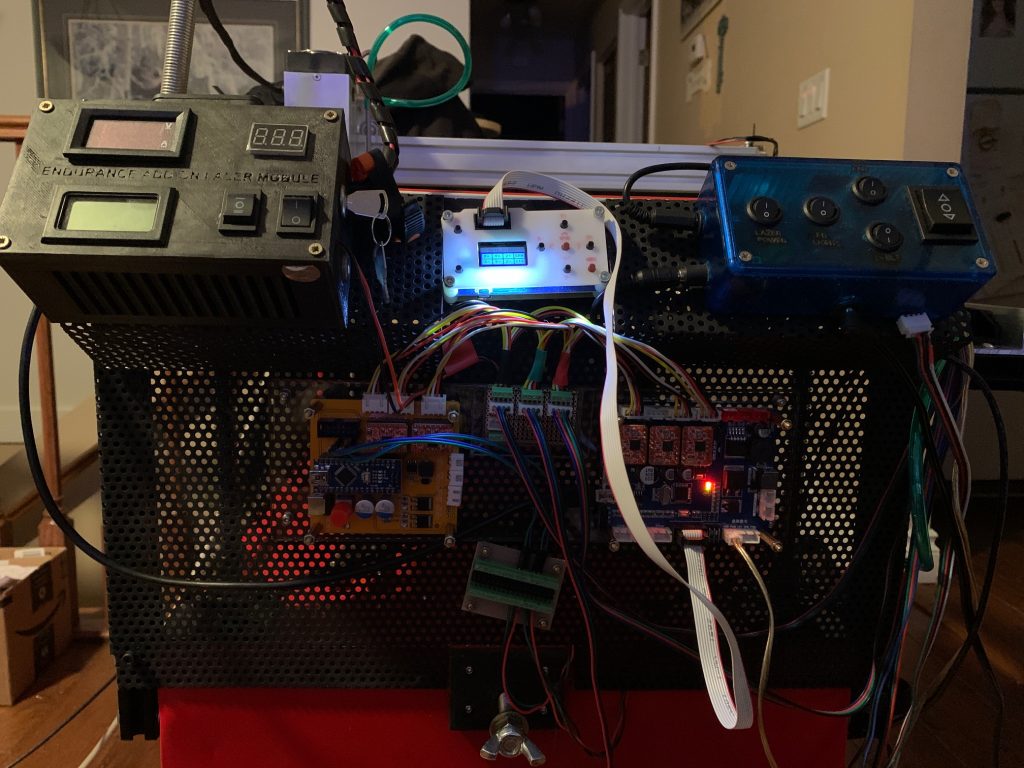

I also made a control box with several switches for power to the laser, as a safety feature separate from the program. It controls the extra fans, LED lights, and a table up/down. For the control panel, I have the most basic PCB boards. One board only does X,Y-axis and the other board includes a few more options e.g., Z-axis and spindle control. Most likely I can just run with one board and one.

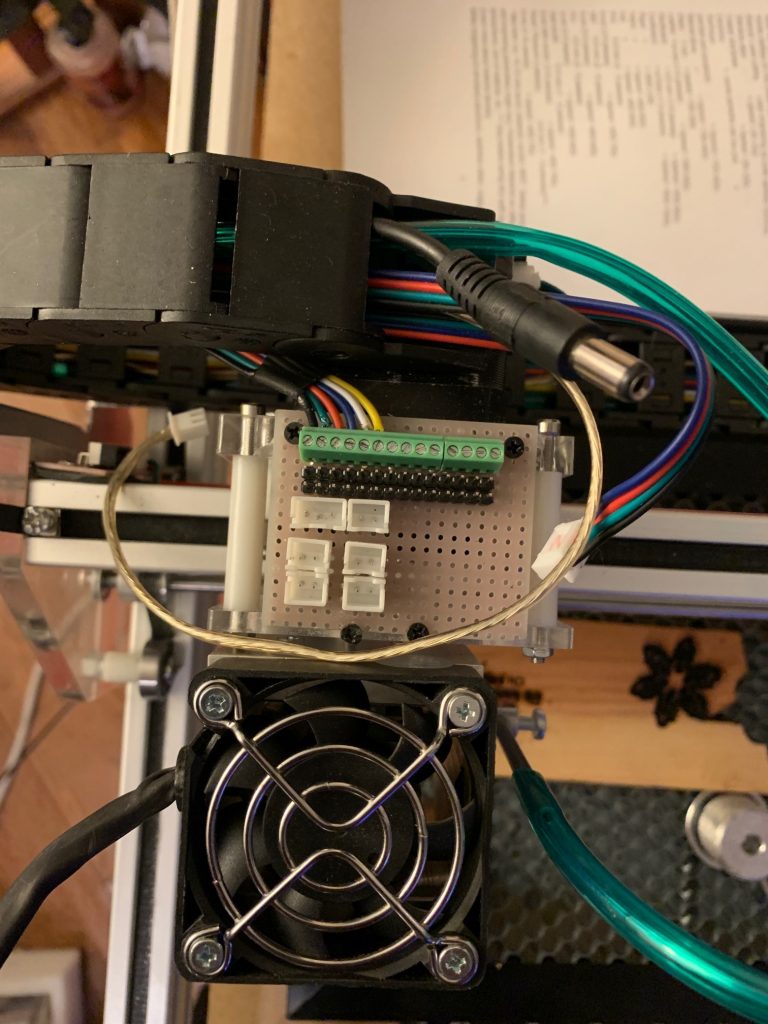

program, I will figure that out later. Made a Y connection between the two PCB boards just so I did not need to unplug and replug all connections. A small terminal board on top of my rail supports the laser/spindle/3d printhead since I have multiple laser modules with different terminal connections. This way it will be easier to add extra lights, fans, and Z-axis control units.

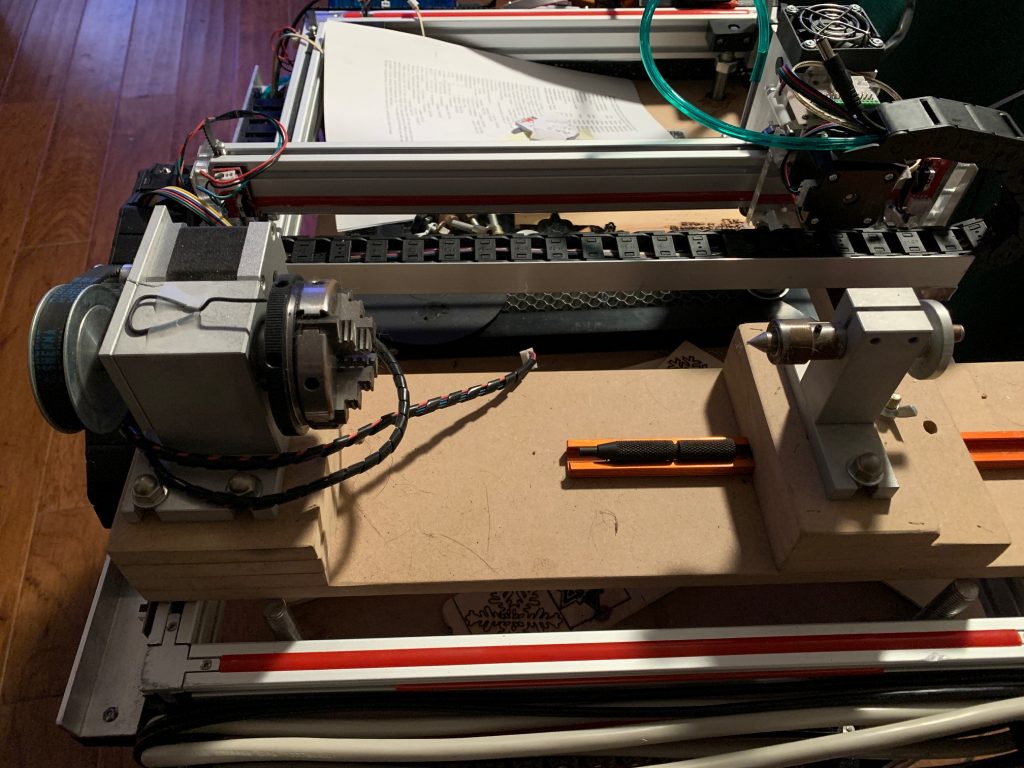

the 5th Axis setup a homemade servo stepper motor and geared belt to a metal 3 jaw chuck, and live center endpin adjustable in length for doing round items like coffee mugs, water bottles extra.

I started out with a program that came with the PCB board Engraver Master. A very good starter program for beginner hobbyists. Now I want more power more capabilities. Started to learn Fusion 360 CAD, just discovered the Lightburn through YouTube.

My goal is to cut and etch metals for my Jewelry hobby metal & wood lathes crafty projects.”

by Rob Blair

Calgary Ab

Email [email protected]