Slate engraving with 405 nm violet diode laser

In the current article, we are going to test how our new violet 1700 mwW-laser with a wavelength of 405 nm process slate. We have not worked with this material before.

Slate is an extraordinary natural material widely used in construction.

Slate is a rock, the key feature of which is its ability to split forming flat planes of various thicknesses.

Slate may be roughly divided into two groups: clay-slate and crystal slate. The color of natural slate varies. Grafite-gray and brownish-red are the most common slate shades. The slate from England and Spain is dark gray, while in the USA they mine green, brown, and purple slates.

It’s worthwhile pointing out that slate is a natural, ecologically clean material, that is why it is widely used in various fields of construction, such as facade finish, roofing, tyling, interior and exterior design.

Slate properties:

- Easy to split into separate sheets, the thickness of which may vary from 0,1 to 2,5 mm; Maybe processed using various methods: cutting, chopping, drilling. This enables to creation sheets of any size and form.

- Resistant to temperature falls;

- Does not lose shape;

- Good isolating and soundproofing properties

- A high index of hardness (despite its layered structure);

- Low water absorption;

- Freezeproof, UV-tolerant, fireproof, resistant to aggressive environment and corrosion;

- Does not fade in the sun and retains its unique color throughout its service lifetime;

- Durable.

At first, we tested the laser on different materials. It cuts and engraves perfectly cardboard, paper, plywood, removes paint without issues. But due to its low power, the laser cannot process any metals (brass, steel, stainless steel, titanium, aluminum). Because of its wavelength, we failed to process acrylic of any color and transparency.

At the end, we set to test the laser on a slate sheet.

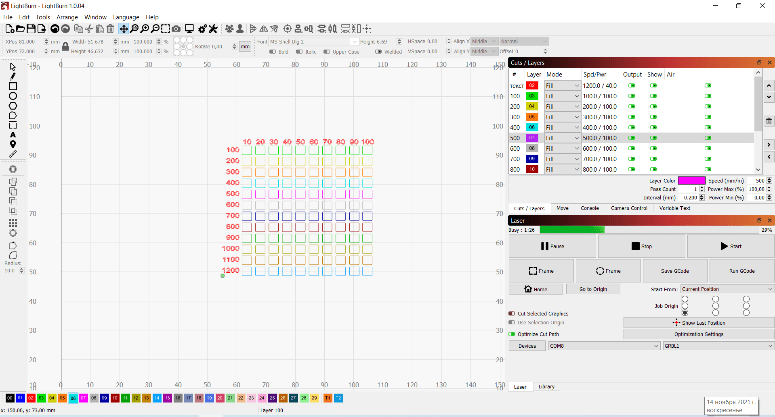

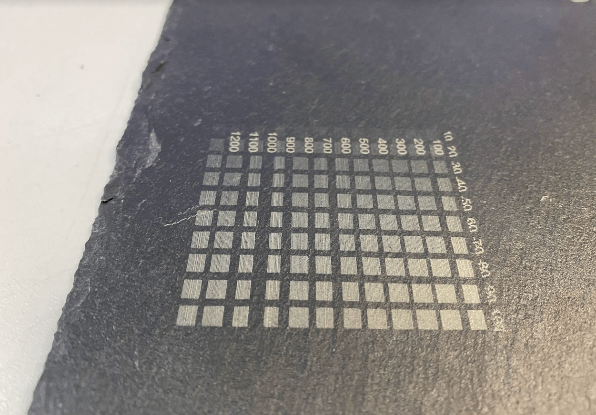

We engraved a test table first.

And did succeed!

Based on the testing results, we may conclude that:

- The laser suits to engrave slate.

- Different parameters make it possible to implement a great many various ideas due to the possibility to create a vast number of shades and tints on the non-painted slate.

- There is no need to spend money for an air assist, ventilation systems and compressor.

Our next step is creative tests.

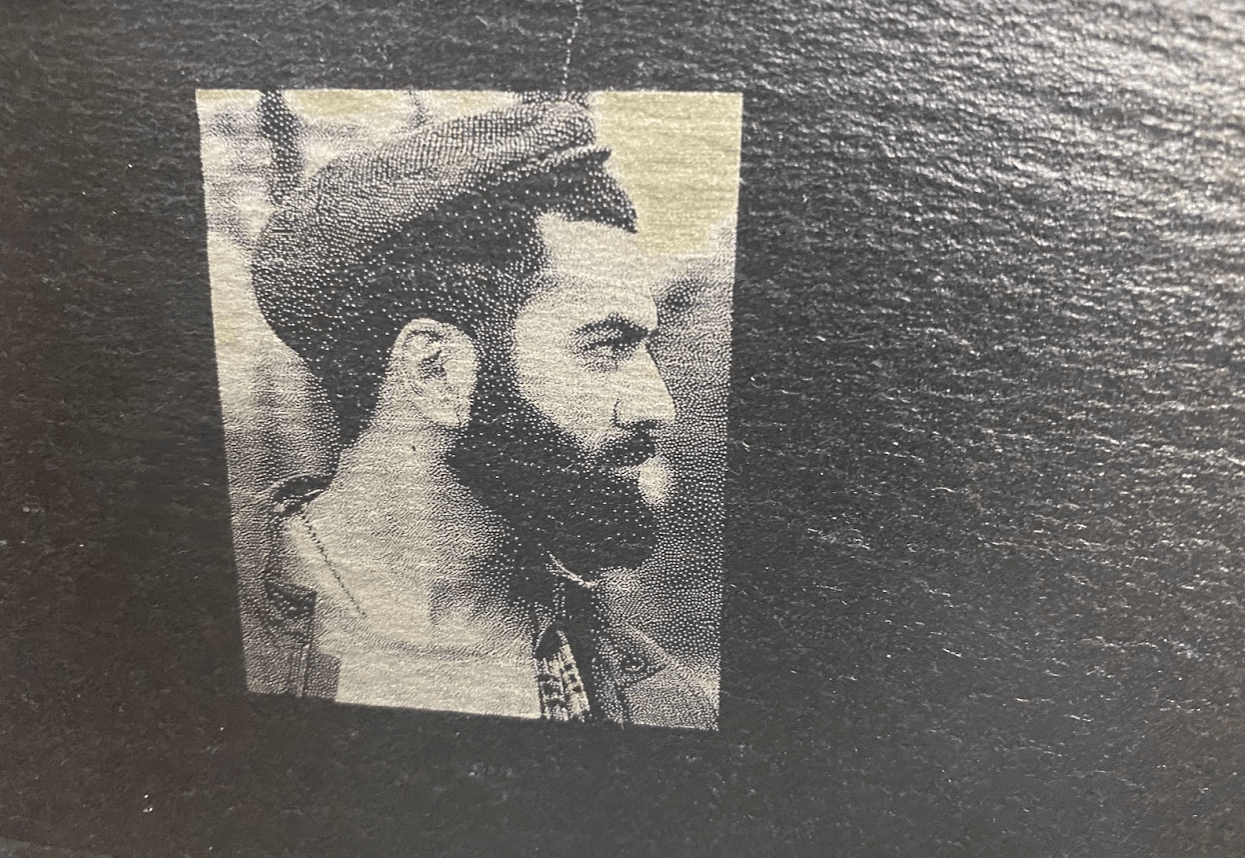

We had two ideas: to make a photo engraving on a piece of slate and a vector design of a DIY logo of our laboratory.

We begin with photo selection.

On https://tech-lagoon.com/imagechef/en/image-negate.html we invert the image colors of the photo.

As the result, the black color turns white and vice versa.

Now we can import the image into LightBurn to work with our laser.

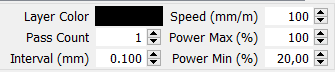

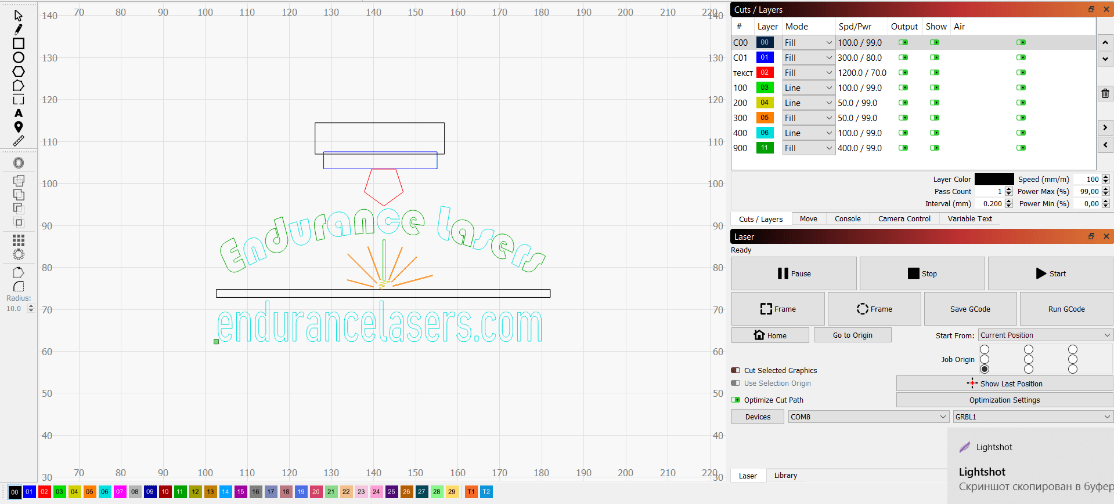

We set up the following engraving parameters:

The last but not the least thing to do is focus. The focal length (the distance between the lens and the engraved surface) in our case is 23,5 mm.

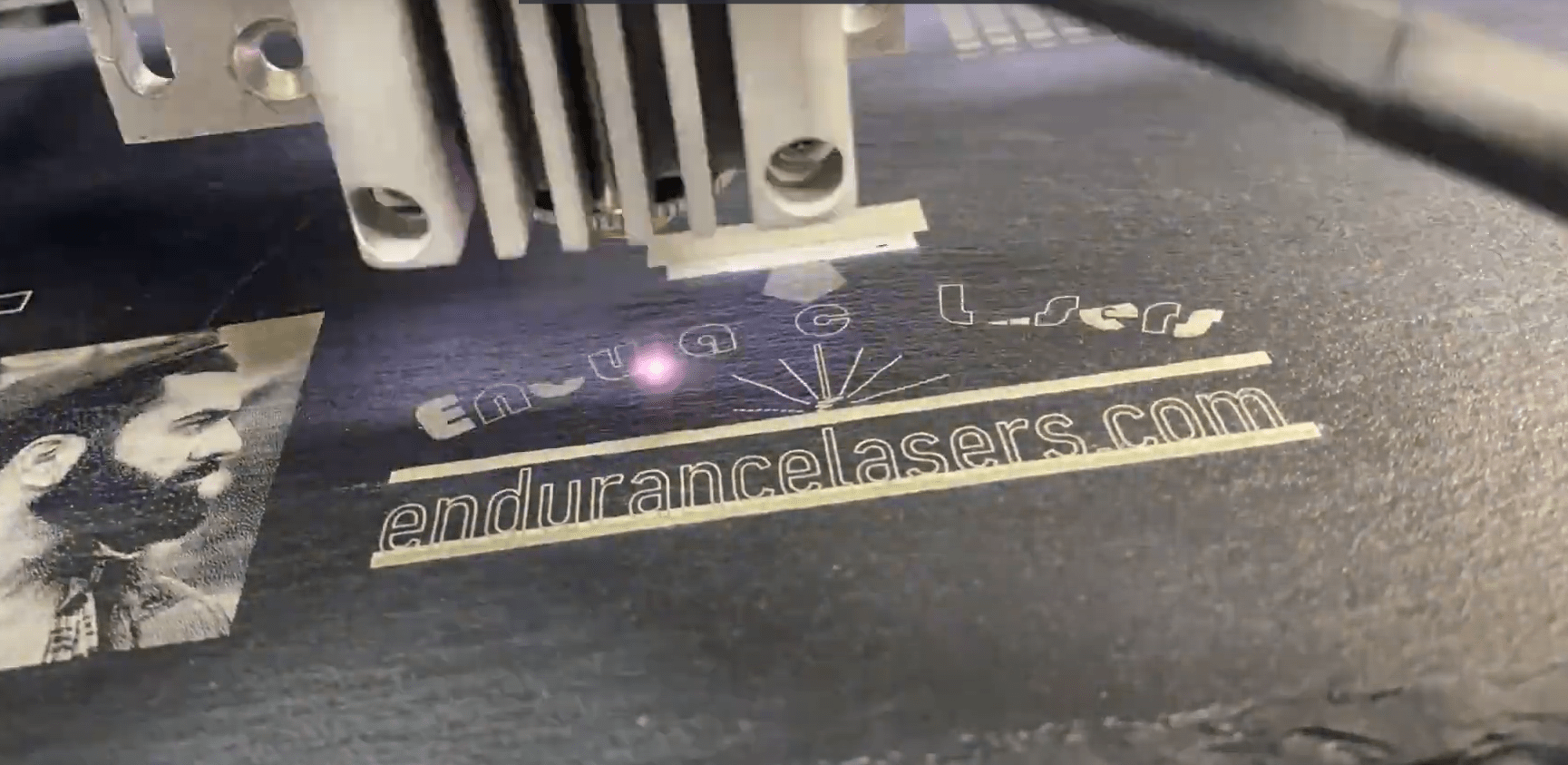

Now we are ready to start engraving!

Here is the resulting photo engaving. As we see, the image is accurate and high quality.

The engraving density is very high due to the small laser beam spot, and the accuracy of this scale is achieved thanks to the low laser power.

The result has pleased us extremely. If we change the speed settings we can shorten the time of processing. But our aim is to get the best possible engraving.

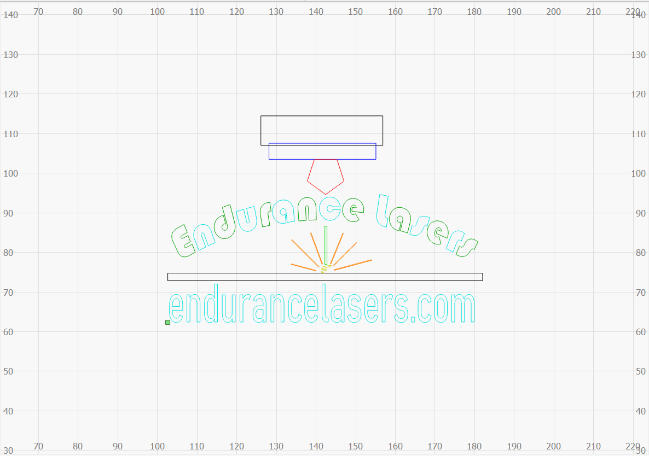

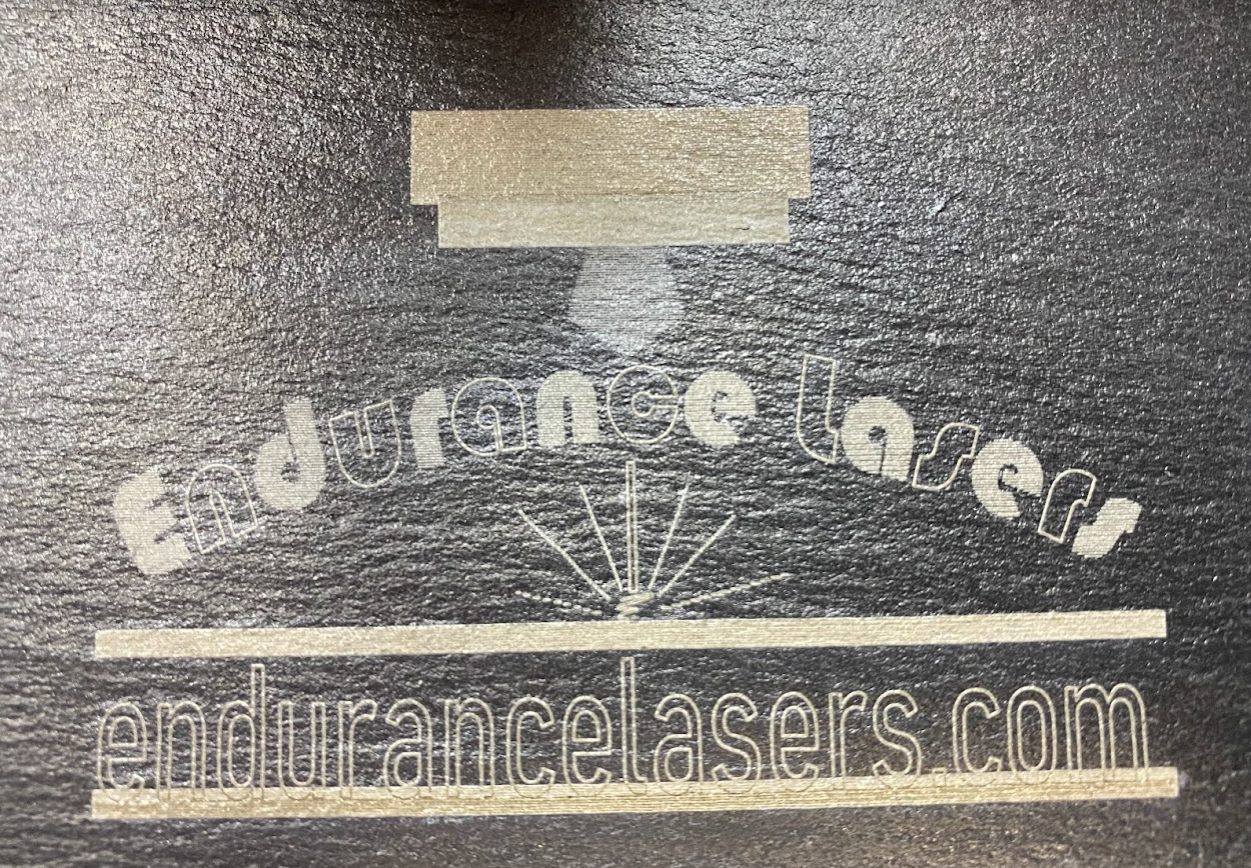

In this article, we mentioned a drawing of a DIY logo of our laboratory. So, while the photo was engraving we managed to create a design of the logo in the CoralDraw program for vector images.

Here is our resulting image after we have exported the drawing as an SVG file to LightBurn.

We divided all the elements into certain groups, and adjust settings for each of the group.

It is necessary for grayscale engraving.

Having checked the focus, we start engraving!

Don’t forget to protect your eyes with safety goggles if you don’t want to damage your eyesight!

As a result, we get a perfectly engraved item!

It takes us about 40 minutes.

This type of engraving and photo engraving will suit to decorate slate dishes and figurines.

Slate is a very durable material. It is temperature-, water- and time resistant.

We are absolutely sure that photo-engravings on the slate will last for ages.

Easy connection, low power consumption, compactness, no noise are good stimulus to buy a laser of this type.

In the nearest future, we plan to launch more articles to disclose the great potentials of this laser. Stay Tuned!

Slate review – personal experience

Working with hard things like slate which is a stone it can be a bit hard at times slate will work without doing anything. But for the best look and clean look you need to clean the slate first and then coat it I use a crystal clear mat coat in a spray can. Some I do not use the paint on one but I find with the spray you can get a better cover and no runs and it is the same all over so when engraving you can get the same all over and not different in other parts with more on. this coat will help it not flake as sometimes when you engrave slate and you rub clean after it can flake this coat will stop that and any other marks on the slate will hold them in place and you can not see them. as always with doing any laser work you don’t want something that can make the beam come back on itself this is why I use a mat as it is a flat look and if you wanted you can coat over after with a shining coat but only after the engraving never before.

Slate laser engraving with Endurance laser

https://www.endurance-lasers.com/

Laser etching on slate (DIY). Slate lasering. Adding different images.

Laser engraving / etching / marking on natural stone (rock, granite)