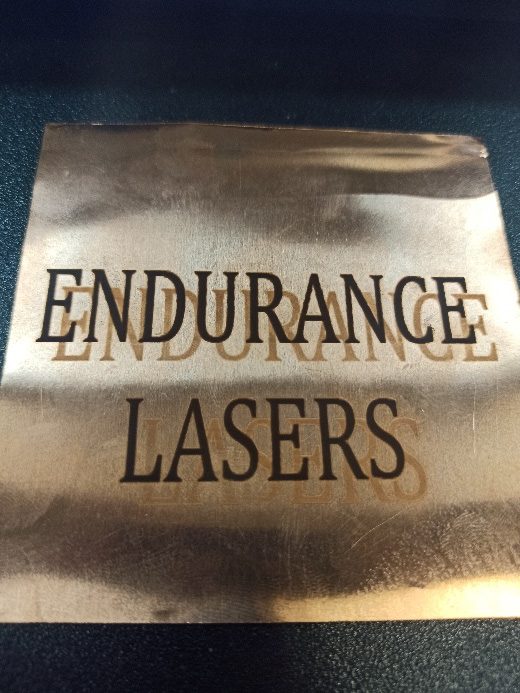

Laser engraving on metal using diode lasers (DPSS / Fiber)

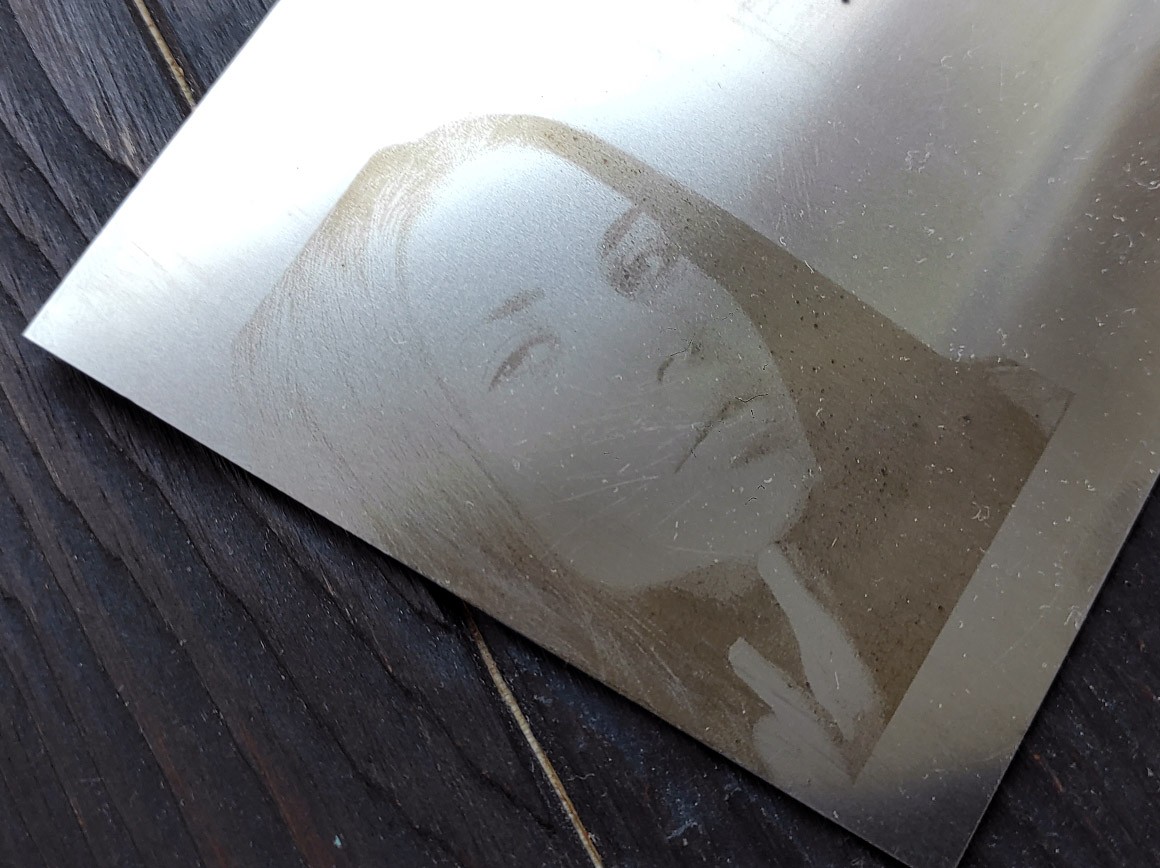

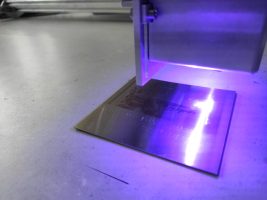

A photo laser engraving on aluminum using 4 watt DPSS infrared laser module

Metal Engraving and Cutting Using Endurance Lasers

What is laser processing of metals?

Every user and manufacturer of laser machines have an itch to come to grips with the processing of as many materials as possible. Metal is undoubtedly one of the most popular materials.

The possibilities of laser application to process various metals cannot but impress. Besides, engraving the laser machine can do cutting and soldering, blade sharpening, chemical metal etching, metal coating of different surfaces; it can also remove dirt and rust from metal surfaces.

It’s no wonder that metal is so popular as a material for laser processing. There are a great number of metals and their alloys with their unique properties. Such properties of metals as hardness, density, heat capacity, thermal conductivity, viscosity directly affect the laser beam’s ability to process this or that metal.

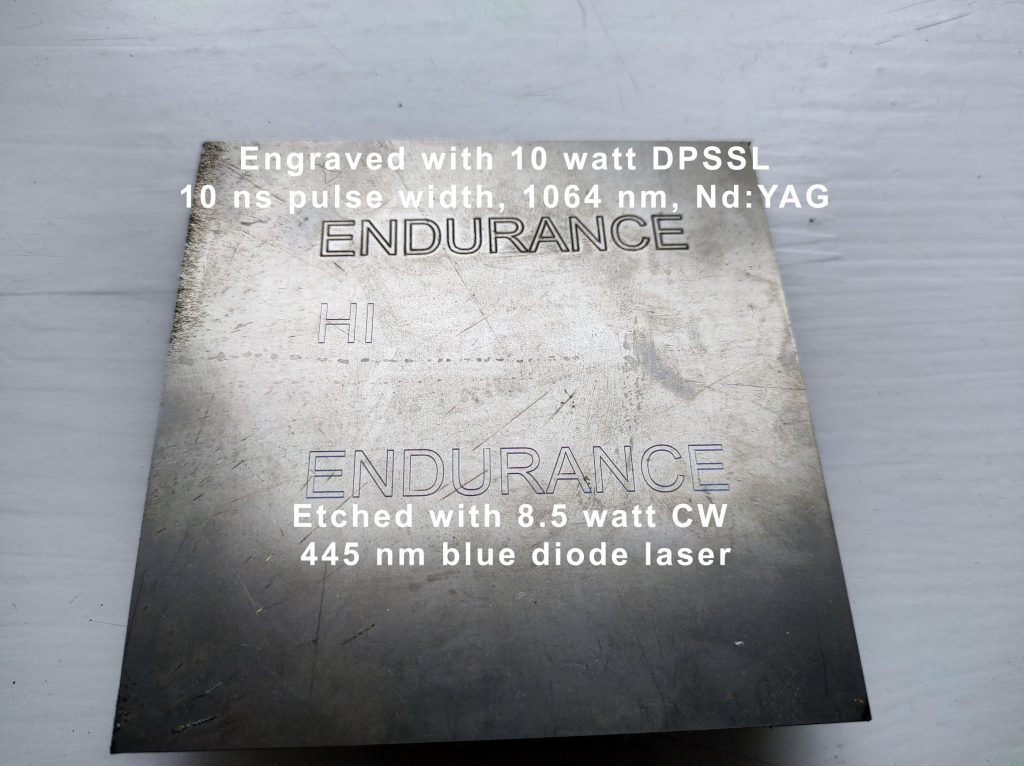

The laser’s ability to process metal depends on the laser parameters, particularly, on its power. The greater is the power the deeper is engraving, the brighter the color of the processed metal surface. Powerful laser machines can engrave and cut metal at higher speeds than their less powerful analogs. The laser ability to process metal depends also on the laser type. Fiber, diode and DPSS lasers perfectly cope with the task of metal processing, while their counterparts with average CO2 tubes are not suitable for this (at least with power less than 150-200 watt).

Operations done by the laser

The laser can perform three main operations on metal:

engraving, that is making an embossed image on the metal surface; an embossment is the result of the evaporation of the molecules due to the laser beam processing the metal surface. The depth of the embossment (engraving) depends on the type of the processed material, processing speed and power of the laser.

To see one of the engraving processes – please watch this video

Engraving on a metal tag

Marking is a process of metal (or alloy) engraving without changing its structure. Depending on the metal type and laser parameters, it is possible to get either black or color marking.

Examples of color marking on titanium

Color marking on titanium (colors can not be removed)

Cutting is similar to engraving. The same processes are at play. The only difference lies in the depth of lasing, i.e. in the case of cutting the laser beam goes through the thickness of the material.

Copper plate cutting

Metals for laser cutting and engraving

Practically all metals and their alloys fit for lasing. The choice of the operations depends on the type of the material and laser power.

Here are some examples:

– Aluminum. Light, corrosion-resistant, relatively soft metal. It fits for deep laser engraving.

– Copper. This metal has high thermal and electrical conductivity. It is ideal for printed circuit boards. It is very easy to engrave. To get color marking you need precise laser parameters.

– Stainless steel. It is an endurable and wear-resistant material. It fits for engraving and color marking.

– Zinc. It is corrosion-resistant and easy to engrave. Black marking is also possible.

– Titanium. It is a very hard metal and is widely used in the medicine and space industry. Only very powerful lasers are able to engrave it. Color marking is easy to be done.

Laser plus metal. What will come of it?

Here, we’ll tell in detail what happens to the metal surface when the laser beam, generated by a laser machine (a DPSS or diode laser) and focused by a lens, hits it. The laser point or spot when focused decreases to a tiny size of a few microns. The entire energy of the beam concentrates on this point. When the beam hits the processed surface, metal, in our case, it transfers the pulse energy to the molecules of the metal resulting in heating of the metal. Heating, as we know, is accelerating the movement of molecules.

Various interesting processes based on a number of factors start to take place. Thus, a 10 Watt DPSS laser engraver makes an embossed engraving on an aluminum surface without changing its color at a moderate speed and power. The same device (a 10W DPSS laser) at high power of 90% and 400 mm/min speed makes a black or dark gray engraving on copper, zinc, brass, or bronze. A 30 Watt Raycus can cut aluminum, iron, zinc, copper, up to 1 mm thick at the maximum power and speed with many passes. To increase the processing speed you need to have a galvanometer option (Sino-Galvo SG7110).

With high power, you will get a black or dark gray engraving on copper, zink, brass or bronze. A 30 Watt laser can cut aluminum, iron, zinc, copper up tp 1 mm thick. For this you need to run the laser with maximum power and speed, doing many passes.

Other methods of metal laser processing

Color marking of metals

As we go further, it’s getting more interesting. Using certain speed and focus parameters, we can make a colored image on the surface of titanium, stainless steel, silver and copper with a 30 Watt Raycus plus a Sino-Galvo SG7110 or with a 10 Watt DPSS Laser Nd:YAG, 1064 nm (due to the tarnishing effect – changing of the metal color when its surface is heated up to a certain temperature). Noteworthy is the capability of the laser to remove rust (at minimal power and maximum speed using a 30 Watt Raycus + Sino-Galvo; or at moderate power and maximal speed with a 10 W DPSS). During this process, the laser beam destroys a rust layer without damaging the metal surface below. The same laser engravers can do metal spray coating. For example, if after rust removal you spray a steel or iron surface with “liquid zinc” and then process the surface with the laser you will get an oxidation-resistant zinc coating.

One more creatively different application of the laser during metal processing is paint removal. You clean a given area of metal and then treat it with chemicals.

Here is an example of this work performed with a 10 Watt DPSS laser engraver.

The processing procedure: a metal workpiece is covered with acetone-soluble paint. Once dry, the paint is processed with the laser. The laser removes the paint according to a given template. The start of template engraving and control of the laser engraver is done via the EzCad or LightBurn program. The parts of the metal free from the paint are treated with dipping liquid (aqua solution of copper sulfate). In a few minutes a coat of copper, 0.2-0.3 mm thick, is formed on the metal surface making an embossed image. It is worthwhile noting that in addition to paint removal the laser is able to clean the metal surface practically from any chemical contaminations such as oil, oil products, resin, etc.

The laser engraver is used for making items of metal. Practical application

How can you use a laser machine in practice? What can you make for yourself and your business?

How to make a color metal engraving on stainless steel – all you need to know.

Here are some examples:

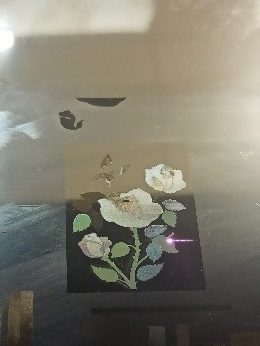

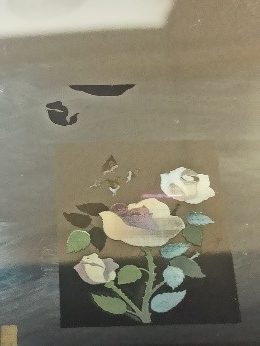

This colored laser engraving was made on AISI 304 stainless steel using a 30 Watt Raycus fiber laser and Sino-Galvo SG7110. The engraving was done with a number of passes in different modes. Every color was engraved separately. The image was divided into separate sections according to the color, which was processed one by one using EzCad.

This method of metal processing can be used for industrial colored marking of metal products and for making souvenirs.

Rust removal from a metal surface

This method of metal processing can be used for industrial colored marking of metal products and for making souvenirs.

Rust removal from a metal surface

This method of laser application is hard to overestimate. Rust and dirt removal from metal equates the laser machine with the sandblaster. Only the laser machine needs neither sand nor a compressor. It is not bulky and much easier to work with. The ability of the laser machine to do metal spray coating makes it indispensable for cleaning and rust protection of auto parts and bodies, various construction units and assemblies of machines, metallic parts of constructions and buildings.

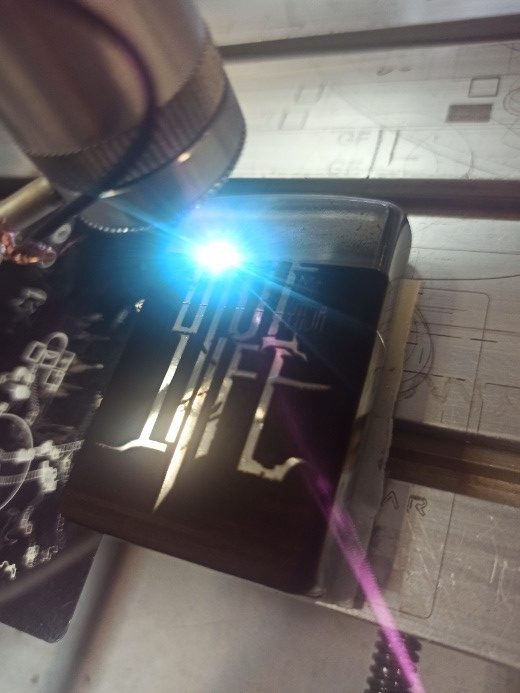

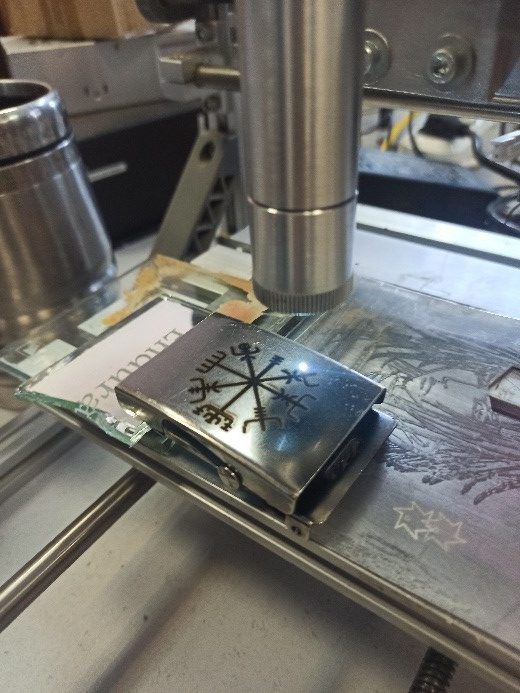

Various engravings on metal cigarette lighters

Different types of engravings on metal cigarette lighters

The laser engraver can easily and quickly turn a simple lighter into a real piece of art. Using a software for vector graphics work you can create any images and individual solutions. The laser will help bring them to life.

This laser ability can be used both for home and for more complicated production.

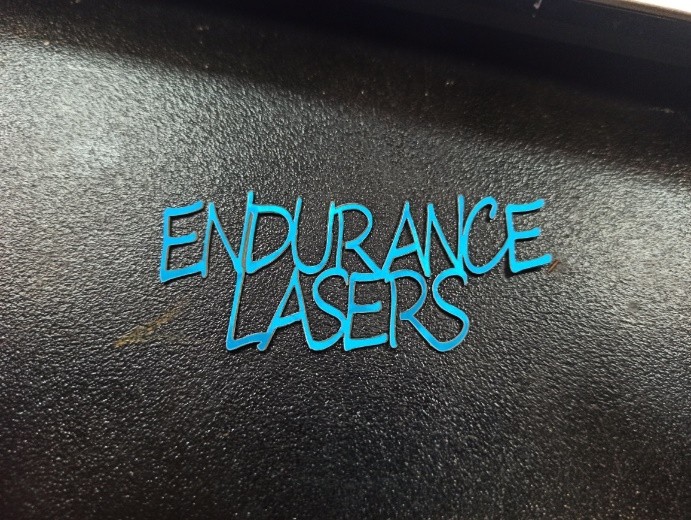

This inscription is cut out of an aluminum 0.2 mm plate.

The laser machine can cut metals. The final result depends on the metal type and thickness, the laser type, and its power. The size of the cutout inscription is 3cm by 5cm. It was made with a 10 Watt DPSS laser. The cutting parameters: power 99%, speed 300 mm/sec, number of passes 10. With a more powerful laser machine, the speed can be increased. This operation can be used for souvenir and promotional items production.

Engravings on various materials

Engraving of various materials

The most popular use of lasers in metal processing is engraving. This operation is easy to come to grips with and you will always find its practical application.

Color engraving on silver

One of the most thrilling applications of laser engravers for metal processing is colored engraving on silver. In this case as well as with stainless steel and titanium engraving, the tarnishing effect is at play. The only discomfiting difference is the engraved image of short life. It does not last and can be easily erased with a drop of water or finger touch. But we are working on methods of silver image protection.

Metal engraving using a thermal grease/paste 15 watt (15000 mW) Endurance “Duos” laser

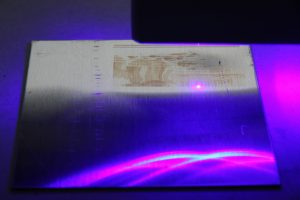

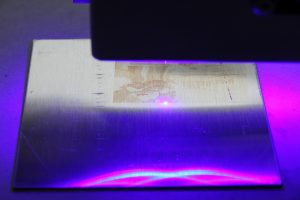

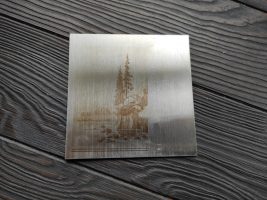

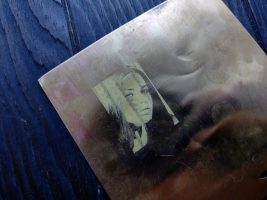

Laser photoengraving on stainless steel

Photoengraving using diode and DPSS lasers

Stainless steel and titanium engraving using 10 watt “Delux” 445 nm laser module

Steel laser engraving using a pulsed diode laser

The Endurance Company offers equipment for laser engraving on samples of painted or anodized aluminum. Thanks to Endurance semiconductor (diode) lasers, you can make marks or memorable inscriptions, engrave various logos or images on your personal items, and other things.

Engraving on metal using 10 watt Endurance laser

To engrave on the surface of painted aluminum, the nominal laser output power should be not less than 3.5 W. To engrave on anodized aluminum, 5.6W or 8W Endurance lasers are recommended.

To engrave on other metal samples, Endurance specialists propose to use electrolysis or electric engraving with the help of a graphite pencil.

Laser etching vs. laser engraving: comparison

Other options of laser applications

Every year opens up new possibilities for laser machines application. As progress evolves, new laser models are being created, which are able to perform operations that have been beyond our reach. Here are some examples of them:

Laser welding of jewelry

Laser photo engraving on metal

Laser soldering of electronic components to a printed circuit plate.

Examples of engraving on metal samples can be found on our website: EnduranceLasers.com in the section “Video instructions”.

For laser engraving, you need to install a semiconductor (diode) Endurance laser on a CNC machine or 3D printer. To know more about this not complicated process go to the video instruction section on our website.

Please remember that direct or reflected laser radiation is dangerous for your eyes and can damage your eyesight. We strongly recommend that you wear safety goggles when working with laser equipment. Do not look at laser radiation without protection.