Diode lasers can help in engine repair.

TAGS: #car #carrepair #auto #autoservice #gasket #gasketsheet #enginegasket #enignegasket #enginerepair

Samples

|  |  |

| Asbestos-rubber sealing sheet

0.5 mm thick Density 2 g/cm^3 | Asbestos-free sealing sheet (Klingersil) TEMASIL FA-MA-1-0

1 mm thick Density: 2 g/cm^3 | Asbestos-free sealing sheet (Klingersil) on the basis of kevlar Gambit FA-AM1-0 1 mm thick Density2 g/cm^3 |

To cut the material we’ll use a 10W “DeLux” laser because it is equipped with a nozzle for air-cooling of the cutting site to avoid scorching of the material. Since the material gives off an unpleasant smell of burning rubber during the cutting process, we’ll do cutting in an enclosed transparent cube with an air extraction system.

Learn more about our sealed chamber (airtight camera) >>>

An Endurance airtight box (sealed chamber) for laser cutting-engraving and other experiments.

Parameters of cutting

Laser power: 100%

Speed: 50 mm/min

| Material | |

| 1 | Asbestos-rubber sealing sheet |

| 2 | Asbestos-free sealing sheet TEMASIL |

| 3 | Asbestos-free sealing sheet Gambit |

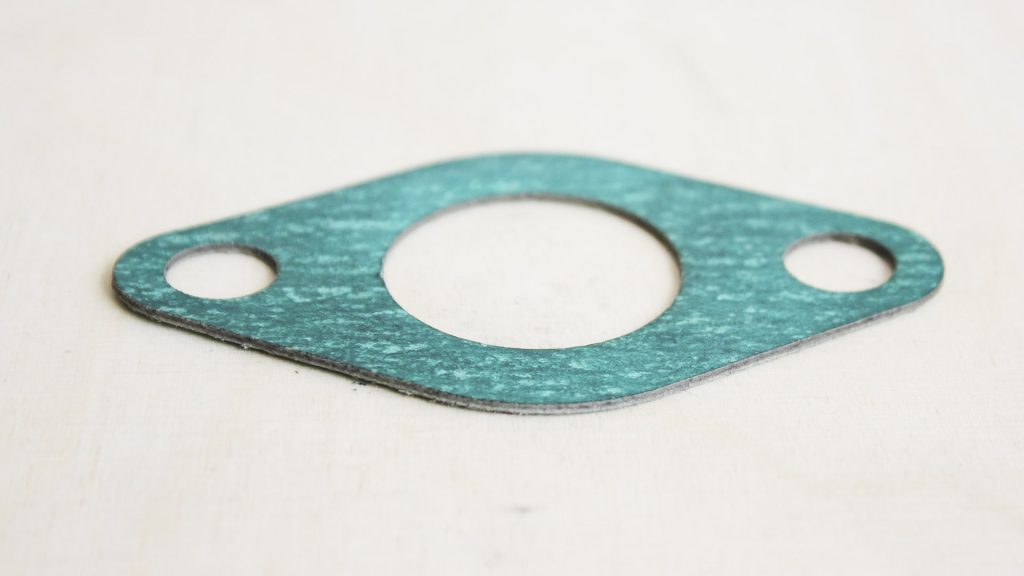

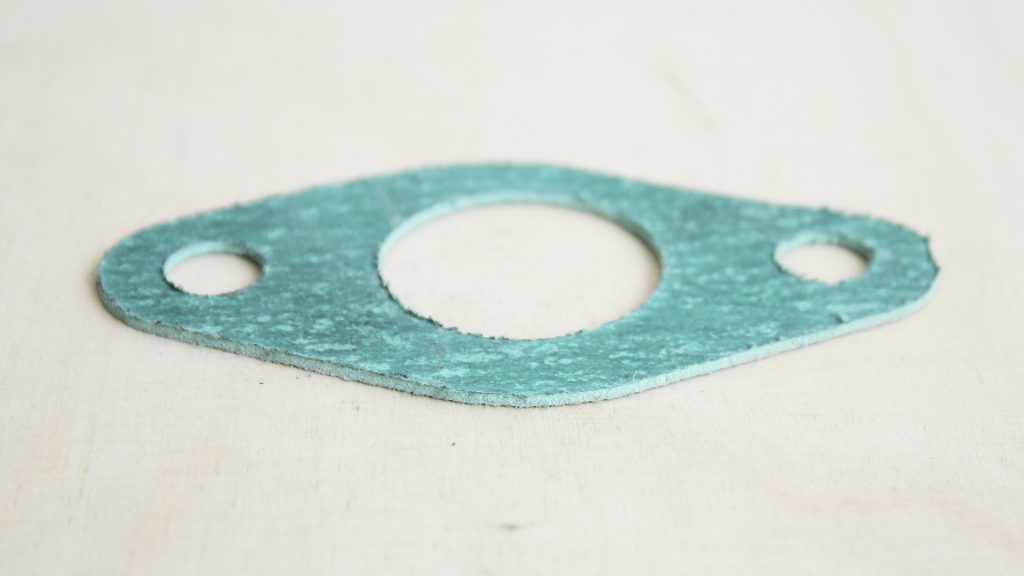

Carbon deposits form along the cutting lines. You should brush it off (a regular toothbrush will do a good job of it).

After brushing, sample 1 might show a fiber fringe along the cutting lines. To remove it you can use fine sandpaper. To avoid this increase the number of passes up to 3.

Despite the similar thickness and density of samples 2 and 3, they differ in the basic composition. Sample 2 is more rigid and needs more cutting passes.

|  |  |

Download g-code examples for CNC 3018 milling machine >>> Gasket_Sheets g-code examples

At the end let’s compare the gaskets made from the Gambit sealing sheet with a milling cutter and a laser.

|  |