Introduction

An aligner is a transparent bite plane resembling a plane for home whitening of teeth or a mouthpiece used by boxers. The only difference is in the material they are made of. Aligners are usually made of transparent hyperallergic plastic while mouthpieces are made of silicone.

Aligners are used for bite correction. The patient changes them gradually until the expected result has been achieved. The dentist together with the dental technician does computer modeling of the dentitions and creates a step-by-step protocol of dentures correction. In accordance with it aligners are cast in the dental laboratory. The aligners differ in the shape and size of the dental arch. The first aligner corresponds as much as possible to the current situation in the mouth cavity. Every subsequent piece has minor changes aimed at the dentures correction. The last one demonstrates a fully corrected dentures model with the optimal position of every tooth, the result that the dentist and patient seek to obtain.

The patient gets a set of 10-40 aligners (depending on the complexity of the anomaly), which he should change every 2-3 weeks. One should wear aligners 24 hours a day, removing them only for hygienic procedures and eating.

Speaking about this method of dentures correction, we need to mention some of the aligners downsides. Firstly, they can improve only slight deformation of the dentition such as light teeth crowding, relatively small tremes and diastemas, slight tilt, or rotation of individual units. Secondly, this treatment takes more time than braces. Thirdly, the cost of aligners is in most cases higher than that of braces, except for bite correction using lingual or esthetic systems.

Stages of aligners making:

- Impressioning

- Mounting a model

- Scanning

- Diagnostics.

- 3D printing of the dentures model

- Aligners molding on the basis of the 3D model. Molding of a polymer plate according to the 3D dentures model.

- Cutting.

Aligner Cutting

We carried on a number of molded aligners laser cutting experiments. Our goal was to make a high-quality cut so that exclude the finishing processing (polishing) of the cut line.

The quality of the cut line is very important because this part of the finished aligner will be in tight contact with the soft tissues of the oral cavity for a long period of time. Any roughnesses of the aligner surface will injure the soft tissues of the mouth.

In the public domain, there is not much information about the material used for aligners. It looks like some kind of transparent plastic; flexible, strong, mouldable, medical-grade thermoplastic, to be exact.

From the very beginning, we expected to obtain the best results using a CO2 laser. This laser has a wavelength of 10,6 µm. This wavelength parameter fits for transparent materials processing.

At first, we tested clean (not molded) plates of the material. It was important to check the material reaction to the laser beam exposure and to define approximate parameters of the laser speed and power.

We found out that the material used for aligners was similar to polyethylene terephthalate in the way of processing. It easily yields to lasing, both cutting and engraving.

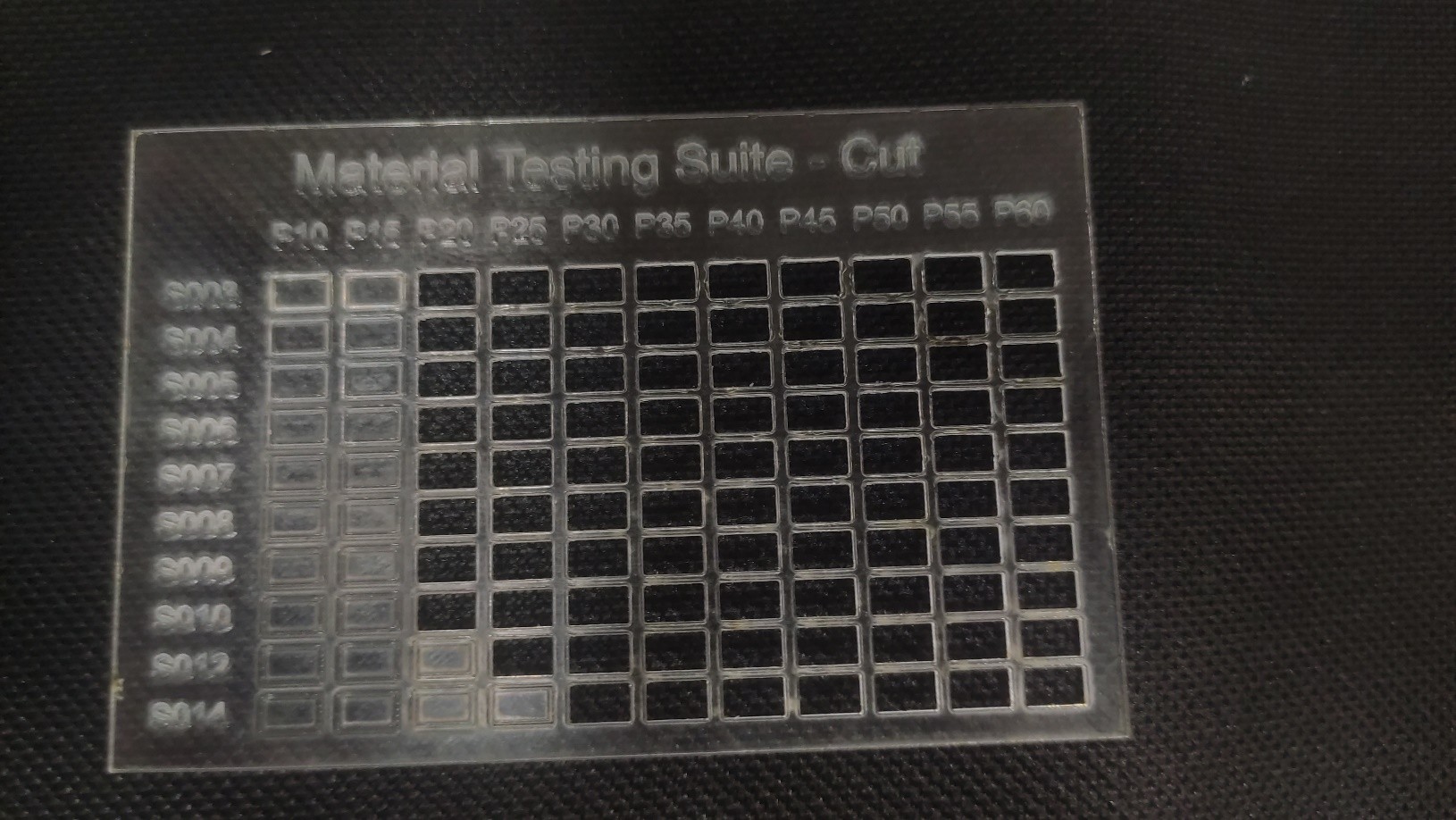

We have tested 110 various parameters. When choosing the best of them we took into account not just the absence of carbon deposits and cokes but also the scale of the material damage under the processed plastic, as the aligner cutting is done on a printed dentures model. In case of its damage, the material of the model will weld on the aligner itself, which is unacceptable.

We obtained the best result at 15% power and 3 mm/sec speed. The cut line was clear and devoid of any carbon deposits or cokes. The material under the plastic looked also practically intact.

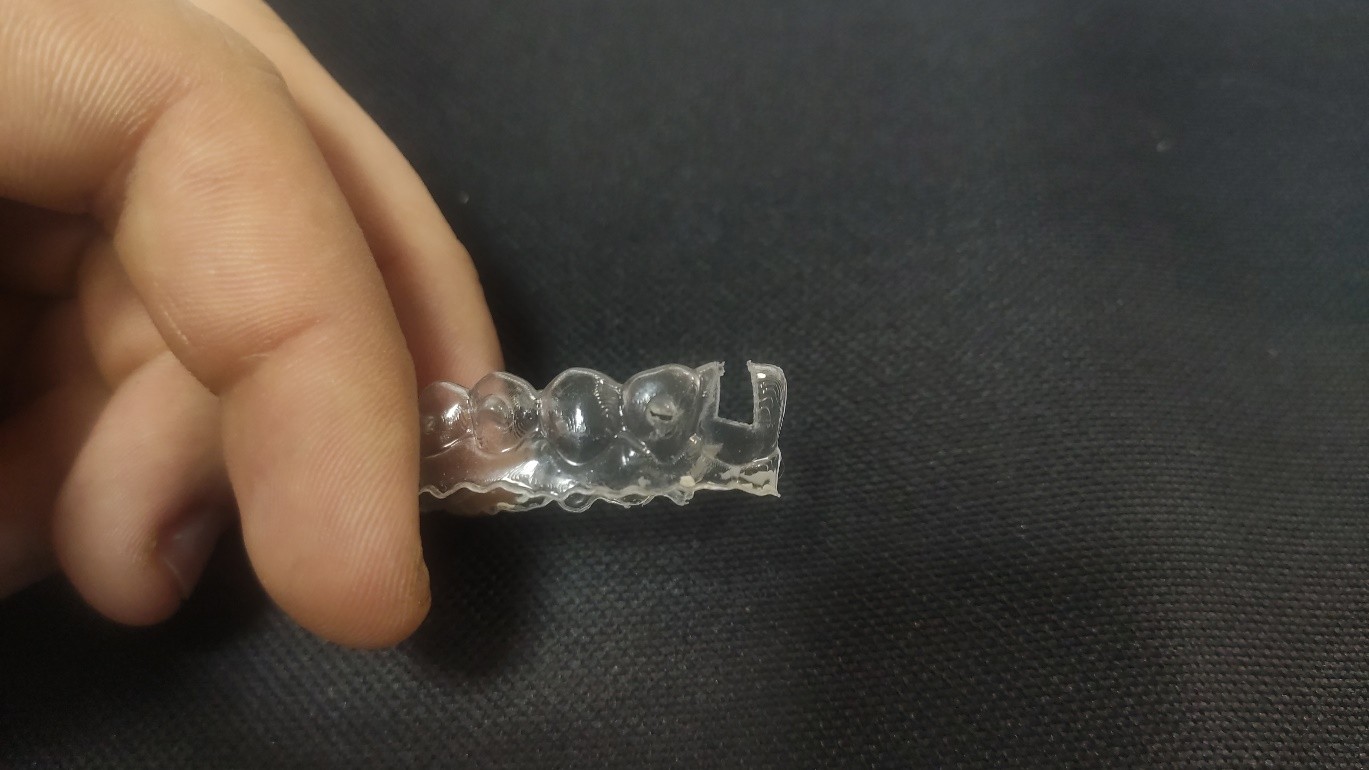

In the following tests, we checked the defined parameters on the molded plastic. As we were limited in our technical means we tried to cut out a simple form on a vestibular surface of a tooth. The result was just the same. We had a clear cut with lines along the edge. This problem is still to be solved.

Aligner Engraving – adding numbers

We also tried to engrave this material. Since every patient needs a set of many different aligners to wear them in a certain sequence, it is important that the patient know exactly the sequence of the aligners. With this in mind, it is necessary to number every unit.

During our experiments, we tried to engrave a small number on an aligner surface without cutting it through. We managed to obtain an excellent result. The laser is capable of engraving a small number anywhere on the aligner.

For engraving, we used 30 mm/sec speed and 18% power.

Endurance plans to make more tests with aligners!

If you have any questions – you are welcome to ask in our LiveChat!