A real story about 3D Printing

Hello, all this is my story on 3d printing. When I turned the corner of 60 years. I was in hunt of something to do that was creative and interesting. It got into my brain to purchase a 3d printer.

I reviewed a lot of 3d printers looked at the mechanics of all of them I found a few that were of interest to me. I didn’t like the shaking bed modules I could just see the parts falling off of them and flexing as they got taller. I did like some of the design were as the bed was not shaking but it would be moving up and down and some of the designed seemed ridged with good space for printing all sorts of goodies. Simplicity of design with less moving parts came in the form of a Delta 3d printer. It has 3 stepper motor that moved 3 arms that moved the printer head. It gave good height for tall items. One stepper motor for feeding the plastic wire into the headed printer head. I loved the design and purchased my first 3d printer. Noted the local Comuntie college had course in 3d printing it shown how to build a 3d printer and you got one as part of the money your paided to the program. “ I did not take the course.” I purchase a MicroMake 3d Mini Delta printer assembled in and begain the adventure in 3d printing.

Micromake 3D Printer Makeboard Mini Control Board Main Control panel Compatible Ramps 1.4 Support Heated Bed 3D Printer Parts and it had a 32bit mother board. I used Cura software for printing items. I combined the printer and my Dell 17 laptop with USB cable. The printer was supposed to come with Rails and a heated bed but it came with the rails and not the heated bed. So I was printing PLA plastic as it came with samples. I ordered the heated be and it came with an upgraded power supply. I also installed 3 new rods that have magnetic ball joints to keep the print even more accurate.

I searched high and low for some great easy design software and found DesignSpark Mechanical it is a free download and works great. I also purchased a copy of Matter Hackers 3d software. It has a feature were as you can join multiple parts together and print as one. You can save these as a single obj or STL file and load into Cura for printing.

With my new 3d printer and software design program the fun has just begins. A example is I was watching you tube a man was fishing in the ocean and used his drone to bring the line out several hundered yards from where he was standing and released the bait and line with wifi message to drop the line. Wow so what I did is because I have a drone and like to fish when possible. I designed and device that clamps under my drone and brings the line out to were you want to release it. My design was R&D until it worked perfectly with a sight tug on the line it opened intstanly and released the line with out disturbing the drone flight.

So if you can think it and picture it and design it you can 3d print it and test it all from your mine and office place. I have found 3d printing a real handy tool to have If you need something you can make on your own Just do it.

Ok my MicroMake 3d Mini Delta printer was great for many years I designed and printed all sorts of objects for household uses. Noted as many 3d printers bed prep was needed clean and then as a paint need primers so do most 3d printers.

The Chemical you will find very handy is Acetone. Acetone for cleaning the bed it cleans well and drys fast.

Acetone mixed with your 3d filaments in a jar as it dissolves the plastic and becomes a paint solution brushed on your print bed makes an excellent bonding material to keep your item on the bed while printing. Yes, it can be a mess but it is needed for success in most 3d printers. I had several great years with my Micro make 3d mini then the connector to the mother board burned up and damage the board. I went shopping for a new mother board and prices were insanely high but not only that nobody had this board and was selling a replacement board that had the wrong pin counts for the stepper motors. Ouch! So I went out shopping for a new printer to replace my great old printer.

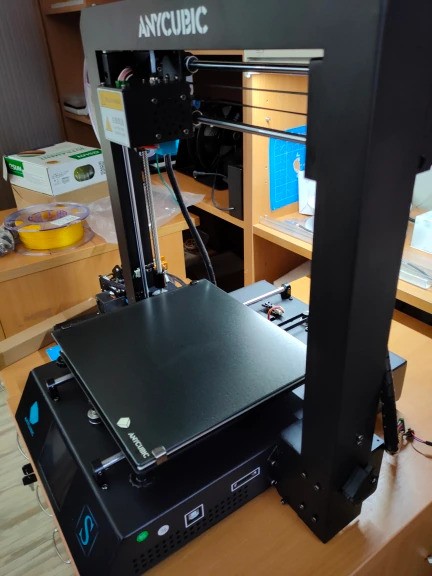

3d Printer #2 I found a super size Delta 3d printer ANYCUBIC N version of the predator.

I did not come the with rails or magnetic rods. It is huge and a heavy strong constructed 3d Delta printer. I purchased an solid old office desk to mount this printer on. I tried the USB connection and it was not working like the Micromake. I tried the sd card system and fell in love with that because it loads the hole program for each print job. It has a huge round heated Bed that needs only to be clean and at the right temp for each type of for each type of filament you use to print with these temps are on the spools of filament print and bed temps from each supplier. It has an auto-leveling system that works great. Also when you set the nozzle height with a peace of printer paper you might fine not all filaments like that clearance. But you can change that on the fly with the touch screen as it is printing layer one. Very nice feature. The heated be is of German design glass coated and dimples thru out keep the layers stuck to the bed untill coolling then most all filements will release with no effort PLA ABS PETG. I have found one filament that really sticks hard is the flexible type.

Boeing Aircraft most likely has the world’s largest 3d printer. The highest percentage of parts in the Boeing Aircrafts today are 3d printed. Wow.

Now if your having a problem with your printing search it on Youtube is a very handy resource.

PLA is ok to print with but it degrades rather fast.

ABS treat with care while printing no drafts air flow in the print area it will cause separations of the layers.

PETG layers stay together but it can be stringy when printing with lasts a long time.

PLA Glow in the dark best use up the role while fresh.

PLA wood prints ok but also will degrade printed objects.

TPU flexible prints well

3d resin printers:

Digital Light Processing (DLP)

Digital light processing is similar to SLA in that it cures liquid resin using light. The primary difference between the two technologies is that DLP uses a digital light projector screen whereas SLA uses a UV laser. This means DLP 3D printers can image an entire layer of the build all at once, resulting in faster build speeds. While frequently used for rapid prototyping, the higher throughput of DLP printing makes it suitable for low-volume production runs of plastic parts.

For more information:

https://www.protolabs.com/resources/blog/types-of-3d-printing/

Resin base printers are used for the dental working of people’s teeth.

They make a mold then scan it with 3d scanner then clean up where needed then put objects into a resin base 3d printer. And the rest is your smile.