The 3D printing technology in 2022 is no longer considered to be something extraordinary. A 3D printer is an affordable device, which you can place onto a table beside your PC monitor and keyboard. For our top 10 overview we have selected the most popular models all over the world both budget-friendly and expensive professional ones. But before we proceed to the description of the models, let’s have a closer look at the features that affect the quality and convenience of printing, and, as a result, its popularity among the users.

For the beginning, let’s discuss printing technologies. For home use most hobbyists choose FDM devices. FDM stands for fused deposition modeling. FDM printers are more common in the budget-friendly segment. A little less popular are photopolymer devices. They work on the basis of laser stereolithography (SLA). Here, every layer of the liquid photopolymer material grows hard under the influence of a laser beam or a powerful LED. The Multi Jet Fusion (MJF) technology also involves layer-by-layer application of melted material followed by UV curing. There is also a 3D printing method involving the use of a powder material. It is evenly applied to the print surface, then the necessary areas of the product are hardened under the selective laser radiation. FDM and SLA technologies are most popular with 3D printer users.

SLA 3D printing

Making your own car part (LEXUS GS 300 headlight washer)

Another important feature is a 3D printer design. The end result of 3D printing depends on the kinematic properties and the table type. Next, we’ll turn our attention to the print head and the plastic feed mechanism. Besides, buyers take into account the print speed, print layer height, and materials to be used for printing. Additional options that make work easier, such as WiFi and a self leveling table, are also very important for many 3D printer users.

Flying Bear Ghost 5

Printing technology: FDM/FFF

Number of extruders: 1

Print area: 255×210×200 mm

Thread diameter: 1.75 mm

Table heating temperature: 60-110 °C

Maximum printing temperature: 260 °C

Printing speed: 20–150 mm/sec

Material type: PLA, ABS, PETG, TPU, HIPS, Wood, nylon etc.

Price: $400

The FDM printer from the Chinese company Flying Bear is supplied as a model for assembling. It is quite popular among those who like to assemble devices with their own hands. The kit comes with a video assembly guide. This is a top table 3D printer, 388х337х411mm in size. The plot area size is 255х210х200 mm.

The kinematics of the device is of the «Makerbot» type. The table moves along the Z axis, the print head moves along the X and Y axes. The table moves along the Z-axis due to an 8 mm double-thread screw. Two 10 mm shafts serve as guides that pass through the linear bearings of the table platform. The screw is attached to the split muff coupling of the X-axis motor.

На Flying Bear Ghost 5 is equipped with an FBG5 print head with a popular E3D V5 model of the hot end. Besides, this Flying Bear version has a modified forced-air cooling system. The users of the previous models complained on a poor air cooling and invented their own modifications to enhance it. Now the air flow is rather powerful, which thwarts plastic drips, still some printer owners offer to improve the air cooling system of this model.

The table is made of hardened glass covered with a Magnetic Mat. The table platform not only heats up and cools down quickly enough to the required temperatures but also withstands high heating.

The electronic stuff is at the base of the 3D printer. There is a 24V/300W power supply unit, a 32-bit FlyingBear Reborn v2.0 control board, drivers and a Wi-Fi module there.

The Flying Bear Ghost 5 is equipped with ТМС2208 drivers; that makes its operation less noisy as compared to the previous models. Now the working printer will disturb neither your office mates nor your home people.

The 3D printer has a built-in 3,5″ color touch screen display. The Flying Bear Ghost 5 control is very easy. Its menu displays standard options, such as extruder and table heating adjusting, table calibration, movement along axes, plastic replacement. Besides connection via WiFi, this model has one more useful option: input of the G-code using a separate console; this allows performing of the necessary tasks absent in the menu.

The dual-drive filament feeding mechanism is installed on the back side of the printer. This means that the extruder is of a bowden type. The feeding is done by two cogs. The transparent mechanism case allows you to see the bar is moving through. Here, there is also a filament end sensor. It not just warns about the lack of the material but also allows you to continue the process from the place where it paused immediately after the filament reel replacement. The printer has also a function to continue printing from the same place in case of the power loss.

This 3D printer is compatible with the most popular slicer Ultimaker Cura. But before setting to work, you need to configure the printer profile in the slicer. For this, it is ncessary to enter the start and finish G-code. The Flying Bear Ghost 5 works with Windows, Mac OS and Linux.

https://www.youtube.com/watch?v=PWbSERM26uM

Reviews:

Dmitry: I recommend it. It’s a good alternative for a beginner in 3D printing. There are a lot of guides, instructions and hacks for this model. Besides, you can always upgrade and modify it darn well. Then its potential concerning the printing quality will be comparable with expensive printers.

Drumstickmaestro: This is a good, durable printer for home. High-quality parts, user-frindly, easy assembling (it took me only an hour and a half). The printing quality is decent for this printer class. Very appealing is the possibility to print using WiFi. Absolutely useful! The bottom line is to have a flash drive in the printer. Strange as it may seem, but it is less noisy than my previous printer. It is so quiet that you can easily stay in the same room going about your other work, or speak on the phone without any discomfort. Good configuration. It looks, as if the printer has been much improved. This product really works out of the box. The location of the filament reel is not very convenient (you have to turn the device). The first layer does not adhere well (on small parts).

Adding the 10 watt Delux laser on Flyingbear Ghost 4S (3D Printer)

FlashForge Adventurer 3

Printing technology: FDM/FFF

Number of extruders: 1

Print area: 150х150х150 mm

Thread diameter: 1.75 mm

Table heating temperature: до 100°C

Maximum printing temperature: 220°C

Printing speed: до 100 mm/sec.

Material type: ABS, PLA

Price: $530

The next 3D printer on our top list is the Adventurer 3 from one of the most large-scale manufacturers of 3D printers, the FlashForge company from China. Belonging to the low-budget segment, nonetheless, this model is full of many various options, which are usually found in professional devices.

The printer design asserts its safety. This device is a closed box. This is done for a reason, since the printer is designed for children and educational purposes. More than that, the print area is protected from curious pets. The sides and the front panel are transparent, so that you can watch the printing process. With this in mind, there is also a LED backlight near the nozzle. But that’s not all, you can watch the printing process from far off, since the printer has a built-in-camera.

Though the device is not small in size – 388х380х405 mm – its plot area is only 150х150х150 mm. Inside, it has a closable filament spool compartment, but not every brand spools fit in. In this case, it is necessary to think of an external accessory to hold plastic spools.

The FlashForge Adventurer 3 works with PLA and low-temperature ABS. This is due to the low maximum operating temperature of the extruder, up to 220 degrees.

As for its kinematics, the printer operates on the Prusa principle: two trapezoidal screws are located on the Z-axis. The FlashForge Adventurer 3 has an option of table heating and a special sticker on the print surface, due to which it is easier to remove the finished product. The table itself is also removable.

This device has a bowden bar feeder. The filament end sensor is located sideways inside the motor. We have already mentioned safety, for this purpose, the filament feed mechanism is protected by a plastic case to avoid burns.

The Adventurer 3 is controlled by means of the touch screen. The device uses the FlashPrint software, which has print profiles, the function of layer slicing, and manual fine-tuning options. The printer is equipped with a wi-fi module, in addition, you can download files from the cloud or via a flash drive.

Reviews:

Alien: This is a great printer for home. Suits for a child. You bring it home, take it out of the box, plug it in and set it like a TV. I think, the latter is more difficult to set up. There are pictures in the manual. That’s it. You are ready to print. Straightaway! No assembly or fussinng about. No calibration or setting the plastic temperature. You just import the model into the program and run the printing process. And a miracle happens!

Guest: In general, this is not a bad printer for beginners. It works rightaway out of the box… Almost. If it were not for a not so friendly software. It spoils the picture. With a 5 year printing experience, I sometimes was dopy and could not do simple operations available in Cura and Polygon… The printer is very slow. Other printers with the same advertised speed work twice as fast. Working twice as fast, they, nevertheless, place layers better, creating a better-quality model.

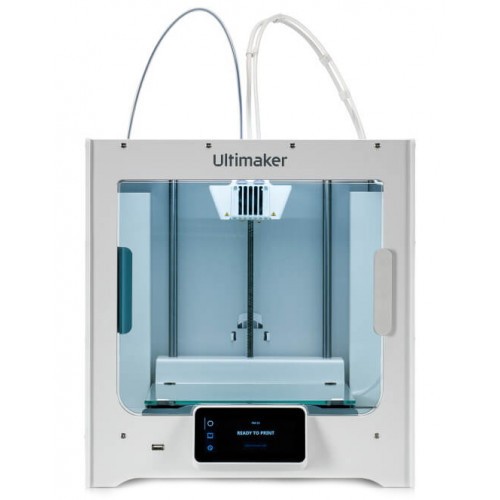

Ultimaker S3

Printing technology: FDM/FFF

Number of extruders: 2

Print area: 230х190х200 mm

Thread diameter: 2.85 mm

Table heating temperature: 20-140°C

Maximum printing temperature: 280°С

Printing speed: 30-300 mm/sec

Material type: ABS, PLA, PVA, nylon, etc.

Price: $6200

The Ultimaker S3 is a device of a premium class that is seen by its price. It has an elegant, intellectual design. This professional 3D printer from a Dutch flagship in 3D printing belongs to the FDM type and has a print area of 230х190х200 mm.

The device frame is made of composite material, and the sides of semi-transparent plastic. The frame is light weight but durable that is important as all the mechanical parts are attached to the sides.

The main advantage of the Ultimaker S3 is a unique possibility to print using two material simultaneously. This is not only about two color printing but also about two different materials. For example, it is possible to print supports with soluble PVA plastic. Quickly replaceble Print Cores are installed in the print head. Ultimaker produces a range of its own diverse materials, including abrasives. The printers of this series prints perfectly with these materials. Their spools have a NFS chip, which the machine detects and the material settings are automatically recognized. The device supports also third-party filament, It is important to know that the machine works with an atypical diameter of the bar 2.85 mm.

Ultimaker used a non-standard kinematics with crosswise arranged shafts, which was called scissor. The X and Y-axes are driven by GT2 belts and Nema 17 stepper motors. The Z- axis has a free end trapezoid screw. Thanks to it, the table moves, the frame of which is made of cast aluminum with replaceable adhesive plates. Despite the presence of table clamps, it’s automatically levelled.

This printer is equipped with a bowden extruder. The spool mount is installed on the back side of the printer. The model has a filament flow sensor. If the plastic runs out or an error occurs, the printing process stops. The upgraded system allows you to change the plastic spools very quickly.

The printer has a 4.7-inch color touch-screen display that allows you to easily and quickly control the device, adjust the printing speed, temperature, etc.

To work with Ultimaker printers, Ultimaker has developed the software Cura. In addition to the standard wired connection, a smartphone application has been created for these purposes. You can send the model to the device using a wire, wi-fi or a USB flash drive. Notably, printing can be monitored remotely; a camera is installed on the device.

Reviews:

IskenAsana: One of the top FDM 3D printers with two extruders. There’s a possibility to print with two filaments: multi-color or with soluble supports HIPS and PVA for complex models. The printing speed is rather high due to the use of filaments, 2.85 mm thick. When printing at a high resolution of 20 microns, the surface of the printed model is very smooth, so there’s no need to sand it.

It’s better to put the printer in a garage or at non-residential premises, as some filaments are bad for health, and the machine produces too much noise when operating.

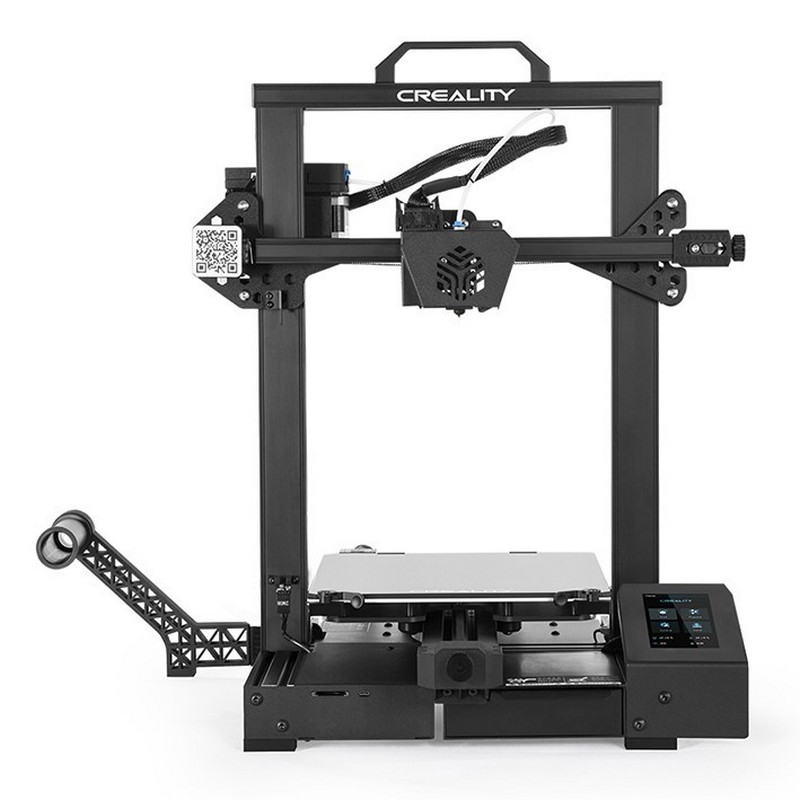

Creality3D CR-6 SE

Printing technology: FDM/FFF

Number of extruders: 1

Print area: 235х235х250 mm

Thread diameter: 1.75 mm

Table heating temperature: up to 110 °C

Maximum printing temperature: 260 °C

Printing speed: 80-100 mm/sec.

Material type: PLA, TPU, PETG, ABS, Wood

Price: $400

The low-budget desktop FDM 3D printer from the Chinese developer and manufacturer Creality made it to our list too. The model with a build area of 235x235x250 mm is sold almost fully assembled; it will take a few minutes to complete the assembly yourself.

At first glance, you can see that this model has an open design. The kinematics works according to the Prusa principle. The two trapezoidal screws are attached to the motor and tied together with a belt to avoid disruption in timing.

The printer frame is made of aluminum material. The filament spool holder is attached to the frame on the flank. The developers endowed the printer with a built-in drawer for storing accessories, which was appreciated by users. This device has a 4.3-inch touch screen display, where there are all the necessary options for managing the printer.

The table with heating tracks is also made of aluminum and is not insulated. There is a removable cover on the table. Leveling is performed automatically. The table supports the heating temperature up to 110 °С.

The Creality3D CR-6 SE has got a bowden filament feed-in system, where the print head is located separately from the extruder. This made it possible to lighten the head and improve the quality and printing speed. However, this system reduces the ability to work with soft materials. The model supports such types of filament as PLA, TPU, PETG, ABS, Wood. The maximum heating temperature of the Creality3D CR-6 SE nozzle reaches 260°C. The optimal printing speed is 80-100 mm/sec. It should be noted that the thickness of the layer during printing varies, with a minimal thickness of 100 microns. This model has an improved airflow; it is also easy to replace the components of the print head: nozzles, fuser, etc. The Creality3D CR-6 SE has Trinamic silent drivers (up to 5dB), which allows you to use the printer at home or at work without disturbing others.

Just like in the models discussed earlier, this 3D printer has a photoelectric filament end sensor that gives a signal if the plastic is running out.

The Creality Slicer software was created for Creality devices, but this printer model supports not only its own software, but also popular slicers, such as Simplify 3D or Cura.

Reviews:

Radmir: The printer is 80% assembled, it remains only to put the stand, tighten 4 bolts, connect the cables. It prints perfectly out of the box. I did not flash anything. It doesn’t seem to be needed.

Igor: No need to adjust the table, since there’s an auto leveling system. It uses TPU plastic. Very quiet drivers. Magnificent printing quality if the plastic is good. There’s a handle and a holder, though you can print them, a print area backlight, a touch screen display. The printer fans are rather loud . And it makes an unleasant bleep. But you can stop it by sealing up the speaker.

Creality3D Ender 3

Printing technology: FDM/FFF

Number of extruders: 1

Print area: 220x220x250 mm

Thread diameter: 1,75 mm

Table heating temperature: 110 °C

Maximum printing temperature: 255 °C

Printing speed: 180 mm/sec.

Material type: ABS, PLA, TPU, PETG

Price: $210

Here we have another representative of the Creality company, but this is a budget kit for assembling that will be interesting for an experienced printing worker or a curious beginner with a wealth of technical knowledge.

The Creality3D Ender 3 has an elder brother the Ender 3 Pro; this is a DIY kit too, but it additionally includes a removable magnetic table cover and a more powerful power supply unit. For those who are not interested in assembling a constructor, the manufacturer has produced the Ender 3S model. This is a fully ready for printing device.

As we see, the Creality3D Ender 3 is also a printer with the Prusa kinematics and a typical for FDM printers appearance. This model frame is made of aluminum profiles and has an open design. Trapezoidal screws put the Z-axis into action. The electronic stuff is inside the bottom part of the device that makes it more stable. The printer is not very quiet.

A built-in display in the base of the 3D printer shows the info about the nozzle and table temperature, printing time of the model and the printing progress. It does not have a touch-screen and is controlled by an encoder.

This model has a table with an ultrabase, 220×220 mm in size. It does not have a magnetic cover, but there are no problems with adhesion either. The calibration of the table is carried out manually at the corners with a sheet of paper; for this purpose, there are special large nuts under each corner of the table.

The Creality3D Ender 3 is equipped with an MK10 extruder, providing bowden plastic feeding, which, as we have already stated, makes it possible to increase the speed and improve the printing quality, but at the same time makes it more difficult to work with soft plastics. The printer supports such materials as ABS, PLA, TPU, PETG. However, you need to take into account that due to the open design, printing of large parts with ABS plastic will be problematic without an additioanl thermochamber. The printing speed of the Creality3D Ender 3 is 180 mm/sec. And the minimal thickness of the layer is 0,1 mm.

This printer works with the familiar slicer from the Creality company, with the set of functions similar to the Cura software. The information transfer to the device is done via either USB or a SD-card.

Reviews:

Zlopay: Affordable, user-friendly, a vast community, not expensive, easy to repair and solve issues, the best among printers with the same kinematics. The standard model is noisy, 80dB. It won’t take you long to find all the necessary information, community, modifications, to learn to maintain the printer, to join the 3D printing community.

UnitAlex: Not expensive. Prints out of the box. Reliable. I made up my mind to purchase an Ender-3 at the beginning of 2019. At first I was choosing for a long time, reading, learning, studying the difference between the 3D printer kinematics, guide rails, hot ends,etc. In general, I plunged into the materiel. The choice was: Ender-3 vs Anet a8 vs i3 mega. After all the wanderings, views on YouTube, reading reviews, I chose the Ender-3 and never regreted it! The Ender-3 assembling is not difficult, since there is a detailed instruction in the kit and a lot of reviews and videos on the Internet. In general, the printer is very popular. You can always find answers to your questions.

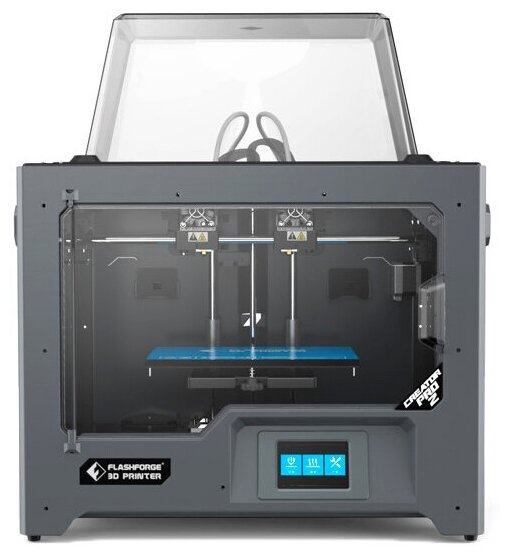

FlashForge Creator Pro 2

Printing technology: FDM/FFF

Number of extruders: 2

Print area: 200х148х150 mm

Thread diameter: 1.75 mm

Table heating temperature: 120 °C

Maximum printing temperature: 240 °C

Thread diameter: до 100 mm\sec.

Material type: ABS, PLA, HIPS, etc.

Price: $850

The next name from our list is an FDM printer with two extruders developed by the Chinese company Zhejiang Flashforge 3D Technology. It’s not a budget model, but, nevertheless, this device is not too expensive in comparison with other printers of this category.

Notably, the printer has not just one but two print heads with two hot ends fastened to the Y-axis. The IDEX system makes it possible for the two print heads to move along the X-axis independently of each other. This design provides opportunities not only for printing with two colors or materials, but also for the parallel printing of two identical or mirror products. However, it is worth noting that the build area is 200×148×150 mm, and with parallel or mirror printing of two parts, it will be reduced to 80×148×150 mm and 95×148×150 mm.

The FlashForge Creator Pro 2 supports printing with PLA, HIPS, ABS, as well as with soluble PVA, which is perfect for printing support structures using duel-head printers. The maximal hot end temperature is 240 °C and that of the table 120°C. This model has direct extruders installed above the print heads. The maximal printing speed is 100 mm\sec. There’s also a filament runout sensor.

Dual-extruder printers often face a problem of filament drips from an idle hot end. The developer has seen to it. The FlashForge Creator Pro 2 has a residue-scraping system – two attachments to remove excess material. The idle extruder moves perpendicular to the head movement scraping the plastic residue.

The device frame is fully closed. It is made of metal, the front door and the removable top cover of transparent acrylic. This solution helps print large ABS-plastic parts nonshrink, as a closed chamber is created in the build area. You can remove the top cover when printing with PLA filament for a better ventilation.

The filament spool holders are located on the back side of the machine that is not very convenient, as some users think. The table is equipped with a paste-on BuildTak mat for a good adhesion.

The printer works with its conventional software Flashprint, developed on the basis of Cura, and has a USB interface and a card reader.

Reviews:

Ruthger Hauer: Take it, if you need a printing line. Prints great if configured correctly. The closed case allows you to get rid of odors, and if you make a good sound insulation, you can print at home. Among the advantages of the printer are a closed body, excellent positioning and Flax / PLA printing; parts are easy to replace, a fairly frequent update of the slicer on the manufacturer’s website, and fast printing. The disadvantages include printing only through an SD card, the noise level is 60db, the difficulty of leveling the table with three bolts.

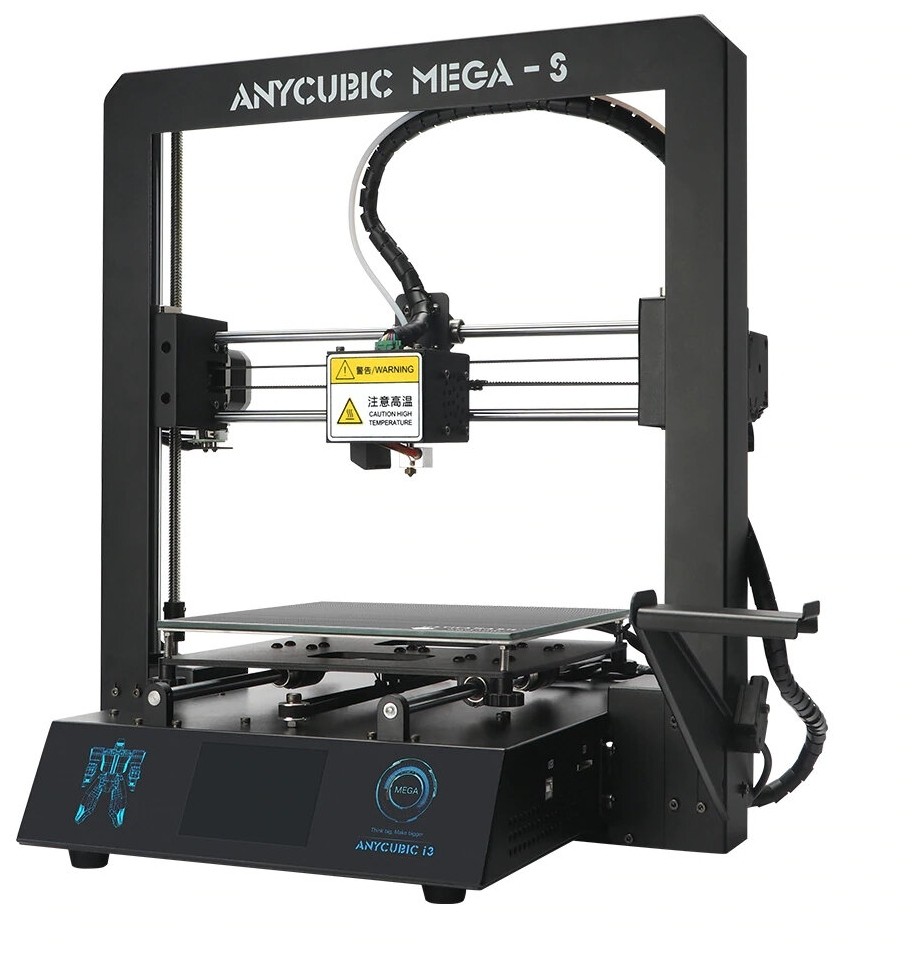

Anycubic Mega-S

Printing technology: FDM/FFF

Number of extruders: 1

Print area: 210x210x205 mm

Thread diameter: 1.75 mm

Table heating temperature: 110 °C

Maximum printing temperature: 260 °C

Printing speed: 20-100 mm/sec.

Material type: PLA, ABS, HIPS, Wood

Price: $230

One more popular model for home and office. This is a reliable low-budget printer from the Chinese Anycubic company with a print area of 210x210x205 mm. On purchasing it, you will have to finish its assembling, but it will not take much of your time or efforts, given that you’ll have to tighten only 8 screws and connect 3 wires.

This printer has a rigid metal frame that gives the device stiffness. The Trigorilla 1.1 printer motherboard is located inside the printer body. Stepper motors function with A4988 drivers, which are reliable but rather noisy. The positive side is that they are removable and can be replaced by quieter ones.

The Anycubic Mega-S kinematics belong to the Prusa type. Let’s have a closer look at the device. The print head moves along the X-axis with the help of two 8mm-shafts, installed on two linear bearings. The Y-axis is responsible for the table (??? Или все же ось отвечает за печатный стол???). ( The print table is in charge of the Y-axis. За ось Y отвечает печатный стол (??) It is driven by two guides with three bearings. The table is made of aluminum and has a glass cover – ultrabase. The platform is heated up to maximum 110º C. The leveling of the table is done manually by means of screws. As for the Z-axis, the head is driven by two motors, two guides and two trapezoidal shafts.

The Anycubic Mega-S is equipped with a bowden extruder made by analogy with Titan. This design makes it possible to improve the accuracy of the material feeding and to ensure high-quality hold-down of plastic. This ptinter model has also a filament flow sensor, which suspends the device operation until you replace a filament spool.

There’s a touch-screen display on the front panel of the device that allow you to control options, such as automatic pre-heating, nozzle tempreture adjustment, printing speed, home point return, plastic loading and unloading, etc. But you cannot set up speeding-up and air-flow parameters.

You can send the model for printing using USB-wires or a CD-card; there’s no wi-fi module. As a slicer, the users of this printer are offered an outdated version of Cura, which doesn’t have a full set of advanced functions. Since the Anycubic Mega-S identifies the standard G-code for the Marlin firmware, any other slicer will work well too.

Reviews:

Alexey: Great printer for this money! The package includes everything and even more: a spare hot end, for example. Of course, after assembling, you need to tighten the belts, and if you use cheap plastic, you need to modify the cooling system (the original plastic prints perfectly without modification). Shafts are no rails, of course, but I perfectly understand the cost of a printer on rails, and the print quality of the Mega-S suits me very much. Speaking of cons, the original firmware does not maintaing printing from the computer, but, by and large, this is not necessary. There may be interruptions from the computer if it goes to sleep or refreshes.

Night a.: An amazingly enduring printer that combines cheapness and an excellent printing quality with all plastics, except for high-temperature ones. It’s been working for almost a year now, almost 24/7. A lot of efficient improvements have already been invented and posted on the Internet. After modification, it is hardly inferior to expensive printers in speed and quality

PICASO Designer X PRO

Printing technology: FDM/FFF

Number of extruders: dual

Print area: 200х200х210 mm

Thread diameter: 1,75 mm

Table heating temperature: 150 °C

Maximum printing temperature: 410 °C

Printing speed: up to 100 cm3/h

Material type: ABS, PLA, FLEX, NYLON, ASA, ABS\PC, PET, PC, PVA, HIPS

Price: $3935

The next one on our top list is a professional FDM printer with a dual extruder from the Russian company PICASO 3D.

The first thing that catches your eye is the dimensions of the device. The dimensions of the printer are 492x430x390 mm and the weight is 16 kg. The material for the body is composite aluminum, the door is made of translucent plastic material. Some parts of the device are made of ABS plastic. Despite the large dimensions of the printer, its build area is 200x200x210 mm. A significant area inside is occupied by a chamber for installing two spools of material.

The electronics are located at the base of the printer. The motherboard developed by the company is based on the ARM CORTEX M4 processor.

The printer works on the principle of the CoreXY kinematics, that is, two motors drive two belts. Since there is no motor installed on the X-axis, which reduces the weight of the machine, printing at high speeds has become possible. In contrast to the classical principle of operation of devices with such kinematics, in the model under consideration, the contour of the X-Y axes is fixed not in the printer case, but on a separate steel frame. Typically, such printers have cylindrical shaft guides, steel rails are also installed here. The design upgrades the positioning accuracy and the speed of the print head, in addition, the system is more wear-resistant.

The printer is not the quietest, in operation, the noise level can reach 55 dBA.

Another unexpected detail is the absence of end switches. To determine the coordinates of the head, the printer uses feedback drivers.

As for the extruder, this model has a rotary one, for which the JetSwitch technology has been specially developed. It implies that when printing with two materials, the inactive nozzle is not just retracted to the side, but hides inside the housing. This mechanic prevents material leaking from the inactive nozzle, and also improves the printing quality at high speed with two materials. The printer is equipped with all-metal thermal barriers, due to the work at high temperatures. The maximum heating of the nozzle reaches 410 degrees. This allows you to use not only popular materials, such as ABS, PLA, PVA, HIPS, but also expensive ultra-refractory engineering plastics, such as SBS, AEROTEX, ULTRAN and PEEK.

The table moves along the Z-axis with the help of a 12 mm screw and two 12 mm shafts. A removable magnetic attachment is installed on the glass base of the platform, which makes it easier to remove large items from the surface. The table holds the temperature up to 150°C.

The printer display is not very good. It’s monochrome with a yellow font color and is controlled by an endcoder. The menu has both standard options and various settings for each nozzle, automatic cleaning of the print head, the filament spool drying on the table, night slow-speed printing mode.

The device interacts with the Polygon X slider, which already has the standard profiles with the settings for work with soluble supports, for example. The ready model can be transferred to the printer via a LAN-connection or a flash drive.

Reviews:

Yevgeniy: Been using this printer for a month already. Have tried printing with pla, petg, nylon. Runs faultlessly. The print quality is suitable. Many systems of control. Not a bad set of tools, including a 32 GB flash drive. Perhaps, somebody will find it too loud and too expensive.

Dopelngager: The positive side includes an excellent print quality and printing speed, failure sensors, auto-leveling, the ability to print with refractory plastics. When the nozzle is clogged, it tries to push through the plastic on its own. The printer can print over the network and manage a whole stack of printers from this firm, roll out one job to a bunch of printers.

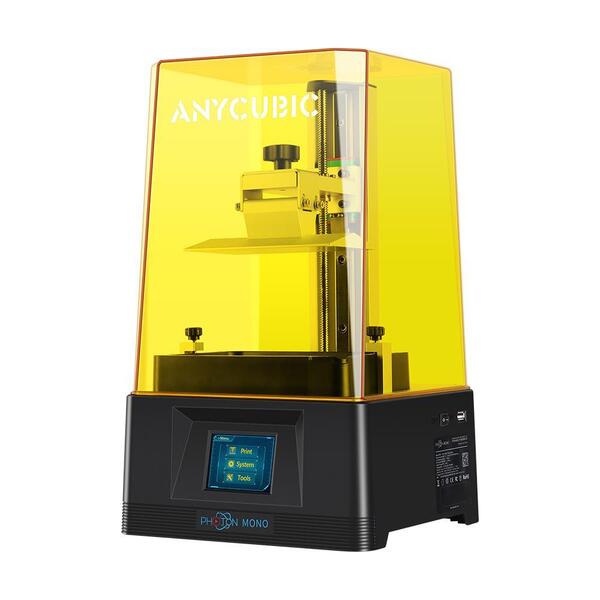

Anycubic Photon Mono

Printing technology: MSLA

UV wavelength: 405 nm

Print area: 165×80×130 mm

Material type: photopolymer resin

Light source: LCD/LED, diode matrix, 405 nm

Printing speed: 50 mm/h

Price: $250

Here, we have a low-budget compact photopolymer printer from Anycubic. It works on the MSLA technology, that is, the resin is exposed to a UV radiation, but between them there is a mask of LCD LEDs. This model is notable for the fact that it has a monochrome 2K matrix. This solution significantly increases the printing speed. So, standard materials need about 2 seconds to harden.

The printer has a plastic housing with a removable, bright yellow UV-blocking case. Below it, on the build platform, there is a tray for photopolymer material. It is also made of plastic and has measuring notches. At the bottom of the tray there is a replaceable FEP film, which wears out rather quickly. The build platform has slopes designed to prevent the platform from the resin residue accumulation. The platform levelling is to be done manually. Despite the small dimensions of the device, its build area is 165×80×130 mm.

The Anycubic Photon Mono supports photopolymer resins with 405 nm UV- curing. It is worth noting that the material is not supplied with the purchase of the printer, so it is worth ordering it separately. It is sold in containers of 0.5 kg and 1 kg.

The printer is equipped with a UV-blocking cap sensor. If you remove the cap when printing, the process will stop and a beep will be sounding until the case is back.

The Z-axis is driven by a linear guide, this allows for high-quality printing without stripes and failures. The layer is 10 microns thick, the maximal printing speed is 50 mm/h. The photopolymer printer allows for clarity in printing and high precision even in tiny details. The printer works quietly, and the users do not report any smells.

The Anycubic Photon Mono is controlled via a 2,8-inch touch-screen display, in the menu of which you will find regular printing setting options for a MSLA-device.

The Photon Workshop is a standard slicer for printing a model on this device. Here, you can generate supports, form cavities, split the model. The finished model is sent to the printer via a USB connection.

Reviews:

Oleg: An excellent quality of the materials out of which the printer is made, beautiful, low-noise when printing, intuitive instruction and software. I gave it to my son for his 17th birthday. He loves it! When buying, order as well a can of photopolymer resin, it is not included in the kit, but it will be very useful.

Phrozen Sonic Mini 4K

Printing technology: MSLA

UV wavelength: 405 nm

Print area: 165×80×130 mm

Material type: photopolymer resin

Light source: LCD/LED, diode matrix, 405 nm

Printing speed: 50 mm/h

Price: $250

The photopolymer 3D printer of the Taiwanese brand, Phrozen Sonic Mini 4K, follows on the rear of our review. The company also specializes in the production of printers that ideally fit for printing parts used in dentistry and jewellery.

The printer is shipped fully assembled and ready to go almost straight out of the box. This model has a yellowish-brown protective cover to block UV rays. The size of the build chamber of the printer is 134x75x130 mm. If we remove the casing, we will see a build platform with beveled corners for free draining the material excess. The photopolymer is poured into a tray made of aluminum. It has a slightly rough surface, so you need to wipe it gently, leaving no fibers from the cloth. Note that the tray does not have a resin drain.

From the kinematics point of view, this is a standard MSLA printer. Movement is maintained by a rail guide and a single-start 8mm screw only along the Z-axis. The optical end switch, which allows precise positioning of the platform at the start of printing, is integrated into the body of the device. It is located at the bottom of the structure.

For the light exposure, the printer is equipped with a ParaLed 2.0 module. That is a matrix of LEDs, above which special lenses are located. The Phrozen Sonic Mini 4K works with any photopolymer resin for this type of printer with 405nm UV curing.

The LCD screen of the printer is monochrome with a resolution of 3840 by 2160 pixels. Because it lets in more light and heats up less than an RGB screen, it lasts longer. The curing time of the resin is about 2 seconds, and the layer width is 10 microns and more.

The front panel of the printer has a touch screen display with simple and intuitive control. Here you can use such functions as calibration, backlight and LCD screen check, manual moving of the Z-axis. In the menu there is also an option of tray cleaning, which involves curing of the polymer left in the tray, which is hard to remove.

The manufacturer suggests using the Chitubox software as a slicer. You can transfer the model to the printer via USB.

Reviews:

Alexander: I bought this printer to master 3D printing. Pros: compact, a simple menu, and, of course, a low price. First imression: the printer is interesting, good matrix, powerful LEDs. Quiet. Test printing went well.

Danila7373: Good printing quality, can be used for jewelry.

A personal experience about Prusa MK3s

My printer is a Prusa MK3s, I have own this 3d printer for almost 2 years now. I have been very satisfied with this purchase, this little machine is a workhorse it has print for over 48 hours straight with no problems. I am mechanical minded, so I went with the kit. The instruction where easy to follow with step-by-step process with clear pictures. although I was eager to get started, I was in no hurry to build it, so I took my time and built it over 2 days. the only advise I can offer about the build process is do not over tighten things especially the build plate / heat bed as it can bow from over torquing.

The excitement of the first power up was intense, I flick the power switch and it alive. It passed all the self-checks ever got the highest rating parallel for the bed level score. Now for the hard part, as a complete noob, trying to get the first layer right was a pain. Moving the dial and changing the number not really knowing what it meant or what it doing as it changes the z height. As a rookie I wish they had a better of explaining the filament squish during this first layer calibration process, but I now know it all about experience and trial and error.

The first real printed parts I printed was the kit for the Ikea Lack enclosure. During this project I learned a lot about 3d printing like have a clean fresh washed flex sheet helps the part stick, or how nozzle drag can trigger the crash detection. In the end thought I ended up with a nice piece that gave my Prusa printer a finished touch, not to mention a certain piece of mind that my pet could not just jump on to the build plate also my curious sons would not just put their finger into the moving work area.

I was asked about mods, I can honestly say that I have not felt the need to mod my 3d printer it just works. I load a file into the slicer, slice it save it to SD card and print it. now with that said I have added a set of harden steel nozzles and got rid of the brass nozzle. the Prusa come with a e3d hot end more then capable of heating up abs plastic so I have not felt the need to change it , it just works, but I have had to replace the fan shroud a couple of times due to warping while printing with high temps like abs. since replacing the fan shroud few time due to warping I now take the time to just remove the shroud when printing high temp plastic. Next, I have added 2 parts to the printer and some gcode to the slicer to do some experimental time lapse without the need of modding for octo-print. This is one thing that I wish the 3d printing world had, a simple plug and play time lapse camera nothing is neater then watching a part just appear out of thin air. I would also like to maybe add a laser cutter to make custom boxes and carving.