All you need to know about how to make a nice photoengraving on wood / plywood with and without bicarbonate!

Preparation for laser engraving on plywood treated with bicarbonate:

With this short guide, I would like to explain, in the simplest possible way, the preparation for laser engraving on plywood treated with bicarbonate.

Required material:

Bicarbonate, classic in white powder

1 glass

1 brush

Paper towels

After having cut out the plywood to the desired size; dissolve the bicarbonate in half a glass of water until saturated (until it is no longer able to dissolve in water and there is always a little left at the bottom of the glass).

Stirring constantly, evenly apply the solution on the wood with a brush and wait for it to dry completely (24h).

Lightly wipe the dry surface with kitchen paper (a paper towel) in order to remove any residual bicarbonate crystals.

Proceed with cutting.

With this method, you will do with much less laser power for engraving and get much better results.

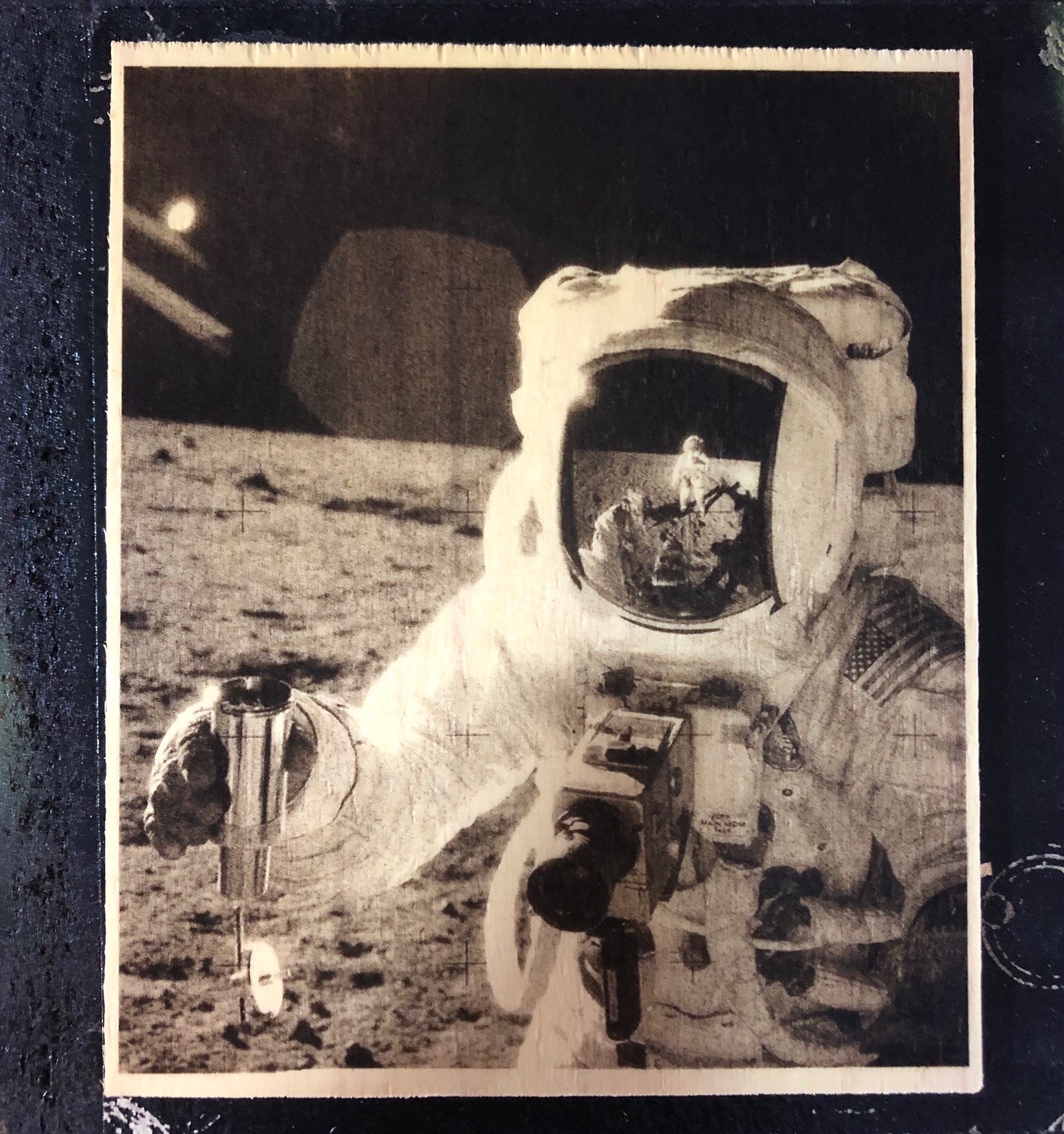

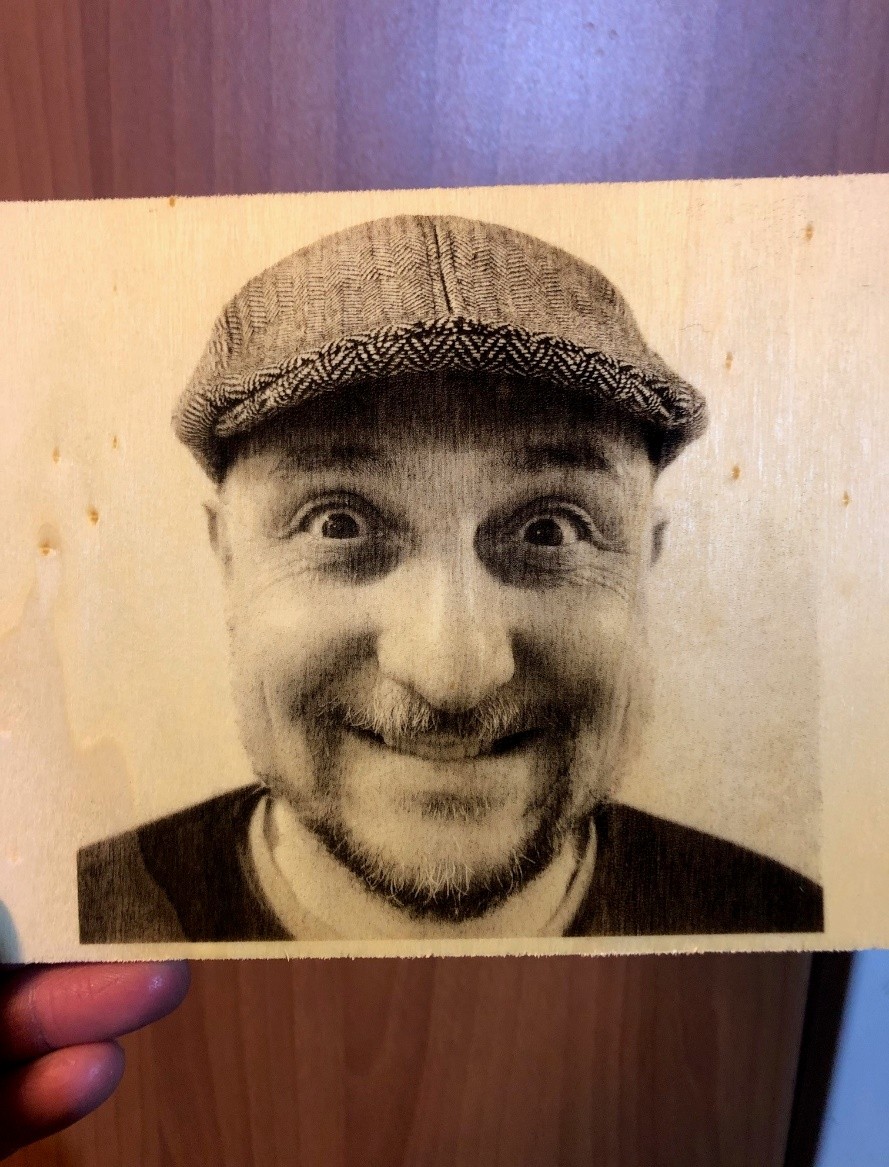

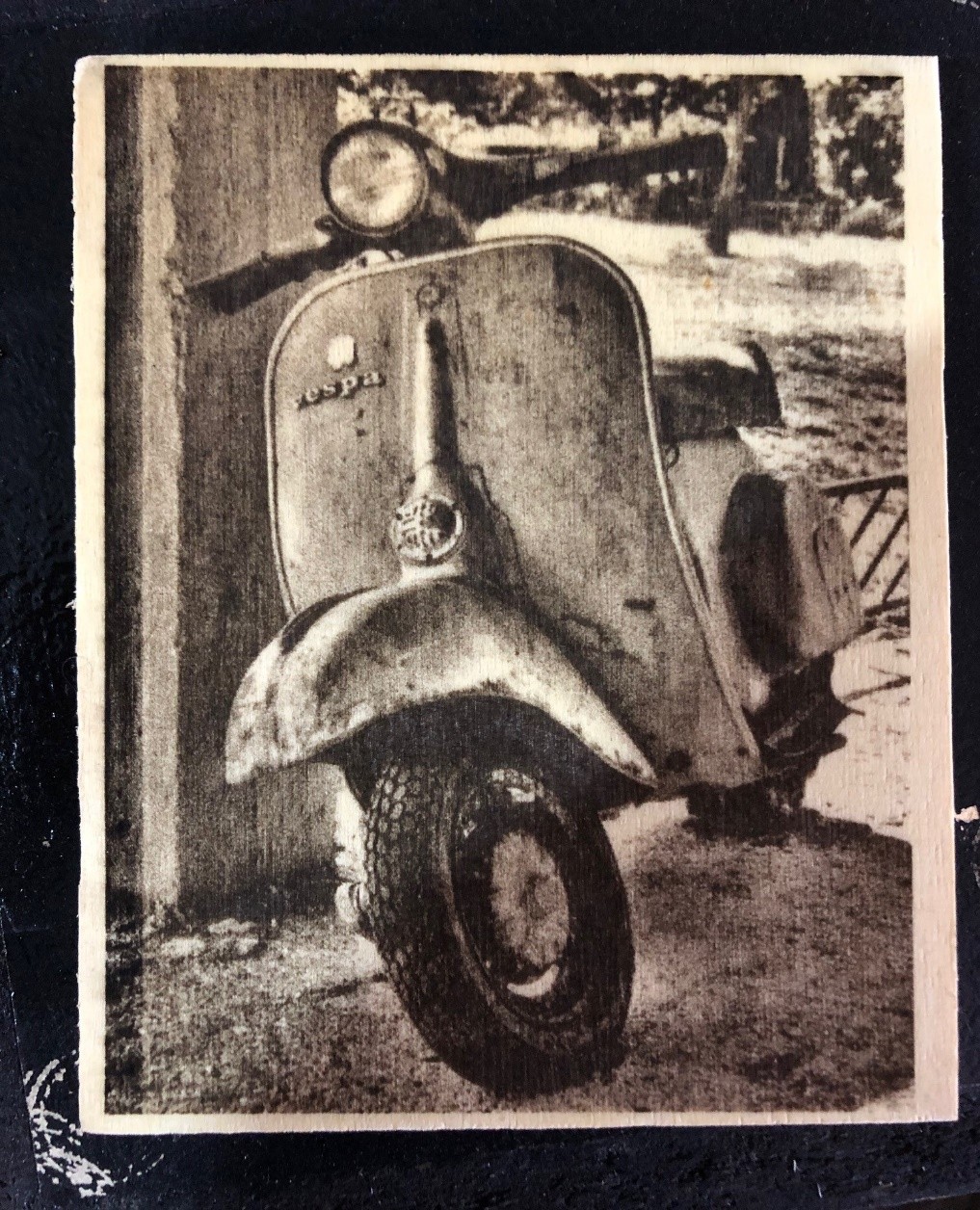

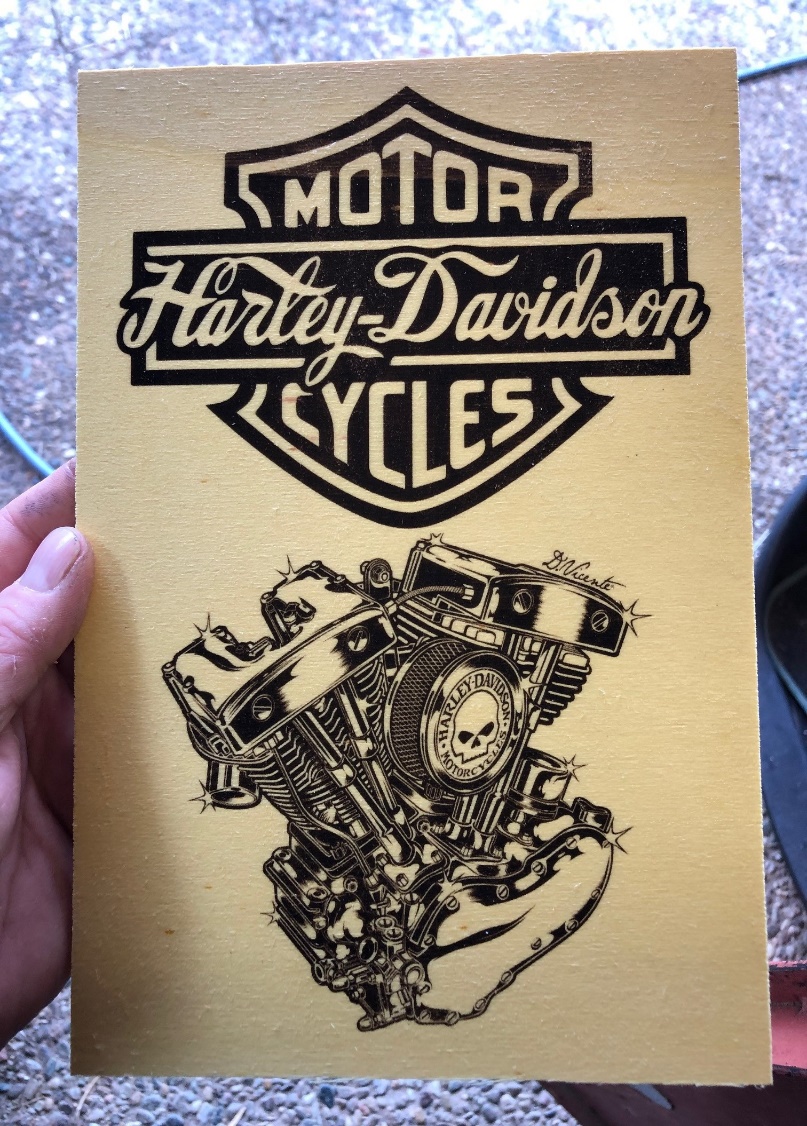

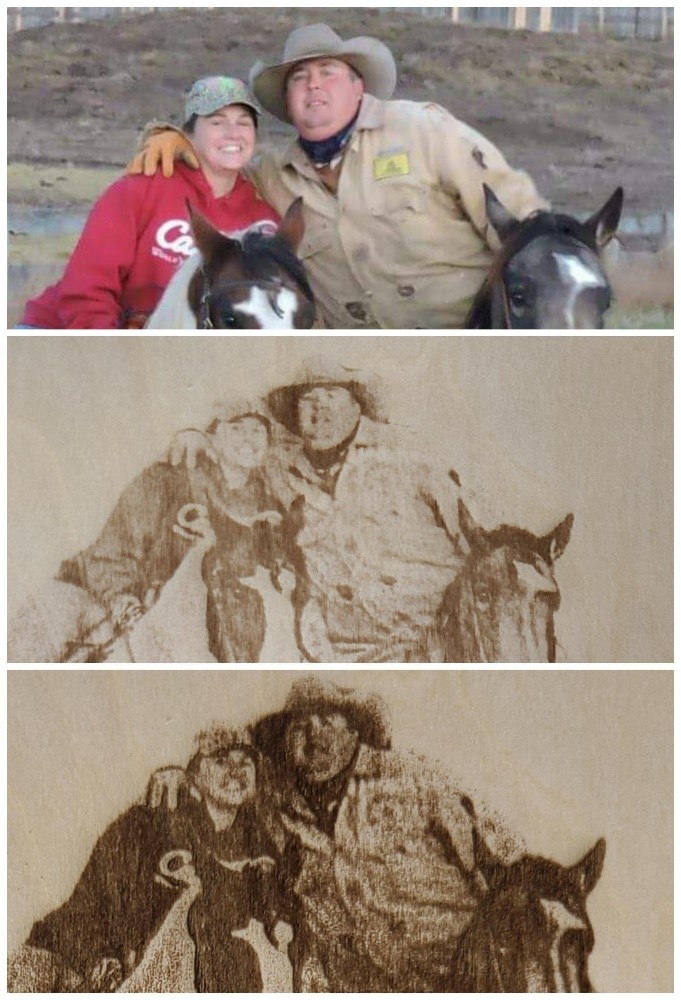

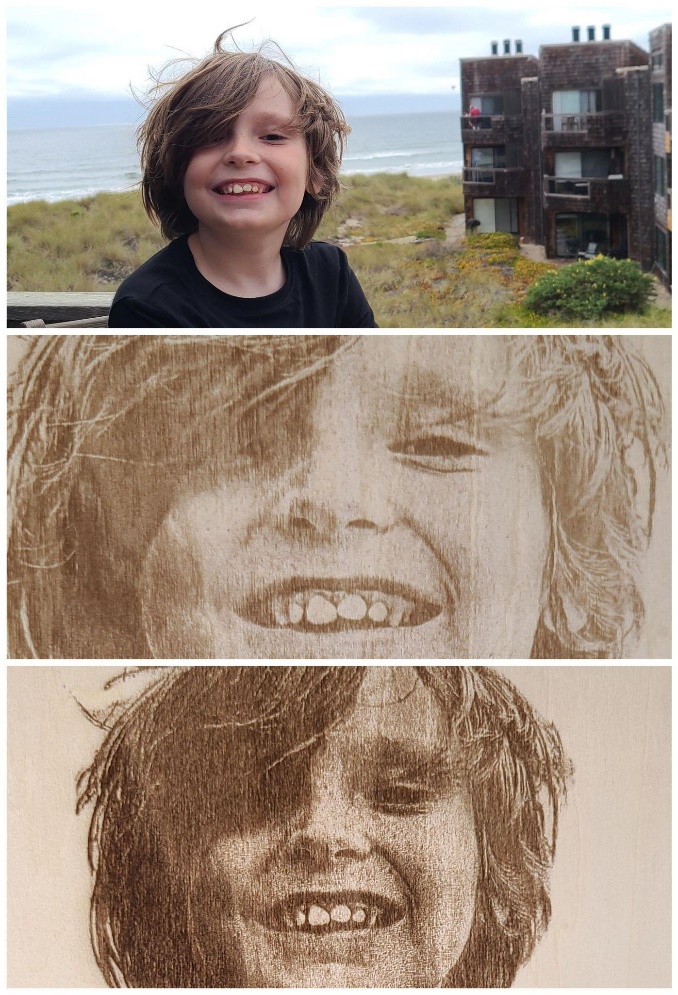

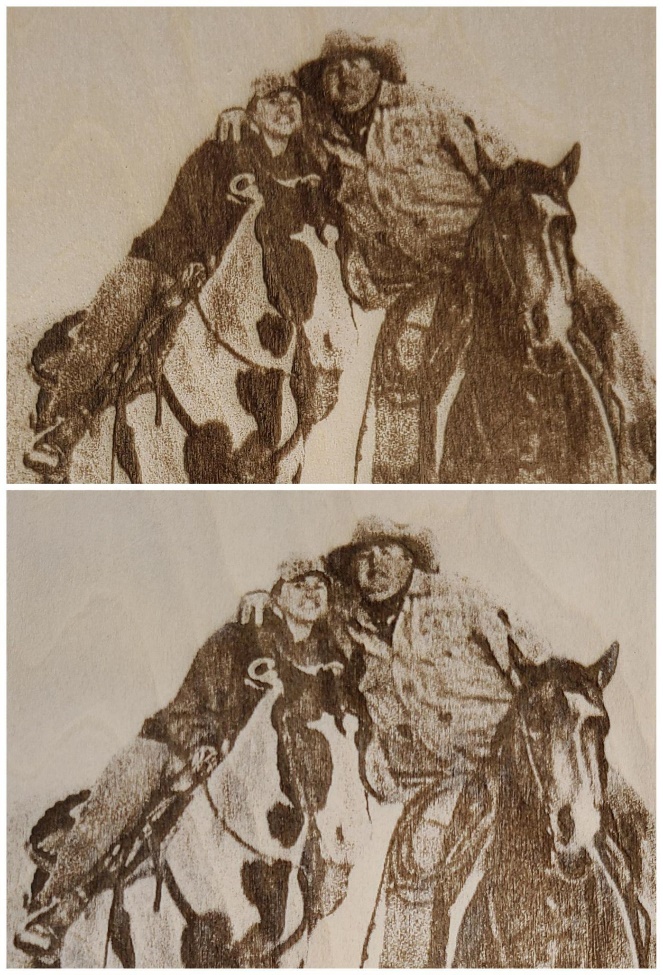

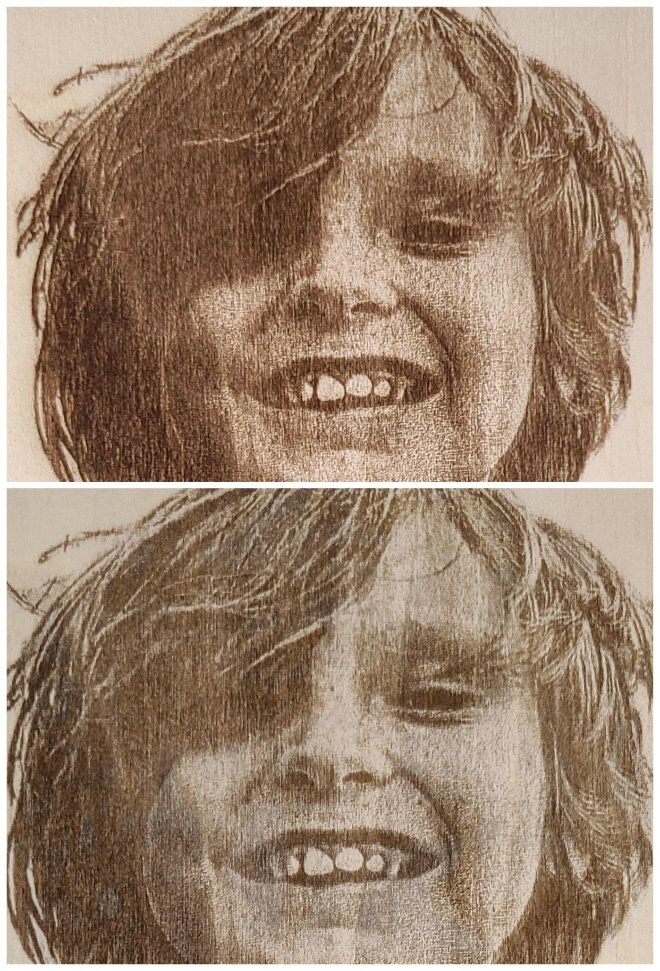

The first two attached photos show some works of mine done with and without bicarbonate, using the same power and speed, a CNC 3018 pro with a 5.5 watt laser diode, 1500 mm/min, 23% power, sierra 3 9,000 lines.

In the rest of the photos, the type of dithering changes substantially.

Bicarbonate laser photoengraving

Without bicarbonate laser photoengraving

Watch live video about laser photo engraving process on plywood

Photoengraving is also possible in slate

This material tells us about the algorithm of using a laser while graving of photos. You can change its size and quality.

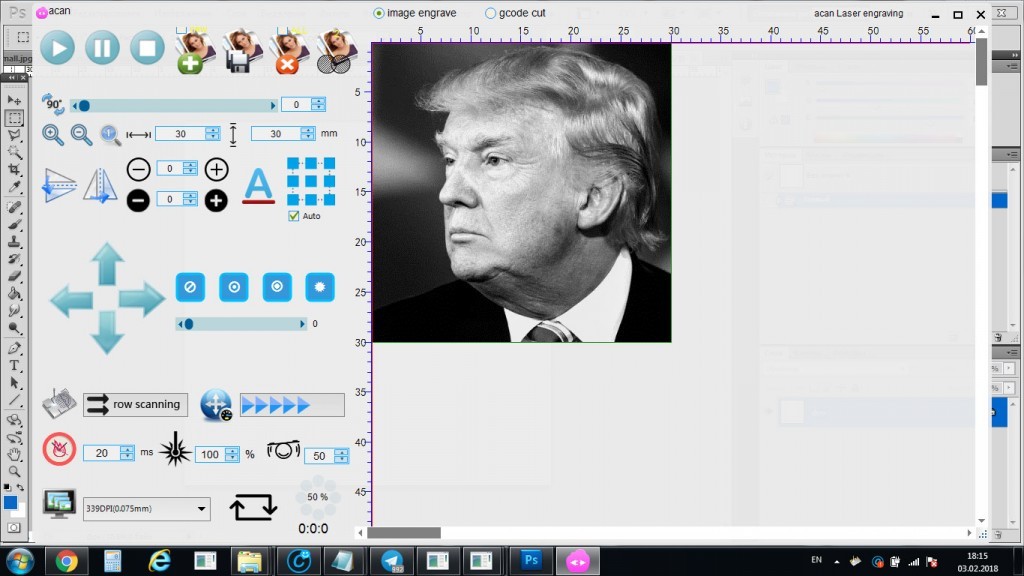

To make a beautiful laser engraving of a photo you don’t need to have special knowledge or experience. You can easily do it with the help of the Acan / Acan mini / CNCC LaserAxe programs.

We have already explained how to use CNCC LaserAxe:

Now we are going to tell how to use Acan.

You just need to run the Acan program, the connection is performed automatically. You can download the program here on our special page.

Photoengraving using Acan software

Let’s open an image.

Choose the settings: burning time and laser power.

Start engraving.

The choice of the parameters depends on:

• the material for the engraving;

• laser power;

• the image itself.

We use a 3.5 W Endurance DIY mini.

The chosen time of burning appeared to be too little for this light plywood.

So we went on experimenting with other settings values.

The optimal burning time for the 3.5W Endurance laser is 4-5 ms with 100% of the laser power.

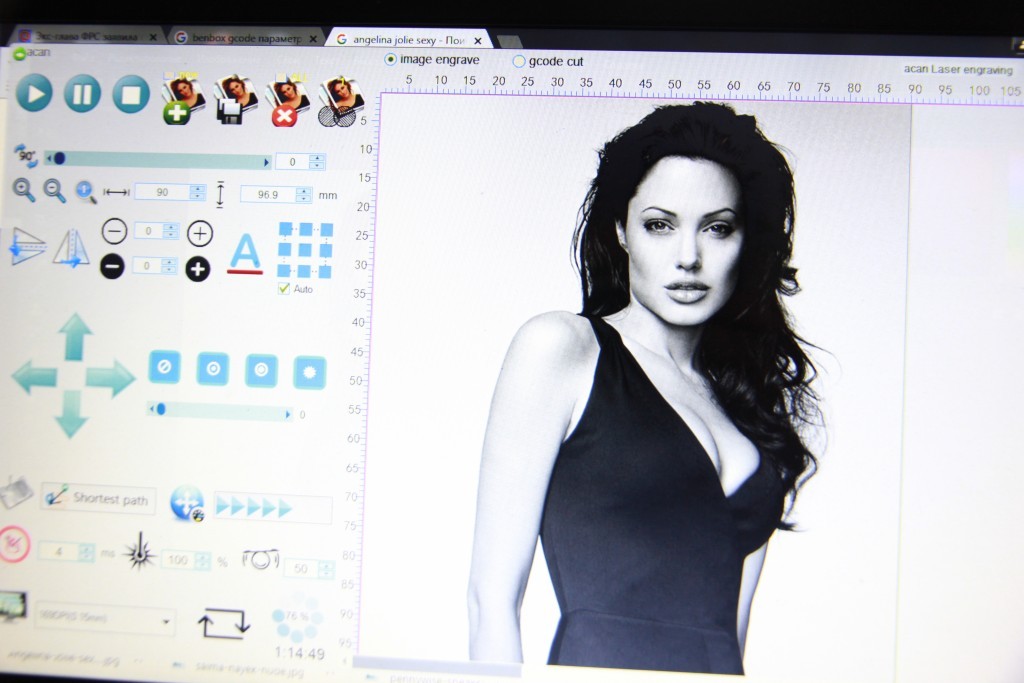

Now let’s engrave a picture of the most beautiful woman of the world using these settings.

It takes about 60-90 minutes to engrave an image 10 х 10 cm depending on the burning time.

This is what the program looks like when engaged in the engraving process.

It is possible to change the image size. The size of the Endurance DIY mini worktable is 10 х 10 cm, so we need to fit in the photo on the worktable.

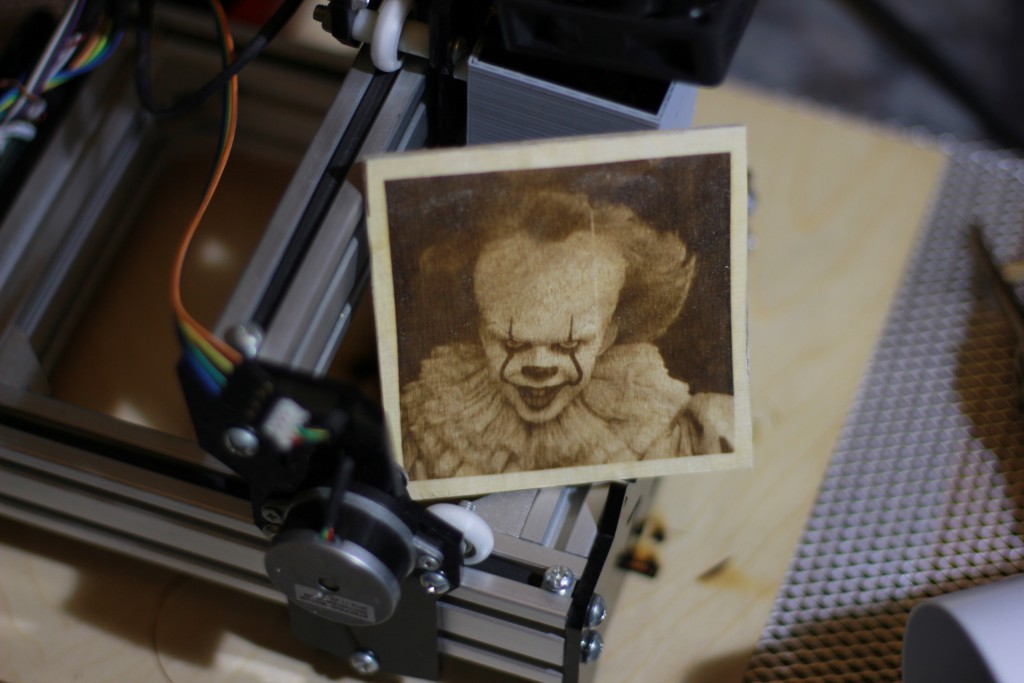

As it is seen, the ready engraving does not need any additional treatment of the image or surface processing.

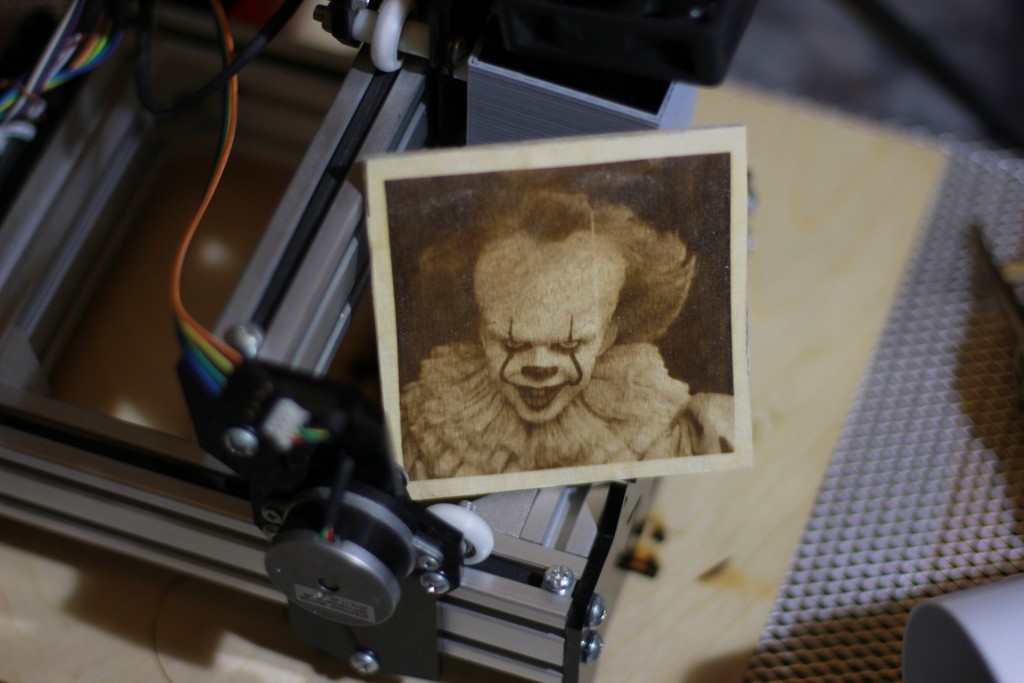

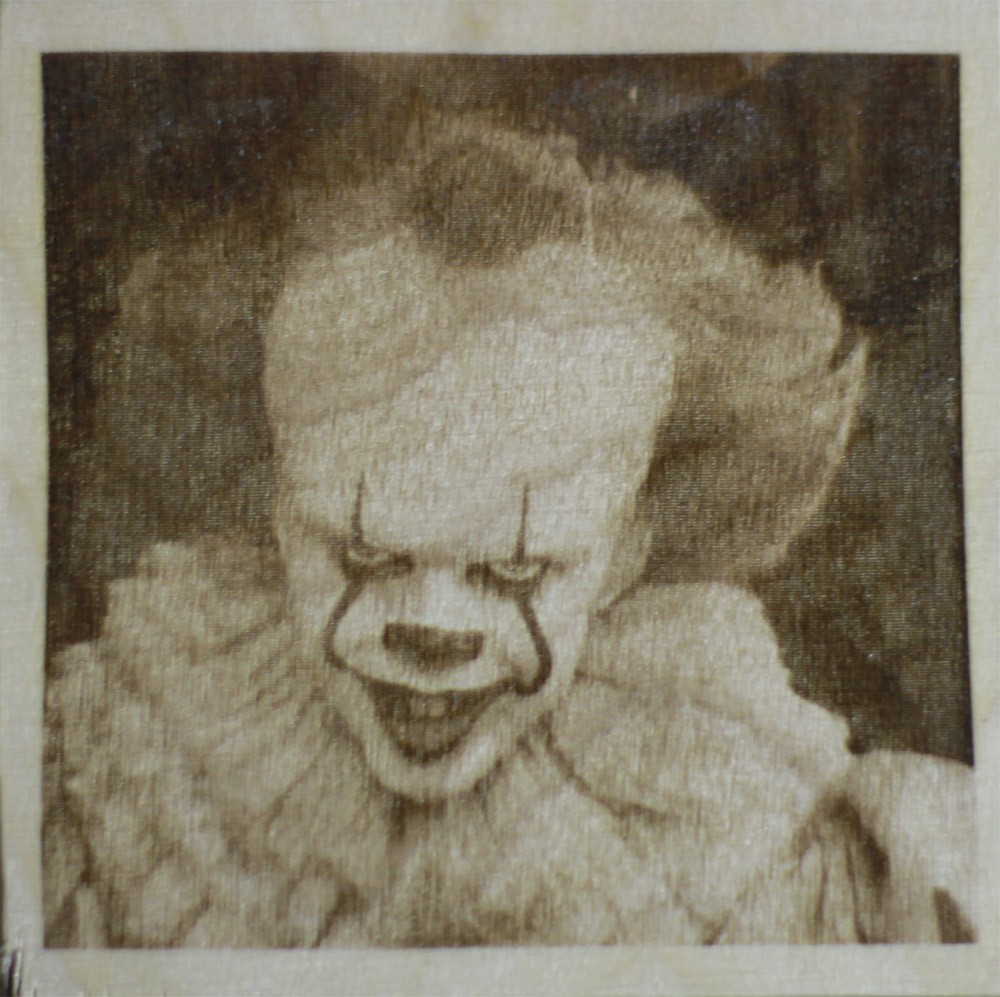

Pennywise, the clown from “It” looks very realistic as well and seems to come to life any minute.

Even at a close look you see a high quality of the picture.

No doubt, you will be able to engrave images of the same quality or even better if you use Endurance DIY engravers.

Our customers make and share

If you have any questions or concerns, please share them with us!

Join our facebook community >>>

Acclaim Crafts – Photo Engraving with a 10 Watt Endurance Laser (Read a full PDF guide)

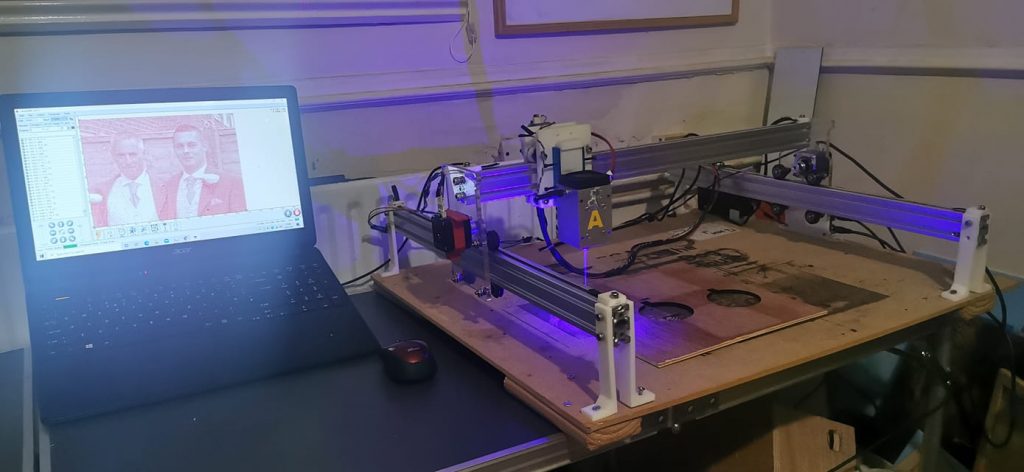

Our customer Ady Penney making a photoengraving using our 10 watt diode lasers

Photo engraving 2night with endurance laser head.

More inputs about laser photo engraving process

“This is 5% doing, and 95% mucking around and finding out. You *will* have failures, and that’s both ok and normal. Get yourself some waste material, the cheap stuff, and see what happens.” – Me

Time for a quick(ish) lesson in photo engraving. Sure, anyone can toss an image into their burning software of choice and get a result, maybe even a good result. But it’s very unlikely that it will be a great result. As the saying goes, garbage in, garbage out. This lesson is to help you put in less garbage and get something great out. For the impatient, see the Quick Version down at the bottom.

Items needed

- Some wood/plywood to experiment on

- Some time to spend experimenting

Material Considerations

Ideally, your material is flat. If it’s warped, then you need to work out a way to make it flat. I tend to tape thin plywood (1-6mm) around the edges if I have a warped piece, convex side down, which is often with cheap materials.

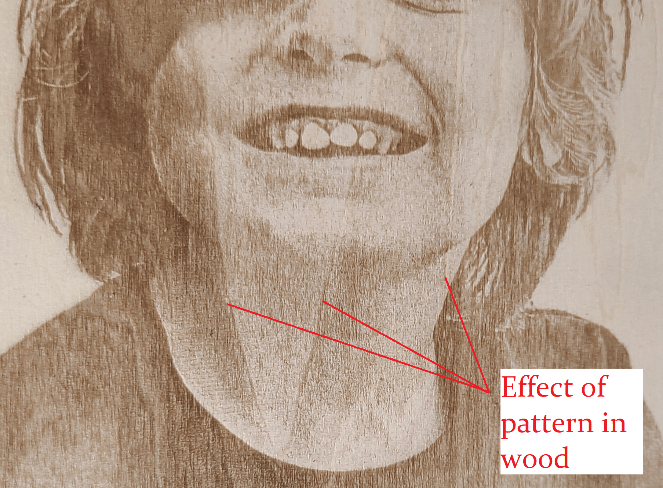

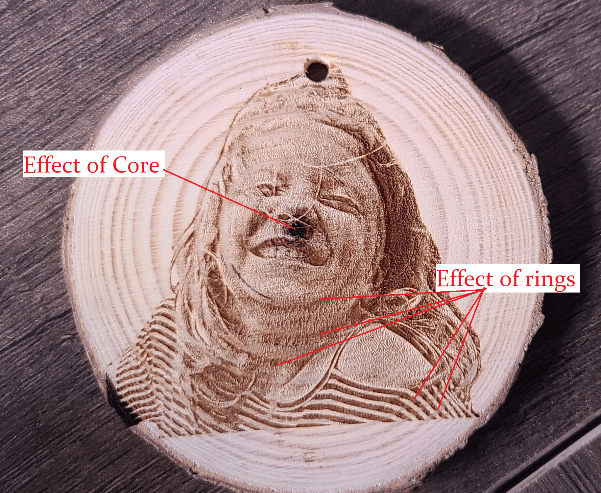

Different types of wood can have very different characteristics when it comes to engraving/cutting. Even the same type can vary from section to section, sheet to sheet, etc. So, what worked on this bit may be a little off on the next bit. Just expect that and learn to compensate when needed.

Patterns in the wood will have different burn characteristics. For example, if you’re using unprocessed slices (literally a slice of a tree), rings of different colors will show up in the burn and the core will have an exploded look. Plywood that shifts in color will also show color shifts in the burned image.

Material Prep Options

Before getting started on the image work, take some time to consider what you can do to the material itself to make it more compliant to what you want to do.

- Sanding – Remember that bit above about being flat? This can help. Some 400-600 grit sandpaper will help smooth out the surface of your material so you can get a more even burn. This is a really good idea if using slices, which have probably not been sanded at all.

- Pretreatments – There are a few tricks you can do to get the engraving to be extra black from the get go instead of the usual brown. These also allow for high speed and lower power burns without loss of detail.

- Baking Soda/Borax treatment – mix in 1 part of either of these with 10 parts of hot water. (Hot water helps dissolve the powder.) When dissolved, brush/spray the material with the solution, giving it a light coat. Not too much, as it can cause warping. Now let the material sit overnight so that it’s completely dry. (Cheating at this step yields yucky/uneven results.) And that’s it! Give it a whirl and see how it looks compared to the same burn on untreated wood.

- This one is based on an old wood working trick for giving wood an aged appearance, and it will change the color of your material depending on the dilution rate. Most recently, this has been referred to as the “Kenny Hack” which you can find a video about over on Youtube (https://youtu.be/zsnldGA1U98 & https://youtu.be/4td-UAW8YB4), but I’ll do a quick and dirty version. Get yourself a glass container with a non-metal lid, throw in a pad of steel wool (non-coated, fine is good), then add vinegar until the pad is covered. Let that sit for a few days, stirring occasionally. The vinegar will have eaten all/most/some of the steel wool (it’s an acid, and that’s what acids do). Take some of the liquid, mix it with a bit of water, and brush/spray on a light coat. Let that sit overnight so it’s fully dry. Honestly, I haven’t had great results with this, but it may have been because I was impatient, didn’t dilute properly, or some other issue.

The Photo Itself

It kind of goes without saying, but the better a photo you start with, the better the result you’re likely to get. Now, just because the photo *looks* good on your screen doesn’t mean that it’s actually good quality. Often, photos are compressed in such a way that they can look good but lack actual detail. This makes their file size smaller and easier to transport around the internet. For engraving them though, that’s not beneficial. Blurry photos, tiny photos, photos of photos (yes, really), and the like are going to be difficult to work with. There is only so much that can be done with those, and they still won’t look great. I’m not going to go down the rabbit hole of various techniques that can be attempted to save/recreate a bad photo, but instead focus on some tools that can take a reasonably decent image and make it laser ready.

The Software

Your main software probably has methods for manipulating a photo and making it laser ready. Laserbox, LaserGBRL, Lightburn, etc all come with various tools and algorithms like grayscale, Stucki, Dither, Newsprint, etc. And don’t get me wrong, I’ve seen some really good stuff come from them. But those options are not what we’re going to go over. Instead, we’re going to look at Imag-R, which is a free online multitool for making your image laser ready. Why Imag-R? Besides being free (unless you want to get rid of the ads or get the offline version), it has a load of nifty tools that aren’t available elsewhere, and it’s all in one place. Wanna remove the background in a photo or make a puzzle? Yeah, they have those tools there too. Oh, and, you can do it all through your phone, tablet, or PC.

Prep the image

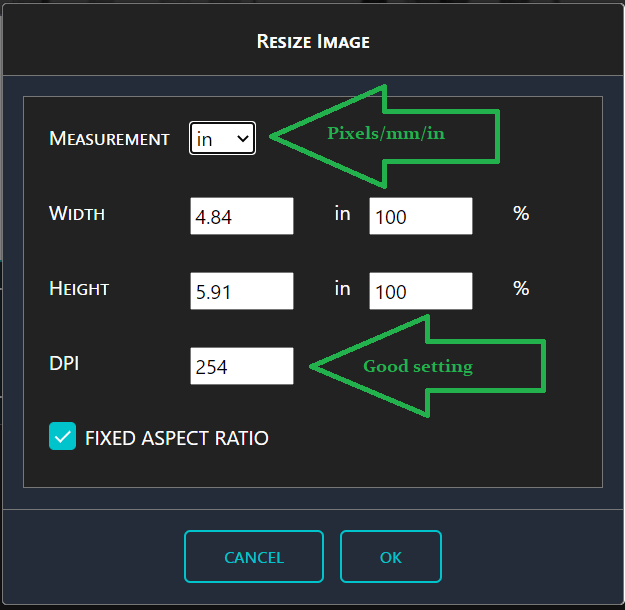

Regardless of what you’re etching on, image preparation is important. Your image should be sized to match your material, DPI set to match what your laser can do (or looks best), and processed so that it’s laser ready. Even better, processed to match the material. With Imag-R, it’s easy to set the size, DPI, material, etc for an image, and, you get a nice preview of what it should look like. I’ve found that a DPI of 254 looks better than 318 (what the laser is capable of), but your mileage may vary. This equates to 0.1 line interval.

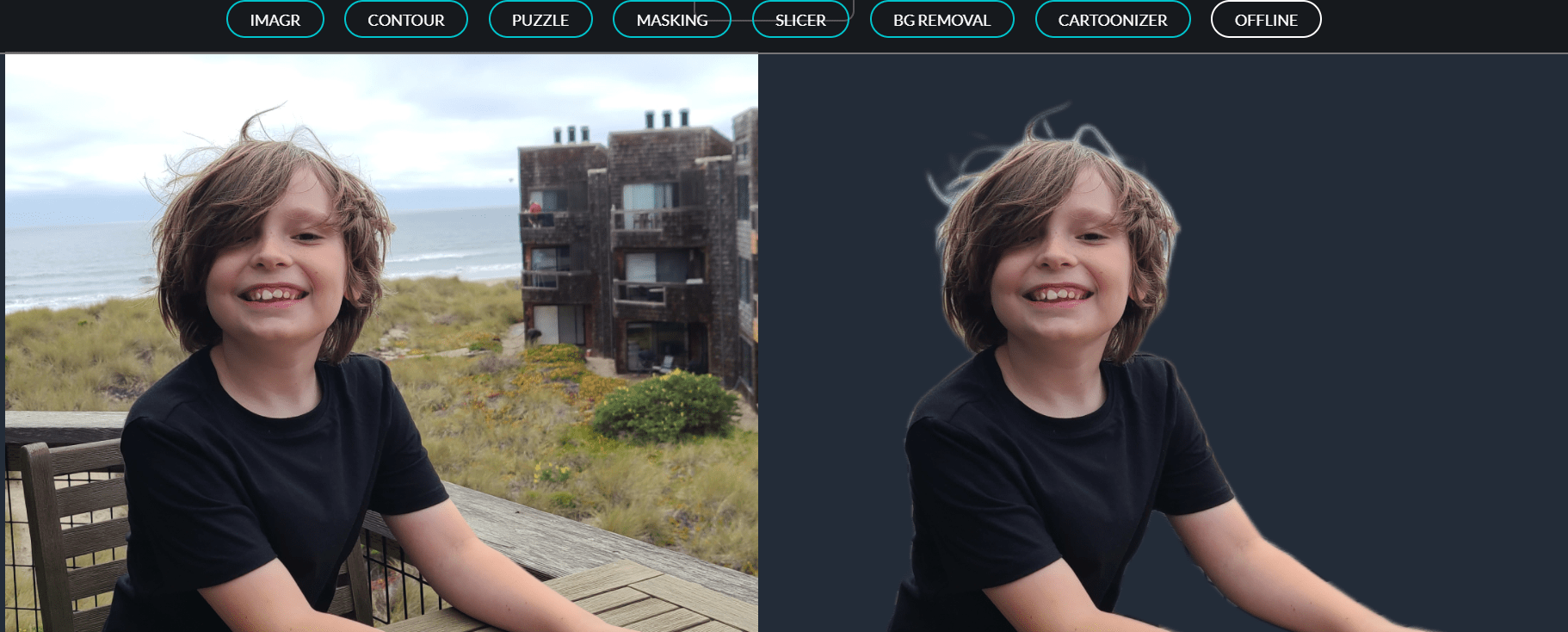

So, first things first, we go to the Imag-R site. Myself, I run any given photo through the background remover tool first, unless there is something special about the background that I want to keep. Warning, that tool isn’t 100% perfect, but I’d guess that it’s done me right 90% of the time. If I like what I see, I download the resulting image.

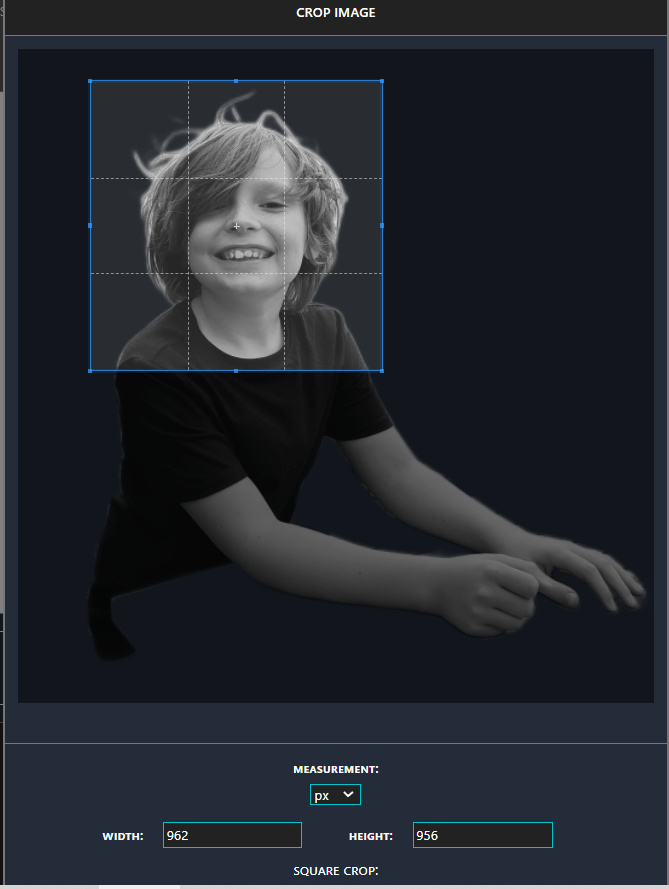

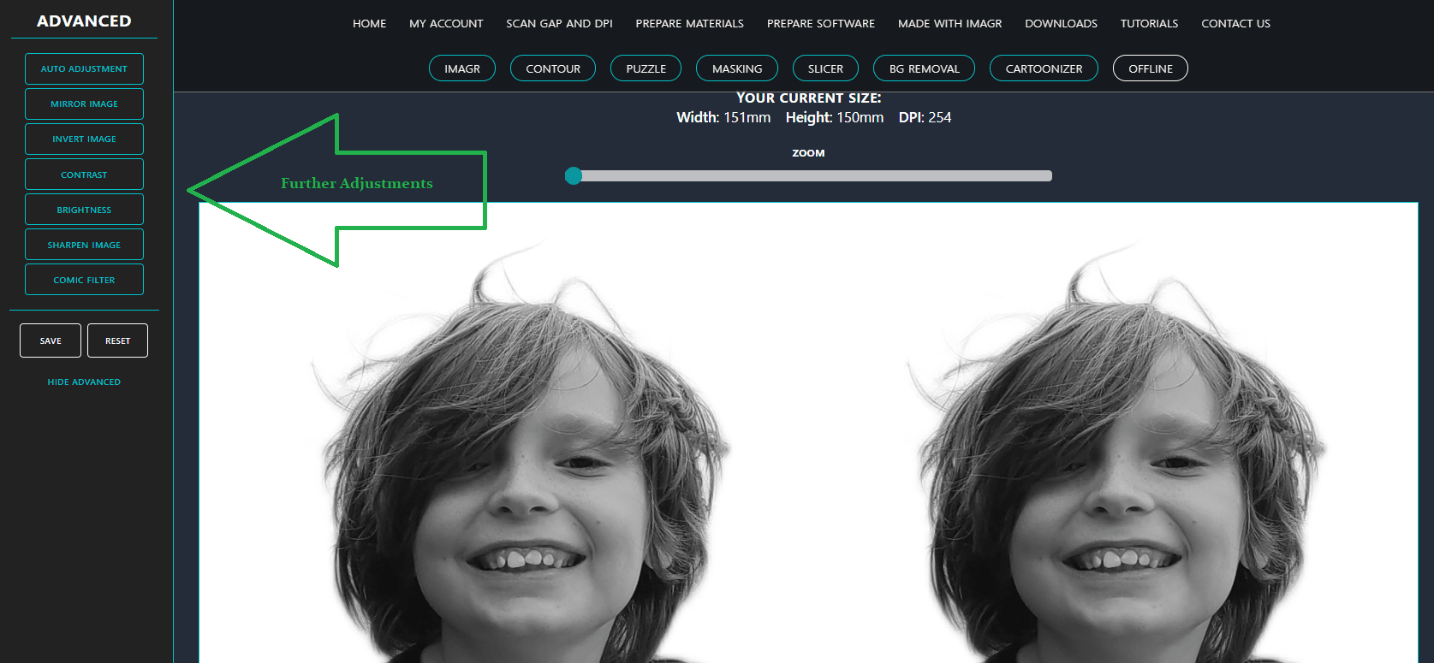

Next, we need to upload our image for processing. That’s either the one you got from the background removal tool, or the raw one if you skipped that step. Once uploaded, crop the image as needed. Resizing will be the next step. Here, you want to have it change the physical size of the image to match your expectations. For example, if you want an 8×10 engraving, then you need to have the image resized to match that. While you’re there, bump the DPI up to 254. If you’re feeling spicy, go ahead and change it to 318 and see how you like that. After this process is done, I download the image as a BMP, so that I have a working base, then return to the image on Imag-R. Be sure to check out the other tools there, such as sharpness, contrast adjustments, etc.

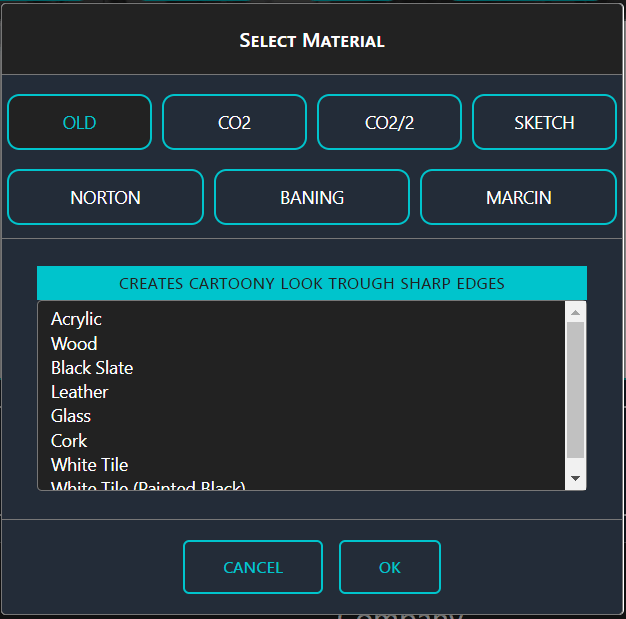

Now on to material. Each of the items at the top is an algorithm, and under each of those is a material at the bottom. Though some are indicated as being for C02 machines, feel free to try them out. Myself, Marcin is my goto favorite. Select one, click Ok, and you will get a preview of what the image will look like. If you zoom in on the preview, you will see how it’s been changed for lasering. Materials like glass and acrylic will automatically be created as a negative, which may or may not be your thing.

Prep to burn. Settings

The rule of thumb is that the grain of your material should be running up/down while your engraving is done left to right, which is called the scan angle in Lightburn. That usually works well, so orient your material in the engraver that way. Generally speaking, the faster the laser moves, the lighter the engraving will be. Likewise, the greater the power level, the darker/deeper your engraving. There is a balance there, which will vary a bit from machine to machine, material to material. What I find to be a good starting point for non-pretreated wood is 6000mm/m with 40% power for one pass at 0 degree scan angle, then a second pass at a 90 degree with power at 45%. It seems to make some details pop better than making a second pass at the original angle. How I do this is by creating a second copy of the image, put it on a different layer, then aligning the two images so they are on top of one another. You could simply do one pass, change the settings, and then do the other.

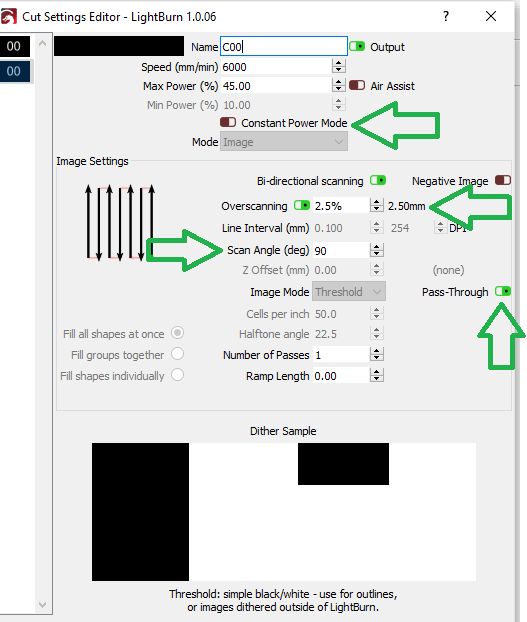

Because we already processed the image on the Imag-R site, you will select to engrave as a Pass-Through. This means the software, Lightburn specifically, will not do any further processing of the image with its built-in algorithms and will not change the DPI/Line interval (these two are linked, FYI). In addition, turn off Constant Power Mode, ensure Overscanning is at least 2.5% (5% is better), and verify the Scan Angle.

Burn

Once you’re all ready, kick off the job and wait.

Start, first, and second pass

Finish

One of the nice things about engraving on wood is that you have options to change the result afterwards. Not dark enough? Give it another pass. Too dark? Give it a light sanding with 400 grit or high sandpaper to take off the top layer. (This takes care of scorch marks too!) Remember to blow off the dust after sanding, so you have a good idea what the result looks like. If you want to seal it up so it stays nice, go easy with some spray clear. Give it a dusting coat first to kind of hold any loose ash/soot in place, let the piece dry, then give it a better coat. Brushing clear on may work, but there is a chance iit will stir up some ash/soot which will then bleed around your image.

Sanded after burning

The Quick Version

- Select your material

- Complete any pretreatment options for the material

- Remove background if you like

- Adjust your image to the size of the engraving you want it to be, at a DPI of 254.

- Make any further image corrections

- Select algorithm and material

- Export image

- Change settings in Lightburn to match needs

- Burn and wait

- Apply any post-treatments

Learn more about laser photoengraving

Photo engraving on PLA plastics with 4/10 watt Endurance DPSSL

All you need to know about photo laser engraving: testing your board and your firmware

Laser engraving of halftones & greyscale. How to do a laser print of a beautiful photo.