There is a myth that TEC cooling plates (Peltier) should not be controlled via PWM.

The misleading concept described that TEC cooling can be damaged with high-frequency PWM signals.

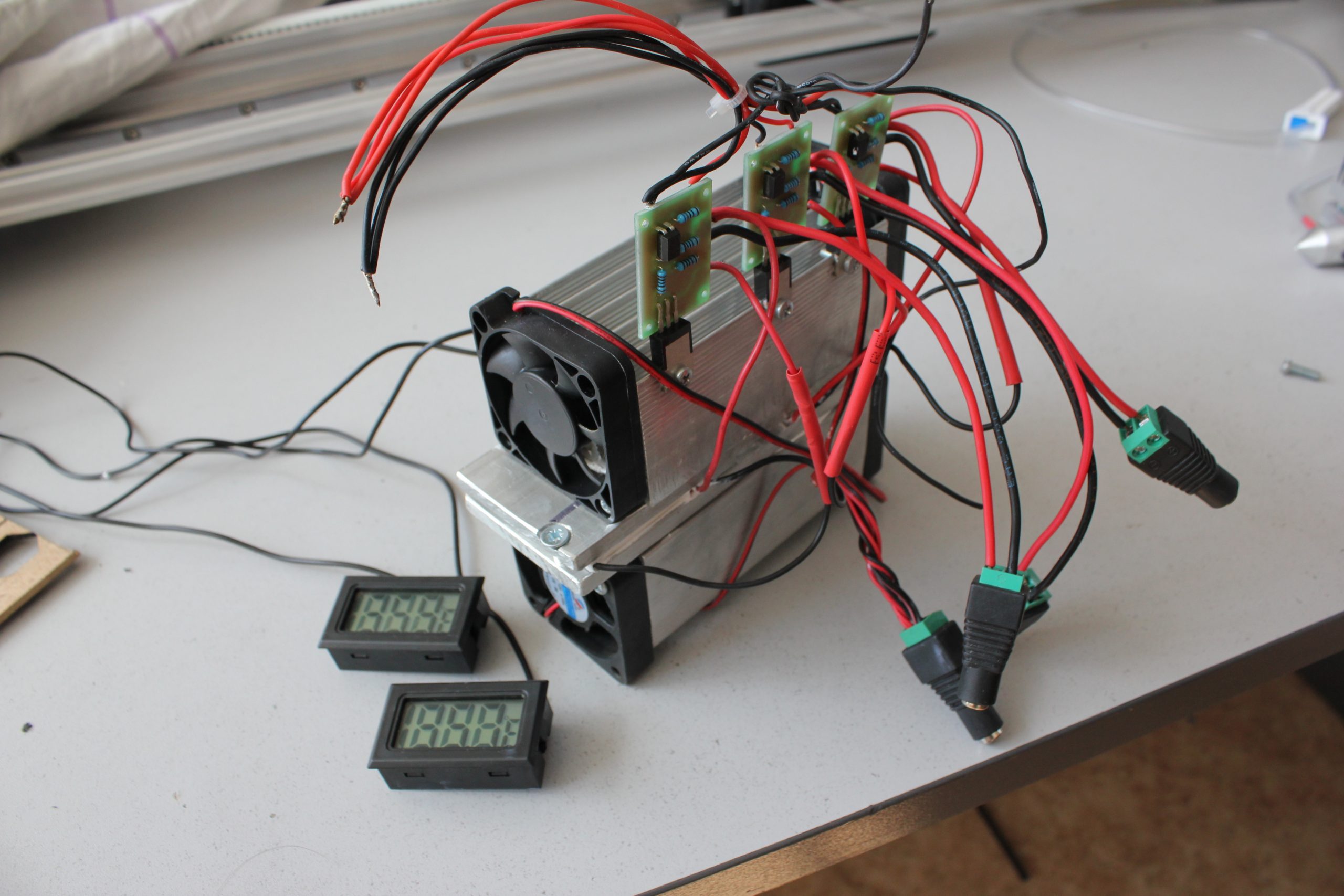

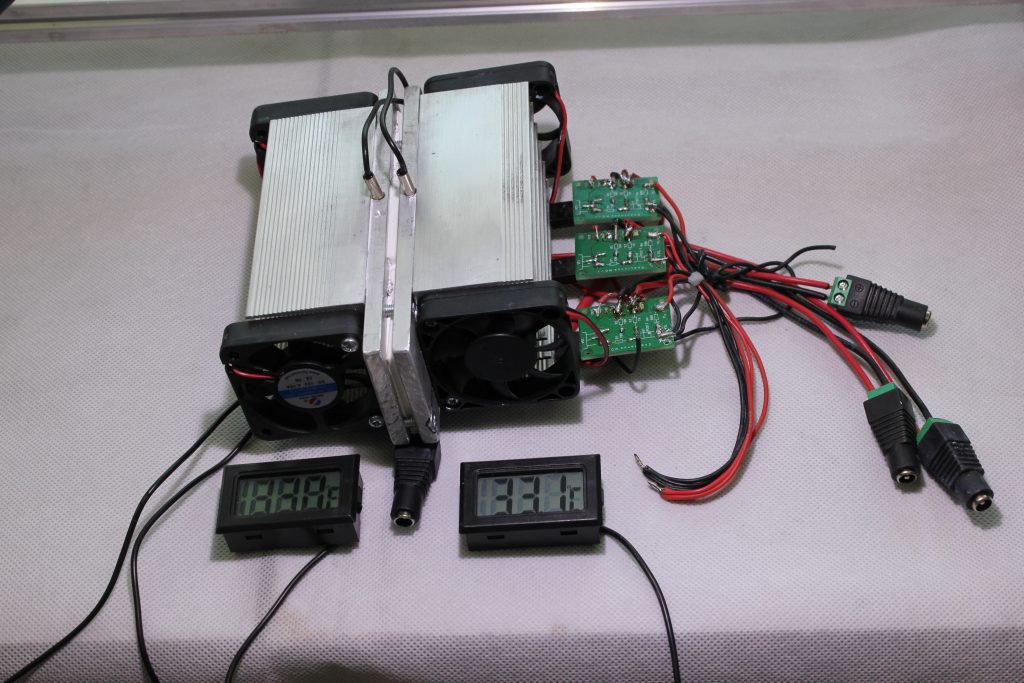

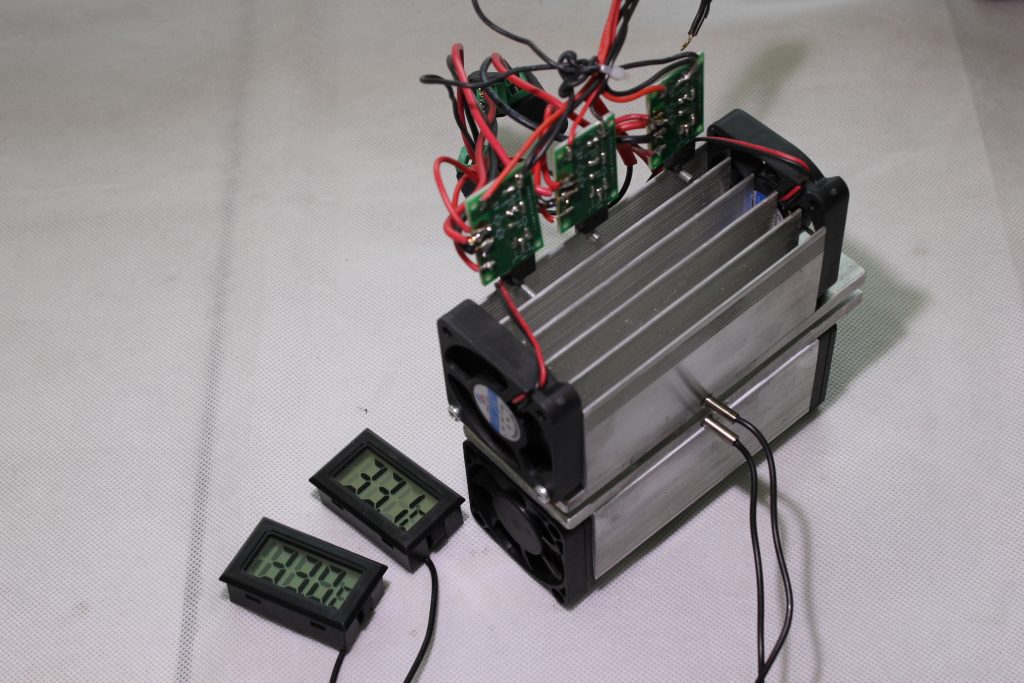

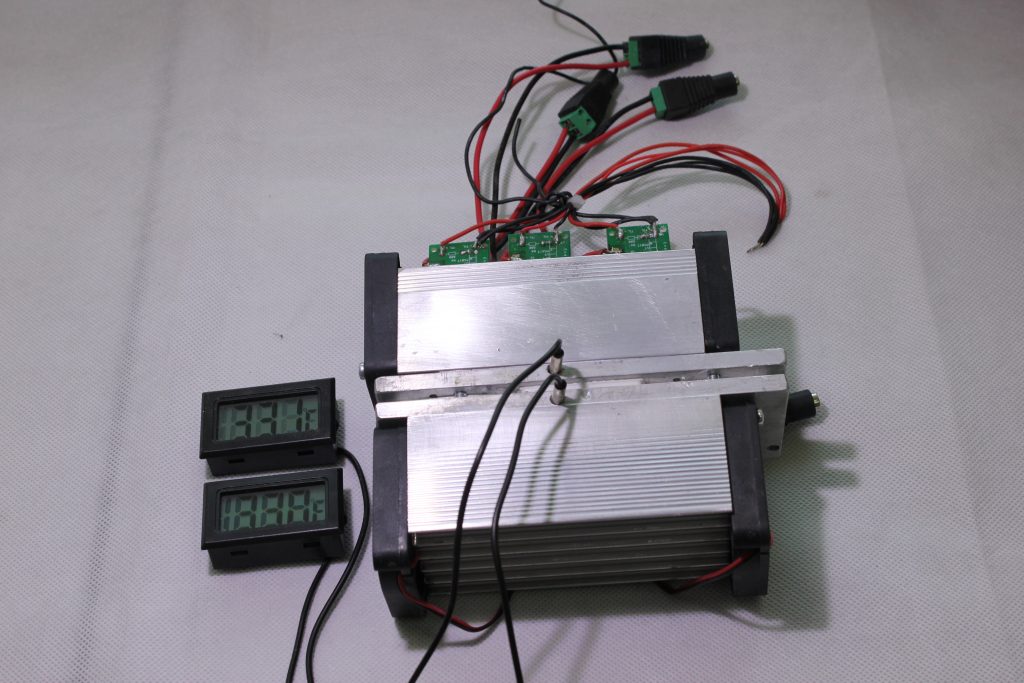

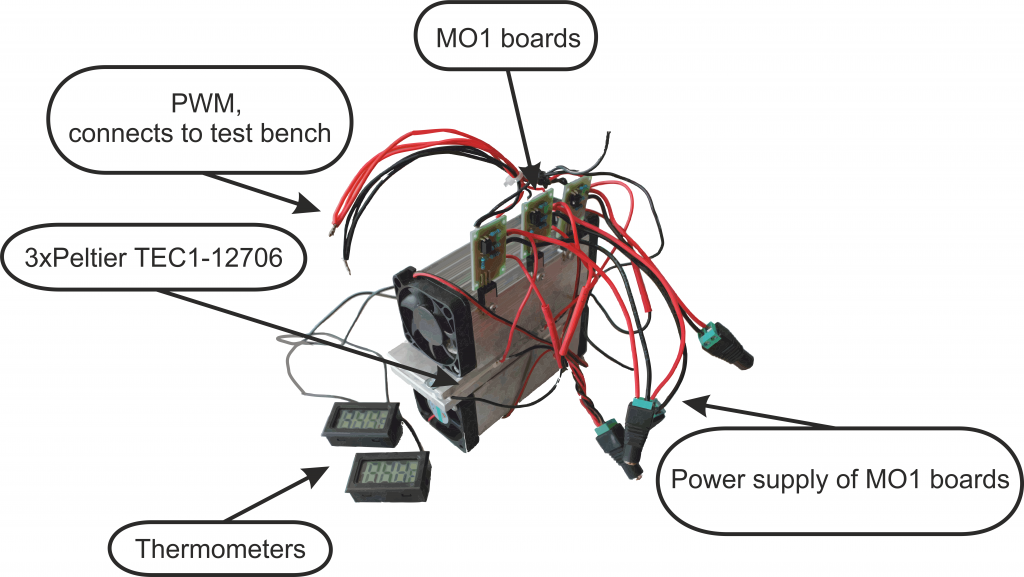

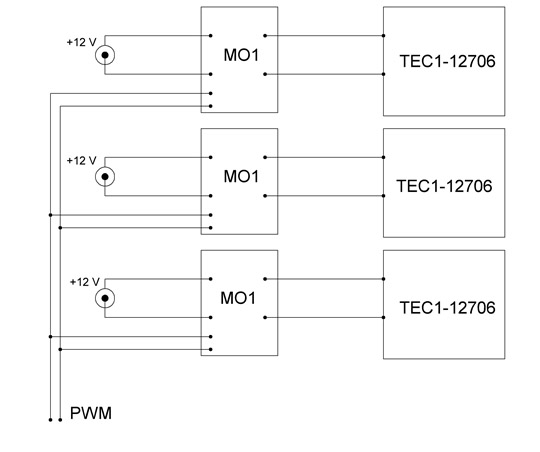

The purpose of the experiment was to determine the effect of PWM on the Peltier, i.e. whether the peltier loses its properties when the applied current decreases. For this, a test bench was assembled: three peltier from different manufacturers were selected, tightly clamped between two radiators with fans, the current was changed through the MO1 boards, and the temperature was controlled through two thermometers, on the “hot” and “cold” sides of the peltier.

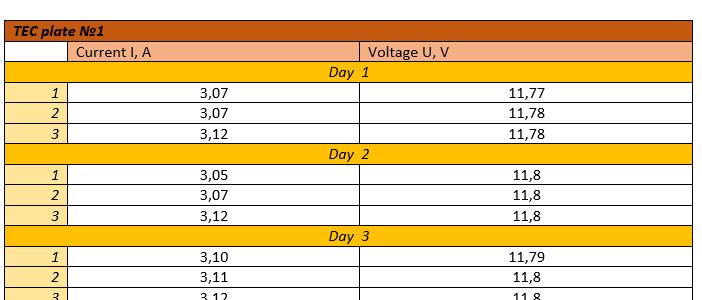

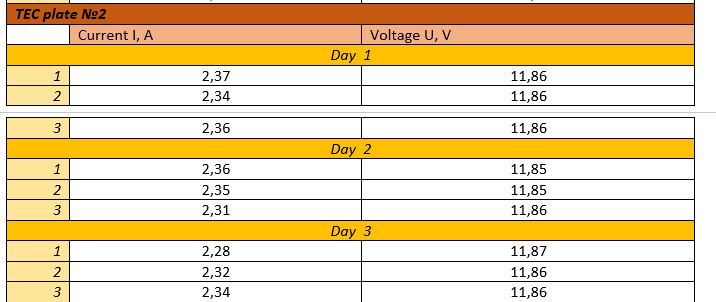

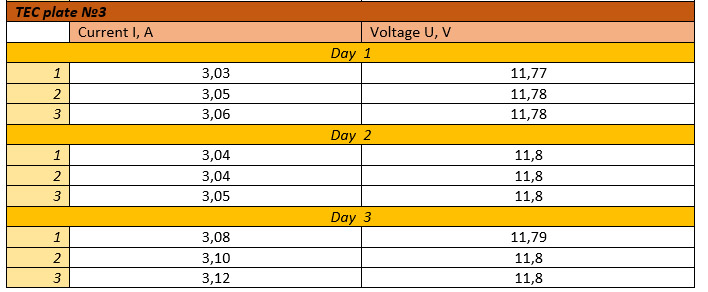

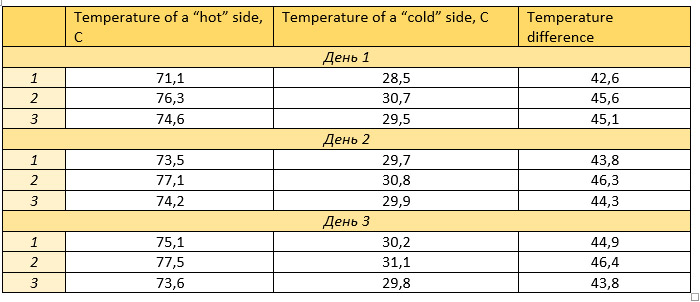

Initial measurements were made at 100% of the load to determine the operating mode of the peltier. Then the load was reduced to 50% and the peltier worked in this mode until the next control measurements were taken. Measurements were made three times a day at 100% load, i.e. an ammeter was soldered into the circuit, and after setting 100% of the current and entering the operating mode, the current and voltage across the peltier were recorded. After taking measurements from all peltier, they remained at 100% load and the temperature difference between the “hot” and “cold” sides was recorded, after which the load was reduced to 50% and the peltier continued to work until the next measurements. For three days, the following readings were recorded:

The tables show that the change in current insignificantly affects the performance of the peltier, a much more significant factor is the heat removal from the “hot” side. While maintaining the delta temperatures, the better the heat removal from the “hot” side, the more efficient the “cold” side will work.

TEC testing installation setup

Endurance TEC (Peltier) controller. Keeps the laser temperature in the optimal range

Available on 10 watt PLUS PRO / 15 watt DUOS lasers starting from 5-th of November 2021.

Adjusting TEC cooling capacity (older version)