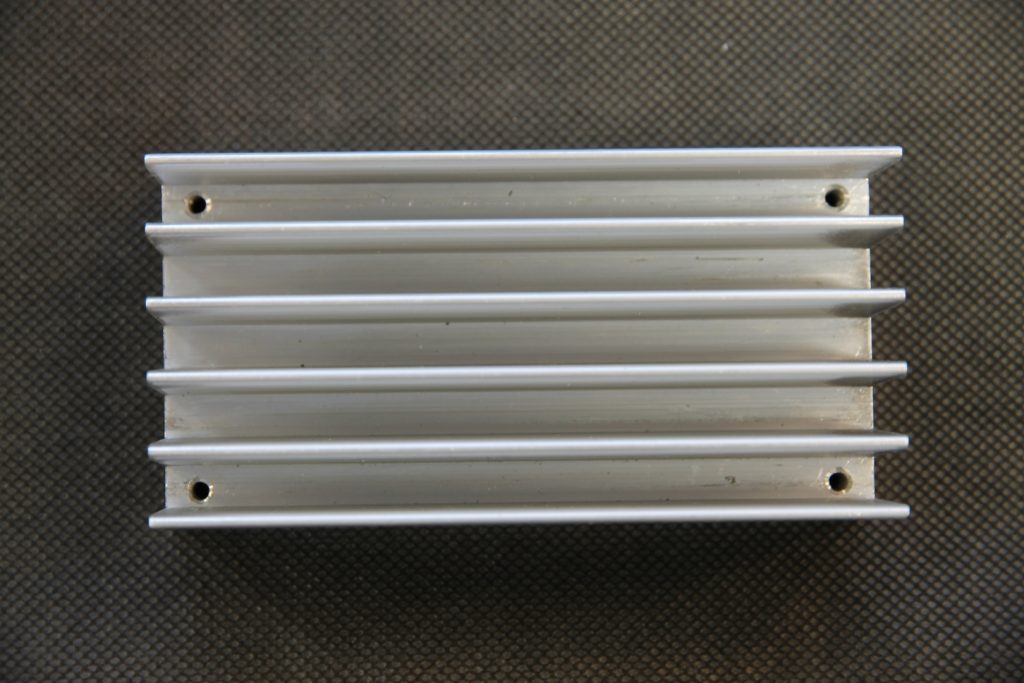

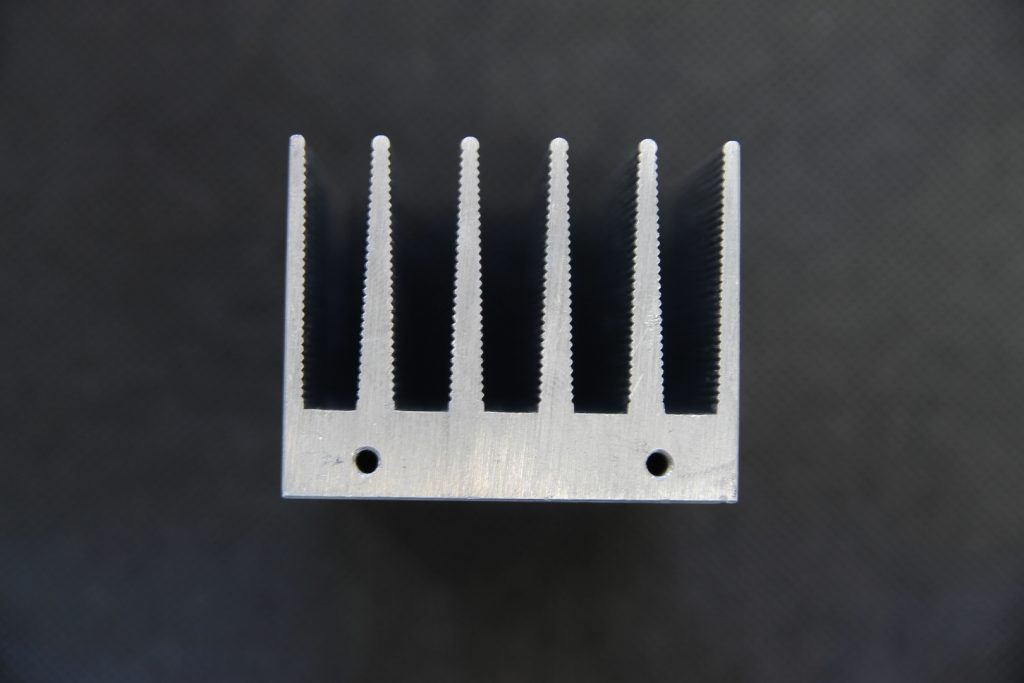

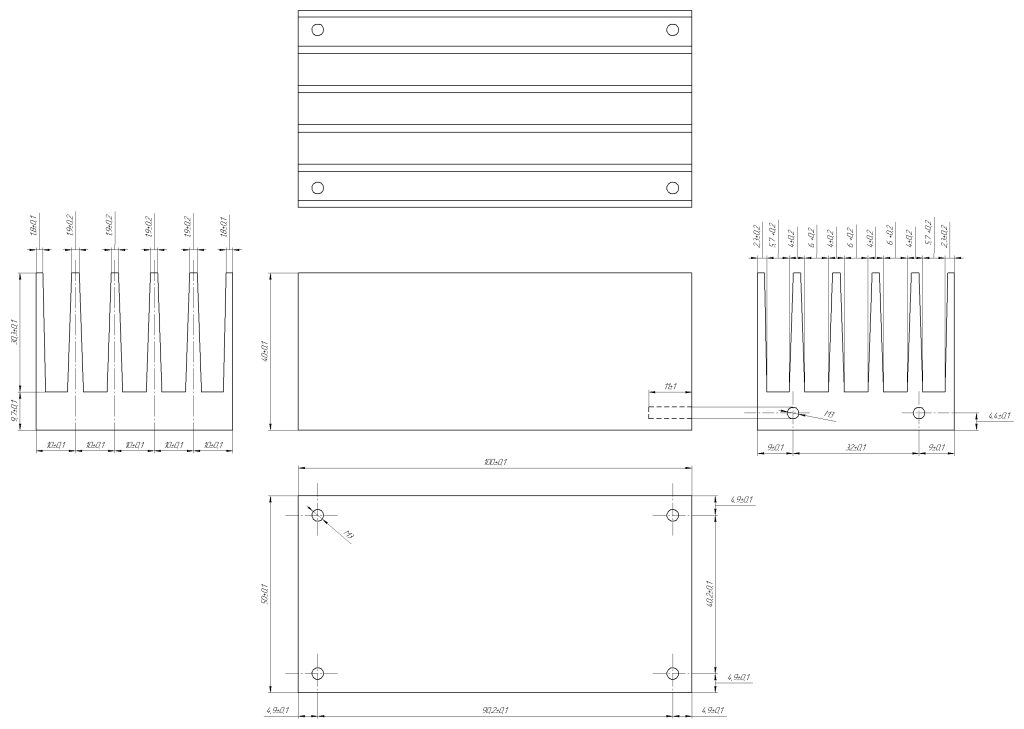

An Endurance external heatsink 2x TEC cooling plates

Main characteristics:

Dimensions 100x50x40mm (3.9×1.9×1.5″)

Weight 245g (0.55 LBS)

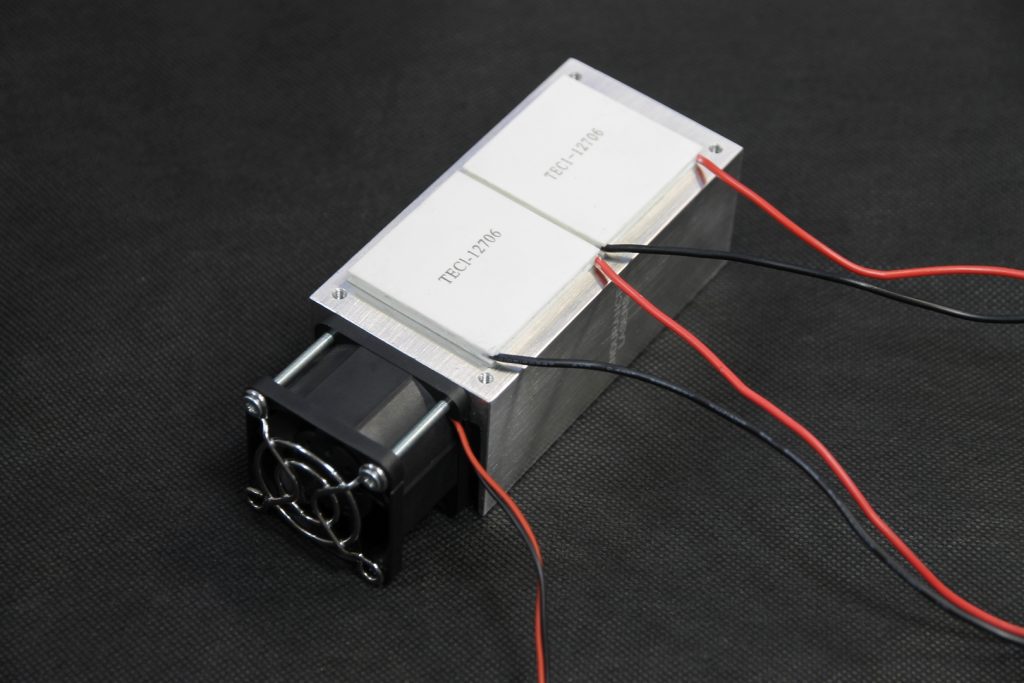

Enduracne 10 watt PLUS PRO uses this external heatsink with 2X TEC coolers

Endurance lasers is using Peltier Element TEC1-12706 in most of our applications.

Description, Application, Operational Conditions

A Peltier element is a thermoelectric converter that creates a temperature difference on its surfaces when electric current flows. Its operation is based on the Peltier effect consisting in the temperature difference occurrence at the point of the conductors’ contact caused by electric current.

Design and function of the Peltier element.

- Application.

- Advantages and disadvantages

- Peltier elements parameters.

- Operational requirements

- Peltier thermoelectrical module TEC1-12706. Parameters and features.

Design and function of the Peltier element.

To my mind, only physics experts can understand how the Peltier element functions in practice. The main thing for practical persons is a minimal module unit – a thermocouple unit consisting of two connected p- and n-type conductors.

When current is passed through the thermocouple the n-p contact absorbs heat and the p-n contact dissipates heat. As a result, one part of the semiconductor adjacent to the n-p contact becomes cooler, while the opposite site becomes hotter. If you change the current polarity, then the other way around, the n-p section will heat up and the opposite one will cool down.

There is also a reverse effect. When one of the thermocouple sides is heated electric current is produced.

For practical application, the heat absorption energy of one thermocouple is not enough. Many thermocouples are used in a thermoelectric module. They are connected in series and in such a way that the cooling and heating junctions are located in different parts of the module.

The thermocouples are installed in between two ceramic plates and are connected by copper busbars. The thermocouples may run to several hundred. The module efficiency depends on their quantity.

The temperature difference between the hot and cold sides of the Peltier module can be up to 70 °C.

It is important to bear in mind that the thermoelectric Peltier module reduces the temperature of one side relative to the other. In other words, for the cold side to have a low temperature it is necessary to remove heat from the hot surface reducing its temperature. To increase the temperature difference, a serial (cascade) module connection is possible.

Application.

Thermoelectric Peltier modules are used in:

- small household and car refrigerators;

- water coolers;

- cooling systems for electronic devices

- thermoelectric generators.

Advantages and disadvantages of Peltier modules

It is somehow wrong to compare Peltier elements with compressor cooling units. They are totally different devices: a big mechanical system with a compressor, gas, liquid and a small semiconductor element. But there is nothing else to compare with. Therefore, the advantages and disadvantages of Peltier modules are a fairly assumed notion. There are fields in which they are irreplaceable, and where their use is absolutely impractical.

The advantages of Peltier elements include:

- absence of mechanically moving parts, gases, and liquids;

- noiseless operation;

- small sizes;

- ability to provide both cooling and heating;

- possibility to smoothly adjust the cooling power.

Disadvantages:

- low efficiency;

- need for a power source;

- a limited number of start-stops;

- high cost of powerful modules.

Peltier element parameters

- Qmax (W) is the cooling capacity at the current-carrying rating and 0° temperature difference between the hot and cold sides. It is considered that all the thermal energy entering the cold side is instantly transferred to the cold one without loss.

- Delta Tmax (grades) is the maximum temperature difference between the module sides under ideal conditions: the hot side temperature is 27 °C and the cold side has no heat rejection.

- Imax (А) is the current providing the temperature difference delta Tmax.

- Umax (V) is the voltage at Imax and delta Tmax temperature difference.

- Resistance (Ohm) is the module DC resistance.

- COP (Сoefficient Of Рerformance) is the coefficient, the ratio of cooling power to the electrical power, consumed by the module. Something similar to the efficiency. Usually 0.3-0.5.

Peltier element operational requirements

Peltier modules are unpredictable devices. Their use is associated with a number of requirements ignored of which results in: module degradation or failure, and system deficiency.

- The modules generate a significant amount of heat. To dissipate heat a proper heat-sink should be installed. Otherwise:

- It’s not possible to attain the desired temperature of the cold side, since the Peltier element reduces the temperature above the hot surface.

- The warming-up allowance of the hot side is + 80 °C (up to 150 °C in high-temperature ones) as a rule. Elsewise, the module may simply fail.

- At high temperatures, the module crystals degrade, i.e. the module efficiency and life cycle get reduced.

- A steadfast thermal contact of the module with the cooling radiator is important.

- The module power supply should provide a current with a ripple of no more than 5%. With a higher ripple level, the module efficiency will decrease, according to some reports, by 30-40%.

- The use of relay controllers is not allowed to control the Peltier element. This will result in fast module degradation. Each switching on and off causes breakdown of semi-conductor thermocouples. Due to sudden temperature changes between the module plates, mechanical stresses take place at the semi-conductor soldered joints. The manufacturers of Peltier elements limit the number of module start-stop cycles. For household modules, this is about 5000 cycles. A relay controller will disable a Peltier module in 1-2 months.

- In addition, the Peltier module has a high thermal conductivity between the plates. When turned off, the heat-sink from the hot side will be transferred through the module to the cold side.

- It is not allowed to use PWM modulation to control the PWM power.

- A current or voltage source should be used for the Peltier module. A voltage source is usually used. It’s easier to implement. But the current-voltage characteristic of the Peltier module is non-linear and seep. That is, with a little voltage change the current changes significantly. Additionally, the characteristic changes when the temperature of the module sides changes. It is necessary to stabilize the power, i.e. the product of the current through the module and the voltage across it. i.e. the product of the module current by its voltage. The cooling ability of the Peltier element is directly related to the electrical power. But this requires a fairly complex controller.

- The module voltage depends on the number of thermocouples in it. Typically, it has 127 thermocouples, which correspond to 16V. The developers of the Peltier module recommend apply 12V or 75% UMax. This voltage ensures the optimal efficiency of modules.

- The modules are hermetically sealed and can be used even in water.

- The module polarity is marked with the wire color: black and red. As a rule, the red (positive) wire is located to the right of the cold side.

I have developed a Peltier element controller for a fridge, answering all these requirements. It:

- generates power for the Peltier element with ripples of no more than 2%;

- stabilizes the module electrical power, i.e. the product of current by voltage;

- ensures smooth module activation.

- The temperature control is based on the analog control method, i.e. smooth power change on the Peltier element.

- The controller is developed for a fridge which is why the controller’s mathematics takes into account the inertia of the air cooling in the chamber.

- It provides the temperature control of the module hot side and fan control.

- It has high efficiency, and wide functionality.

Peltier thermoelectric module TEC1-12706

This is the most common type of Peltier element used in many household appliances. Not expensive, with good parameters; a good option for building low-power fridges, water coolers etc.

The TEC1-12706 module specifications TEC1-12706.pdf by the manufacturer – HB Corporation.

Operating Tips · 138oC ·. · Please consult HB for moisture protection options (seeling). TEC1-12706 · · · 0.2%.

Operating tips

Max. Operating Temperature 138 °C.

- Do not exceed Imax or Vmax when operating the module.

- Life expectancy: 200,000 hours.

- Failure rate based on long-time testings: 0.2%.

- Manufacturer – HB Corporation.