Innovative rust removal method

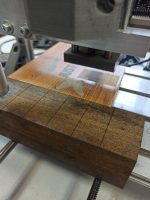

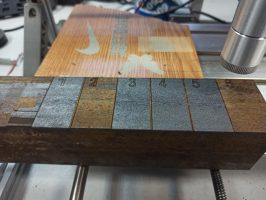

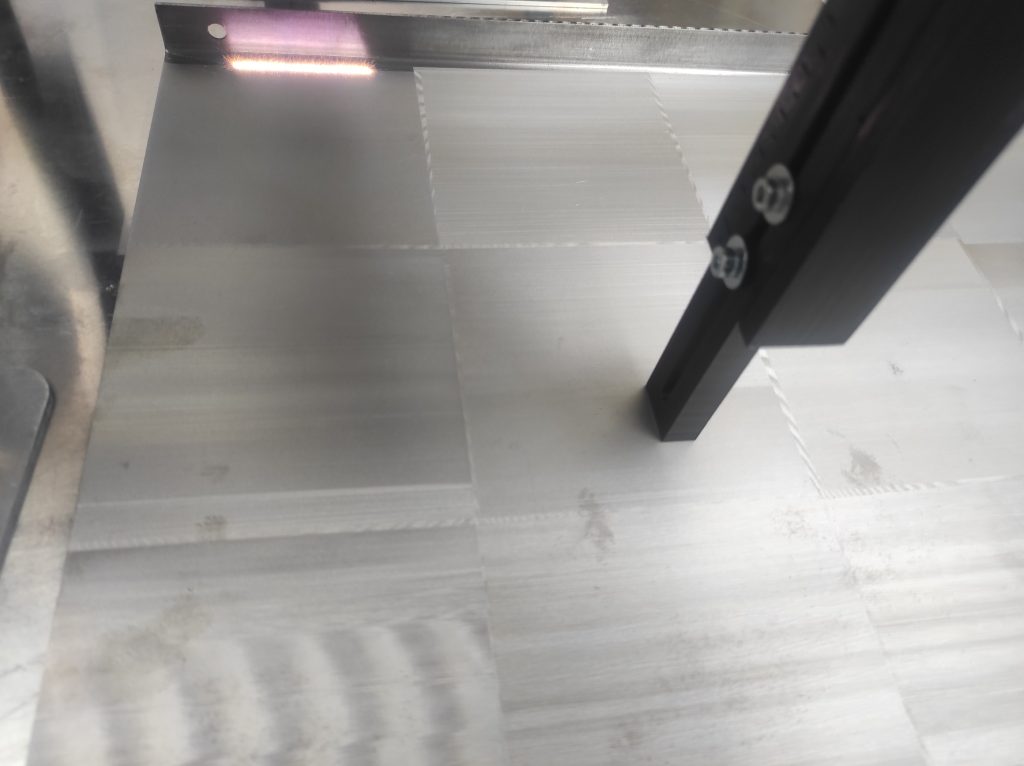

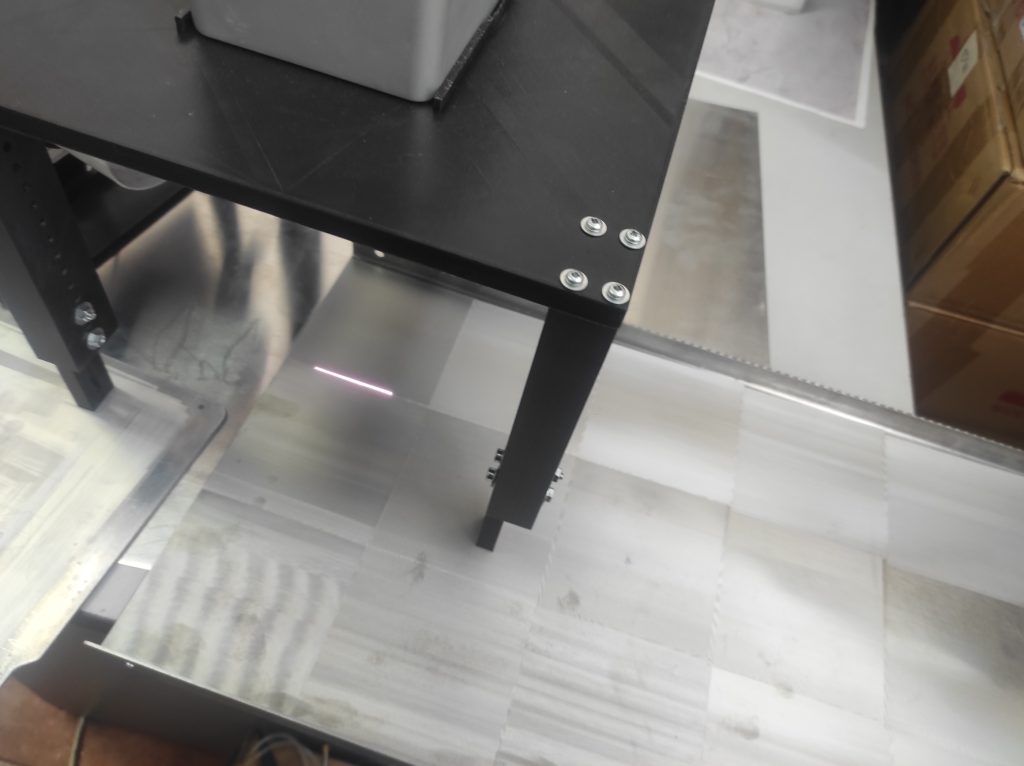

A new approach to save iron from rust. Laser metal processing using 10 watt DPSSL installed on DIY galvo frame

A detailed video about laser rust removal

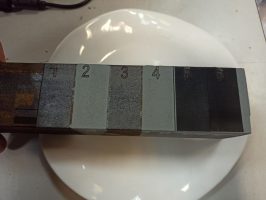

Glass zinc coating

Photo laser engraving on granite. DIY.

Transparent acrylic engraving

Fiber cloth (fiberglass) cutting

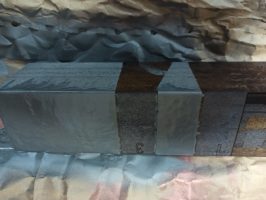

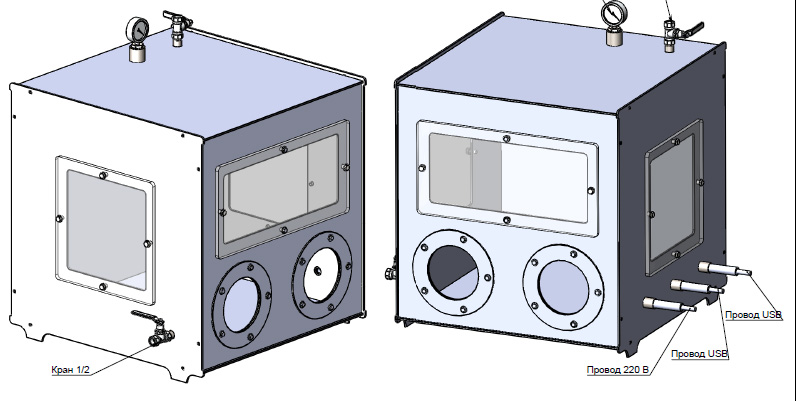

Endurance plans to develop a rust removal system.

The basic idea is to make a fully automated system that can remove rust from metal surfaces.

1. Following 3D surface.

As soon as a lot of surfaces are not smooth and have a different height range the need to keep the laser in focus all the time

Therefore you need to get a 3D model of an object.

If you do not have a 3D model of an object then you need to make it using a 3D scanner.

2. Positioning the real object and a 3D model.

Once you are ready to remove rust you need to put the piece on a worktop and make 2-5 dots on the perimeter. That dots will allow you to locate the item properly on a worktop.

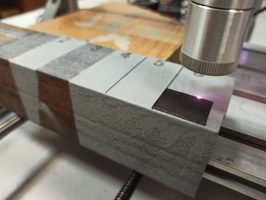

3. Generate a rust removal g-code so that the laser will remain on the same height. Remaining on the same hight will allow you to do a rust removal efficiently.

4. Real video.

You may add a real-time video from a camera that will combine a real image with a 3D model.

5. Additional height adjustment system.

A special range finder tool can be added to check the real height of the laser to remain in focus.

Camera for an engraver

The stainless steel cutting 500 uM (0.5mm)

Laser soldering of lead on a copper plate

How to create aluminum tracks on the tape. Adding them with the laser