Laser soldering / cutting and welding of polyethylene film with the laser

For this task we will use 80 watt Endurance Co2 laser.

An Endurance 80 watt Custom Co2 Laser Machine with 6×5′ (2×1.7 m) working size area

On other types of lasers, the film was either burned through or excluded and not soldered.

Welding of materials was carried out with an overlap, when soldering joints in a joint, the edges were melted and the difference between them increased.

The material was fixed with paper tape to prevent it from being blown away by prolonged cooling of the laser.

Both ends of the plastic film must be tightly fixed to each other, otherwise, the soldering will not work and the material will not swell.

The first material is a white polyethylene film (marked W )

Parameters under which soldering was carried out

- the number of repetitions – 4;

- speed – 200 mm / s;

- power – 8%.

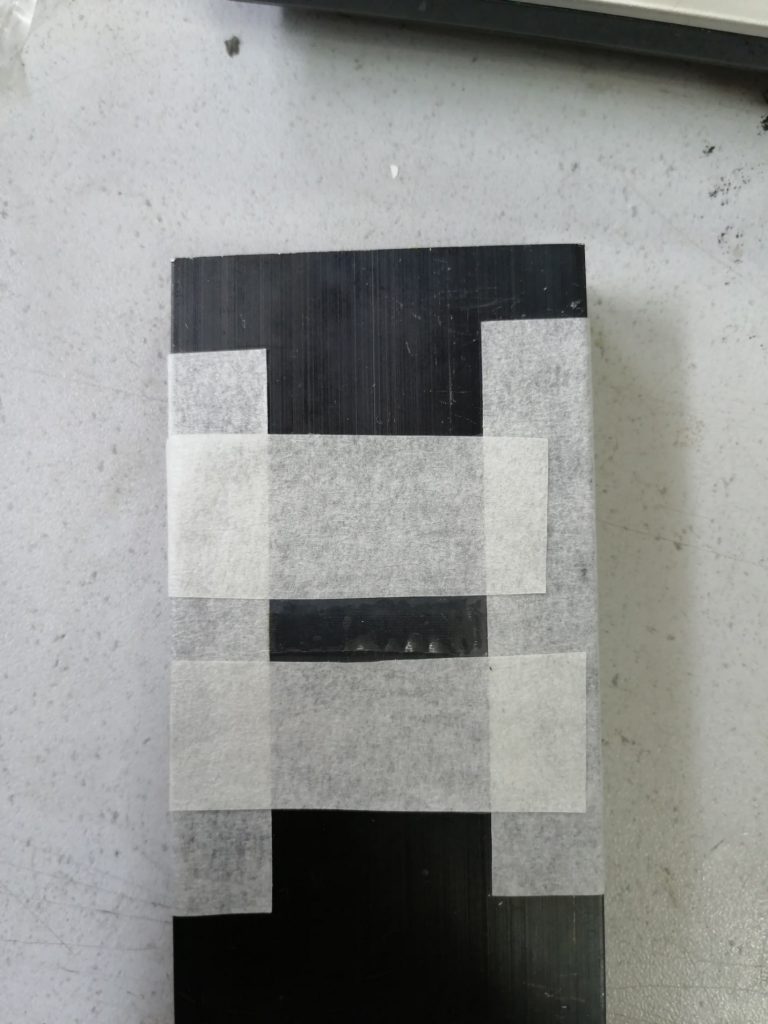

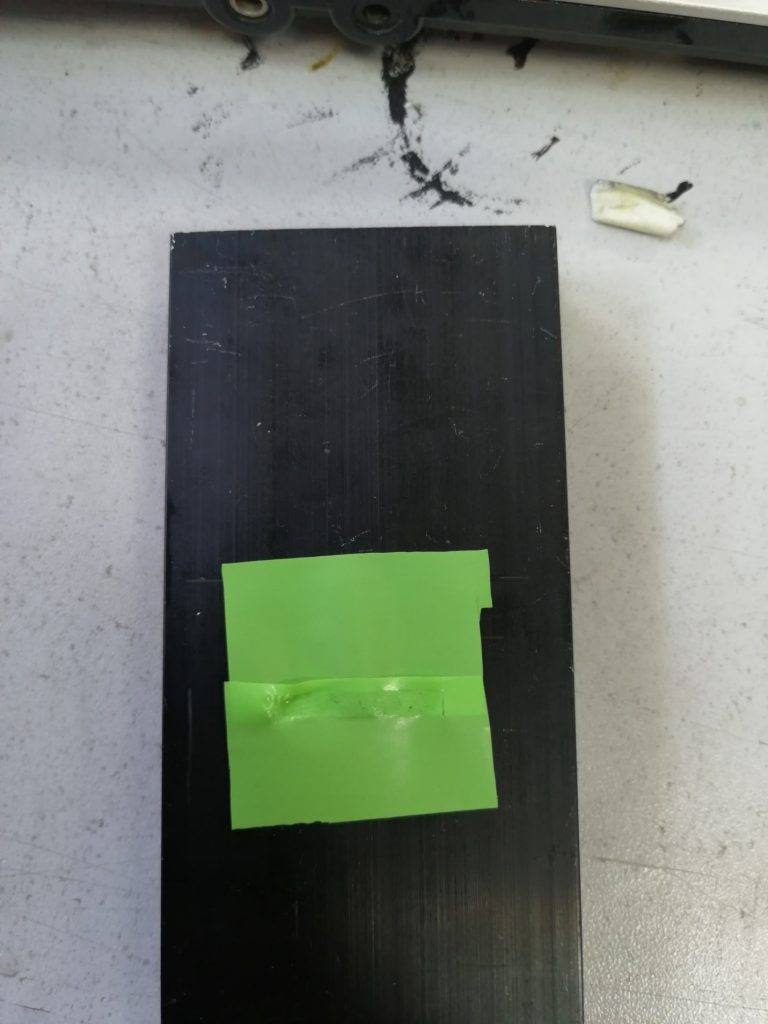

Installing the material on the surface of the surface (Fig. 1).

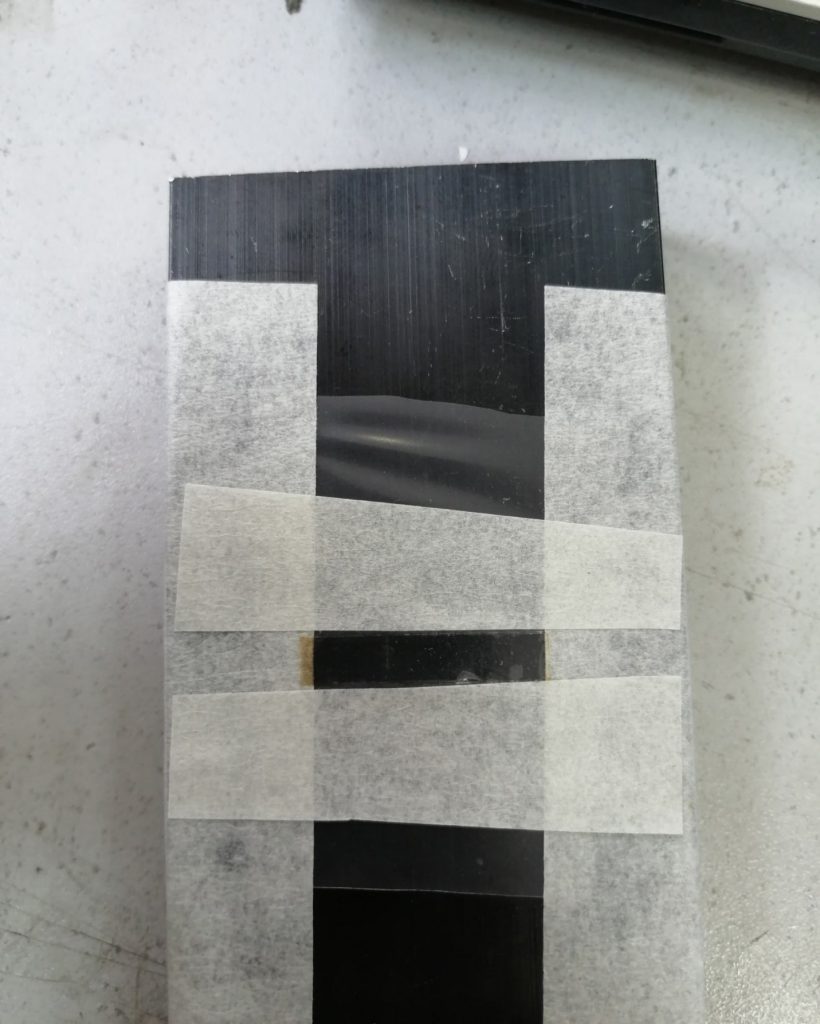

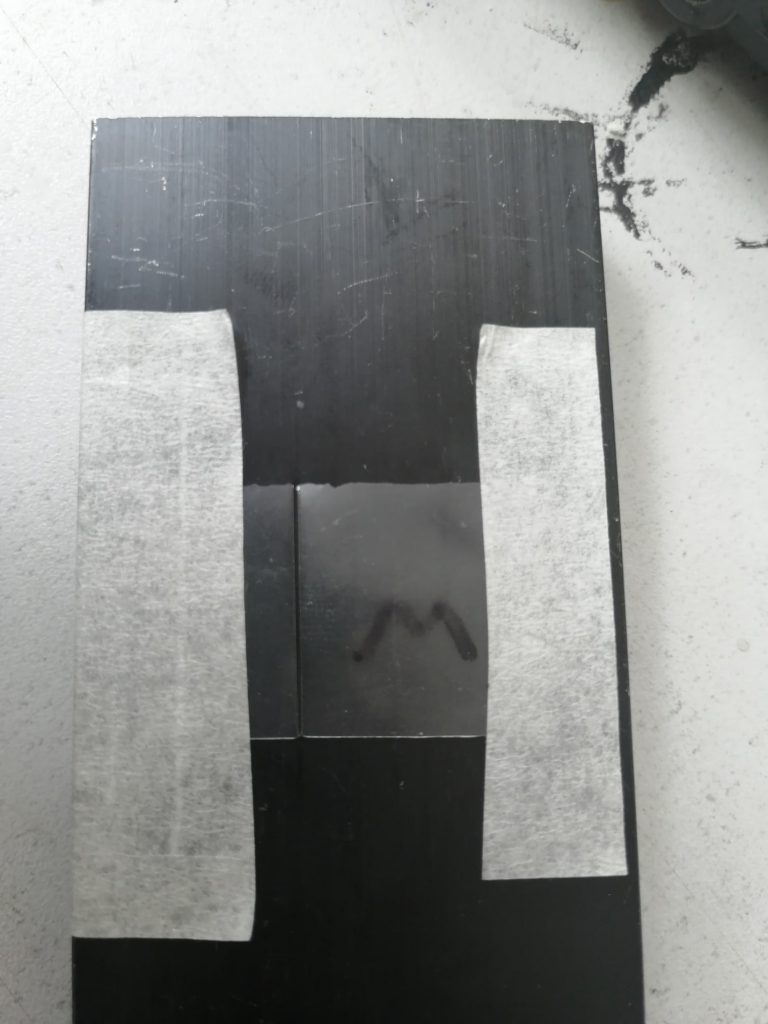

Fixation with paper tape (Fig. 2).

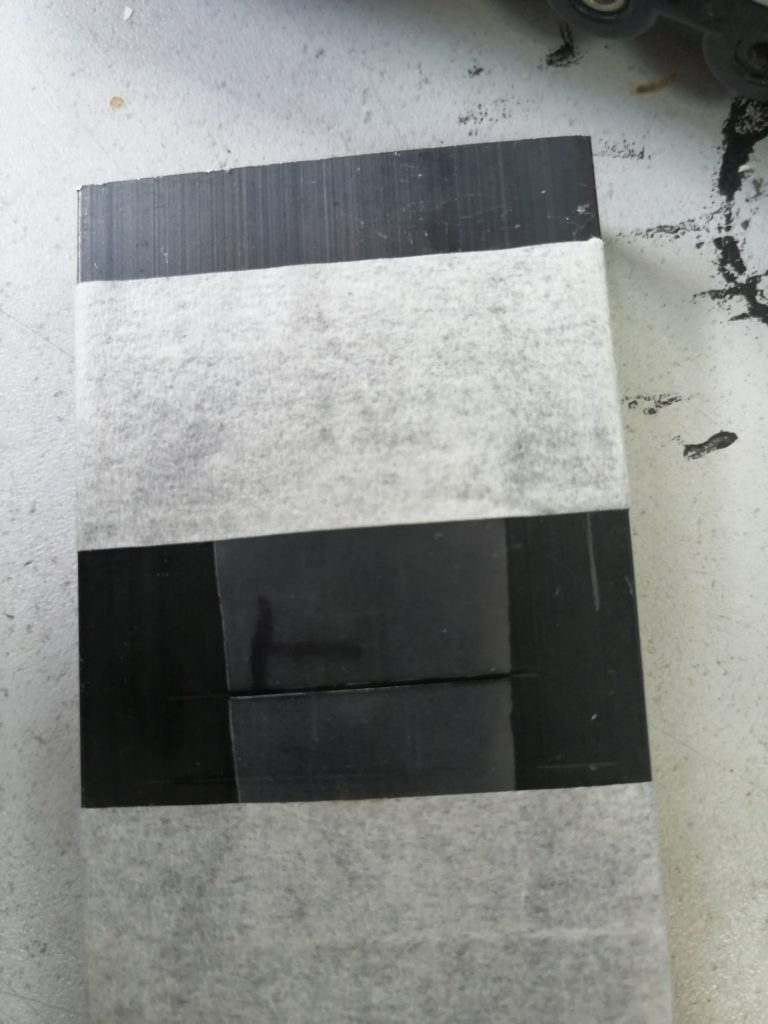

Soldering results in Figure 3 and Figure 4.

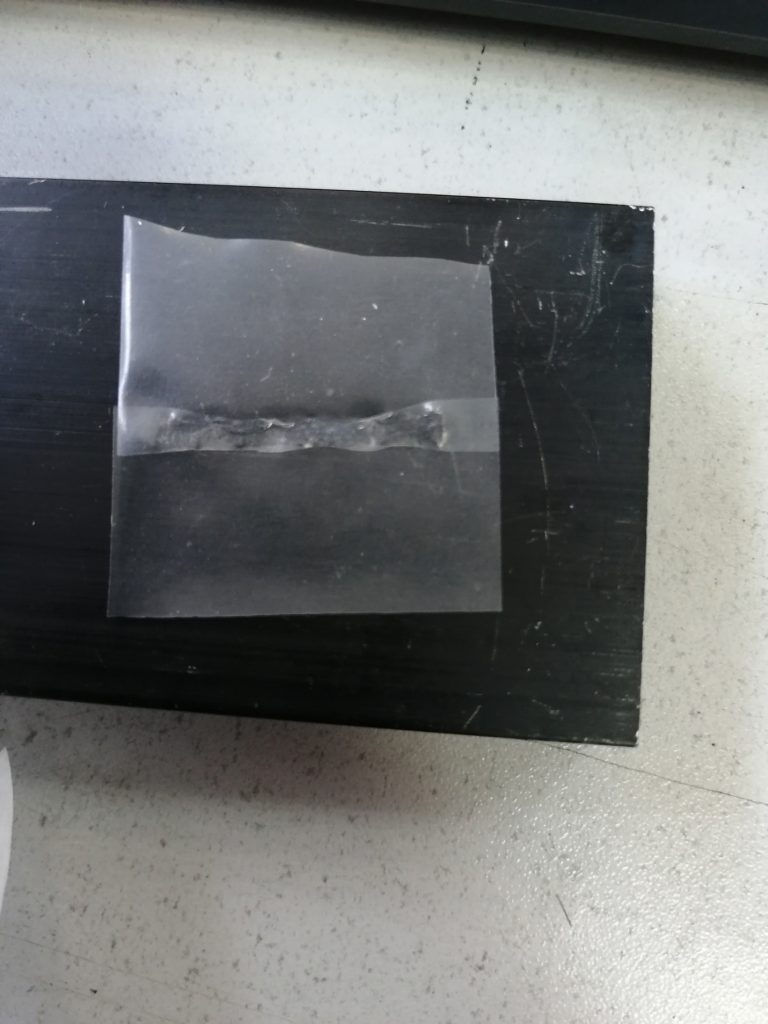

The second sample is a transparent polyethylene film (marked T )

Parameters under which soldering was carried out

- number of repetitions – 8;

- speed – 200 mm / s;

- power – 8%.

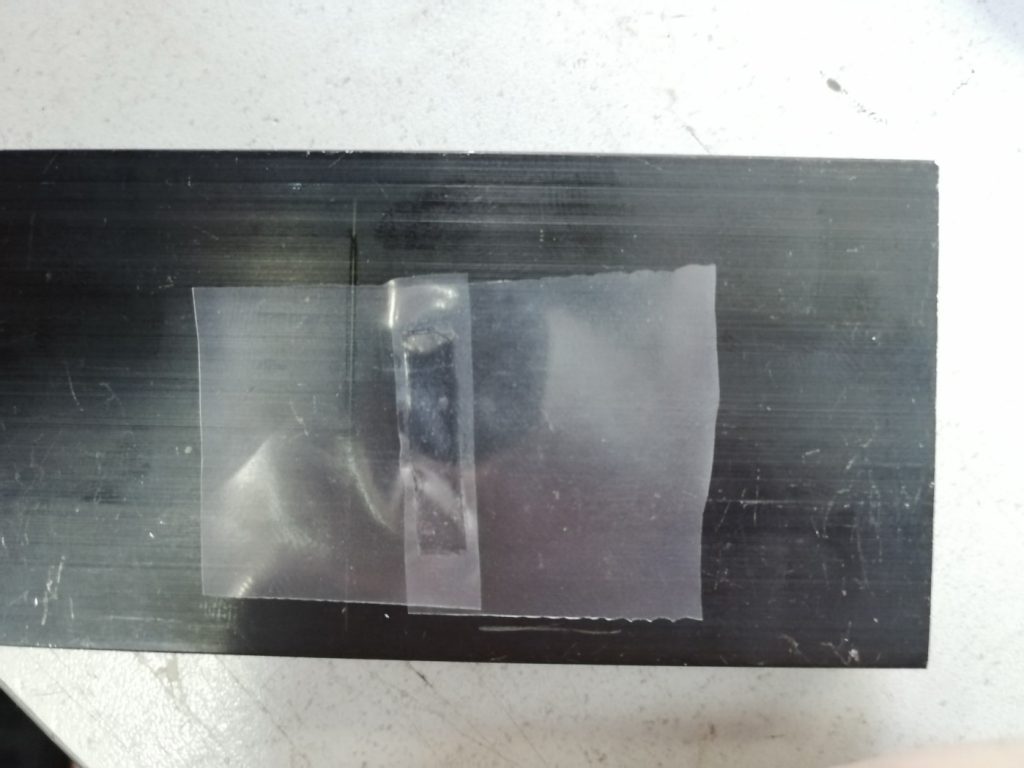

Installing the material in Figure 5.

Fixing the material in Figure 6.

Soldering results in Figure 7 and Figure 8.

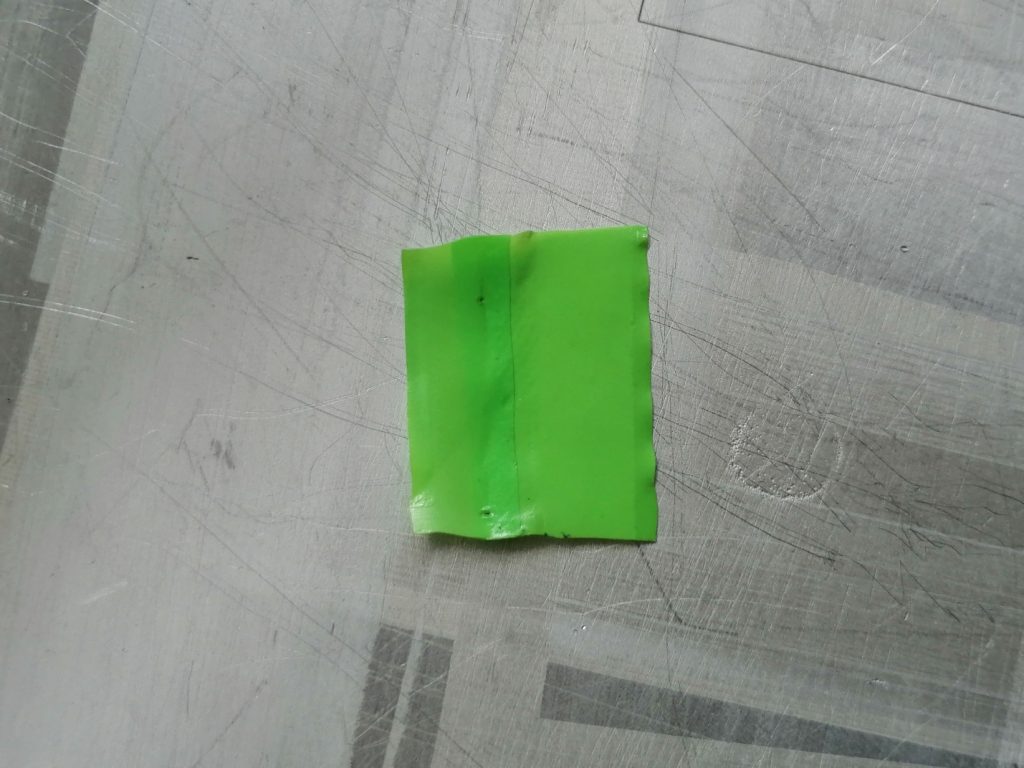

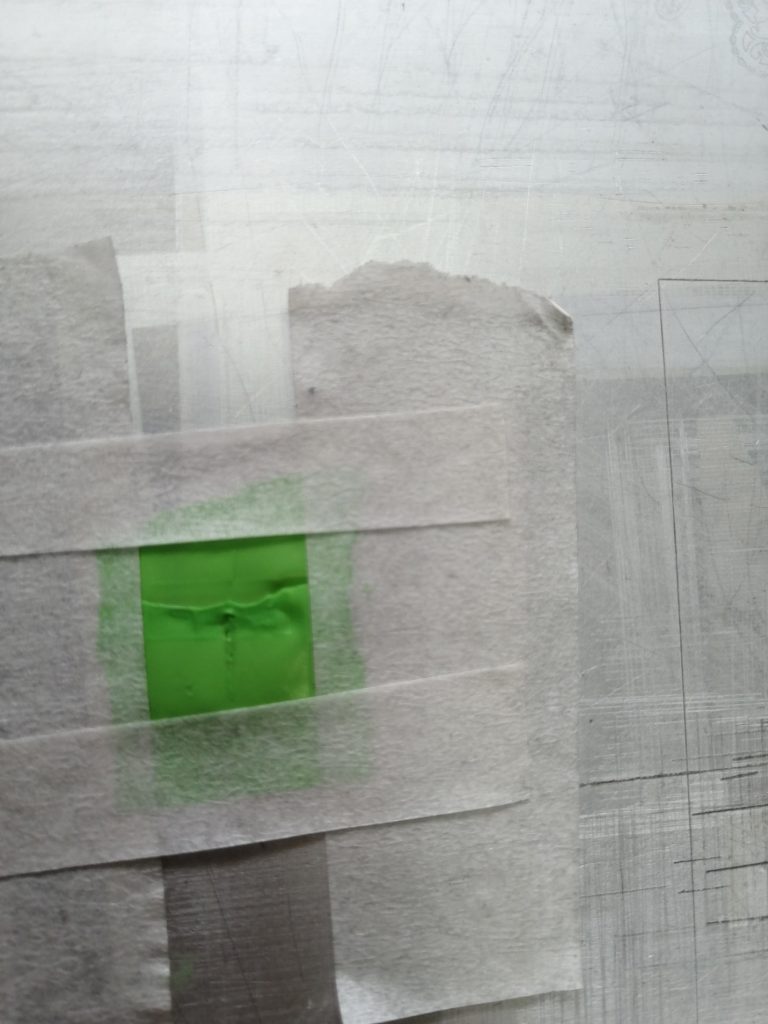

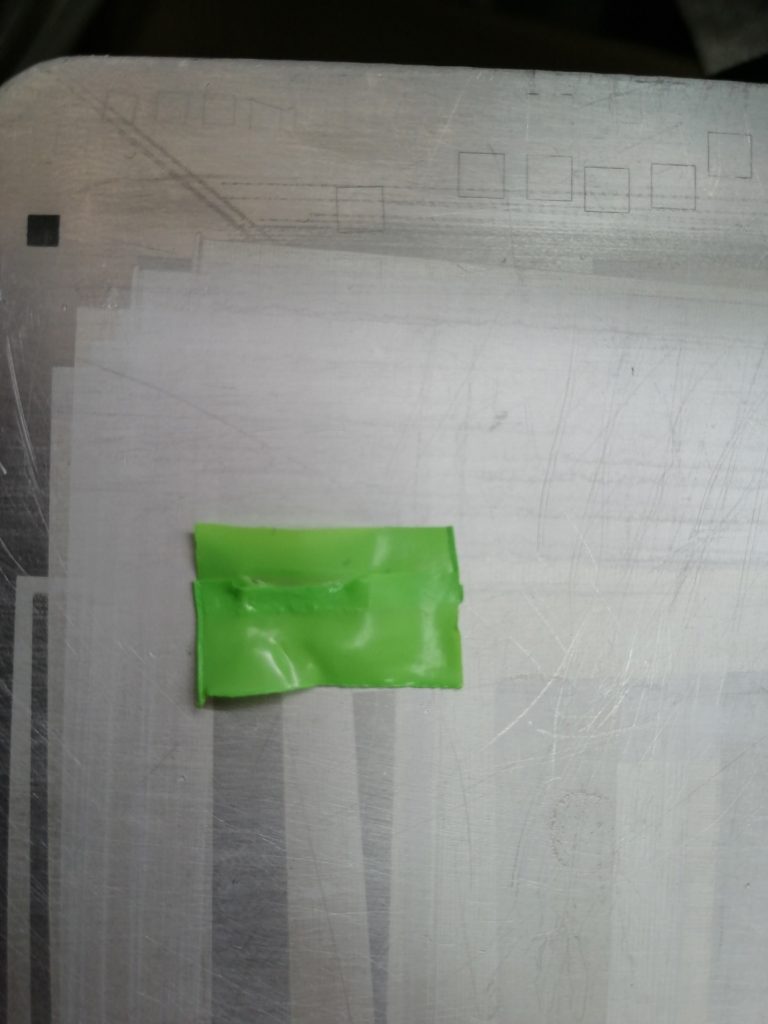

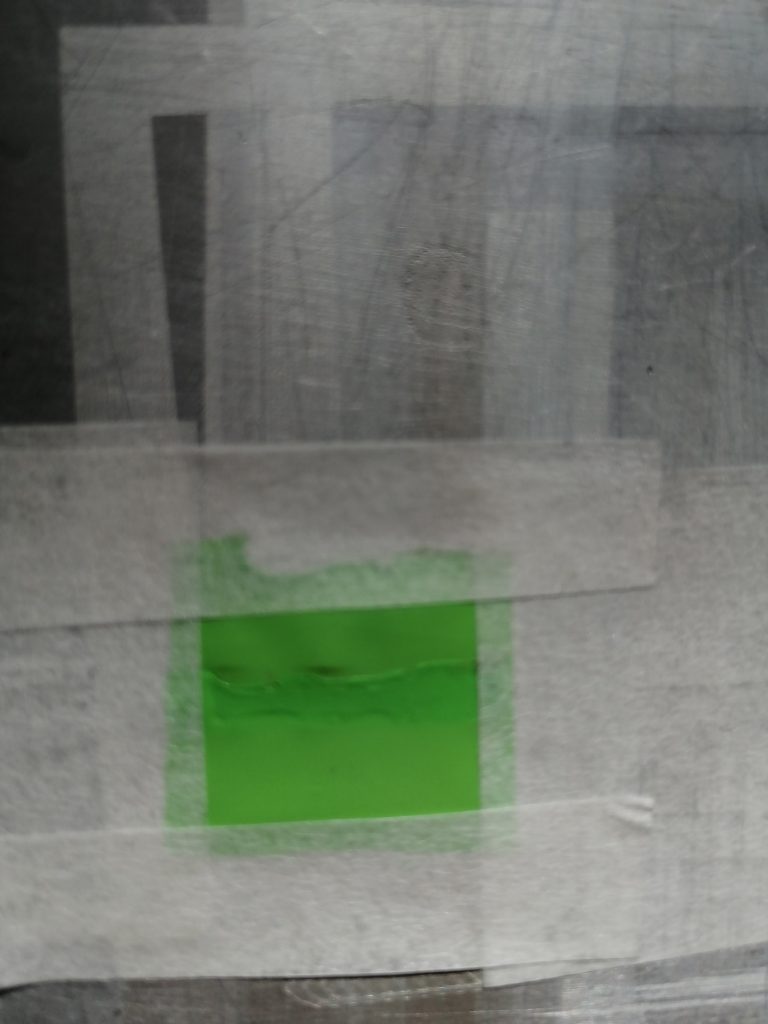

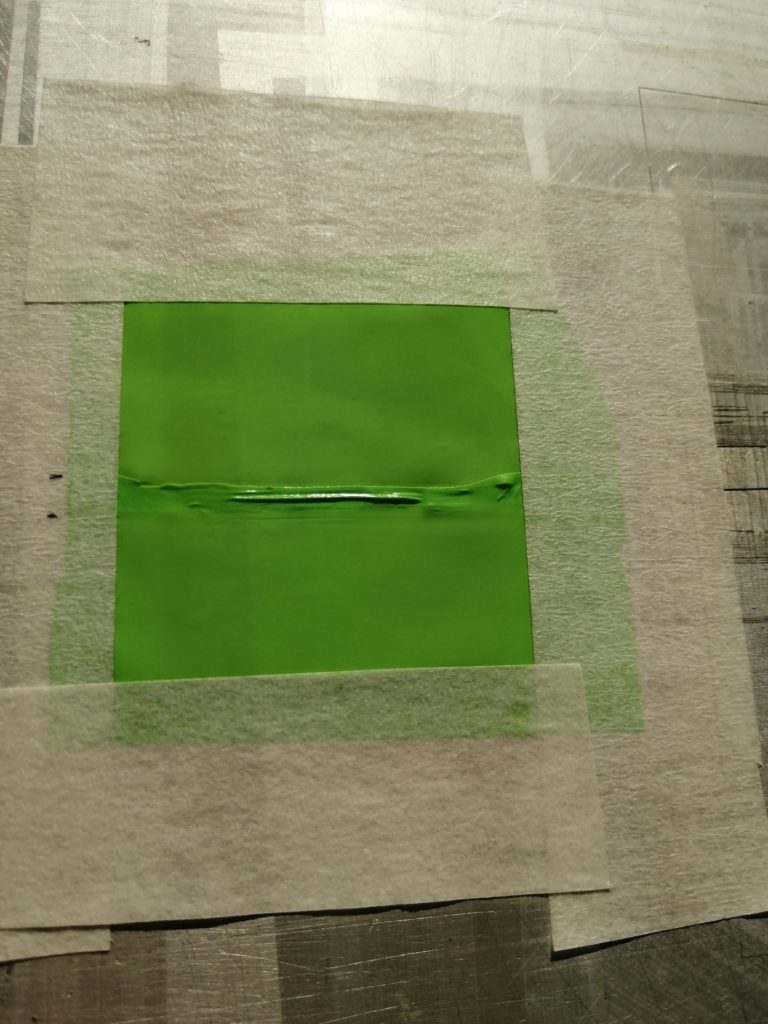

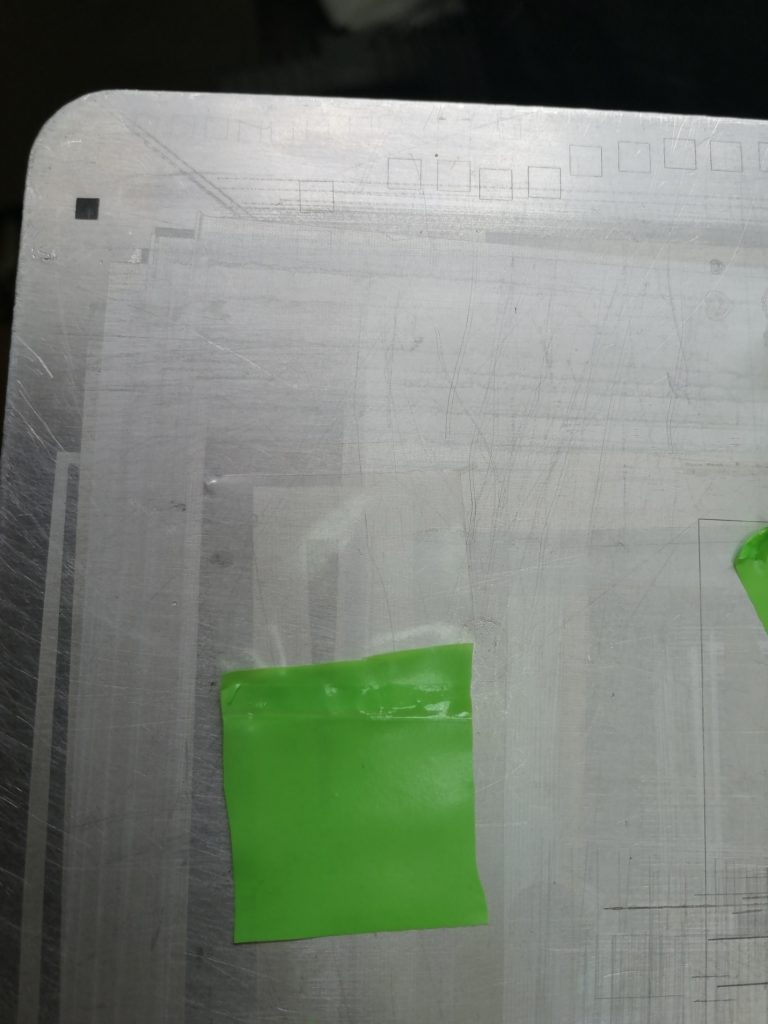

The third sample is a green polyethylene film

Parameters under which soldering was carried out

- number of repetitions – 5;

- speed – 1000 mm / s;

- power – 9%.

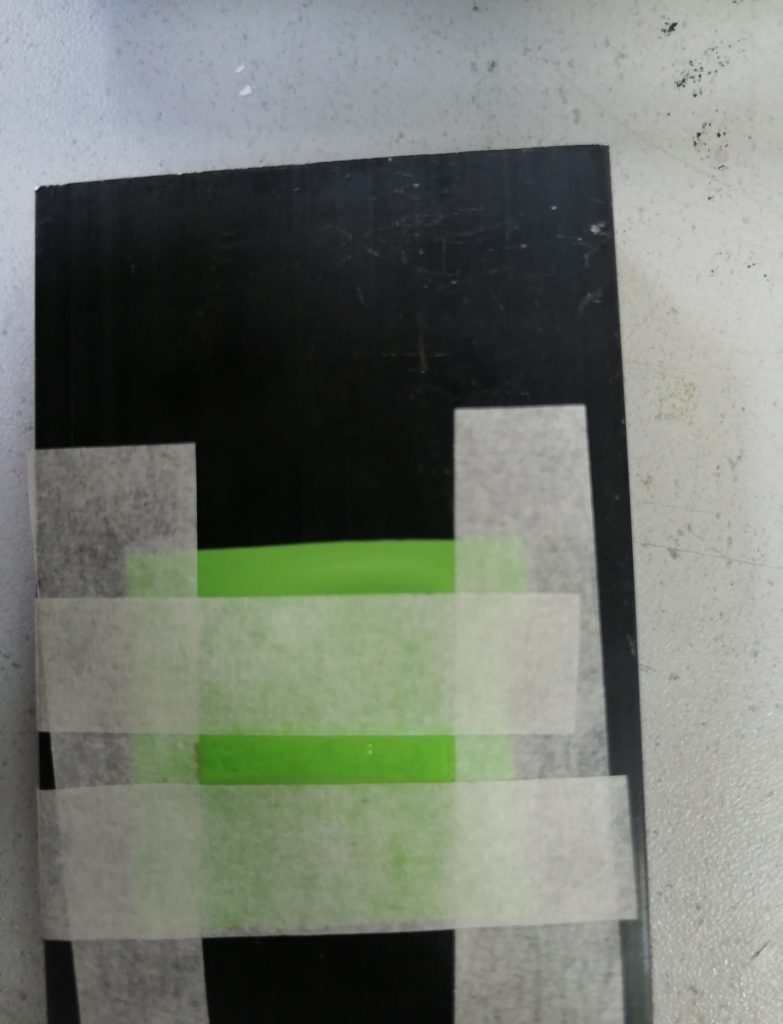

Installing the material in Figure 9.

Soldering results in Figure 10 and Figure 11.

Conclusion on the adhesion of a polyethylene film using a 80W CO2 laser

The entire polyethylene film was soldered at a fairly high speed. The Spanish film was torn in the same way as its entire part, which indicates its other connection to each other.

PE film cutting with 80W Endurance Co2 laser

When using a laser, Co2, as well as on other laser films, either did not burn through right away, or there was no effect on the film.

The material was fixed with paper tape to prevent it from being blown away by prolonged cooling of the laser.

Let’s consider a cut of a white polyethylene film (marked W ).

Parameters under which cutting was carried out

- number of repetitions – 1;

- speed – 200 mm / s;

- power – 20%.

The cutting result is in Figure 12.

The second sample is a transparent polyethylene film (marked T ).

Parameters under which cutting was carried out

- number of repetitions – 1;

- speed – 200 mm / s;

- power – 20%.

The cutting result is in Figure 13.

The third sample that we plan to cut off is a plastic film.

Parameters under which cutting was carried out

- number of repetitions – 1;

- speed – 200 mm / s;

- power – 15%.

The cutting result is in Figure 14.

General information about the conclusions for cutting polyethylene film with an 80 W CO2 laser.

Cutting polyethylene films with a Co2 laser is very fast. Visible charring, subsequent or excessive melting was not purchased.

For the third experiment we will do more tests using 10 watt diode 445 nm laser

The same task is to solder 2 polyethylene films to each other

Polyethylene welding results on a CNC 3018 machine with a 10 W plus laser professional Endurance lasers

Thr Endurance CNC 3018 laser engraving / cutting machine / carving machine

- repetition of numbers – 1

- Speed – 1000 mm / m

- Power – 1%

- number repetition – 4

- Speed – 1000 mm / m

- Power – 1%

- number repetition – 4

- Speed – 1000 mm / m

- Power – 3%

- repetition of numbers – 2

- Speed – 1000 mm / m

- Power – 5%

- number repetition – 4

- Speed – 1000 mm / m

- Power – 5%

- number repetition – 4

- Speed – 1000 mm / m

- Power – 5%

We decided to try an alternative way to weld/weld the material using a 10600nm 80W Co2 laser with a galvo scanner.

Unlike the diode laser, the Co2 laser can solder transparent/translucent types of polyethylene.

Co2 laser parameters

- repetition of numbers – 5

- Speed – 1000 mm / m

- Power – 10%

- repetition of numbers – 5

- Speed – 1000 mm / m

- Power – 10%

- number repetition – 4

- Speed – 700 mm / m

- Power – 10%

In general, the connections are relatively strong.