All you need to know about laser rust removal – parameters, settings, a full detailed guide. How to reduce corrosion speed.

Endurance old metal items renovation >>>

Old eyeglasses temples renovation

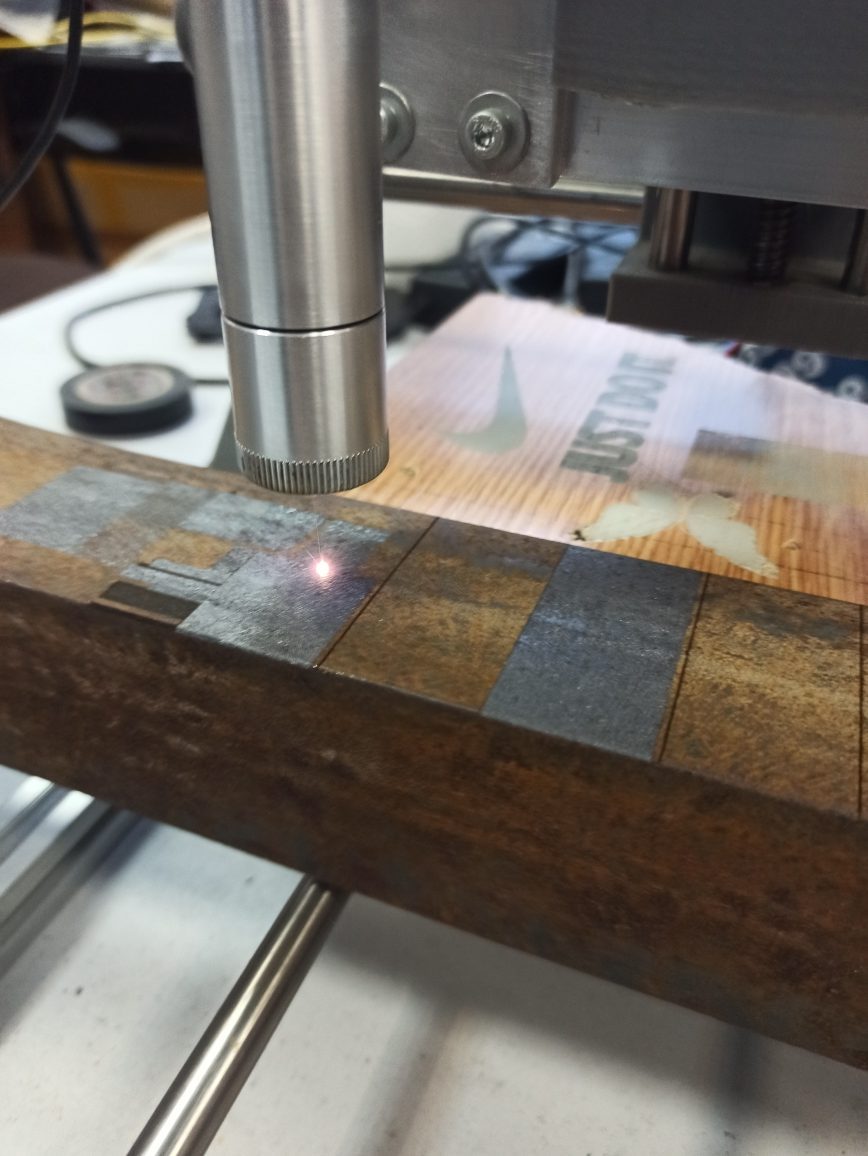

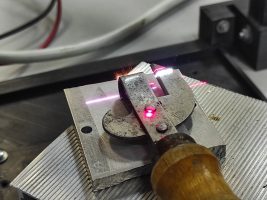

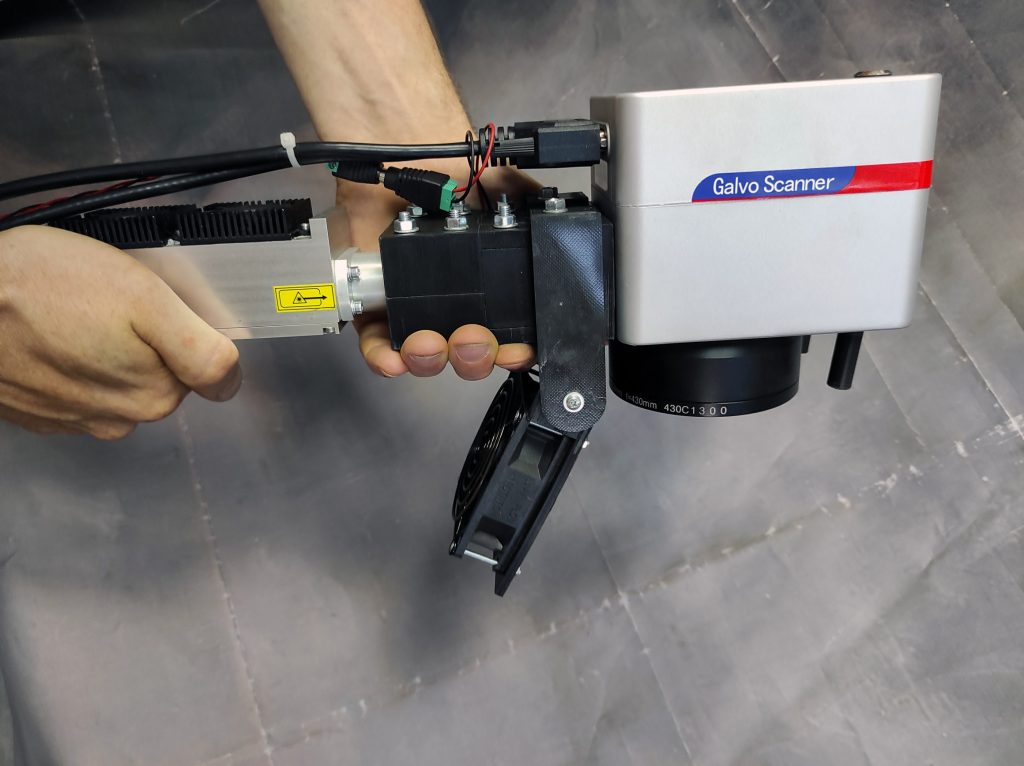

Laser rust removal with an Endurance 10 watt DPSSL DIY galvo machine

Experimental Rust Removal from a Metal Surface Followed by Zinc Coating Using a Diode Laser (Endurance 10 Watt DPSS Laser Nd: YAG, 1064 nm, F = 30 mm short focal lens)

Task:

to determine a laser operation mode and processing sequence to obtain a corrosion-resistant coating of a metal workpiece.

For the experiment, a rusty piece of iron, a can of zinc spray, and technical nitric acid were taken. The task was done with an Endurance 10 Watt DPSS Laser (here is its description: https://endurancelasers.com/an-endurance-brand-new-fiber-marking-module-for-metal-engraving/ )

Working process – all steps you need to follow:

Getting started

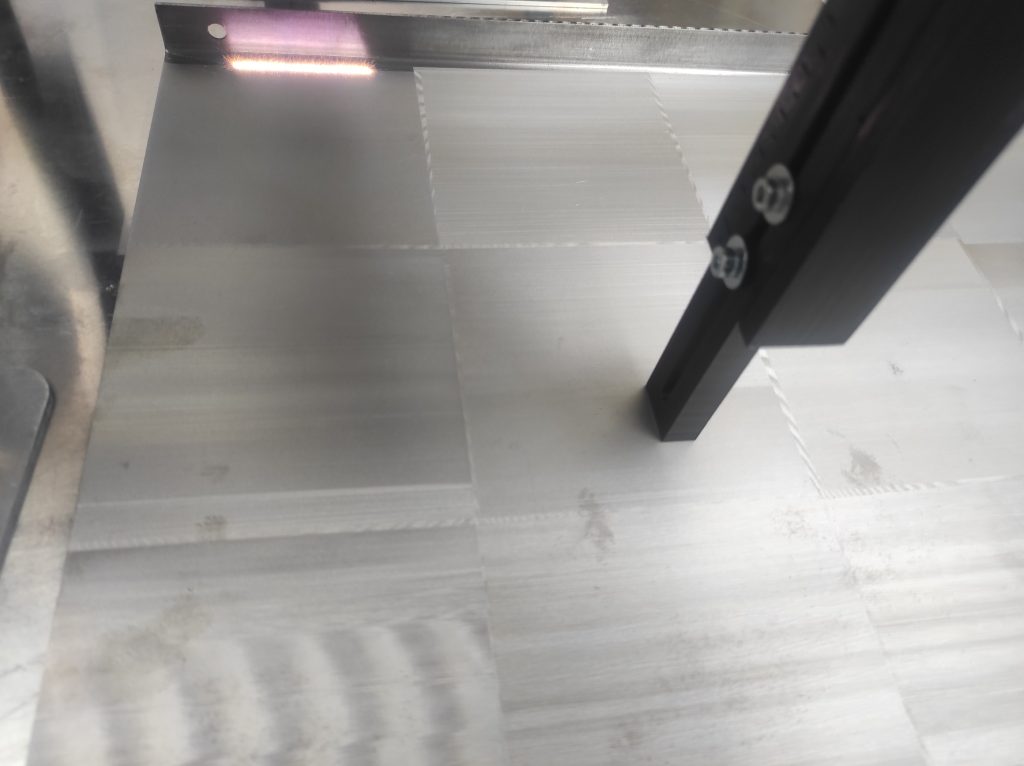

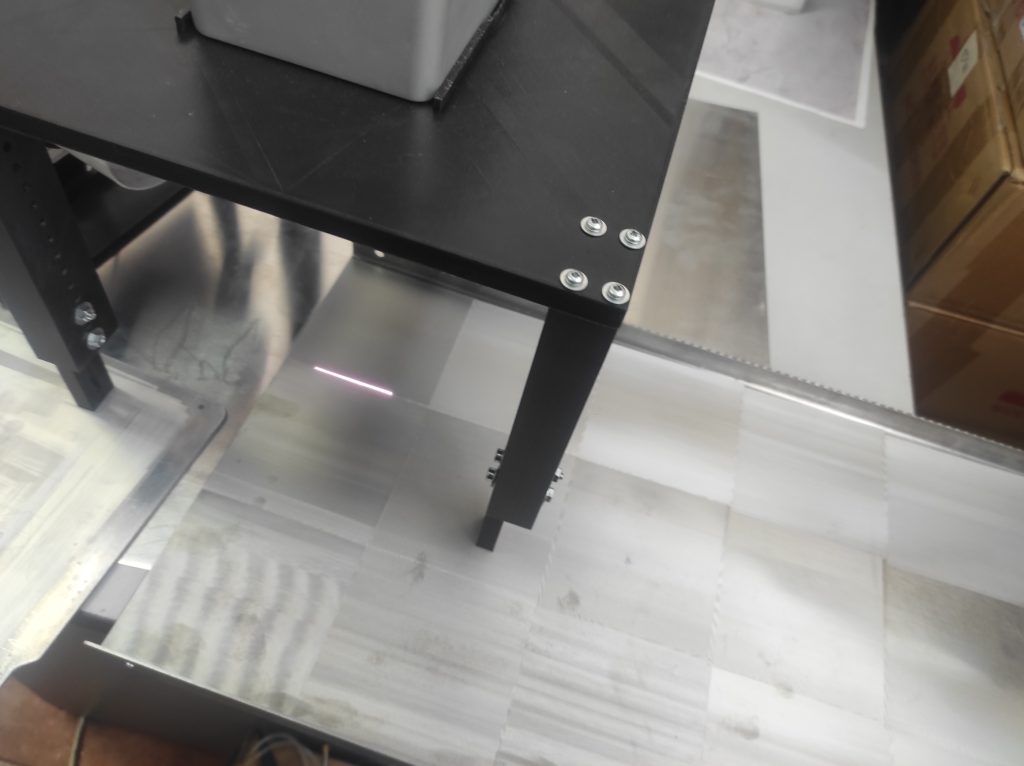

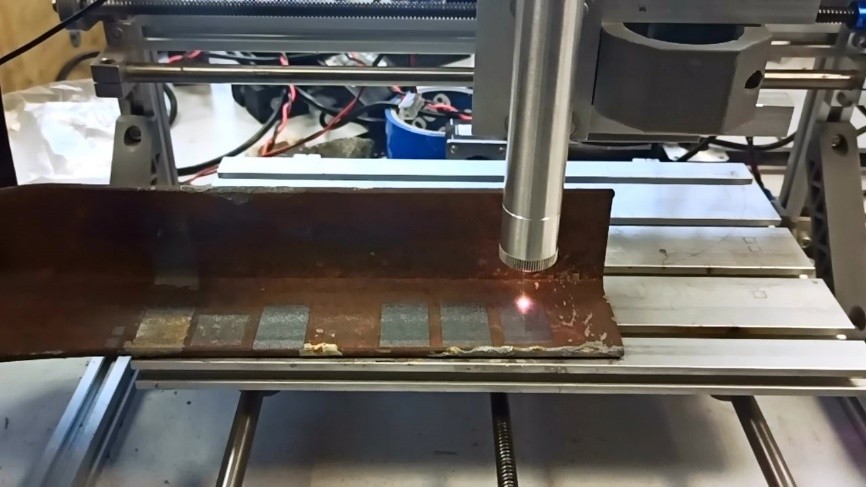

We used a rusty unprocessed metal plate, as we needed a surface with a thick rust layer. We divide the metal surface to be processed into 6 segments. Each of them will be processed in a special way.

Here are the processing methods for each segment:

1. Laser treatment (no zinc or acid application)

2. Zinc treatment → acid application (no laser treatment)

3. Laser treatment → acid application (no zinc)

4. Laser treatment → zinc treatment → acid application

5. Laser treatment → zinc coating → second laser treatment → acid application

6. Zinc treatment → laser treatment → acid application

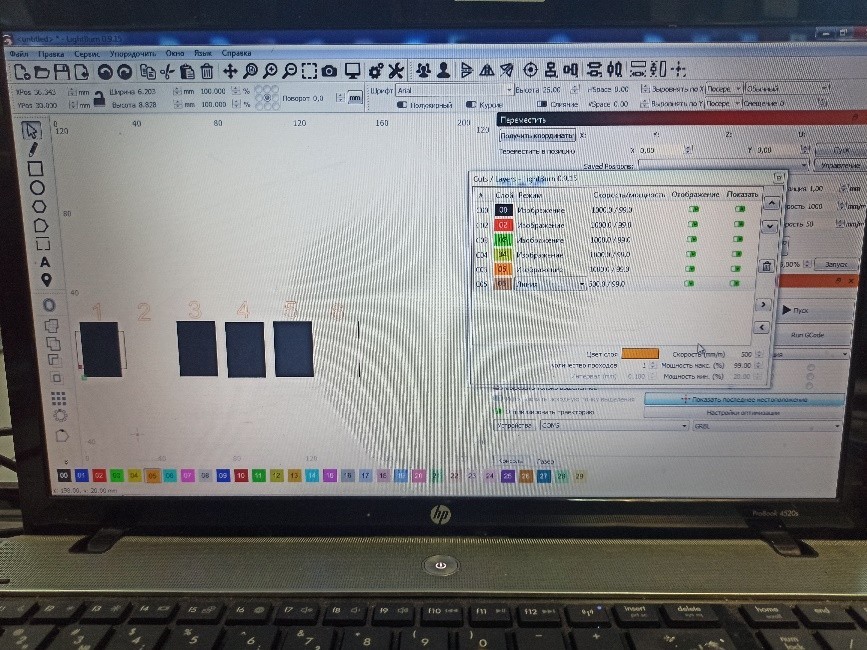

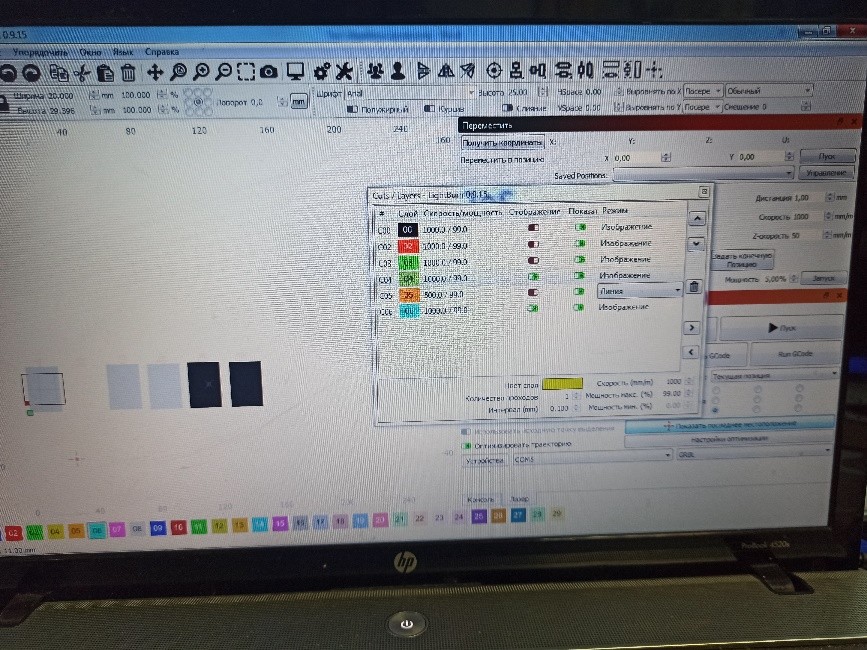

2. Lightburn settings

In the LightBurn 0.9.15 program, we set the laser parameters and limit its working area to segments 1,3,4,5. The laser processing is carried at a speed pf 1000 mm / min, power 99%, and interval 0.1 mm. Important – the focal point should be 2 mm above the surface to be treated. Otherwise, engraving instead of rust removal will take place. We run the laser and wait.

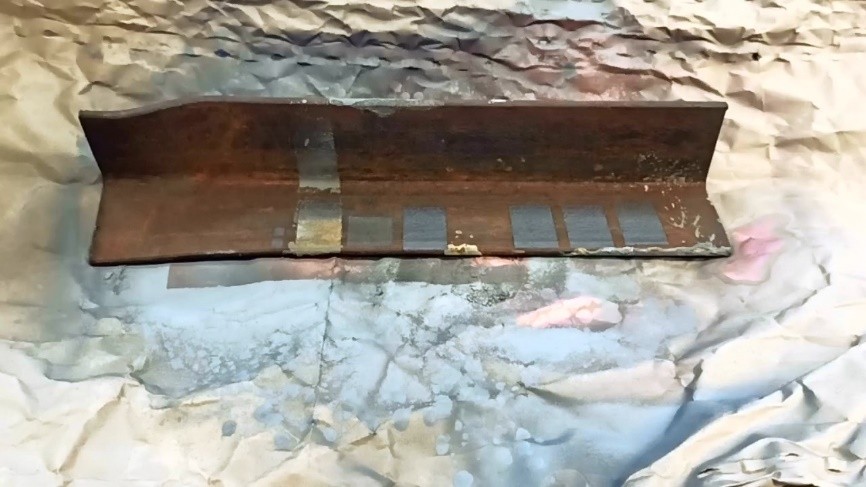

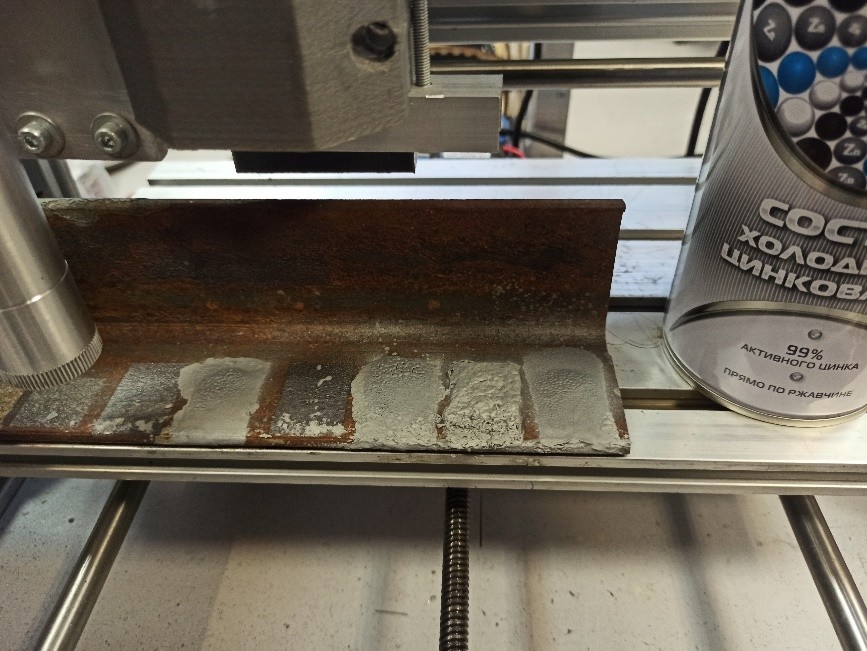

3. Adding a liquid zinc spray

After processing segments 1,3,4,5, we zinc spray areas 2,4,5,6 trying to apply an even coating, approx. 1 mm thick. It takes the zinc spray coating about a quarter of an hour to dry completely.

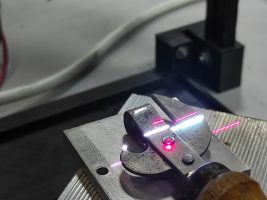

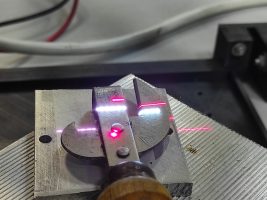

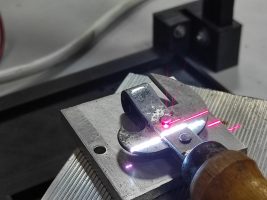

4. Laser processing

After this we repeat laser processing of areas 5 and 6. Now the metal surface should be 4 mm below the focal point. Otherwise, zinc might burn out or not alloy with the surface of the workpiece. ( For more information on metal processing go to this page>>> )

5. Removing the rest of the zinc

When the laser processing is done we brush the surface of the plate to remove zinc residues, carbon deposits and excess rust. Now it’s time to use the acid.

6. Testing with a nitric acid

In a well-ventilated area, or using a hood, we proceed very carefully to the nitric acid application, observing all safety rules, wearing a respirator, protective gloves and safety goggles. We apply a few drops of the acid with a special chemical pipette to areas 2,3,4,5,6.

It should be mentioned that the acid reacts with the metal surface instantly but is rather short. 10 minutes later corrosion formation is observed in sections 3 and 6. It means that the method of treatment applied for these sections is unacceptable. After another 30 minutes, rust begins to appear in section 2, indicating the imperfection of its treatment method too. No other changes of the metal surface occurred for a long time, so it was decided to put aside the processed sample for a couple of days.

7. Checking the result

Two days later we checked the state of the experimental metal plate and found that all the areas looked rusted, almost as bad as before the experiment. All segments but number 5. This area was less corroded. A distinct zinc coating covered a significant part of its area. This fact suggests that the best way to protect an iron surface from rust might be laser treatment, followed by zinc coating and another laser treatment.

Save iron and protect stainless steel from rust and chemical corrosion.

If you have any more questions about laser rust removal or you would like us to build you a custom solution or an entire laser frame – let us know in Livechat!