Here we’ll tell how to cut materials using the CNCC V2.50 software and a 5.6 W Endurance laser with a short-focal lens G2, installed on a DIY platform.

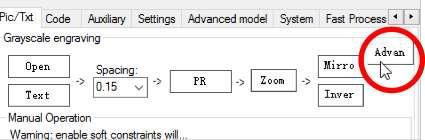

To cut materials we use the Advan mode (see the fig. below).

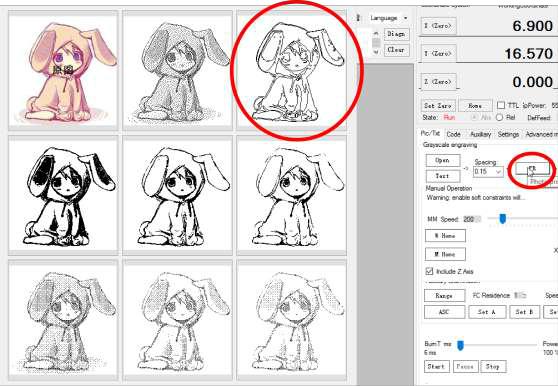

Firs off all we select an image. The thinner the lines of the image the better for the G-code. Click the Open button.

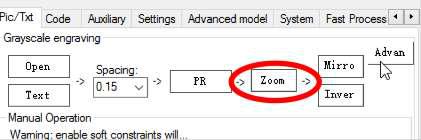

Select the filter (PR), the upper right image is the most suitable.

Set the image size in mm using Zoom. The bigger the image the thicker the lines, that’s why we need an image with thin lines.

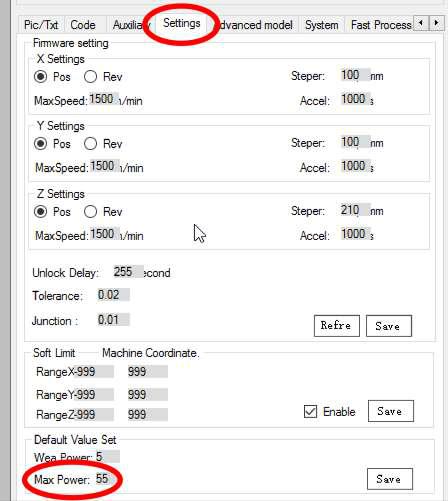

Then we select the laser power in the Settings. In the Max Power we set the necessary limit and Save the parameter.

Why Do We Need to Change the Power?

If the laser power chars the material and you cannot fix the problem varying the cutting speed, you need to reduce the laser power.

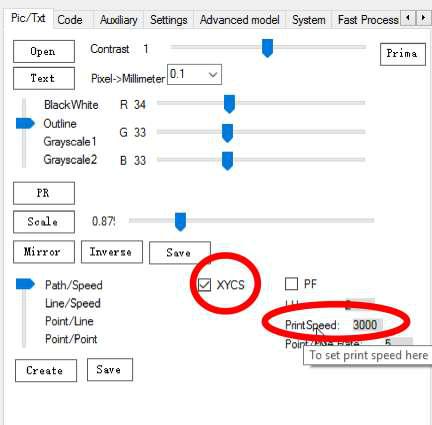

Then we set the laser speed and check the XYSC button box; this button balances the X and Y axes speeds. This is necessary for even cutting out of the image.

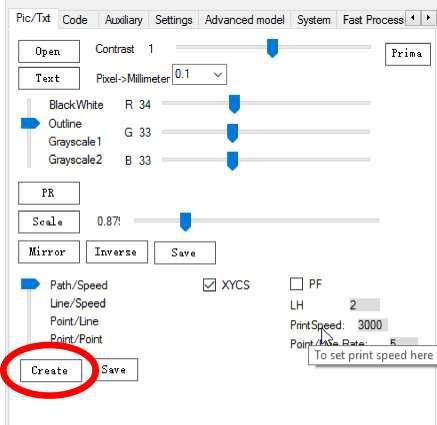

Now we create the G-code by clicking Create.

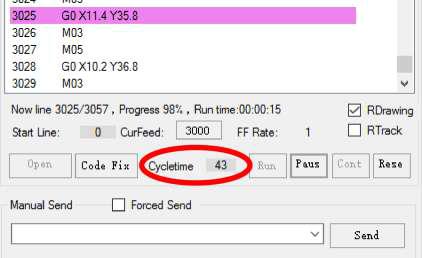

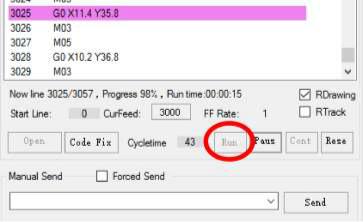

Then we set the necessary number of passes in the Cycletime window.

Attention!!! Don’t forget to wear safety goggles.

But I’d better explain once more the main aspects.

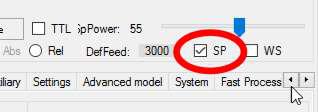

- To check the laser focus we need to put under the laser beam some material (resistant to laser radiation). Check the SP button box.

- Select the height. When using a long-focal lens the laser beam point becomes the minimal at 8-10 cm. When using a short-focal lens – at 4-5 mm.

- Then we reduce the laser beam point to the max by regulating the laser ring.

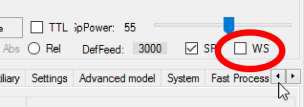

Choose the starting point for cutting out on our workpiece. We check the WS box.

The laser beam indicates the starting point.

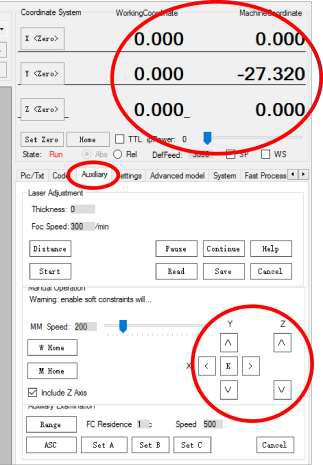

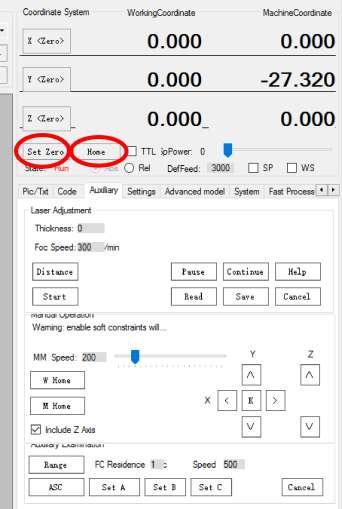

You can change the location of the starting cutting point using arrows and coordinates in the Auxilary.

To set the zero point of the laser click the Set Zero. To send the laser to the zero point it is necessary to click the Home button.

If the laser location is okay we click the Run button. (Don’t forget safety goggles.)

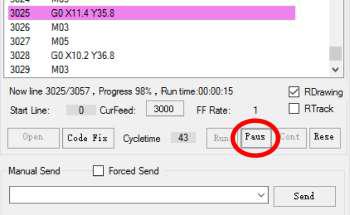

To pause click the Paus button.

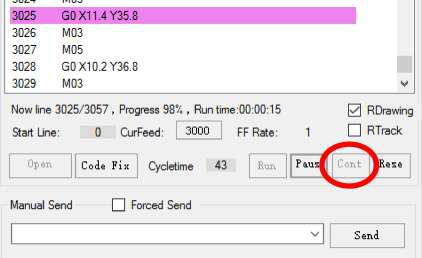

To continue click the Cont.

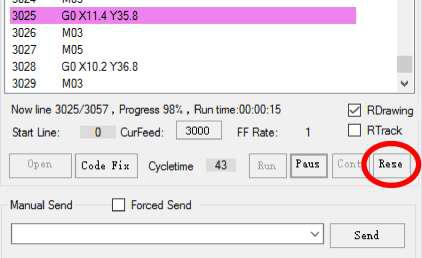

To stop the process click the Rese. This button has two important features: 1) When creating the code even when you stop it you cannot move the laser without clicking the Rese. 2) You cannot load another G-code without clicking the Rese.

Good parameters for cutting plywood of different thickness with a 5.6 W laser.

A regular long-focal lens with the focal length of 2-10 cm.

| Plywood | Speed | Number of | |||||

| thickness | passes | ||||||

| 2 mm | 3000 | 10 | |||||

| 3 mm | 8000 | 30 | |||||

| 4 mm | 500 | 10 | |||||

A short-focal lens G2 with the focal lengths of 5 mm.

| Plywood | Speed | Number of | ||

| thickness | passes | |||

| 2 mm | 3000 | 8 | ||

| 3 mm | 1400 | 10 | ||

| 4 мм | 500 | 10 | ||

| 5 mm | 550 | 20 | ||

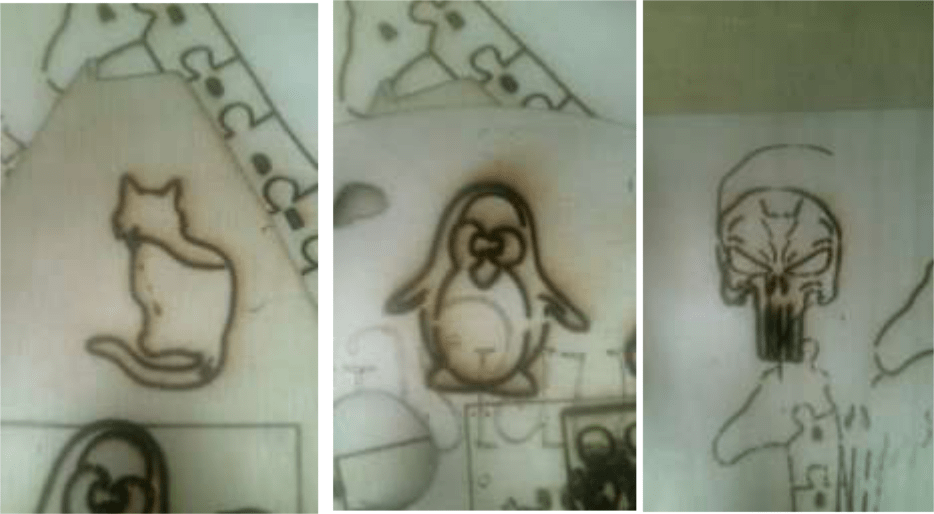

Cut out figures

Our failures

Wrong parameters:

| Cat | Penguin | Skull | |

| Speed | 700 | 1000 | 400 |

| Number of passes | 5 | 7 | 10 |