Introduction – how to make a key holder

Copper is known to humans from the ancient era and it is used till now for a lot of applications. The color, the relative soft texture and its ability to last in time has made copper very popular. Having in my small scrap yard two pieces of Φ40 copper tubes laying around I decided to use them as a material in order to make motorcycle key holders.

I will make a try to share my little experience on transforming copper from tube to sheet and on milling copper with a CNC router machine, and also I will share my way of making a gift package with alternative materials…

Maybe the following process, the choice of the router bit and the data for feeds and speeds are not ideal, but they worked pretty good for my case and my machine…

Designing the key holder

Photo: YAMAHA logo 1898

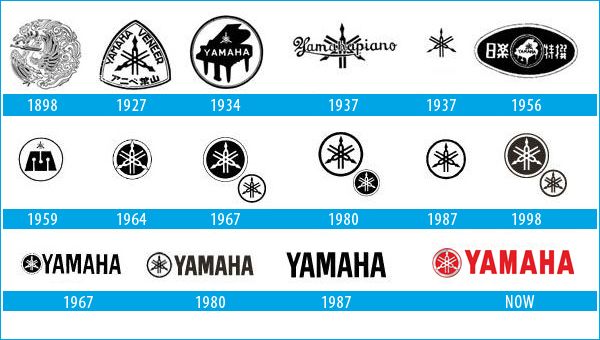

The specific design is the first logo of YAMAHA, the most complicated logo in the history of the company. I found a raster image on the web and transformed it to vector using Vectric Aspire.

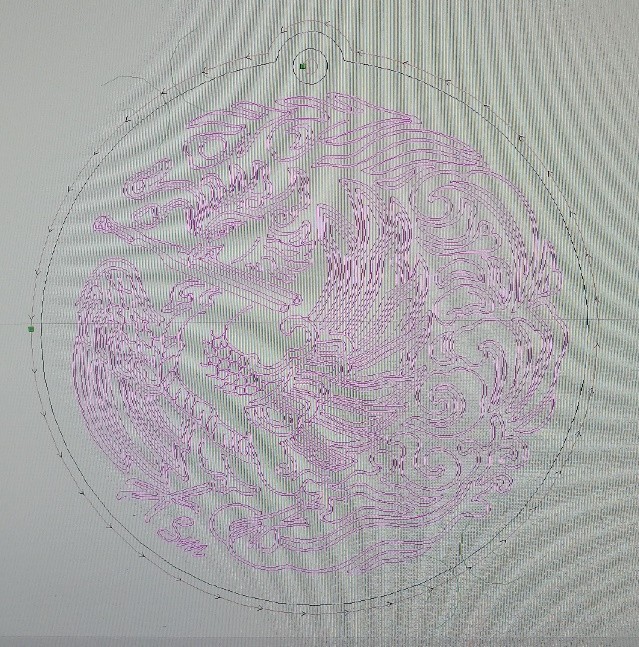

Photo: YAMAHA logo toolpaths

The diameter of the key holder is 40mm.

Photo: YAMAHA logo from 1898 till now

Tools and materials

As I have mentioned before, the material is Φ40 copper tube

The tools that have been used for the final product are:

- A chop saw with a multi material cutting disk mounted on it

- A sledgehammer

- A heavy and flat piece of iron stock (or an anvil)

- A 0.25mm, 2 flute, 10 degrees, Φ6 router bit

- A diamond engraving bit

- A CNC router machine

- Some two-sided carpet tape

- Two pieces of predrilled aluminum flat bar and some wood screws

The tools and materials that have been used for the packaging of the product are:

- Substrate for laminate floor

- A ready-made paper box

- An Endurance 10W “invincible” mounted on a modified Openbuilds ACRO, you can find the .dxf plans for the machine here: https://openbuilds.com/builds/hydra-multi-tool-cnc-based-on-acro.9793/

Step I _ cutting

Cutting the copper tube

Tools:

- A chop saw with a multi-material cutting disk mounted on it

Photo: copper tube cut in pieces

Step II _ straightening

Straightening the copper tube pieces after the cut, has been done by hand, with a sledgehammer and a heavy piece of iron stock to act as an anvil.

Tools:

- A sledgehammer

- An anvil or a heavy and flat piece of iron stock

Photo: copper straightened pieces and copper chips for future projects…

This is not the ideal way! I could not achieve to make a completely even surface and the hammer leaves some marks on the surface. I have also tried a 4-ton benchtop hydraulic press with the press the process is slower and the piece is being straight only in the middle. With a 15-ton press, at a local machine shop, the results was better, but still the copper stock piece was not completely flat, especially at the edges.

Step III _ engraving

Mounting the plate on the wasteboard:

The best way for my case was to use a two-sided tape for carpets in combination with aluminum flat bars that acted as clamps. First I screwed a scrap piece of floor laminate on the waste board and after cleaning with IPA I applied the tape with the copper stock and then the aluminum flat bars with wood screws, in order the copper to stay as much flat as possible to the surface of the waste board.

For the engraving I used a diamond engraving bit. The specific bit is handmade and has been bought from eBay some years ago. Unfortunately I have lost the name and the address of the maker…

Having not available a 7mm collet for my Kress router, I used some aluminum tape and an 8mm collet.

Photo: 7mm diamond engraving bit, fixed with aluminum tape to an 8mm collet

I set the value of the engraving bit to 0,15mm and used the following settings for my machine:

Stepover : 36%

RPM : 0

Feed : 1250 mm/min

DOC : 0.3mm

Plunge Rate : 1000 mm/min

Passes : 3

Step IV _ milling

Tools:

- A 0.25mm, 2 flute, 10 degrees, Φ6 router bit / for the cuts

- A diamond engraving bit / for the engravings

- A CNC router machine

- Some two-sided carpet tape

- Two pieces of predrilled aluminum flat bar and some wood screws

I used the bit of the picture for the cut, bought from Vallder, a shop located to Balcans

https://vallder.com/en/c/cnc-cutting-tools/wct-deep-carving-tool-detail

Photo: 0.25mm, 2 flute, 10 degrees, Φ6 router bit

Feeds and speeds

I found on Utube a pretty nice video about milling copper with a Nomad cnc and I kept in mind the suggested values, adapting them to my CNC machine.

As I mentioned before the copper sheet after hammering is not completely straight. Using aggressive values for speeds and feeds, the cutters were breaking one after another!…

After a lot of trials and some broken bits I used these values:

RPM : 12000

Feed : 450 mm/min

DOC : 0.06

Plunge Rate : 350 mm/min

From time to time, using a long paintbrush, I was cooling the bit with petroleum and at the same time I was cleaning the surface from copper chips.

Photo: cleaning the copper chips and cooling the bit with petroleum

I realized that cooling the bit with petroleum is not critical, maybe due to the morphology of the cutter and the very low DOC.

Step V _ finishing

I left the surface of the copper key holder unfinished in order to take advantage of the nice contrast between light and dark. For the edges of the product I used locksmith files.

Photo: locksmith files

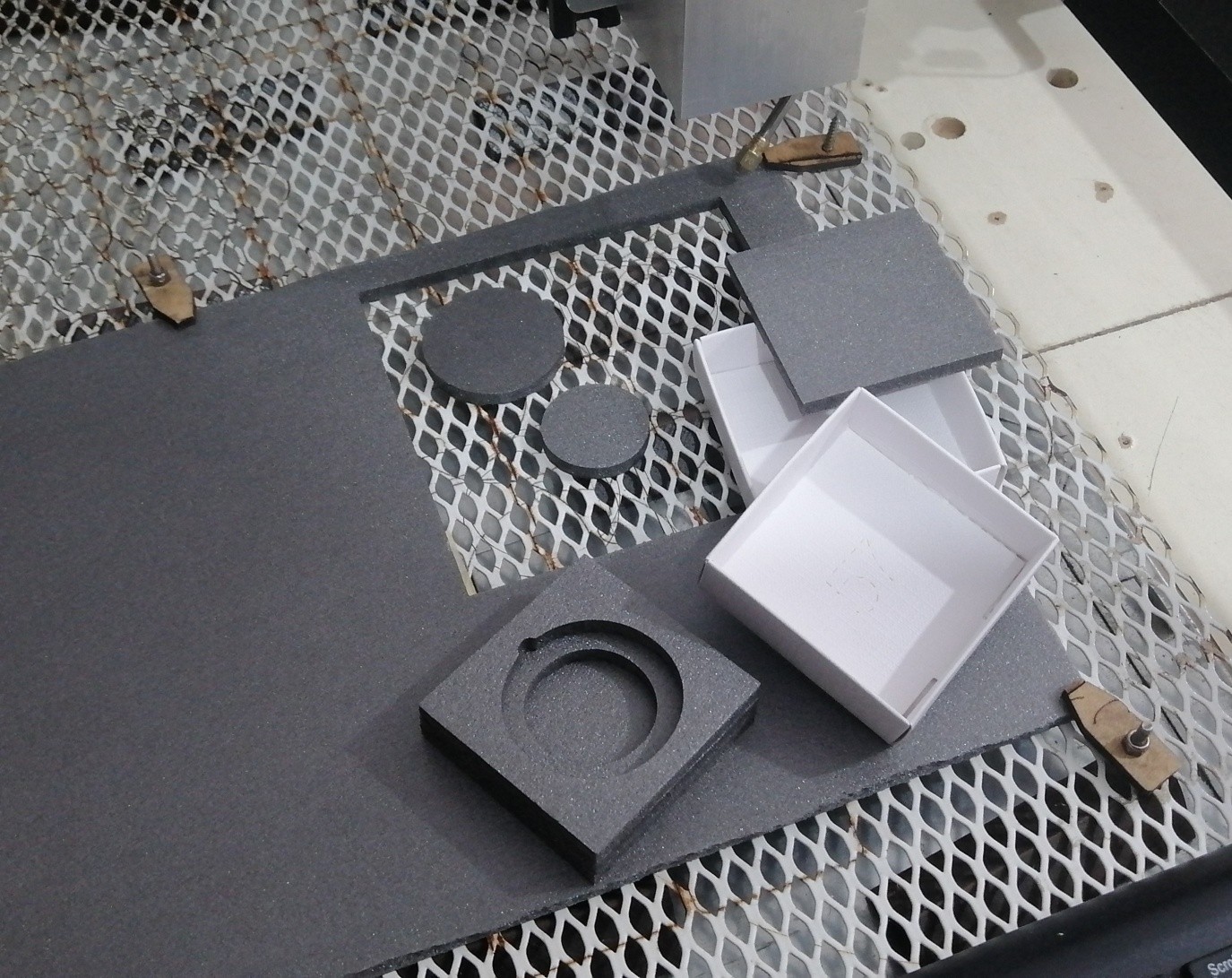

Step VI _ Packaging insert

The design

The Substrate for laminate floor I used as material for the packaging, is a polypropylene foam sheet 5mm , we will use 4 layers for the insert. The first one, the base, is just a square 0.2mm smaller than the paper box.

The second one, has the outer dimensions of the base and an offset insert, 0.1mm bigger than the ring of the key holder.

The third one, has the outer dimensions of the base and an offset insert, 0.1mm bigger than the copper key holder

Finally, the fourth one is just like the base and acts as a lid and keeps in place the product in the box.

Step VII_ laser cutting

Working with a diode laser from Endurance, I used the following values for cutting the 5mm polypropylene foam sheet:

Power : 95%

Feed : 1800 mm/min

Passes : 1

Photo: the insert is ready to be nested in the paper box

Photo: unboxing! (1 of 4)

Photo: unboxing! (2 of 4)

Photo: unboxing! (3 of 4)

Photo: unboxing! (4 of 4)

Thank you for reading my story!

Feel free to visit my Instagram page #fabrika.cw …

… and Happy making! 🙂

Michail Gedeon